TSMC Solar TS-110C1 User guide

Installation and Safety Manual

Version 2.4, 12/1/2014

TS CIGS C1 Series

TS-110C1, TS-115C1, TS-120C1, TS-125C1, TS-130C1, TS-135C1, TS-140C1,

TS-145C1, TS-150C1, TS-155C1, TS-160C1, TS-165C1,

TS-130C1HV, TS-135C1HV, TS-140C1HV, TS-145C1HV, TS-150C1HV,

TS-155C1HV, TS-160C1HV

Revision History

Date

Version

Description

11/15/2012

1.0

Original version

5/8/2013

1.1

Add some statements about grounding hardware to comply UL 1703 Standard with its

revisions dated May 8, 2012. Moreover, the Electrical Ratings were changed for Models

TS-145C2, TS-150C2, and TS-155C2.

5/15/2013

2.0

Add a new Model TS-160C2 and deleted Models TS-125C2, TS-130C2, TS-135C2 and

TS-140C2 for UL certification.

10/1/2013

2.1

Update product specification in section 6A and add new models TS-165C2, TS-170C2 and

statements in Section 6, Installation and Operation

3/1/2014

2.2

Update product specification in section 6A and statement in Section 6D.

9/30/2014

2.3

Update 8.mounting methods and configurations

12/1/2014

2.4

Add a new model TS-165C1, TS-xxxC1HV(xxx=130~160) and WEEB grounding.

Moreover, the electrical ratings were changed for all models.

1. Introduction

With proper operation and maintenance, TSMC Solar modules will provide clean and renewable solar electricity

for years. This manual contains necessary installation, maintenance and safety information.

This Installation and Safety Manual will hereafter be referred to as “this manual”.

TSMC Solar Ltd., TSMC Solar Europe GmbH and TSMC Solar North America Inc. will all be referred to herein as

“TSMC Solar”.

TSMC Solar TS CIGS Series solar PV modules will hereafter be referred to as “TSMC Solar module(s)”or

“module(s)” or “the module(s).

Please retain this manual for your future reference.

2. Disclaimer of Liability

The use of this manual, the conditions and methods of installation as well as the operation, use, and maintenance

of TSMC Solar modules are beyond TSMC Solar’s control. Therefore, TSMC Solar assumes no responsibility and

expressly disclaims liability for loss, damage, injury or expense arising out of or in any way connected with such

installation, operation, use or maintenance of the modules. Furthermore, TSMC Solar assumes no responsibility

for any infringement of patents or other rights of third parties that may result from use of the modules, unless we

are automatically liable.

If you do not adhere to the instructions given in this manual, your rights under the TSMC Solar warranty may be

forfeited. Please check the warranty for the full details of your rights and obligations relating to your purchase and

use of TSMC Solar modules

3. General Information

This manual contains information regarding the installation and safe handling of TSMC Solar modules. All

instructions must be read and understood before attempting installation. If there are any questions, please

contact your sales representative or TSMC Solar for further information.

Installers must conform to all safety precautions in the manual when installing modules. Before installing, the

installer must become familiar with the mechanical and electrical requirements for PV systems.

Danger of death from electric shock!

Modules generate direct current (DC) electricity as soon as the front face is exposed to light.

Individual modules and especially connected systems can be an electrical hazard. Follow these general safety

and installation guidelines to avoid safety and electrical hazards.

WARNING

4. Warnings and Cautions

4.A Warning

All instructions must be read and understood before attempting to install, wire, operate, and/or maintain the

module. When modules are exposed to sunlight or other light sources, they generate DC electrical energy.

Contact with electrically active parts of the module such as terminals can result in burns, sparks, and lethal

shock whether the module is connected or disconnected.

Shock hazard increases as modules are connected in parallel, producing higher current, and as modules

are connected in series, producing higher voltage. The installer assumes the risk of all personal injury or

property damage that might occur during installation and handling of modules.

