Trimax Solar TMX-MH7-120A User manual

1 ANLEITUNG 04_21

INSTALLATION AND OPERATING

INSTRUCTIONS

TRIMAX Solar GmbH

Leitzstraße 45

70469 Stuttgart

GERMANY

Tel : +49 711 490 66 278

Mail : info@trimax-solar.com

Web : trimax-solar.com

2 ANLEITUNG 04_21

CONTENT

PRELIMINARY REMARKS.........................................................................................................................................................................3

PACKAGING......................................................................................................................................................................................................3

Recommended unpacking method.................................................................................................................................................4

Horizontally packed modules............................................................................................................................................................4

Vertically packed modules..................................................................................................................................................................5

PRODUCT LABELING...................................................................................................................................................................................6

Label.................................................................................................................................................................................................................6

Serial Number............................................................................................................................................................................................6

SAFETY................................................................................................................................................................................................................6

General safety instructions...............................................................................................................................................................6

Fire protection...........................................................................................................................................................................................6

Mechanical installation........................................................................................................................................................................7

Electrical installation............................................................................................................................................................................8

PLANNING AND INSTALLATION..........................................................................................................................................................9

Intended use................................................................................................................................................................................................9

Shading...........................................................................................................................................................................................................9

Tilt Angle.....................................................................................................................................................................................................10

Glare behavior / Glare assessment.............................................................................................................................................10

Bifacial Modules......................................................................................................................................................................................10

Electrical design.....................................................................................................................................................................................10

System dimensioning.......................................................................................................................................................................11

Connectors............................................................................................................................................................................................12

Cable..........................................................................................................................................................................................................12

Grounding/ (Potential equalization)......................................................................................................................................13

Design substructure............................................................................................................................................................................13

Load capacity............................................................................................................................................................................................13

Mounting with screws...................................................................................................................................................................14

Mounting with clamping systems...........................................................................................................................................15

Mounting with insertion systems...........................................................................................................................................16

MAINTENANCE............................................................................................................................................................................................18

Cleaning.......................................................................................................................................................................................................18

Module at end of life.............................................................................................................................................................................19

DISCLAIMER...................................................................................................................................................................................................19

List of Figures:........................................................................................................................................................................................20

List of Tables:...........................................................................................................................................................................................20

3 ANLEITUNG 04_21

PRELIMINARY REMARKS

Thank you for choosing TRIMAX PV modules. This manual provides you with information to ensure that your

PV system generates optimal yields over its entire life cycle. This manual is intended for professionals

involved in the design, installation and commissioning of photovoltaic systems.

TRIMAX Solar produces high quality and reliable photovoltaic modules according to international standards

(ISO 9001 : 2015, ISO 14001 : 2015, ISO 45001 : 2018). TRIMAX Solar HALF-CUT PERC modules are certified

according to IEC 61730 and IEC 61215 and have also undergone salt spray and ammonia corrosion testing.

The 100% PID-free solar cells reliably provide stable yields throughout the warranty period and beyond.

Before installing the solar system, check with your local authorities and utility companies for applicable

guidelines and approval requirements.

Observe all necessary safety regulations during design and installation. This is the responsibility of the

installer of the system.

Keep the manual for the entire service life of the solar modules and ensure that this manual is accessible to

the operator at all times.

Pass the manual on to any subsequent owner or user of the solar modules.

We reserve the right to make changes to the product, specifications or instructions without prior notice.

Failure to do so may result in serious injury and damage and/or void the limited warranty and

guarantee.

PACKAGING

•Do not exceed the maximum stacking capacity of 2 pallets (standard packaging for shipping).

•Place the pallets only on firm and horizontal levels to prevent them from toppling over.

•Upon receipt, look for visible damage to the packaging and the product itself.

•Check the order information and the product nameplate to ensure that the products match the type

ordered.

•If you notice any problems, contact the shipping company and/or your supplier as soon as possible

before you start installing the product.

•Store the pallets in a ventilated, dry place until installation.

•Do not stack individual modules without protection to avoid scratching the glass and frame.

•Do not unpack the pallets in rain or snow.

•Do not pull the module out of the packaging by the cables or junction box.

•Removal of the modules from the packaging must be done by two people.

•Use a stand for removal to avoid damage caused by falling over.

4 ANLEITUNG 04_21

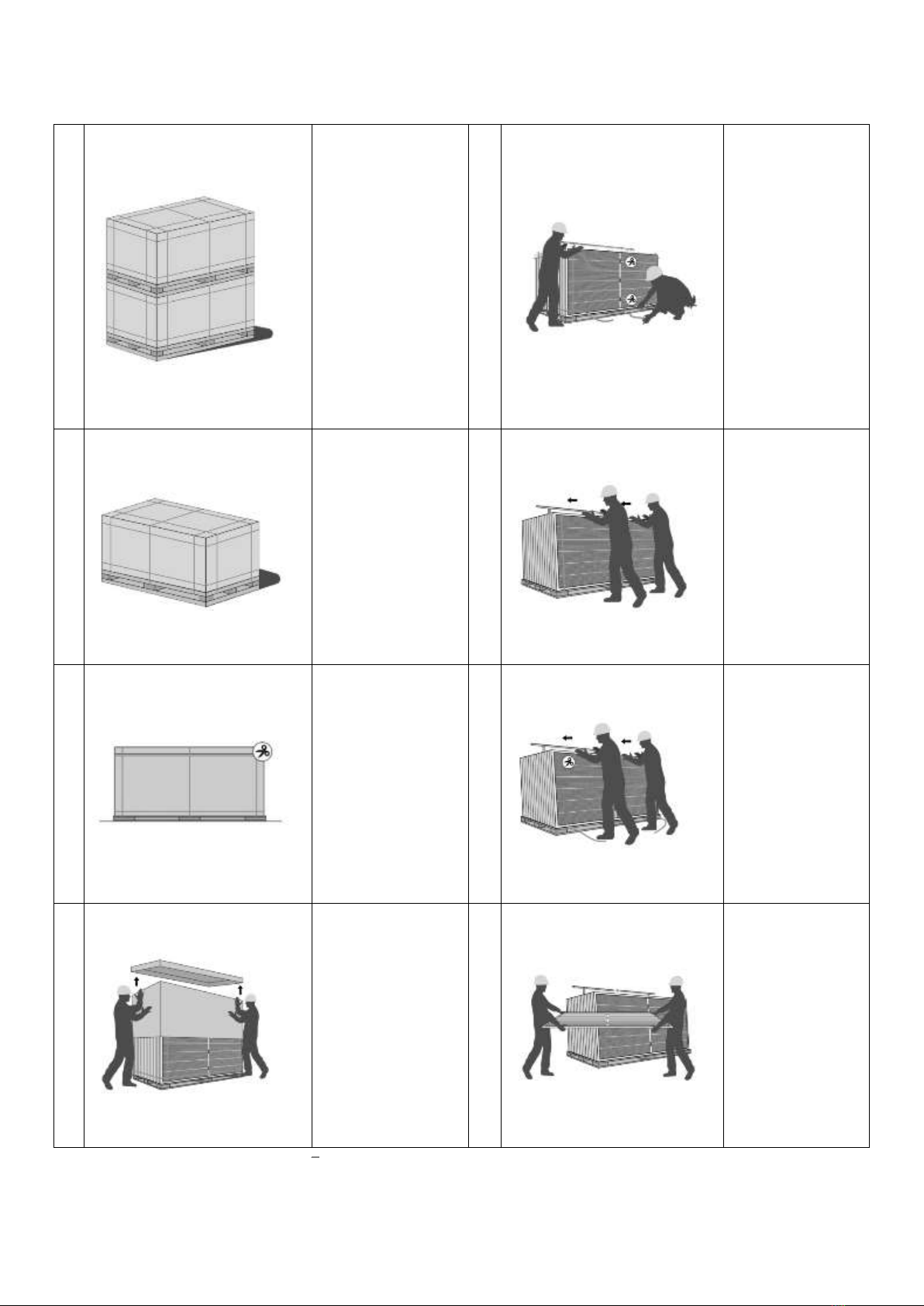

Recommended unpacking method

Horizontally packed modules

1.

