Page

3

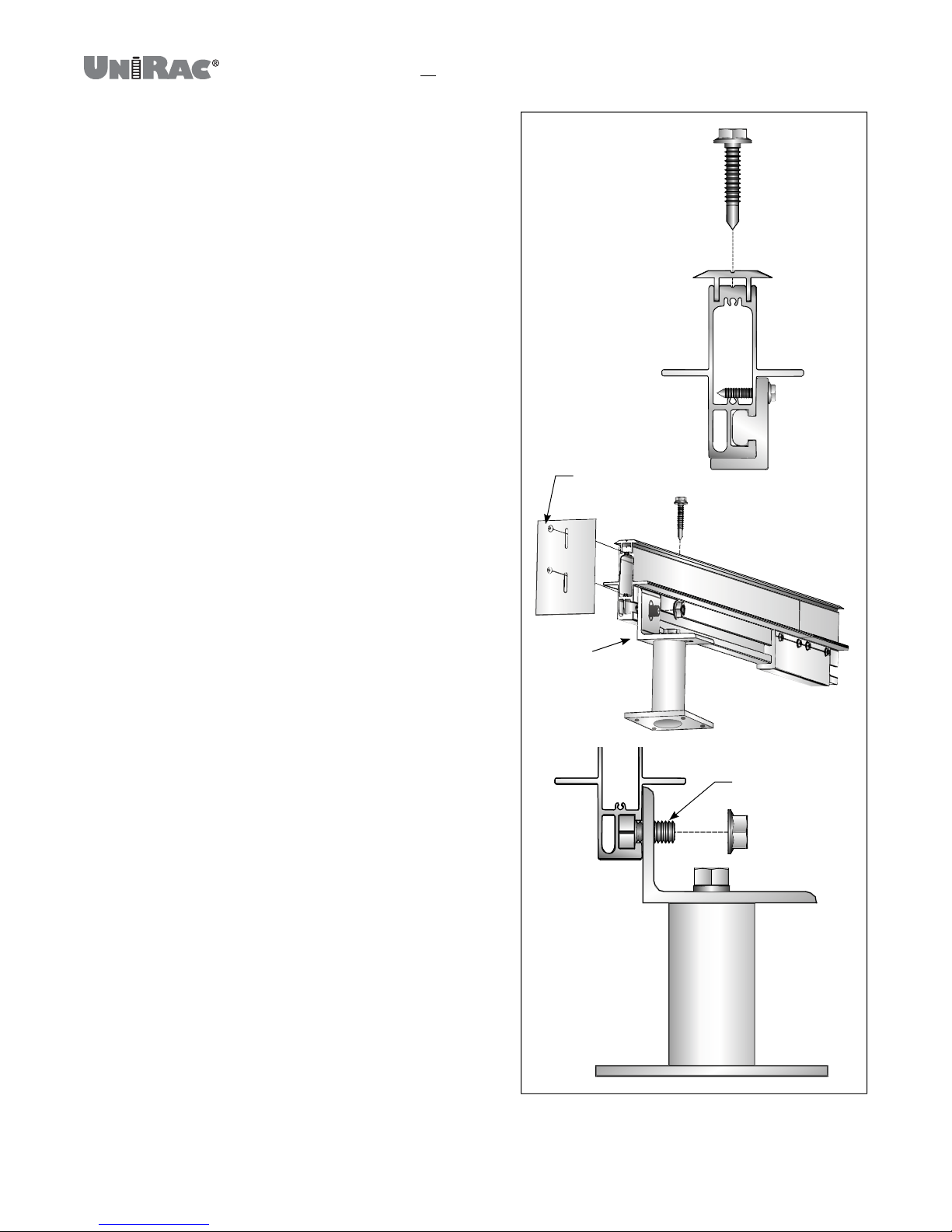

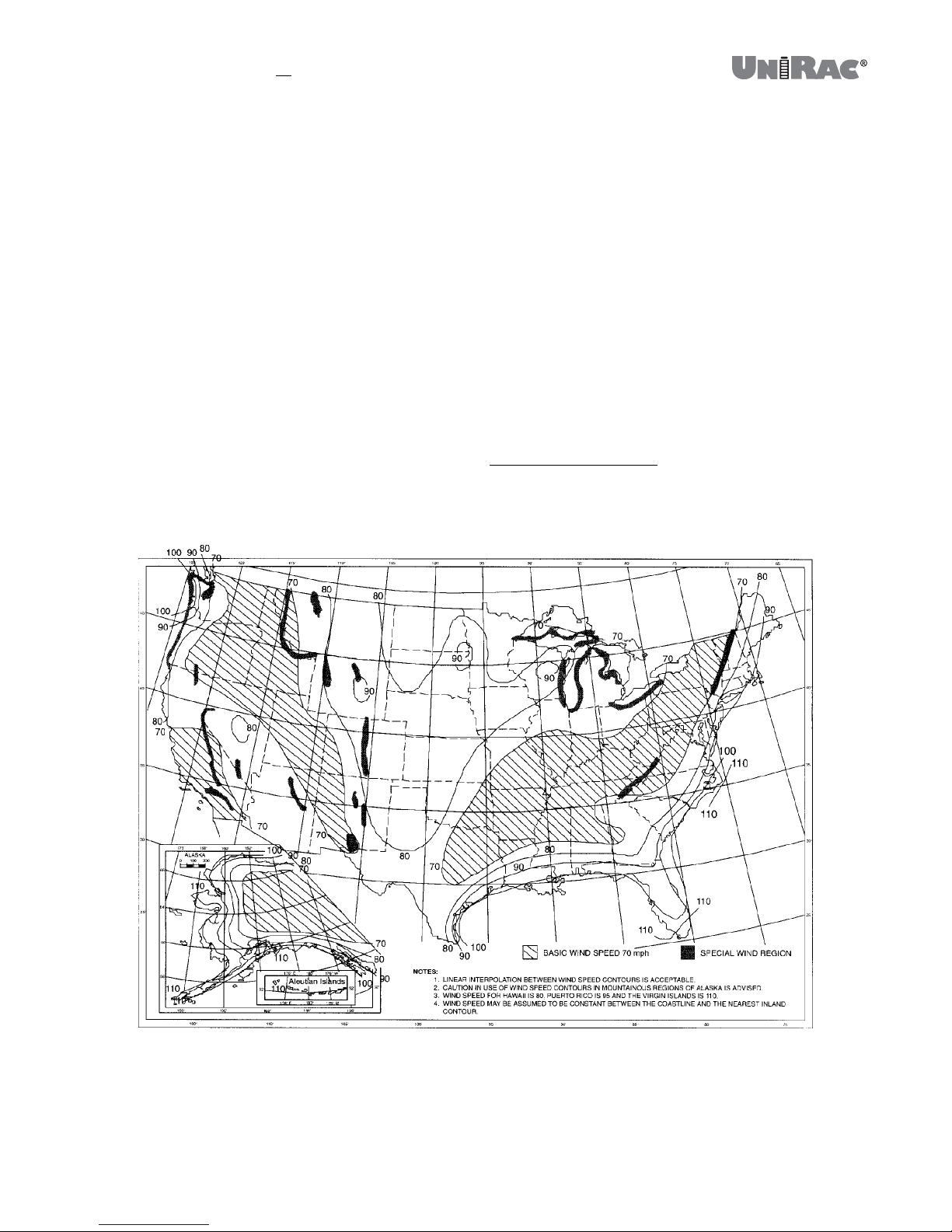

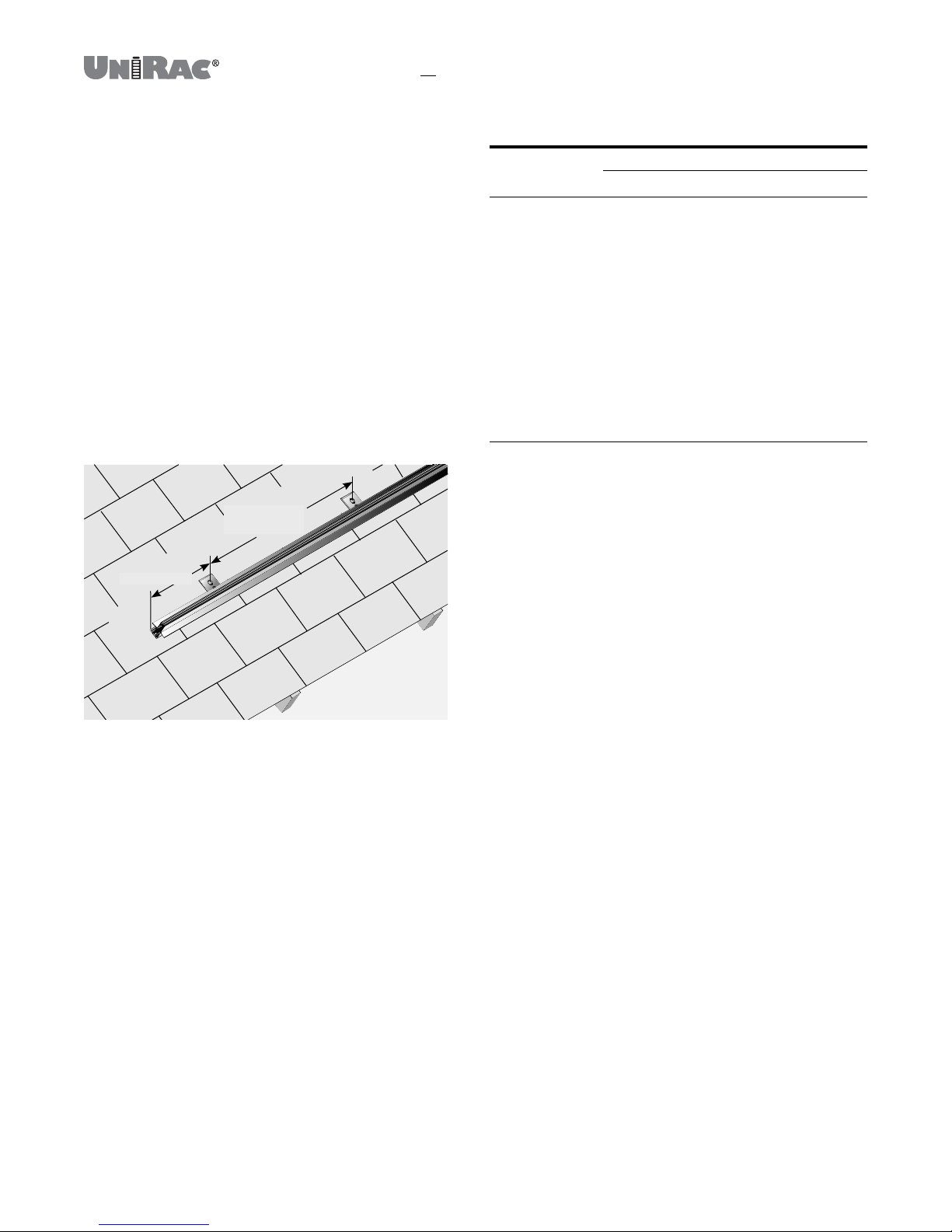

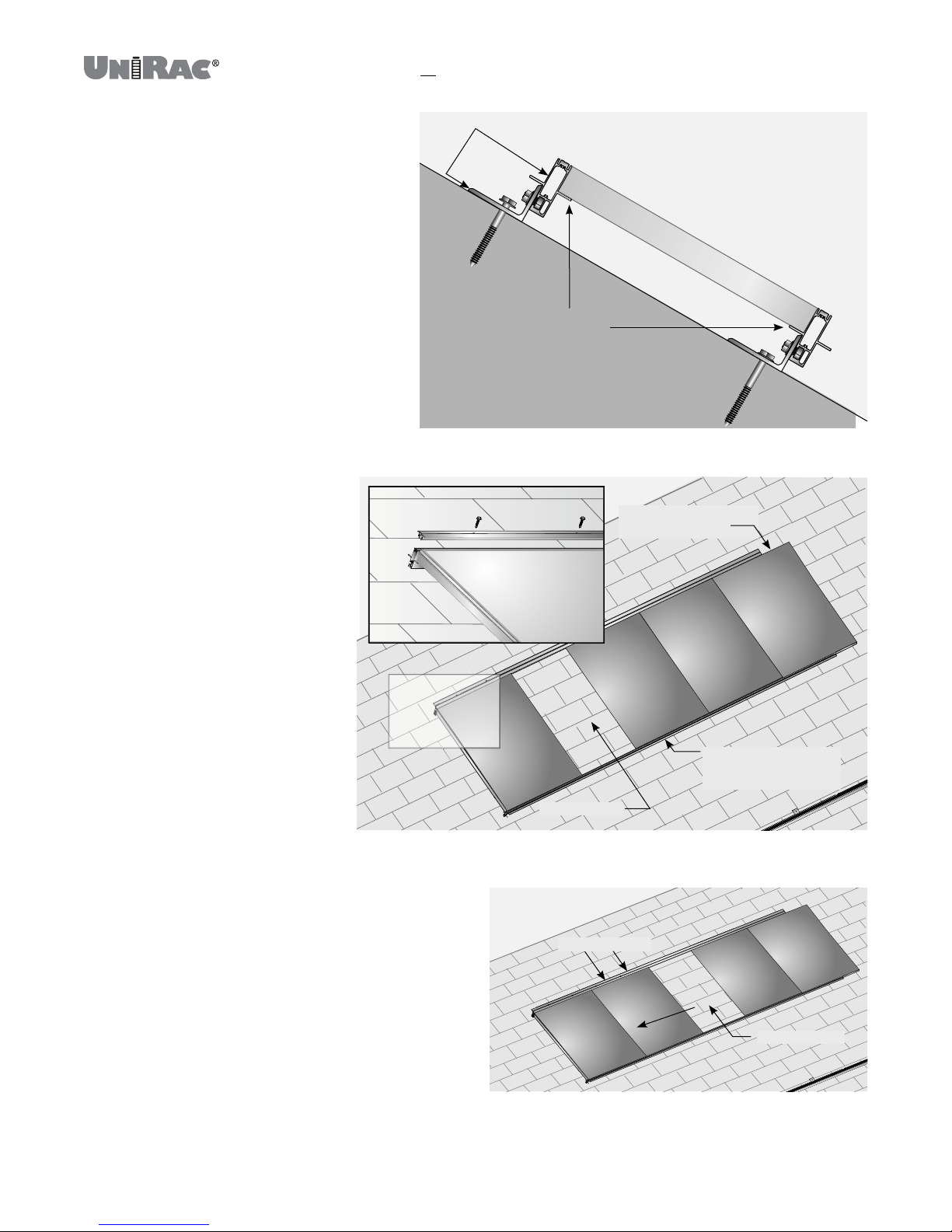

Installation Manual 802 SunFrame™ Code-Compliant Planning and Assembly

Scope, certification, and installer responsibility

Please review this manual thoroughly

before installing your SunFrame.

This bulletin provides (1) support-

ing documentation for building per-

mit applications relating to UniRac’s

SunFrame™ PV module framing and

mounting system, and (2) planning

and assembly instructions for Sun-

Frame.

SunFrame products, when installed in

accordance with this bulletin, will be

structurally adequate and will meet the

Uniform Building Code, 1997, hereaf-

ter UBC 1997; and the 2001 California

Building Code. UniRac also provides a

limited warranty on SunFrame prod-

ucts (below).

The installer is solely responsible for:

• Complying with all applicable local or national

building codes, including any that may supercede

this manual;

• Ensuring that UniRac and other products are ap-

propriate for the particular installations and are

designed for the installation environment;

• Ensuring that the roof, its rafters, connections, and

other structural support members can support the

array under live load conditions;