Do not disassemble, modify or remove parts of the module.

4.B Cautions

Use modules for their intended purpose ONLY.

Do not treat any portion of the module with paint or adhesives, to avoid damage to the module, inoperable

conditions, or reducing the module’s functionality.

5. Handling and Installation Safety

To avoid injury or damage:

Wear non-slip gloves.

Do not allow children or unauthorized persons near the installation site or module storage area.

Do not wear metallic rings, jewelry or devices while installing or troubleshooting photovoltaic systems.

Work only in dry conditions, with dry modules and tools.

Do not install the module where flammable gases or vapors are present.

Never leave a module unsupported or unsecured.

The back of the module must not be exposed to direct sunlight for extended periods of time during storage

or during the installation process to avoid the possibility of heat damage.

When disconnecting wires connected to a module that is exposed to sunlight, an electric arc may result.

Such arcs may cause burns, may start fires and may otherwise create problems. Be extremely careful!

Use only equipment, connectors, wiring and mounting structures suitable for use in a photovoltaic system.

Series connected modules should always be of uniform configuration and electrical specifications.

Cover the entire front surface of the modules with a dense, opaque material such as a cardboard box, when

working on a connected system cannot be avoided. Check for remaining voltage before starting, and

observe the relevant local safety regulations for such working conditions.

6. Installation and Operation

Photovoltaic systems must be installed by qualified and experienced personnel.

Install PV modules with a minimum spacing of 10mm between neighboring frames to allow for thermal

expansion.

Do not step on, or place objects on the module during or after installation. Although TSMC Solar modules

are quite rugged, the glass may be broken if it is dropped or hit by tools or other objects and the module will

no longer work properly. The module must not be exposed to concentrated sunlight, e.g. sunlight focused by

mirrors, lenses or other magnifiers.

The module frame is made of anodized aluminum, and therefore corrosion can occur if the module is placed

in a salt-water environment in contact with a rack made of another type of metal (Electrolytic Corrosion). If

required, stainless steel washers can be placed between the module frame and support structure to prevent

this type of corrosion.

Any module support structures that are to be used to support TSMC Solar modules must be wind rated and

approved for use by the appropriate local and civil codes prior to installation. In Canada, the installation

must be done in accordance with CSA C22.1, Safety Standard for Electrical installations, Canadian

Electrical Code, Part I.

Do not drill holes in the module frame

Any module without a frame (laminate) shall not be considered to comply with the requirements of UL 1703

unless the module is mounted with hardware that has been tested and evaluated with the module under this

standard or by a field Inspection certifying that the installed module complies with the requirements of UL

1703.

The module type has been qualified as “Application Class A”under IEC 61730-1.

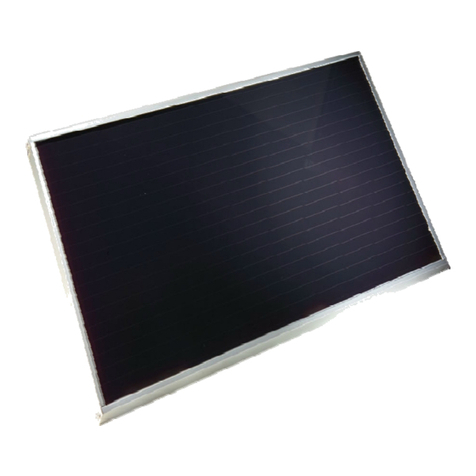

Figure 1 Module Physical Specifications

All measurements in mm [inches]

6.A Module Product Specification

C1 Product

Type of Modules (Series) TS-110C1 TS-115C1 TS-120C1 TS-125C1 TS-130C1 TS-135C1 TS-140C1 TS-145C1 TS-150C1 TS-155C1 TS-160C1 TS-165C1

Maximum power (Pmax)110 115 120 125 130 135 140 145 150 155 160 165

Open-circuit voltage (Voc)62.0 62.3 62.6 63.0 63.3 63.6 63.9 64.2 64.5 64.8 65.2 65.5