Remove the packing

film.

5.

Cut and remove

only the horizontal

packing tapes.

2.

Place the pallets one

by one.

6.

Carefully press the

stack against a

stand.

(Not included!)

3.

Remove the outer

packing tapes.

7.

Cut the remaining

packing tapes.

4.

Remove the cover

and the outer

carton.

8.

Remove the

modules one by

one.

Table 1: Recommended unpacking method horizontally packed modules

5 ANLEITUNG 04_21

Vertically packed modules

1.

Remove the

packing film.

5.

Cut and remove

only the

horizontal packing

tapes.

2.

Remove the lid

and detach the

outer carton.

6.

Carefully press

the stack against

a stand.

(Not included!)

3.

Remove the

outer carton.

7.

Cut the remaining

packing tapes.

4.

Place the stand

on the glass

side of the

modules.

8.

Remove the

modules one after

the other. (Min. 2

persons)

Table 2: Recommended unpacking method - vertically packed modules

6 ANLEITUNG 04_21

PRODUCT LABELING

Each module can be identified by the following information:

Label

The nameplate is locatedon the back of the

module. In accordance with the guidelines of

EN 50380, it provides information about the

most important parameters of the module:

Figure 1: Label

Serial Number

Each individual module is identified by a unique serial number/barcode. The serial number/barcode are

permanently embedded in the laminate under the front glass of the module and are visible from the front of

the module.

SAFETY

General safety instructions

The design and installation of photovoltaic solar systems requires special skills and knowledge. Proper

implementation is the responsibility of the system designer and installer.

TRIMAX Solar PV modules may only be installed in compliance with all locally and nationally applicable

standards, rules and regulations. Check and follow all safety instructions, including those given by other

component suppliers.

Please contact our Technical Service if you have any questions about the instructions.

Fire protection

TRIMAX Solar PV modules have been tested in accordance with the provisions of the IEC EN 61730 directive

with application class A.

The fire safety has been evaluated with class C.

Please note the building code requirements. In Germany, it is the Landesbauordnung in your state. The roof

must be covered with a suitable fire-resistant material.

The installation of PV systems on a roof can affect the fire safety of a building. Compared to other technical

installations, they do not pose a particularly increased fire risk.

However, improper installations can lead to a hazard and fire. In particular, defects in current-conducting

components of the PV system can lead to the formation of electric arcs.

For this, please refer to VDE-AR-E 2100-712. This VDE application rule applies to the planning and installation

of low-voltage systems for photovoltaic (PV) power supply systems on or on buildings together with the

requirements of DIN VDE 0100-712.

7 ANLEITUNG 04_21

This VDE application rule contains supplementary recommendations to mitigate the likelihood of electric

shock to emergency personnel in case of fire (or similar) resulting from the fact that PV modules can produce

voltage when exposed to light, even if the AC side is disconnected.

•In order to inform firefighters that there is a PV system on the roof of the house, for example, it is

recommended that a photovoltaic system fire sign be placed on the side of the building where the

main access road is located. By having a PV system sign immediately visible, firefighters will have

advance notice of potential hazards that may be posed by the PV system in the event of a fire.

•Create sufficiently detailed documentation of the PV system ,to support a hazard-free execution of the

extinguishing process. Ensure that the system documentation is accessible to the fire department in

the event of a fire.

Safety distances for an extinguishing process in PV systems (according to DIN VDE 0132)

Low voltage High voltage

Spray jet: 1 meter 5 meters

Full jet: 5 meters 10 meters

•Do not install modules near open fire or flammable and explosive gases/substances.

•Only use plugs and sockets of the same manufacturer and type.

•Only use devices, plugs, cables and support frames that are suitable for use in a solar power system.

•Use temperature and UV resistant materials.

Mechanical installation

General notes

Always use constructions and materials that have been specially developed and certified for the installation of

photovoltaic modules. Always follow the instructions and safety precautions of the mounting system

manufacturer.

•Do not remove any components, such as plugs or cables, or attached nameplates.

•Do not apply paint or glue to the top of the module.

•Do not concentrate artificial sunlight on the solar module.

•Do not disassemble, drill or modify the frame or other parts of the PV module.

Safety instructions

•Do not install in high winds and prevent objects from falling from the roof.

•Secure the work area so that no one on or under the roof can be injured.

•When installing a module on a roof or building, make sure it is securely fastened.

•Avoid subjecting the frame to lateral tension and compression forces, as this could damage the glass.

•Do not bend the module frame.

•Do not damage the frame.

•Do not place the module down hard.

•Do not drop any objects on the module.

•Do not place heavy objects on the module.

8 ANLEITUNG 04_21

•Do not step on the module.

•Make sure that the drainage holes of the PV module are not blocked.

•Roof penetrations must be properly sealed.

•Ensure that cables or plugs are not trapped between the module and the substructure.

Electrical installation

General notes

The electrical connection must be carried out by a competent, authorized person/company. The electrical

installation of the PV system must be carried out in accordance with the respective national electrical

regulations or the applicable national regulations.

Safety instructions

•Exercise extreme caution during all work on the wiring.

•Observe the safety instructions for all other components used in the PV system.

•Do not wear metal rings, watch bands, ear, nose or lip rings, or other metal objects during installation

or troubleshooting of photovoltaic systems.

•Do not install solar modules or wiring with wet male and/or female connectors.

•A single module can generate DC voltages in excess of 30 V when exposed to light of any intensity.

Contact with a DC voltage of 30 V or more is potentially hazardous. Connecting modules in series or

parallel increases the voltage or electrical current.

•During installation, completely cover the module with a dark, opaque material to prevent current

generation.

•Do not install/operate damaged modules, as contact with the surface of the module or frame may

cause electric shock.

•Do not attempt to repair a module with broken glass or defective back panel.

•Do not disconnect modules under load to avoid electrical arcing. Contact with electrically active parts

of the modules, can cause burns, sparks and fatal shock, whether the module is connected or not.

•Do not use the junction box or cables as a handle.

•Do not use lubricant on the connectors.

•Do not remove the rubber rings on the junction box or connectors.

•Do not immerse modules or connectors in liquid.

•Do not insert electrically conductive objects into the plugs and/or sockets.

•Do not short-circuit the solar module cables under any circumstances.

•Ensure correct polarity of the cables.

•Only use or connect plugs and sockets of the same manufacturer and type.

•When connecting the plugs, make sure that they are securely connected.

•Lay cables carefully and protect them from the weather.

•Avoid cable damage due to sharp edges.

•Avoid cable damage caused by cable ties that are too tight.

•Do not fall below the smallest bending radius of the cables.

•Avoid tensile loads, especially on junction boxes and plug connections.

The cross-sectional area of the cable is 4mm2 or 12AWG. The smallest bending radius of the cables must not

be less than 43mm. Cable damage caused by excessive bending or by the cable management system is not

covered by the warranty.

9 ANLEITUNG 04_21

PLANNING AND INSTALLATION

Intended use

•TRIMAX PV modules are suitable for outdoor operation.

•Ambient temperature range: -40°C to +40°C

•Operating temperature range: -40°C to +85°.

