SOLE S150 User manual

GB

SOLAR COLLECTORS

INSTALLATION MANUAL

MODELS: S150 – S200 – S230 – S260

Page 2of 24

Page 3of 24

INDEX

PAGE

1. Presentation ……………………………………………………………………..

4

2. Parts Included ……………………………………………………………………

4

2.1. Solar Collectors …………………………………………………………….

4

2.2. Support Frame …………………………………………………………….

6

2.3. Connectors ………………………………………………………………….

7

3. Placement of the Collectors …………………………………………………….

8

4. Bank of Collectors ……………………………………………………………….

9

5. Flat Roof Installation …………………………………………………………….

13

5.1. Installation of longitudinal profiles D3 and Z angle E1/E2 ……………...

13

5.2 Installation of vertical legs A3 and the long cross pieces X1/1/X2 ………………………

14

5.3. Installation of vertical legs A3 and the longitudinal profiles D3 …………..

15

5.4. Placement of Solar Collectors …………………………………………….

16

6. Tile roof installation ………………………………………………………………

17

7. Connections and Hydraulic Circuit …………………………………………….

17

8. Lightning Protection....................……………………………………………….

20

9. Permissible wind and snow load ………………………………………………. 20

20

10. Care and Maintenance Program ................................................................. 21

21

Page 4of 24

1. Presentation

The present document demonstrates detailed installation instructions for the solar

collectors using the support frames and accessories included in the supply.

Before proceeding with the installation of the collectors, read these instructions and

make sure you have understood. If you have questions about the materials or on the

assembly process described in this document, contact your supplier via telephone,

fax or e-mail. Improper installation of the collectors may cause an unsatisfactory

operation of the solar system, compromising its durability and even be dangerous for

the people or the goods.

The instructions of this document do not exempt in any way the compliance with

existing regulations and provisions of technical and administrative application at the

place where the facility is located.

The installation of solar collectors without following the instructions in this document

and / or regulations will invalidate the warranty of the product.

The installer will check before starting the installation that he has all the necessary

parts and all the security measures have been taken in order to carry out the

installation safely. The installer must use protective gloves to avoid any risk of burns

or cuts during handling of collectors or its support frame.

2. Parts Included

The supply consists of:

One or more solar collectors

One or more support frames

Two or more fitting and connection (except for a single collector)

2.1. Solar Collectors

The solar collectors are supplied individually packaged in carton boxes. The collector

model is indicated on the outside of each box. Depending on the number of units

ordered, collectors can be supplied palletised in groups of up to 10 units. Collectors

should always be during transport and storage placed with the glass facing on top,

otherwise there is danger of water entering in the collectors from the ventilation holes

at the back of the collector.

The main technical characteristics of the collectors are indicated below (figure no. 1)

TYPE

WEIGHT

DIMENSIONS (mm)

A

B

C

D

E

F

S150

27,30kg

960

1540

1010

895

1458

1815

S200

32,00kg

960

1960

1010

895

1878

2183

S230

38,80kg

1165

1960

1215

895

1878

2280

S260

44,00kg

1238

2135

1308

895

2055

2468

Page 5of 24

Absorber

Copper tubes and aluminium fins with selective coating.

Pressure test

15 bar

Pressure max.

10 bar

Isolation

Side: 20 mm glass wool

back: 40 mm rock wool

Casing

Aluminium profile Free of bolts and rivets.

Sea Water resistant.

Glass

Tempered low iron prismatic glass 3.2 mm.

Sealing

Structural Glazing Silicon Sealant

Connector

Compression union 18x18

Flow recommended

40 litres/h/m²

Content of liquid

S150 = 0,85ltr; S200 = 0,95 ltr; S230 = 1,20ltr; S260 =

1,30ltr

Figure 1. Characteristics of solar collector

The manufacturing of the solar collector follow strict quality criteria and is certified by

ISO 9001:2008.

Page 6of 24

2.2. Support Frame

There are two sets of support frames for a single collector (EST1) or for two

collectors (EST2).