Short-circuit current (Isc)3.61 3.61 3.61 3.61 3.61 3.61 3.61 3.61 3.61 3.61 3.61 3.61

Maximum power voltage (Vmpp)35.6 37.0 38.2 39.7 41.0 42.3 43.6 44.9 46.0 47.4 48.8 50.0

Maximum power current (Impp)3.09 3.11 3.14 3.15 3.17 3.19 3.21 3.23 3.26 3.27 3.28 3.30

Module efficiency 10.1% 10.6% 11.0% 11.5% 12.0% 12.4% 12.9% 13.4% 13.8% 14.3% 14.7% 15.2%

Certified by TUV SUD

Maximum system voltage (Vsys)

Maximum series fuse rating

Temperature coefficient of Pmax

Mechanical load

Dimension ininches (inch/mm)

Weight in lbs (kg)

Frame

38.5 (17.5)

Black Anodized Aluminum

TUV SUD

TUV SUD / UL

1000Vdc / 600Vdc(UL)

6A

-0.31%/℃

2400Pa (IEC) / 1695Pa (35lb/ft2, UL)

25.8 (656) x65.2 (1656)x 1.4 (35)

C1HV Product

Type of Modules (Series) TS-130C1HV TS-135C1HV TS-140C1HV TS-145C1HV TS-150C1HV TS-150C1HV TS-160C1HV

Maximum power (Pmax)130 135 140 145 150 155 160

Open-circuit voltage (Voc)63.3 63.6 63.9 64.2 64.5 64.8 65.2

Short-circuit current (Isc)3.61 3.61 3.61 3.61 3.61 3.61 3.61

Maximum power voltage (Vmpp)41.0 42.3 43.6 44.9 46.0 47.4 48.8

Maximum power current (Impp)3.17 3.19 3.21 3.23 3.26 3.27 3.28

Module efficiency 12.0% 12.4% 12.9% 13.4% 13.8% 14.3% 14.7%

Certified by

Maximum system voltage (Vsys)

Maximum series fuse rating

Temperature coefficient of Pmax

Mechanical load

Dimensionin inches (inch/mm)

Weight in lbs (kg)

Frame

UL

1000Vdc(UL)

6A

-0.31%/℃

1695Pa (35lb/ft2, UL)

25.8 (656) x65.2 (1656) x1.4 (35)

38.5 (17.5)

Black Anodized Aluminum

Measured at STC: Irradiance 1000W/m2 and cell temperature 25°C (77°F) AM=1.5 after factory light soaking.

All ratings +/- 10%, unless specified otherwise. Specifications are subject to change

Pmax Tolerance (UL) after IEC Light Soaking is +10%/-5%, before IEC Light Soaking Tolerance is +/-5%

Refer to datasheet for potential increases in Pmax, Voc and Vmpp after post-installation light soaking.

6.B Electrical Installation

“Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current

and/or voltage than reported at standard test conditions. The requirements of the National Electrical Code (NEC)

in Article 690 shall be followed to address these increased outputs. In installations not under the requirements of

the NEC, the values of ISC and VOC marked on this module should be multiplied by a factor of 1.25 when

determining component voltage ratings, conductor ampacities, overcurrent device ratings, and size of controls

connected to the PV output.”

The multiplying factor at conditions of an irradiance of 1250 w/m2, AM1.5 spectrum, and a cell temperature of

-10°C (+14°F) for Voc is 1.25 and at cell temperature of 75°C (167°F) for Isc it is 1.25.

For field connections, use approved PV Copper wire only, minimum No. 14 AWG (2.5mm2) wires insulated for

minimum of 90°C, rated for wet conditions and resist to ultra violet radiation (where exposed)

6.C Electrical Wiring Method

To ensure proper system operation, correct cable connection polarity (Figure 2) must be observed when

connecting the modules to other modules. If not connected correctly, the bypass diode could be destroyed. If

modules are connected in series, the total voltage is equal to the sum of the individual module voltages. Only

connect modules or series combinations of modules with the same voltage. If modules are connected in parallel,

the total current is equal to the sum of individual module current.