•Humidity: 100% and rain

•Mechanical load capacity: snow load: 5400Pa wind load: 2400Pa

•< 2000m altitude sea level

•Do not expose the module to external light sources.

•There is a risk of corrosion if the module is exposed to salt (e.g. near the sea) or sulfur sources. The

modules have passed the salt spray test according to IEC61701, but galvanic corrosion may occur

between the aluminum frame of the modules and the mounting or grounding elements if these

elements are made of different metals. The modules can be installed in coastal locations <500m, but

the components should be protected from corrosion.

•The module should not be exposed to unusual chemical stresses.

•Ensure that the modules are not subjected to wind or snow loads that exceed the maximum allowable

loads.

•In regions with heavy snowfall, select the height of the mounting structure so that the lowest edge of

the module is not covered by snow and cannot beshaded by plants or trees or soiled by soil.

•Lightning protection is recommended for PV systems that are to be installed in locations with a high

probability of lightning strikes.

Shading

The modules should not be shaded at any time. Shading leads to a

lower power output. Furthermore, systemic shading can lead to

accelerated aging and damage to the module and failure of the

system. Perform a shading analysis. Shading objects such as trees

or houses can have a significant impact on the yield prediction.

Ensure sufficient row spacing for ground-mountedsystems to

avoid self-shadowing. Observe and avoid close shading by

chimneys, dormers, antenna tubes, lightning protection equipment

or overhead cables.

Consider the internal bypass diode configuration of the PV module

when selecting the orientation to ensure optimal electrical

performance against possible shading of the module.

In case of shading or soiling, in addition to the Schotky diodes, the

parallel connection of the half cells has the advantage that current

continues to flow through the unaffected string and thus 50% of

the original power still remains, but systemic shading should be

avoided to prevent permanent stress on the bypass diodes.

•Please do not attempt to open the junction box to replace

the diode.

Figure 2: Circuit Diagram 108 CELLS- HALF-

CUT-PERC

10 ANLEITUNG 04_21

Tilt Angle

PV modules should be installed in a location where they can receive the maximum amount of sunlight

throughout the year. In the Northern Hemisphere, the modules should face south, and in the Southern

Hemisphere, they should face north. As a rule of thumb, the tilt angle should be approximately equal to the

latitude of the project site and point toward the equator.

PV modules connected in series should be installed in the same orientation and with the same tilt angle. The

greatest power is generated when direct sunlight falls on the PV modules.

Dust and dirt accumulating on the surface of the modules can affect performance. TRIMAX Solar

recommends that modules be installed with a tilt angle of at least 15 degrees so that dust or dirt can be

washed off more easily by rain.

Figure 3: Tilt Angle

Table 3: Tilt Angle

Latitude

Tilt angle

0°~15°

15°

15°~25°

The same latitude

25°~30°

Same latitude +5°

30°~35°

Same latitude +10°

35°~40°

Same latitude +15°

40°+

Same latitude +20°

Glare behavior / Glare assessment

Under certain circumstances (e.g. nature reserves, traffic routes, airports), it may be necessary to check the

glare behavior of the PV power plant. Factors for the strength of the reflection include the position of the sun,

module orientation, coordinates of the installation site and the surface properties of the solar module.

Contact a professional provider for a glare assessment. TRIMAX Solar high performance PV modules are

coated with an ARC (Anti Reflective Coating). The glass coating with nano technology ensures that less light

is reflected and more light reaches the solar cells.

Bifacial Modules

TRIMAX Solar high power PV modules are equipped with bifacial PERC cells.PERC stands for Passivated

Emitter Rear Cell. The structure of the PERC cell essentially allows for improved light output at the rear of

the cell, which in turn increases electron yield. The bifaciality (the ratio of front and rear output under the

same conditions) can reach 65% ± 5%. The bifacial extra yield depends mainly on the system design, especially

the row and ground spacing, the angle and the reflectivity of the ground (albedo). Additional yields between 5

and 15% are possible. The reflectance varies depending on the soil resulting in different power generation. The

irradiance reflected to the back of the bifacial glass/film solar modules must not exceed 300 W/m2.

Electrical design

Maximum system voltage (Umax): 1000V or 1500V depending on product type.

Please check the nameplate and data sheet accordingly. For further technical data, please refer to the

respective data sheets - available online at www.trimax-solar.com.

•To avoid power loss or damage to the PV system, use only modules of the same type and

power within the same circuit.

•Protect the solar modules from overvoltage, e.g. voltage peaks from battery charging,

generators, etc.

•Only use plugs of the same manufacturer and type for cable extensions.

11 ANLEITUNG 04_21

System dimensioning

Under intended conditions, it is likely that a PV module will experience conditions which are likely to exist a

higher current and/or voltage is generated than specified for standard test conditions. To determine the

voltage ratings of components, current ratings of conductors, ratings of controls (e.g., inverters) that are

connected to the output of PV modules, the values of Isc and Voc indicated on the PV module shouldbe

compared with values of Isc and Voc should be multiplied by a factor of 1.25.

The reflection of snow or water can amplify sunlight, increasing current and power. In addition, colder

temperatures can significantly increase power. The safety factor of 1.25 for the lowest voltage rating of

components can be modified during the design of a system according to the minimum temperature of the PV

system site and the temperature coefficient for Voc. The Isc can be modified based on maximum temperature,

irradiance and orientation of the module. For this purpose, a complete simulation for the specific site with

long-term weather data is required.

Maximum number of interconnected PV modules

When modules are connected in series, the total voltage is equal to the sum of the individual voltages. For

applications that require high currents, photovoltaic modules can be connected in parallel. The total current

is equal to the sum of the individual currents.

