2

PHONE: 1-800-633-0032 FAX: 1-401-539-2584

REV295-13

Thank you for choosing VIBCO, Inc. for your vibration needs. You are now the owner of the

nest 12 volt DC battery operated vibrator available today backed by complete manufacturer

condence in its quality and dependability. For reference please complete the information below

about your new VIBCO vibrator.

Model Number: ____________________

Serial Number: ____________________

Date of Purchase: ____________________

Warning Labels and Serial Number Tags.......................................................................................3

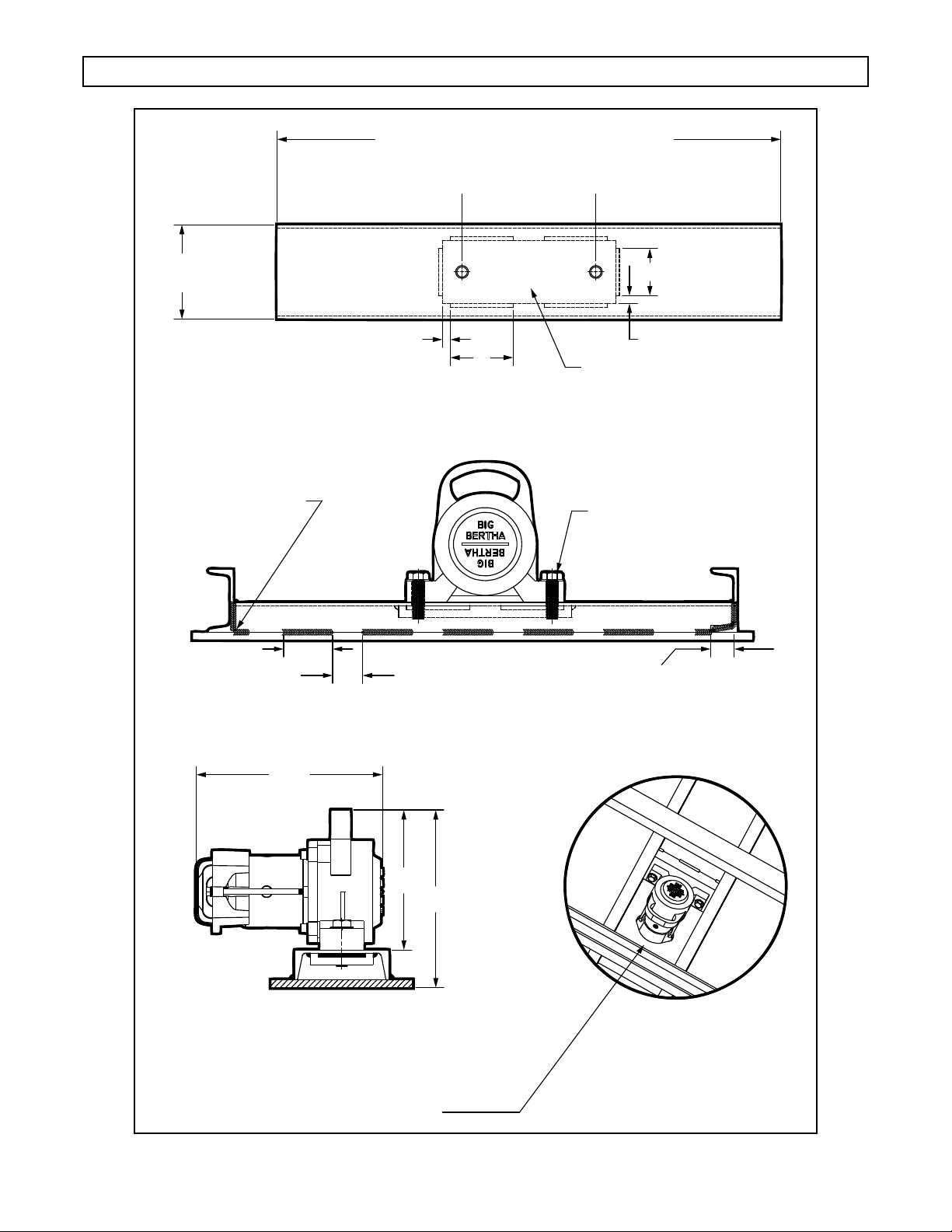

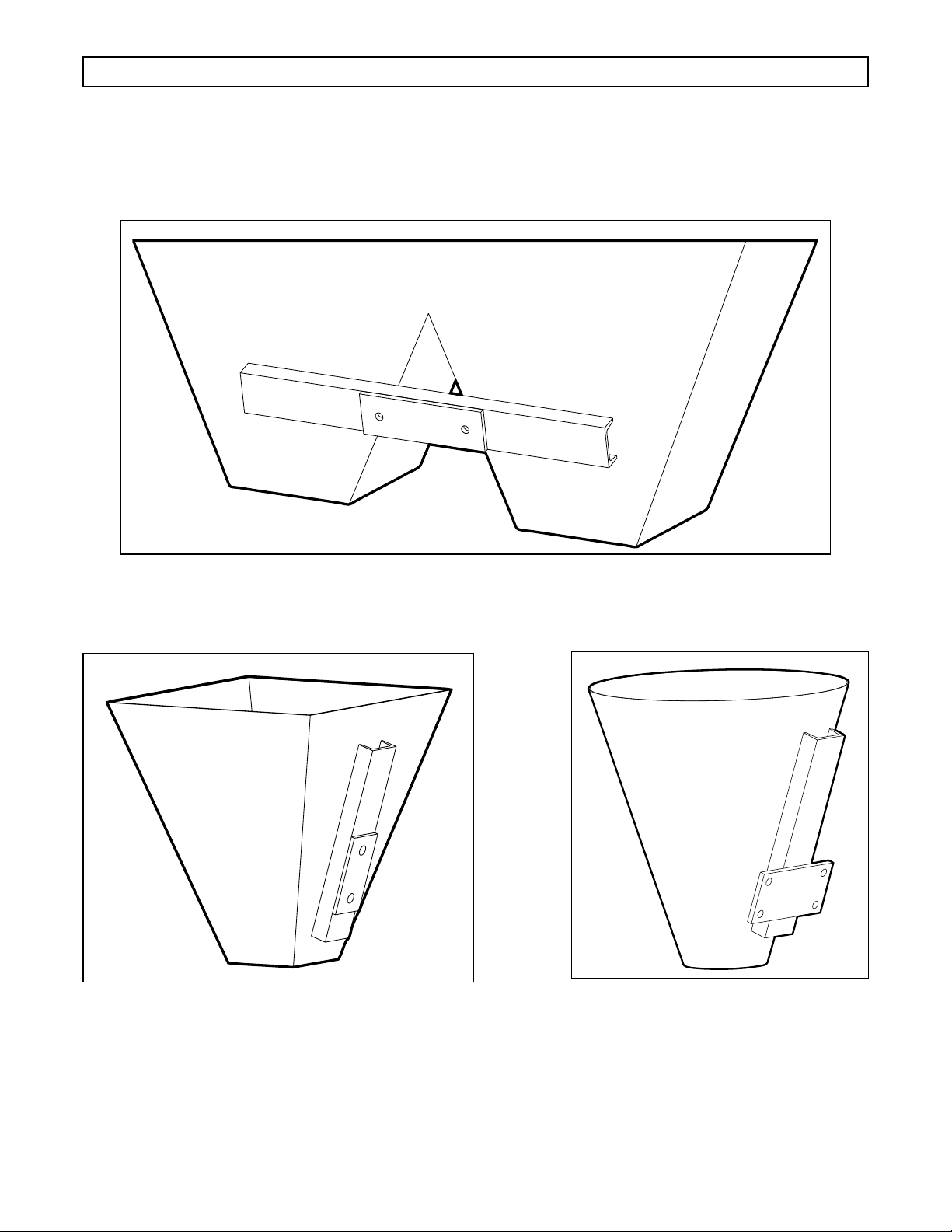

DC-3500 Mounting Instructions................................................................................................4-9

DC Mounting Instructions.........................................................................................................9-12

Operating Instructions.................................................................................................................13

Adjusting Eccentrics..............................................................................................................13-15

Electrical Installation...................................................................................................................16

Electrical Installation Procedure .................................................................................................17

Brush Kit Replacement...............................................................................................................17

Wiring Diagrams..........................................................................................................................18-20

Troubleshooting...................................................................................................................21

Technical Data and Dimensions...................................................................................................22-23

Parts Lists and Breakdown

DC-20....................................................................................................24

DC-50........................................................................................................25

DC-60............................................................................................................26

DC-100....................................................................................................27

DC-200................................................................................................28

DC-300................................................................................................29

DC-450T................................................................................................30

DC-500................................................................................................31-32

DC-700..................................................................................................33

DC-900................................................................................................34

DC-1600................................................................................................35

DC-3500 12 & 24 Volt...................................................................................................36-37

DC-5000........................................................................................................38

Warranty and General Information..............................................................................................39

TABLE OF CONTENTS

WARNING: Failure to read and follow these installation instructions and safety

precautions could result in personal injury, equipment damage, shortened service

life or unsatisfactory equipment performance. All information in this document is

vital to the proper installation and operation of the equipment. It is important that

all personnel who will be coming in contact with this product thoroughly read and

understand this manual.