Figure 2 Wiring Methods

6.D Correct Wiring Scheme

Match the polarities of cables and terminals when making the connections; failure to do so may result in

damage to the module.

Avoid immersion of cables and connectors in water and site them away from areas prone to water

collection. Ensure a minimum clearance of 10mm between the ground/roof surface and the

cables/connectors after installation.

Fix the cables/connectors to the module or mounting structure before commissioning the system.

Use the tool recommended by connector manufacturer when disconnection of connector is needed.

Example: open-end spanner PV-MS (Figure 3).

When routing cable, ensure forces on the cable do not create a visible deformation in the sealing portion of

the insulation. Do not create cable bends less than the 26mm minimum bending radius of our cables

(Figure 4)

In order to limit voltages induced by indirect lightning strikes, keep the area of all conductor loops to a

minimum

Series Wiring (voltage additive)

Parallel Wiring (current additive)

Figure 3 Example: Open-end spanner PV-MS Figure 4 Cable diagram

6.E Bypass diode

Model type

FR607G

GSR1010HD

Voltage rating

1000 (V)

1000 (V)

Current

8 (A)

10 (A)

Configuration

Single in J-box

Single in J-box

6.F Mechanical Installation

There are two mechanical installation methods, the clamp method and the bolt method. Mounting hardware

locations for both methods are illustrated in this section.

No matter which method is used, the modules are recommended to be mounted in portrait orientation (short side

parallel to ground) for best performance. If modules are mounted in landscape orientation (long side parallel to

ground), shading must be minimized as this orientation can significantly increase the impact of shading on

module performance. Please do not mount the module in landscape orientation with less than 10°tilt angle.

Clamp Method:

Modules mounted with clamps must have the center of the clamp positioned within the shaded clamp zones as

shown in Figure 5. This method enables a maximum mechanical loading of 2,400N/m2 (50PSF) (IEC),

.

Figure 5 Clamp Zone

Bolt Method:

The frame of each module has 8 x 6.6 mm [0.26”] mounting holes. Modules mounted by bolting the frame to

mounting structure must use the 4 mounting hole locations denoted “M1”in Figure 6. This method enables a

maximum mechanical loading of 2,400N/m2 (50PSF) (IEC) too, in a static state on the module surface.

The 4 mounting holes located further towards the short edge of the frame than the “M1” holes are reserved for

future product use and may NOT be used with current products.

All measurements in mm [inches]

Figure 6 Bolt Method Mounting Hole Locations

6.G Tilt Angle Selection

Module tilt angle is measured between the module and the ground as shown in Figure 7, with modules generating

the maximum power when they face sunlight directly (incident light perpendicular to module front surface).

The modules should be oriented to face south in the Northern Hemisphere and face north in the Southern

Hemisphere.

For installations where the modules are mounted on a permanent structure, they should be tilted so that the

energy production from the modules will be maximized on an annual basis. Generally this result will be achieved

when the tilt angle is near the value of the latitude of the mounting site. Use photovoltaic system simulation tools

or consult professional installers / system integrators to determine optimum tilt angle.

Tilt angles of at least 10°are recommended to reduce dirt or other substance accumulation. Please do not mount

the module in landscape orientation with less than 10°tilt angle.

Figure 7 Tilt Angle Definition

All measurements in mm [inches]

6.H Fire Class Rating

These modules have achieved aFire Resistance Rating of Class C. The fire rating of this module is valid only

when mounted in the manner specified in the mechanical mounting instructions as described in Section 8 of this

document, “Mounting Methods and Configurations”.

In rooftop installations, installed modules must have a standoff height between roof and module of more than 9cm

[3.54”] for airflow passage.