Module max = Vsys / Voc x 1.25

Maximum number of modules = Modulmax

Maximum system voltage = Vsys

Open circuit voltage = Voc

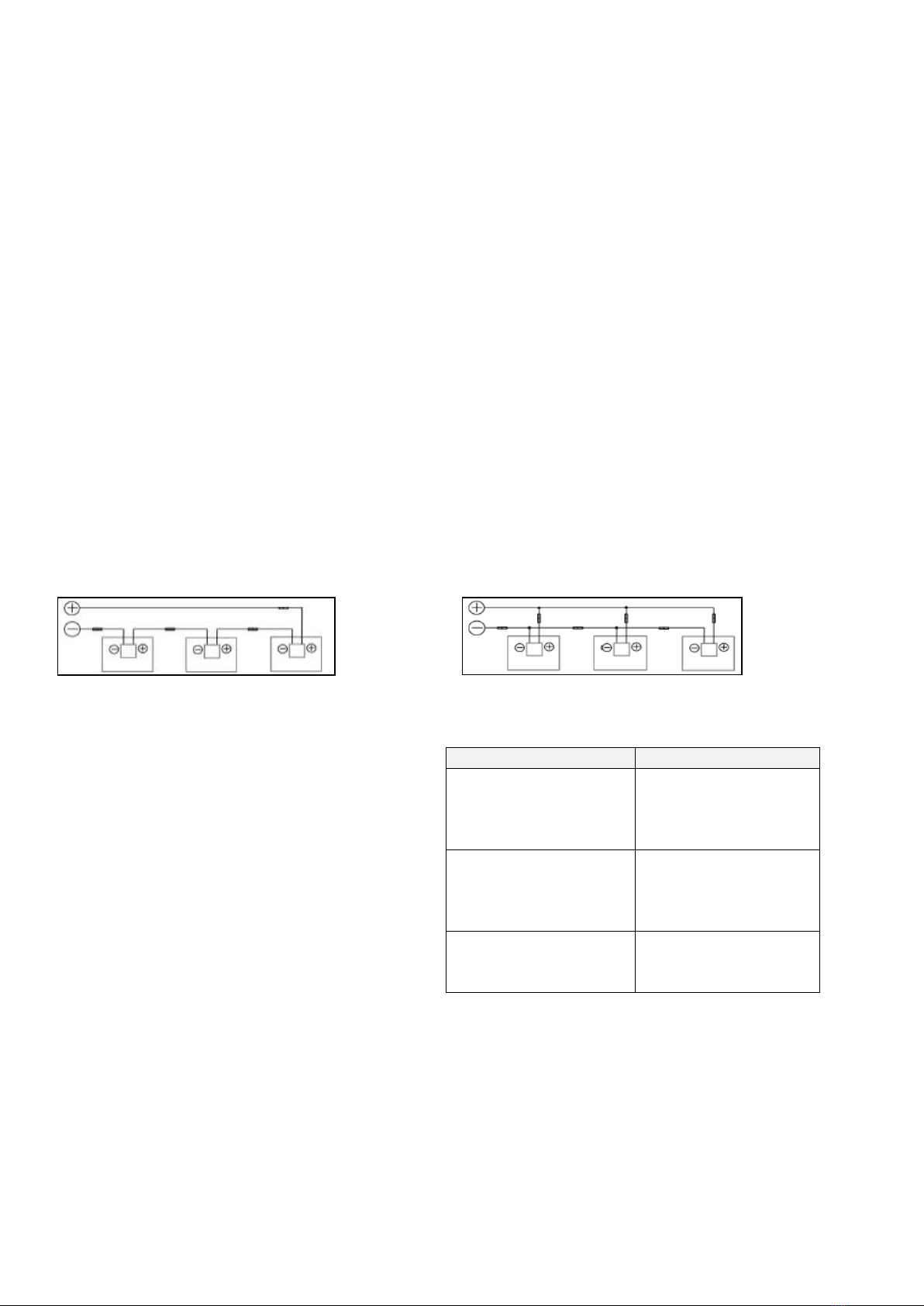

Circuit Diagram - Series/ parallel connection

Figure 4: Series Connection

Figure 5: Parallel Connection

Overcurrent protection device

An appropriately rated overcurrent protection

device should be used if the reverse current

could exceed the value of the maximum fuse

protection of the modules.

An overcurrent protection device is required for

each series string if more than two series

strings are connected in parallel.

Type

Max. reverse current

TMXMH7-120A

TMXMH7-120B

TMXMH7-132A

TMXMH7-144A

20A

TMXMH8-108A

TMXMH8-120A

TMXMH8-132A

TMXMH8-144A

25A

TMXMH9-108A

TMXMH9-120A

TMXMH9-132A

30A

Table 4: Maximum reverse current

12 ANLEITUNG 04_21

Connectors

For the electrical connection of the system, the cables end with connectors from Stäubli MC4 Evo2 (positive

[+] and negative [-]). Further certified manufacturers and possible connector types can be found in the

following overview:

Type

Manufacturer

System Voltage

Rated

Current

Temperature

Rating

PV-KST4-EVO 2/xy-UR;

PV-KBT4-EVO 2/xy-UR

Stäubli Electrical Connectors AG

DC 1500V

45A

-40ºC to +85ºC

05-8

Zhejiang Renhe Photovoltaic Technology

Co.,Ltd

DC 1500V

30A

-40ºC to +85ºC

PV-CY03L

Zhejiang Chuangyuan Photovoltaic

Technology Co.,Ltd

DC 1500V

30A

-40ºC to +85ºC

RHC2xyzu

Zhejiang Renhe Photovoltaic Technology

Co.,Ltd

DC 1500V

35A

-40ºC to +85ºC

QC4.10-cds

QC Solar (Suzhou) Corparation.

DC 1500V

41A

-40ºC to +85ºC

PV-ZPJ030A

The 40th Institute of China Electronic

Technology Group Corporation

DC 1500V

38A

-40ºC to +85ºC

Cable

TRIMAX Solar PV modules are equipped with two pre-terminated, temperature and UV resistant cable leads

(Rated 1500V DC, -40°C to 90 °C). The cross section of the cable is 4mm2 or 12AWG. Outer diameter is

5mm to 7mm. The smallest bending radius of the cables must not be less than 43mm. Cable damage caused

by excessive bending or by the cable management system is not covered by the warranty.

When selecting the size of the cables connecting the module strings to the solar inverter, observe the

electrical parameters specified on the module data sheet. To avoid overheating of the cables and the

connectors, the cross-section of the cables and the capacity of the connectors must be selected according

to the maximum system short-circuit current. The PV cable must be at least 4 mm2. Only use cables that are

certified for use with PV systems.

Observe the requirements of DIN VDE 0100-520. The standard applies to the selection and installation of

cable and line systems. Cable and line installations are the totality of one and/or more cables or lines or

busbars and their fastening means as well as their mechanical protection, if applicable. The standard contains,

among other things, requirements for types of cable and line installations, selection and installation according

to environmental influences, cross-sections of conductors, voltage drop in consumer installations, electrical

connections, selection and installation to limit fires, proximity to other technical installations, selection and

installation with regard to maintenance including cleaning.