Depending on the bank of solar collectors chosen, the appropriate number of support

frames will be provided for one or two collectors. Table 1 shows the sets of support

frames necessary for different banks of solar collectors.

Nº of collectors in bank

1

2

3

4

5

6

EST1

1

-

1

-

1

-

EST2

-

1

1

2

2

3

Connectors

-

2

4

6

8

10

Table 1. The support frames and the connections provided depend on the number of

collectors per bank

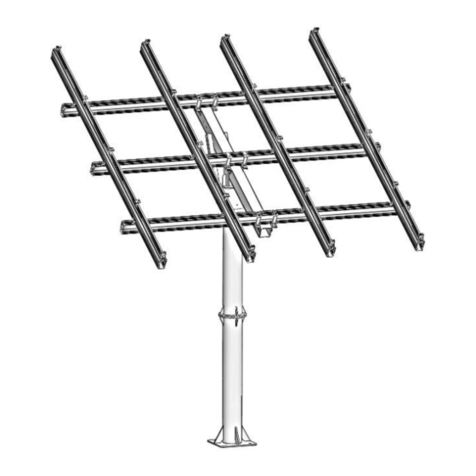

The support frames sets are composed of elements that are shown in Figures 3 and 4.

Figure 3. Support frame components EST1 for a single solar collector

Page 7of 24

Figure 4. Support frame components EST2 for two solar collectors

The support frames allow the installation of the solar collectors with different

inclinations (45, 40, 35 or 30 degrees) using the same profiles and accessories, by

choosing properly the fixing holes.

2.3. Connectors

The connectors supplied are conical-type compression unions with metal ring and

allow the connection of two or more solar collectors in a bank, joining the top and

bottom of the collectors.

This way, the collectors are hydraulically connected between them in parallel.

The number of connections provided is determined by the number of collectors in the

bank, according to Table 1 above.

Figure5. Connections

Page 8of 24

3. Placement of the Collectors

The choice of location, inclination and orientation of the solar collectors has to be

determined at the design stage of the installation. The installation of the solar

collectors in the building should be carried out respecting the instructions of the

person in charge of the project, who should have taken into consideration the effect

of the orientation, inclination and possible shadows in the calculation of benefits of

the solar system.

Particular attention should be paid to the minimum distance maintained between two

rows of solar collectors or between an obstacle in front of a group of solar collectors

and them. During the calculation of this distance one should take into consideration

the latitude of the place, the inclination of the terrain and the period of use of the

facility. Failure to have a more detailed specification by the designer of the facility,

the distance should not be less than that shown in Figure 6.

At the time of its installation, the solar collectors should be stored in a compound

covered and kept in their original packaging. During the assembly phase, avoid

keeping the solar collectors outdoors with the cover glass facing down on wet

surfaces, in order to prevent entry of humidity or water in the rear of the collector.

Figure 6. Distance needed in order to avoid shadows on collectors.

Once at work, in the event that the installer observes the existence of elements that

can cause shadows on the solar collectors and have not be taken into account in the

design of the system, as protection walls in terraces, fireplaces, outdoor air

conditioning units or other elements, should inform the designer of the project or the

owner of the property in order to revise or amend the calculations made for the

location of the collectors, if necessary.

The system of fixing the support frame of the solar collectors to the building also

must be determined in the design phase of the installation, for example by

conducting benches built on a flat roof. In this case, the thickness and size of the

bench should be sufficient to ensure stability of the whole in case of strong gusts of

wind. In any case, the solution adopted should ensure the solidity and stability of the

setting without compromising the watertight integrity of the deck. To facilitate the

design of the fixing system, figures 7 to 13 show the distances between the support

frames of the solar collectors.

Page 9of 24

4. Banks of Collectors

The solar collectors can be connected with each other to form banks of up to 6 units

in parallel, connecting the top and bottom of the collectors through the fittings

included in the set.

The dimensions of pipe connections for collector arrays up to 20m² is 22mm.