Note: During UL testing, the slope of the fire class test for this module is 5 in/ft.

Standoff Height

Module

Roof

Figure 8 Standoff Height

7. Grounding

A module with exposed conductive parts is considered to be in compliance with UL 1703 only when it is

electrically grounded in accordance with the instructions presented below and the requirements of the National

Electrical Code

The company installing the modules will be responsible for professional grounding of the modules. The

factory-provided aluminum frame must be grounded.

All grounding must be performed to be compliant with the latest regulations that are applicable for the jurisdiction

where the system is installed, e.g. the NEC (National Electric Code) in the United States.

If the building is already equipped with an exterior lightning protection system, the PV installation must be

integrated into the protection system against direct effects of lightning

There are eight 4.2mm [0.165”] grounding holes on the module frame, four on each of the module’s short sides.

The grounding holes are identified by a grounding mark (Figure 9) located next to each hole.

Figure 10 illustrates grounding the module. Ground wires must be connected to the module’s frame at one of the

grounding holes. The ground wire must not be smaller than No.14 AWG (2.5 mm²), and sized according local

regulations, e.g. the NEC (National Electric Code) in the United States.

The ground holes must be used with M4 screws. The length of these screws must not exceed 20 mm [0.78”] in

order to avoid contacting the back glass of the module. The screw length must not be less than 12 mm [0.47”].

The torque to be applied to the M4 screw is 3.0~4.0 N-m [22.1~26.6 in-lb].

The material of the frame is aluminum alloy. To avoid galvanic corrosion, all fasteners (nuts, bolts, washers,

9cm [3.54”]

screws, etc.) must be stainless steel unless otherwise specified.

Figure 9 Grounding Mark and Hole Dimensions

Figure 10 Grounding with Washers

WEEB grounding (Certified by UL only)

In addition, WEEB (Washer, Electrical Equipment Bond) grounding parts with UL 467 listing can be used with

TSMC Solar module. The WEEB parts must be installed in accordance to the manufacturers’ installation

instruction. The diagram below (Figure 11) shows how WEEB grounding parts are used with the end/middle

All measurements in mm [inches]

clamp in the installation. And the dimension of end/middle clamp for WEEB grounding parts have to follow our

proposed requirement that the clamp overlap the module frame by at least 5 mm, the clamp overlap length is at

least 38 mm and the fasteners torque of at least 10 ft-lbs (13.5N-m) is suggested.

Figure 11 Grounding with Clips

8. Mounting Methods and Configurations

The module is considered to be in compliance with UL 1703 only when the module is mounted in the manner

specified by the mounting instructions below

As introduced in section 6.F, there are two mechanical installation methods: Clamp and Bolt. Both methods of

mounting and configuration are explained below, respectively.

In all cases, PV modules are to be mounted over a fire resistant roof covering rated for the application.

Clamp Method

The module is secured to the mounting structure by clamping. A clamping solution requires a top clamp piece that

braces the front of the module frame, and a rail or bottom clamp piece that supports or clamps the bottom of the

module. The top clamp pieces hold the module securely at four points against rails or bottom clamps. Except for

modules at beginning and end of a row of modules, middle clamps can be used to hold two modules per clamp.

For the allowed location of each clamp on a PV module, see the clamp zone definition in section 6.F, Figure 4.

An example of top, bottom and middle clamp is shown in Table 1

When using clamping method, make sure the clamping overlap is positioned according to figure 12 and figure 13.

The module clamping method is shown in figure 14 and the clamping material should be anodized aluminum alloy.

Warranty may be void if inappropriate clamps or unsuitable clamping method are used.

Figure 12 Middle Clamp

Figure 13 End Clamp

Figure 14 Module Clamp Mounting Method

Bolt Method

The module can be mounted by bolting the frame to mounting structure. This method requires 4 sets of: M6 bolt,

M6 spring washer, M6 flat washer and M6 nut per module. There are eight mounting holes on the back side of

module, however only the 4 mounting hole locations denoted “M1” in Figure 6 can be used. These 4 holes are

offset from the short edge of module by 407.5mm [16.04”].