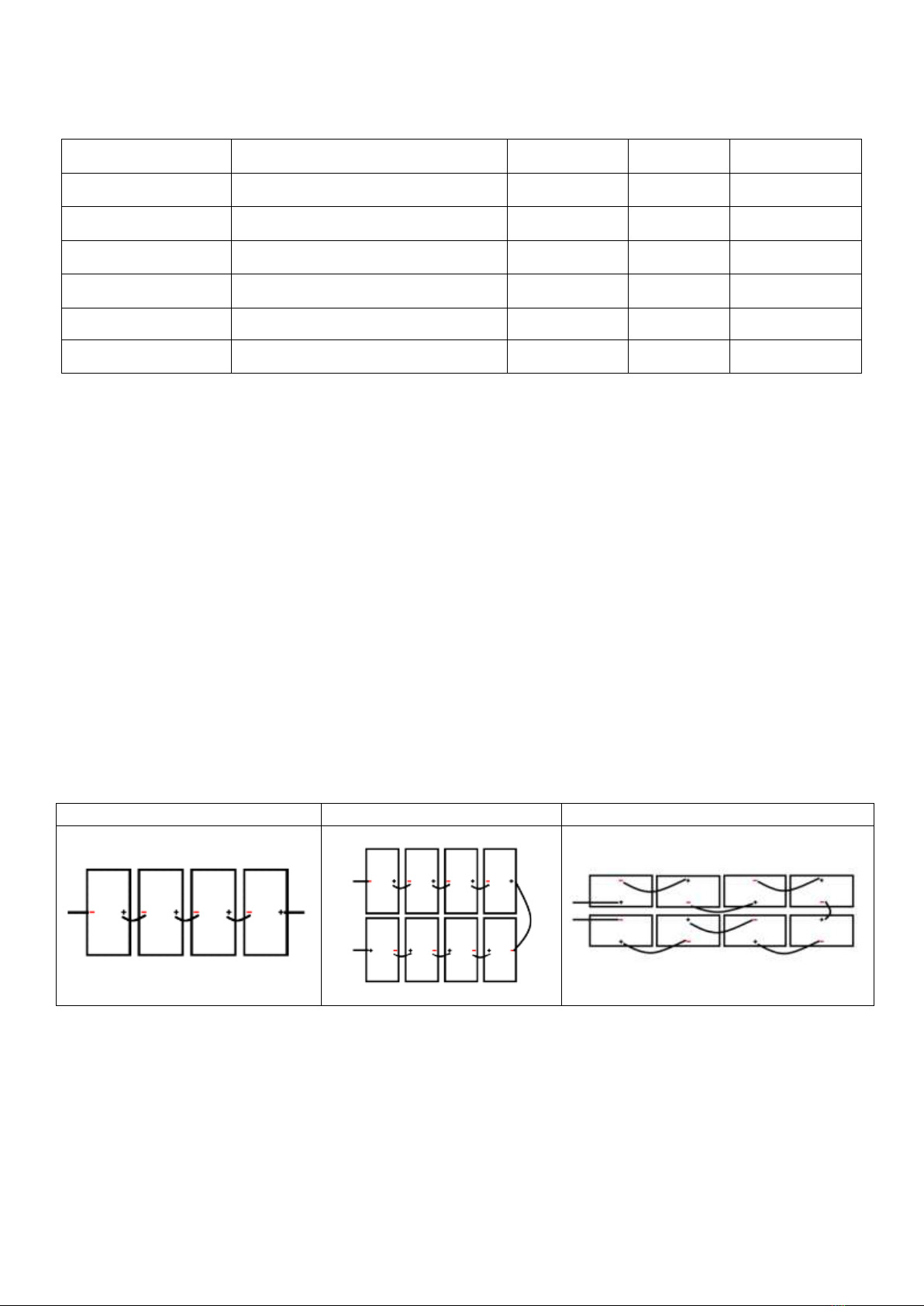

Wiring examples

Single row vertical installation

Two rows of vertical installation

Horizontal installation

Table 5: Connection of Modules

13 ANLEITUNG 04_21

Grounding/ (Potential equalization)

Please observe the requirements and standards of the respective national directives for equipotential

bonding. DIN VDE 0100-540 applies to grounding systems and protective conductors including protective

equipotential bonding conductors with the aim of fulfilling the safety of electrical systems.

TRIMAX Solar uses a frame made of anodized aluminum. Therefore, the modules should be connected to the

protective equipotential bonding to prevent electric shock.

Module frame and equipotential bonding must not be used as part of lightning protection. Have the lightning

protection planned and installed by qualified specialists. Avoid electrical corrosion by taking appropriate

measures.

Grounding methods:

The grounding conductor should be at least the

same size as the electrical conductors. Grounding

cables of not less than 4 mm² are recommended. The

frame has pre-drilled holes marked with a grounding

symbol.

Figure 6: Grounding Symbol

•The grounding holes may only be used for

grounding purposes and not for module

mounting.

Figure 7: Grounding

Additional third-party grounding devices:

TRIMAX PV modules can be grounded using third-party grounding devices. It is required that these devices

are certified for grounding solar modules and are installed according to the manufacturer's instructions.

Design substructure

•For rooftop systems, always make sure the roof structure is suitable before installing the modules on

a roof.

•Make sure that the modules do not overlap or exceed the size of the roof.

•Consider the thermal linear expansion of the frames: The recommended minimum distance between

two modules is 1 cm.

•For ground-mounted systems, the recommended minimum distance from the ground to the bottom

edge of the module is at least 50 cm.

•Provide adequate ventilation under/behind the modules to cool them. A minimum distance of 10 cm

between the roof level and the frame of the module is generally recommended.

•When planning the final arrangement of the modules, keep a suitable access area free to facilitate

maintenance and inspection work.

•Do not place the PV modules near air conditioning units or above ventilation outlets.

Load capacity

TRIMAX PV modules can be installed in both landscape and portrait format. Please refer to the load

specifications for the individual module types in the next sections. Please note that this may vary depending

on the mounting system and configuration. The specified values correspond to the design load according to

IEC 61215: 2016. The cyclic load test is carried out according to the standard with the 1.5 times higher test

load. The substructure should be made of durable, corrosion and UV resistant material. Make sure that the

installation method and the substructure can withstand the loading conditions.

14 ANLEITUNG 04_21

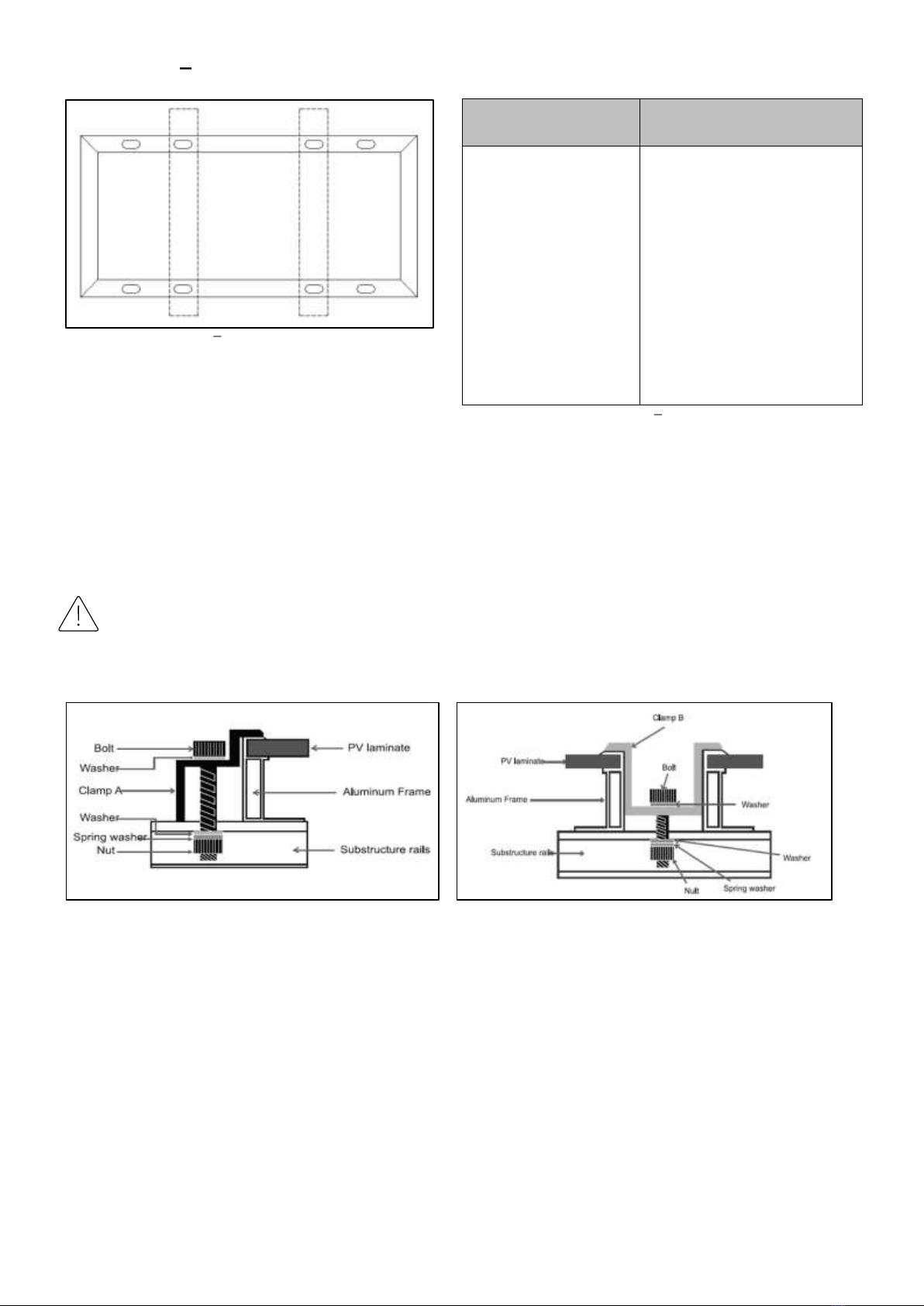

Mounting with screws

TRIMAX Solar - PV modules can be securely fastened to the mounting system (support rails) via the mounting

holes provided. 8 fixing holes are provided to optimize the load capacity of the module and to fix it to the

support structure. If increased wind or snow loads are expected, the additional fixing holes provided should be

used.