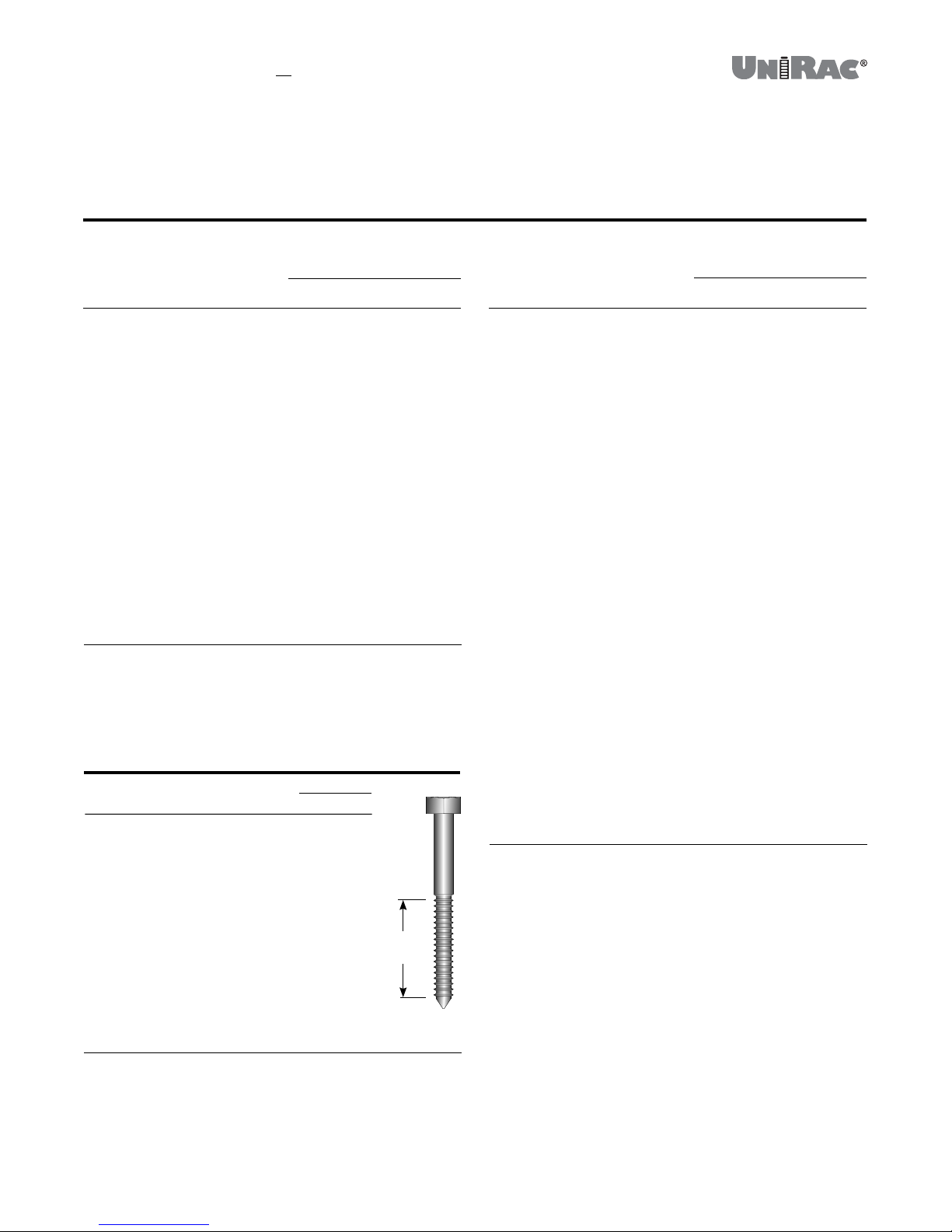

• Ensuring that lag screws have adequate pullout

strength and shear capacities;

• Maintaining the waterproof integrity of the roof,

including selection of appropriate flashing; and

• Ensuring safe installation of all electrical aspects of

the PV array.

UniRac, Inc., warrants to the original purchaser of the Product (“Purchaser”)

at the original installation site (“Site”) that the SunFrame™ PV module framing

and mounting system (the “Product”) shall be free from defects in material and

workmanship for a period of ten (10) years, except for the anodized finish, which

warranty shall be free from visible peeling, cracking or chalking under normal

atmospheric conditions for a period of five (5) years, from the earlier of 1) the

date the installation of the Product at the Site is complete, or 2) 30 days after the

purchase of the Product by the original Purchaser of the Product.

The term “chalking” applies to the powdery residue formed by the breakdown

of the anodized finish. It does not apply to any foreign residue deposited on the

finish by the surrounding atmosphere, including, but not limited to, soot, dust,

plaster, cement, etc. All installations in corrosive atmospheric conditions are

excluded, including, but not limited to chemical fumes, salt spray or surface

temperatures which exceed 200 degrees F. This Warranty does not cover

damage to the finish caused by moisture, condensation, or other contamination

resulting from improper storage, packing or handling. The finish Warranty

is void if normal maintenance and cleaning practices are not followed by

Purchaser as specified by AAMA 609 & 610-02 – “Cleaning and Maintenance for

Architecturally Finished Aluminum” (www.aamanet.org).

This Warranty does not cover damage to the Product that occurs during

shipment, nor prior to or during installation.

This Warranty shall be void if installation of the Product is not performed in

accordance with UniRac’s written installation instructions for the Product,

or if the Product has been modified, repaired, or reworked in a manner not

previously authorized by UniRac in writing, or if the Product is installed in

an environment for which it was not designed. UniRac shall not be liable for

consequential, contingent, or incidental damages arising out of the use of the

Product by Purchaser.

If within the specified periods the Product shall be reasonably proven to be

defective, then UniRac shall repair or replace the defective Product, or any

part thereof, at UniRac’s sole option. Such repair or replacement shall fulfill all

UniRac’s liability with respect to this limited Warranty. Under no circumstances

shall UniRac be liable for special, indirect or consequential damages arising out

of or related to use by Purchaser of the Product .

Typically manufacturers of related items, such as PV modules, flashings and

specialized clamps, provide written warranties of their own. UniRac’s limited

Warranty covers only the Product, and not PV modules themselves or any other

related items.

10 year limited product warranty, 5 year limited finish warranty