The installation method (Figure 15) requires that the spring washer be first placed on the bolt, followed by the

insertion of the bolt first through the module mounting hole in the aluminum frame then through the system rail.

Finally, after putting the flat washer and nut on the bolt, use torque of 6.1 N-m to screw the nut tight to complete

the installation. The bolt mounting method cross section is as shown in Figure 16.

SEE DETAIL A

DETAIL A

M6 BOLT

M6 SPRING WASHER

M6 FLAT WASHER

M6 NUT

Figure 15 Module Bolt Mounting Method

M6 BOLT

M6 SPRING WASHER

M6 FLAT WASHER

M6 NUT

Top edge of system rail

Figure 16 Bolt Mounting Method - Cross Section

Mechanical Components

Mounting mechanical means to be used in clamp or bolt methods are as below and as shown in Table 1:·

Screw/Bolt: M6 Stainless Steel

Nut: M6 Stainless Steel Flange Nut

Washer: M6 Stainless Flat Washer, M6 Spring Washer

Torque Value: 6.1 ~ 7 N-m [54.0~61.9 in-lb]

Clamps: Aluminum

50 [1.96"]

M6 NUT M6 WASHER TOP CLAMP

M6 FLANGE NUT BOTTOM CLAMP M6 BOLT (L: 55~65mm) [2.16"~2.56"]

MOUNTING STRUCTURE BEAM

60 [2.36"]

30 [1.18"]

50 [1.96"]

MIDDLE CLAMP

50 [1.96"]

M6 SPRING WASHER

Table 1 Mounting Method Mechanical Components

All measurements in mm [inches]

9. Serial Number Format and Definition

Every individual module has a unique serial number, with corresponding bar code.

Serial numbers have 11 digits. The meaning of the individual digits and groups of digits are as defined below.

Digit Position 1 2 3 4 5 6 7 8 9 10 11

Serial Number A 1 2 5 0 1 x x x x x

Fab Digits 2-6 encode productiondate

TSMC Solar internal use

In this example: May1, 2012

Serial number naming rules:

Digits Field name Naming rule

1st Fab Code “A” = Fab 1, “B” = Fab 2 etc.

2nd –3rd Year Last 2 digits of year, e.g. “11” = 2011, “12” = 2012

4th Month “1” – “9” = Jan – Sep respectively, “A” – “C” = Oct – Dec respectively

5th –6th Day “01” –“31” = 2 digit day, e.g. “15” = 15th of month

7th –11th Internal Use Defined for TSMC Solar internal use

Contact Information

Europe

TSMC Solar Europe GmbH

Am Kaiserkai 1

20457 Hamburg, Germany

Tel: +49 (0) 40/80 80 745 40

Fax:+49 (0) 40/80 80 749 20

North America

TSMC Solar North America Inc.

2595 Junction Avenue

San Jose, CA 95134 USA

Tel: +1 408 678 2816

Fax:+1 408 678 2800

Asia / International

TSMC Solar Ltd.

No. 5 Keya W. Rd, Daya District

Taichung, Taiwan 428-82 ROC

Tel: +886 4 2703 6688

Fax:+886 4 2569 3884

www.tsmc-solar.com

IM-TSC1-EN-01/15-01

This manual suits for next models

18

Table of contents

Popular Solar Panel manuals by other brands

Wetelux

Wetelux SL-SM-A-2 instruction manual

JIANGYIN TITANERGY

JIANGYIN TITANERGY TT-ADJUSTABLE TILT LEGS installation manual

Dwyer Instruments

Dwyer Instruments SPK quick start guide

Viking

Viking VSLT240-MH Operation and maintenance manual

Technaxx

Technaxx TX-241 user manual

Paua

Paua Air 300 Assembly instruction