Recommended to use corrosion resistant stainless steel

screws.

1. screw - size and length: M8x16mm

2. washer - size: M8

3. spring washer - size: M8

4. nut - size: M8

Torque: 14 Nm - 20 Nm

Load capacity Screw outer mounting holes

Figure 9: Load Capacity Screw outer mounting holes

Module Type

Maximum mechanical load

TMX-MH8-144

Positive: 5400 Pa

Negative: 2400 Pa

TMX-MH9-132

TMX-MH9-120

TMX-MH9-108

Positive: 2400 Pa

Negative: 2400 Pa

Table 6: Approved load capacity Screw outer mounting holes

Figure 8: Mounting with screws

15 ANLEITUNG 04_21

Load capacity Screw inner mounting holes

Figure 10: Load capacity Screw inner mounting holes

Module Type

Maximum mechanical load

TMX-MH7-120

TMX-MH7-132

TMX-MH8-108

TMX-MH8-120

TMX-MH8-132

TMX-MH8-144

TMX-MH9-108

TMX-MH9-120

TMX-MH9-132

Positive: 5400 Pa

Negative: 2400 Pa

Table 7: Approved load capacity Screw inner mounting holes

Mounting with clamping systems

Mounting with clamp systems can be done on both sides of the module frame. Use at least 4 clamps per

module, two on both long sides or two on each short side of the module, depending on the orientation.

Depending on local wind and snow conditions, additional clamps may be required to ensure the module's load

capacity.

•Module clamps must not come into contact with the front glass or deform the frame.

•Take care to avoid shadows caused by module clamps.

Figure 11: End clamp

Figure 12: Center clamp

16 ANLEITUNG 04_21

Load capacity - Clamping Long side

Figure 13: Load capacity - Clamping long side

S = ¼L ± 50mm ( clamping position = S ; module length = L )

Module Type

Maximum mechanical load

TMX-MH7-120

TMX-MH7-132

TMX-MH7-144

TMX-MH8-108

TMX-MH8-120

TMX-MH8-132

TMX-MH8-144

TMX-MH9-108

TMX-MH9-120

TMX-MH9-132

Positive: 5400 Pa

Negative: 2400 Pa

Table 8: Approved load capacity Clamping long side

Load capacity - Clamping Short side

Figure 14: Load capacity - Clamping short side

H= ¼W ( clamp position = H ; module width = W )

Module Type

Maximum mechanical load

TMX-MH7-132

TMX-MH7-144

TMX-MH8-132

TMX-MH8-144

TMX-MH9-108

TMX-MH9-120

TMX-MH9-132

Positive: 1200 Pa

Negative: 1200 Pa

TMX-MH7-120

TMX-MH8-108

Positive: 1800 Pa

Negative: 1800 Pa

Table 9: Approved load capacity Clamping short side

Mounting with insertion systems

TRIMAX PV modules are compatible with insertion systems from selected manufacturers. Installation

methods may vary and depend on the mounting structures. Follow the mounting guidelines recommended by

the mounting system supplier. Each module must be held securely along its entire length on two opposite

sides. Mount and tighten the slide-in profiles to the support structure according to the mounting guidelines

using the fasteners provided by the mounting system supplier. The system designer and installer are solely

responsible for load calculations and proper design of the support structure.

The TRIMAX Solar warranty may be void in cases where unsuitable insertion systems or improper installation

methods are found. Please observe the following recommendations when installing slide-in profiles:

17 ANLEITUNG 04_21

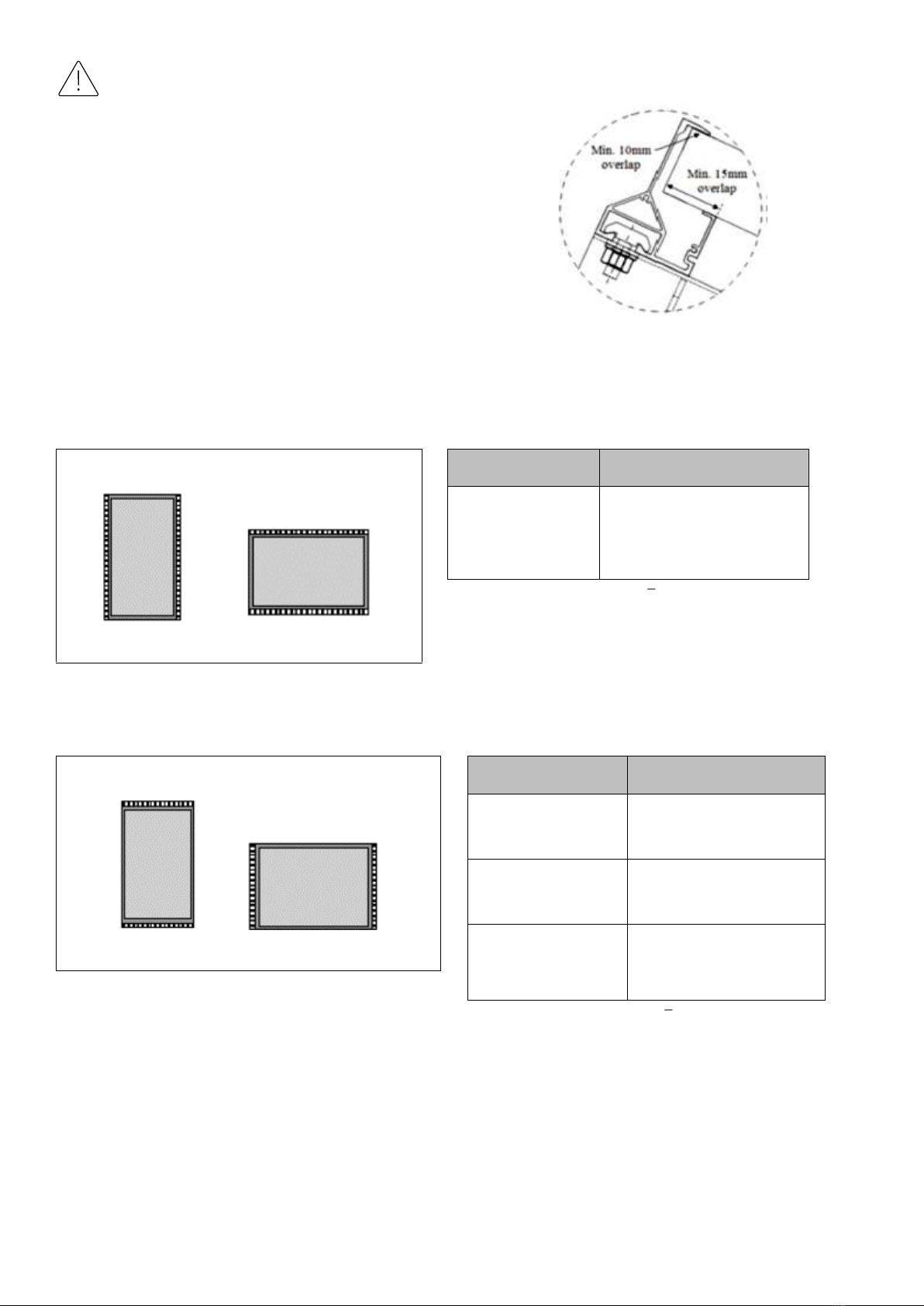

•Pay attention to the dimensions of the module and the

corresponding suitability of the insertion profile.