It is recommended that the connections between the different banks of collectors are

also conducted in parallel. However, the connection of up to two banks of solar

collectors in series is allowed.

In the following figures from 6 to 13 shows the dimensions of the solar collectors

from 1 to 6 units and for different angles of inclination. Additionally, there should be

sufficient space around the banks of collectors to perform with comfort the hydraulic

connections.

Figure 7. A Single Collector

TYPE

A

B

S150

960mm

890

S200

960mm

890

S230

1165mm

890

S260

1238mm

890

Page 10 of 24

Figure 8. Bank of Two Solar Collectors

TYPE

A

B

C

D

S150

1980mm

890mm

555mm

960mm

S200

1980mm

890mm

555mm

960mm

S230

2390mm

1435mm

477,5mm

1165mm

S260

2536mm

1435mm

550,5mm

1238mm

Figure 9. Bank of Three Solar Collectors

TYPE

A

B

C

D

E

F

S150

3000mm

890mm

555mm

960mm

640mm

890mm

S200

3000mm

890mm

555mm

960mm

640mm

890mm

S230

3615mm

1435mm

477,5mm

1165mm

675mm

890mm

S260

3834mm

1435mm

550,5mm

1238mm

784,5mm

890mm

Page 11 of 24

.

.Figure 10. Bank of Four Solar Collectors

TYPE

A

B

C

D

E

S150

4020mm

890mm

555mm

960mm

1150mm

S200

5020mm

890mm

555mm

960mm

1150mm

S230

4840mm

1435mm

477,5mm

1165mm

1015mm

S260

5132mm

1435mm

550,5mm

1238mm

1161mm

Figue 11. Bank of Five Solar Collectors

TYPE

A

B

C

D

E

F

S150

5040mm

890mm

555mm

960mm

640mm

890mm

S200

5040mm

890mm

555mm

960mm

640mm

890mm

Page 12 of 24

Figure 13. Dimensions of the banks of collectors depending on the inclination.(The

above dimensions apply to all sizes of collectors)

.Figure 12. Bank of Six Solar Collectors

TYPE

A

B

C

D

E

S150

6060mm

890mm

955 mm

960mm

1150mm

Page 13 of 24

5. Flat Roof Installation

Next it will be described the procedure for installing a bank of two solar collectors on

a flat roof. The formation of more banks of collectors is done simply by adding the

support frames EST1 or EST2 when necessary.

5.1. Installation of the longitudinal profiles D3 and the Z angles E1/E2

Place the two longitudinal profiles D3 on the floor, at the indicated distance, so that

both profiles U remain outward-oriented. Place the two Z angles E1 or E2 over, in the

correct position (Figure 14a, 14b & 14c) .

Screw the lower Z angle E1 or E2 to the two longitudinal profiles D3 with two sunk

head bolts M8x20 with their nuts and washers and tighten.

Screw the higher Z angle E1 or E2 to the two longitudinal profiles D3 with two sunk

head bolts M8x20 with their nuts and washers, without tighten it yet in order to

facilitate the subsequent placement of the collectors.

Page 14 of 24

5.2. Installation of the vertical legs A3 and the Long cross pieces X1/X2

Place the two long crosspieces X1or X2 forming an X, with the convex part of the

profiles and link them into contact with each other through a bolt M10x20 with nut

and washer, without tighten it yet.

Place the two vertical legs A3 parallel on the floor, so that both U profiles are

oriented towards the interior. Screw the long crosspieces X1 orX2 as the cross-

legged to the vertical legs A3 using four bolts M10x16 with its nuts. Tighten the four

bolts at the ends and the bolt of the central X (Figure 15a and 15b).

Page 15 of 24

5.3. Installation of the vertical legs A3 and the longitudinal profiles D3

Lift the legs A3 coupled with the X formed with the long crosspieces X1 or X2 until

you place them vertically.

Lift the rear part of the longitudinal profiles D3 coupled with the cross profiles E1 or

E2 and join to the vertical legs A3, using two holes depending on the inclination that

should be given to the collectors (Fig. 16b). Tighten with two bolts M10X16 with its

nuts.

Join the short crosspieces X3 to the longitudinal profiles D3 (at its inner surface) and

to the rear legs A3 (at its outer face), use the holes depending on the inclination that

wants to be given to the collectors (Fig. 16b). Both profiles should be horizontal.

Screw with the two bolts M10x16 in each profile, with its respective nuts.

Join the structure to the bench, using the raw plugs and anchored bolts supplied or

with the fixing parts suitable to the characteristics of the support frame. In any case,

the choice of the solution adopted should avoid compromising the watertight integrity

of the roof. (Fig. 16a).

Figure 16b

X3

X3

Figure16a

AAa

Page 16 of 24

5.4. Placement of Solar Collectors

Place one of the solar collectors in the support frame, place it first on the lower

profile cross-E1 or E2 and then on the higher profile cross- E1 or E2. Adjust the

position of the solar collector in the structure, so that matches the holes in the

structure of the holes in the rear part of the collector (Figure 17).

Remove the protection caps

of the collector lateral’

connections and introduce

the two compression union

connectors (see fig. 5).

Remove the protection caps

of the connections of the

lateral of the second

collector and place it on the

structure, on the cross

profiles E1 or E2 lower and

upper.

Slide the second collector so

that the end is introduced into the connector. Verify that the connection has been

done correctly and that the holes in the structure match those holes back of the

collectors. Adjust the position of the collectors if necessary.

Adjust the higher cross- E1 or E2 profile to the collectors and tighten the bolts that

bind to the longitudinal profiles D3.

Screw the solar collectors to the structure, with the bolts M6x20 (four per collector)

with their washers.

Make sure all bolts and the different elements of the structure are properly tightened

and check the solidity of the whole and its correct fixing to the bench. The collectors

and the support system can withstand wind velocity up to 120km/h and weight of

snow up to 80cmheight at 45 degrees.

The bank of two solar collectors is ready to start the hydraulic connections.

Figure 17.

Figure 18.

Page 17 of 24

6. Tile roof installation

The assembly of solar collectors on a tile roof is done in a manner similar to that

described above, with a different position of the vertical legs A3 that have to be

placed horizontally underneath the E1/E2 in a parallel manner. The crosspieces X1

or X2 and X3 shorts are not needed for tile roof installation.

The profiles D3 longitudinal and transverse E1 or E2 have to be fixed to the roof with

strength and without compromising its tightness. The fixing procedure will depend on

the characteristics of the roof. With the installation fittings are supplied some

perforated flexible metal strips to facilitate this fixation on certain roof configurations.

(See fig. 19) The collectors and the support system can withstand wind velocity up to

120km/h and weight of snow up to 80cmheight at 45 degrees.

Figure 19.

7. Connections and Hydraulic Circuit

The collectors or different groups of solar collectors must be connected hydraulically

to form a closed primary solar collection circuit. The use of copper pipes is

recommended, with a wall minimum thickness of 1 mm and an adequate diameter for

the circulation flow of each part.

The entry of liquid to the group of solar collectors will be from the end at the bottom

of the collector. On the top end connection a plug must be installed. The output of

liquid will be done by the top of collector's opposite end of each bank. On the top

connection an end cap must be installed.

The route of the pipeline will be conducted so as to minimize the parts where the flow

of the hot fluid runs (of the collectors towards the tank or to the interchange at the

plant room).

Page 18 of 24

In each group of solar collectors two stop valves should be installed at the entrance

and exit to allow the hydraulic isolation of the rest of the circuit and a safety valve

(figure 20).

The solar collectors reach high temperatures, especially in periods of great sunshine

and low energy consumption, which can cause significant expansion of the materials.

The connection of various groups of solar collectors with each other and / or pipes of

hydraulic circuit must be made so as to ensure that expansion does not cause

excessive pressure (tensions) on the connections or on the collectors, for example

by the use of flexible unions.