•Make sure that the insertion depth is sufficient:

oThe insertion profile must overlap the module

frame at the front by at least 10 mm.

oThe insertion profile must overlap the module

frame at the rear by at least 15 mm.

•The cells of the module must not be shaded.

•The front glass must not be touched by the insertion

profile.

Figure 15: Insertion system - Minimum overlap

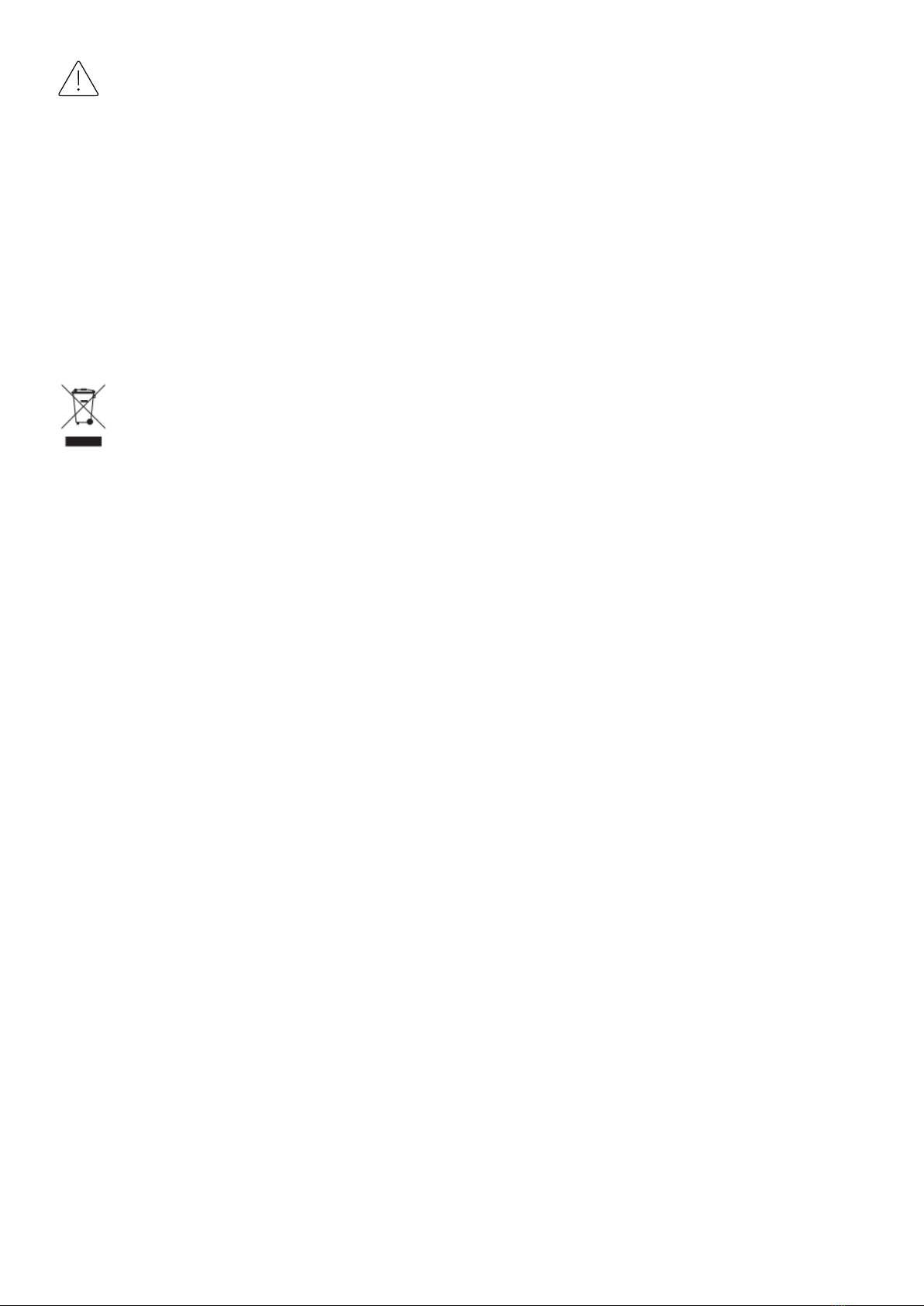

Load capacity - support on the long sides

Figure 16: Load capacity - Insertion system - long side

Module Type

Maximum mechanical load

TMX-MH7-120

TMX-MH7-144

TMX-MH8-108

Positive: 4000 Pa

Negative: 2400 Pa

Table 10: Approved load capacity Insertion long side

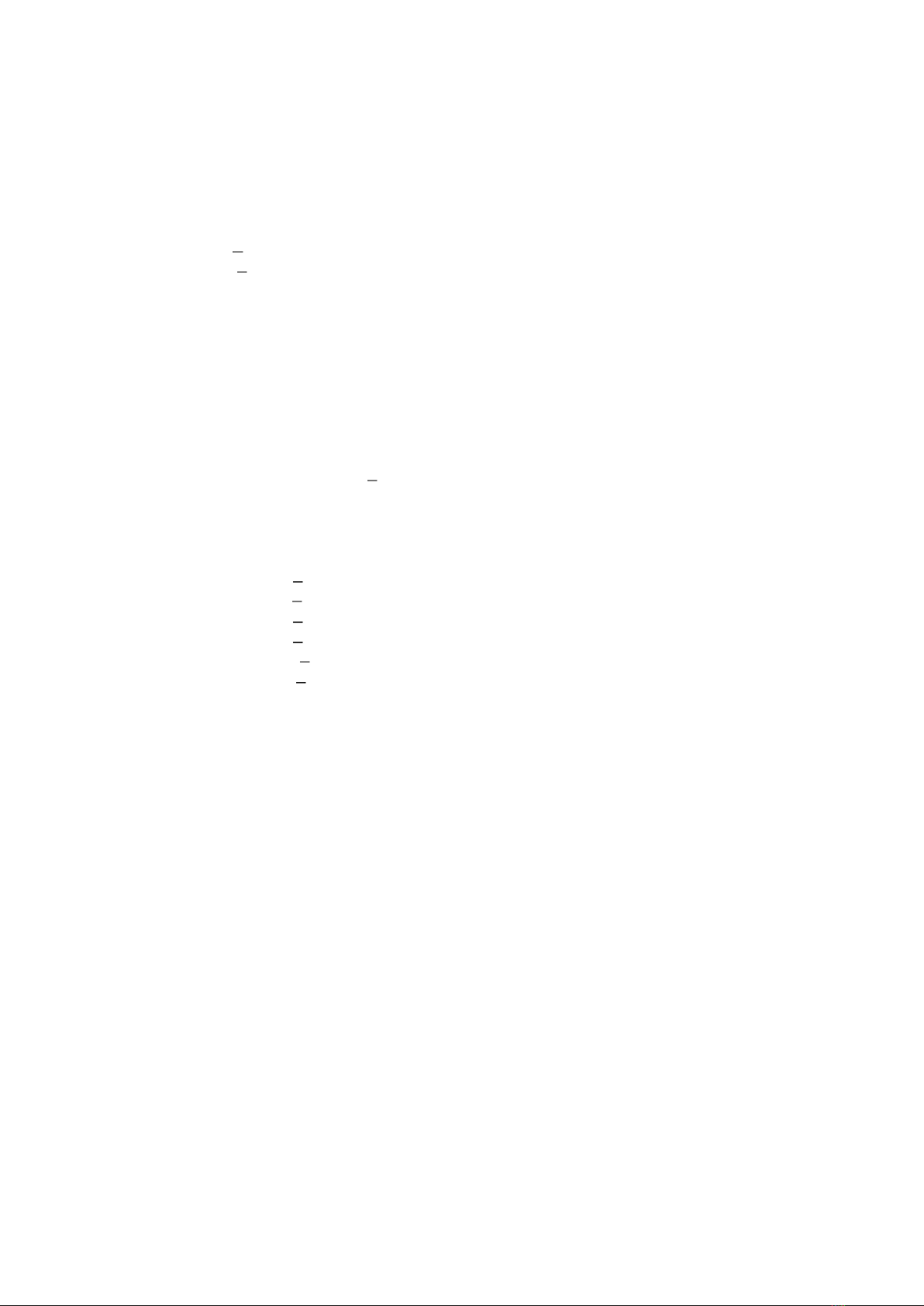

Load capacity - support on the short sides

Figure 17: Load capacity - Insertion system - short side

Module Type

Maximum mechanical load

TMX-MH7-120

TMX-MH8-108

Positive: 2200 Pa

Negative: 2200 Pa

TMX-MH7-132

Positive: 1600 Pa

Negative: 1600 Pa

TMX-MH7-144

Positive: 1200 Pa

Negative: 1200 Pa

Table 11: Approved load capacity Insertion short side

18 ANLEITUNG 04_21

MAINTENANCE

Have any problems that occur investigated by a competent specialist. Repair work may only be carried out by

competent and appropriately trained personnel. Improper maintenance can result in fatal electric shocks

and/or burns.

DIN EN IEC 62446-2:2021-08 Photovoltaic (PV) systems - Requirements for testing, documentation and

maintenance - Part 2: Grid-connected systems - Maintenance of PV systems (IEC 62446-2:2020); German

version EN IEC 62446-2:2020

English title

Photovoltaic (PV) systems - Requirements for testing, documentation and maintenance - Part 2: Grid

connected systems - Maintenance of PV systems (IEC 62446-2:2020); German version EN IEC 62446-

2:2020

•Modules generate voltage when exposed to sunlight. Cover the front surface of the modules with an

opaque and non-scratching material when servicing.

•Use appropriate safety equipment (insulated tools, insulated gloves, etc.) when handling the modules.

•For any electrical maintenance, the PV system must first be switched off.

•Do not touch live parts or cables and plugs.

•Do not disconnect the grounding when performing maintenance on the system.

We recommend the following maintenance to ensure optimal performance of the module:

•Check electrical connections every six months to ensure they are clean, secure and undamaged.

•Check that mounting hardware, terminal screws, and grounding components are tight and not

affected by corrosion.

•Replacement modules must be of the same type as those being replaced.

•Follow the maintenance instructions for all components used in the system, such as support frames,

charge controllers, inverters, batteries, etc.

Cleaning

Dirt and dust can accumulate on the glass surface of the PV module over time, especially in low slope

installations. This can lead to an overall reduction in power output and also to deposits on the bottom edge of

the modules due to dirt accumulation. Under most weather conditions, normal precipitation is sufficient to

keep the glass surface of the PV module clean.

We recommend regular cleaning of the PV modules to ensure maximum power output, especially in regions

with high levels of dust in the air or low precipitation as follows:

•Clean the glass surface of the module as needed, taking into account that a lower slope requires a

higher cleaning frequency.

•Always use water and a soft sponge or cloth for cleaning.

•A mild, non-abrasive detergent may be used to remove stubborn dirt and soaking may be required.

•Water with a high mineral content is not recommended as it may leave residues on the module.

•Do not clean modules with broken glass or exposed wiring. This may result in general electrical failure

of the module or risk of electric shock.

19 ANLEITUNG 04_21

•To avoid possible thermal shock, clean the modules in the early morning hours when the module is still

cold. This is especially recommended in regions with hotter temperatures.

•In cold environments with snow, do not attempt to remove the frozen snow or ice from the module as

this may scratch the front glass. Only soft snow can be removed carefully with a soft brush.

•Do not use abrasive sponges or aggressive tools that could scratch the surface of the module; in no

case should the dirt be removed dry, as this would result in micro-scratches that could negatively

affect the module's performance.

•Do not use high-pressure cleaners.

•Do not use cleaners that are highly acidic or strongly alkaline. Cleaners containing hydrofluoric acid

(HF) and pure alcohol or pure acetone must not be used.

Module at end of life

Please hand in electrical equipment that is no longer required for disposal at the designated

collection points. For information on where to dispose of the equipment, please contact your local

authorities. The garbage can symbol on the TRIMAX product labels means that the equipment must

be disposed of as hazardous waste in accordance with local regulations.

WEEE Reg-No.: DE65803239

DISCLAIMER

The use of this manual and the conditions or methods of installation, operation, use and maintenance of the

product are beyond the control of TRIMAX Solar. TRIMAX Solar expressly disclaims liability for any loss,

damage or expense arising out of or in any way connected with the installation, operation, use or

maintenance. TRIMAX Solar GmbH assumes no responsibility for infringement of patents or other third party

rights that may result from the use of the PV product. No license is granted, by implication or otherwise,

under any patent or patent rights.