In all the high points of the primary circuit of the solar collectors, and particularly the

output of each group of collectors, an air vent must be installed, automatic or

manual. In any case, the air vent must be capable of withstanding temperatures of

up to 150 º C without deterioration. Once the air is drawn out from the circuit, the

vents will remain closed.

A smooth distribution of flow between different groups of solar collectors must be

ensured so that each group has a flow rate close to 100 litres / h for each collector

that is part of this group (i.e. 400 litres / h for every group of 4 solar collectors). This

can be achieved with appropriate design of the route of the pipeline or by installing a

balancing valve in each group, properly adjusted. We recommend the second

system.

The pressure drop within each collector should be taken into account when selecting

the appropriate pump. (figure 21 indicates the pressure drop)

Page 19 of 24

Figure 21.

The pipes must be insulated according to existing regulations. The thickness of the

insulation material must be at least 30 mm for a material with conductivity equal to

0.040 W/mºK. The insulation material must be capable of withstanding pipe surface

temperatures higher than 120 ° C without deterioration.

The circulating fluid must contain a sufficient amount of antifreeze liquid to avoid any

risk of freezing. The freezing temperature of the fluid circuit of the solar collector

should be less than the minimum temperature recorded at the site of the facility.

Propylene glycol makes an excellent choice for use as a heat transfer fluid in

applications where contact with potable water, food or beverages might occur. Its low

toxicity, low freezing point, corrosion-inhibiting composition and high boiling point

make it uniquely applicable for use in such applications.

Below is a table showing the freezing temp. of propylene glycol – water fluid with

respect to the ratio of pure glycol to the water.

Freezing Point

Propylene Glycol Solution

(% by mass)

0

10

20

30

40

50

60

Temperature

(oC)

0

-3

-8

-15

-24

-36

-48

The primary circuit of the solar collectors must be in accordance with all the

necessary security measures, particularly a safety valve correctly set, an expansion

tank designed to even take into account the evaporation of liquid contained in the

collectors and a system of protection against overheating (heat sink or similar), if

necessary.

Page 20 of 24

The primary circuit of the solar collectors must have at least a thermometer and a

manometer to permit recording of the temperature and the pressure of the circuit.

Before the final filling of the primary circuit, internal washing with domestic water

should be carried out to remove any dirt or rests and pressure test should be carried

out to verify the sealing of all, without exceeding the maximum pressure allowed by

solar collectors. This is to verify that the connections between solar collectors have

no leaks. If that is so, the fittings should be tightened, using two keys, so as to avoid

transmitting force (torsion) to the pipes of the absorbers of the solar collectors.

(Figure 22)

Figure 22

During the final filling of the solar system with antifreeze fluid it must be verified that

the circuit is perfectly purged and pressurized. Once this operation is finalized, the air

vents should be closed.

It should be avoided to carrying out operations such as washing and filling the

primary circuit while or after the solar collectors are exposed to intense sun.

8. Lightning Protection

National norms and regulations over lightning protection should be closely followed.

In any case the support(s) of the collectors must be “earthed” with copper wire of

16mm2to the ground grid of the building. This will serve as lightning protection.

This guideline does not release in any way the installer from his responsibility

against lightning protection requirements.

9. Permissible wind and snow load

Permissible negative pressure for wind load is 1500 Pa

Permissible positive pressure for snow load is 2000 Pa

This manual suits for next models

3

Table of contents

Other SOLE Solar Panel manuals

Popular Solar Panel manuals by other brands

Shentai Solar

Shentai Solar SR10 installation manual

Megasun

Megasun ST-2000 Installation instructions and owner's manuals

Huawei

Huawei SmartLogger2000 series quick guide

Redarc

Redarc SOLAR SMSP1050 manual

Ariston

Ariston THERMO HF-2 Instruction manual for authorized service personnel

Comnet

Comnet netwave NWKSP4 Installation and operation manual