20 ANLEITUNG 04_21

List of Figures:

Figure 1: Label....................................................................................................................................................................................................6

Figure 2: Circuit Diagram 108 CELLS- HALF-CUT-PERC...............................................................................................................9

Figure 3: Tilt Angle.........................................................................................................................................................................................10

Figure 4: Series Connection.......................................................................................................................................................................11

Figure 5: Parallel Connection.....................................................................................................................................................................11

Figure 6: Grounding Symbol......................................................................................................................................................................13

Figure 7: Grounding.......................................................................................................................................................................................13

Figure 8: Mounting with screws.............................................................................................................................................................14

Figure 9: Load Capacity Screw outer mounting holes..............................................................................................................14

Figure 10: Load capacity Screw inner mounting holes..............................................................................................................15

Figure 11: End clamp......................................................................................................................................................................................15

Figure 12: Center clamp..............................................................................................................................................................................15

Figure 13: Load capacity - Clamping long side...................................................................................................................................16

Figure 14: Load capacity - Clamping short side................................................................................................................................16

Figure 15: Insertion system - Minimum overlap...............................................................................................................................17

Figure 16: Load capacity - Insertion system - long side................................................................................................................17

Figure 17: Load capacity - Insertion system - short side.............................................................................................................17

List of Tables:

Table 1: Recommended unpacking method horizontally packed modules...........................................................................4

Table 2: Recommended unpacking method - vertically packed modules................................................................................5

Table 3: Tilt Angle...........................................................................................................................................................................................10

Table 4: Maximum reverse current........................................................................................................................................................11

Table 5: Connection of Modules...............................................................................................................................................................12

Table 6: Approved load capacity Screw outer mounting holes.............................................................................................14

Table 7: Approved load capacity Screw inner mounting holes.............................................................................................15

Table 8: Approved load capacity Clamping long side..................................................................................................................16

Table 9: Approved load capacity Clamping short side...............................................................................................................16

Table 10: Approved load capacity Insertion long side.................................................................................................................17

Table 11: Approved load capacity Insertion short side...............................................................................................................17

TRIMAX Solar GmbH

Leitzstraße 45

70469 Stuttgart

GERMANY

Tel : +49 711 490 66 278

Mail : info@trimax-solar.com

Web : trimax-solar.com

This manual suits for next models

20

Table of contents

Popular Solar Panel manuals by other brands

Panasonic

Panasonic EverVolt EVPV HK Series General installation manual

SOLE

SOLE S150 installation manual

Daikin

Daikin EKSV21P installation manual

TSMC Solar

TSMC Solar TS-110C1 Installation and safety manual

Baxi

Baxi Solarflo Commissioning, maintenance & servicing guide

REC

REC REC235 Series installation manual