Trimod Besta Bxxx5 Series User manual

www.trimodbesta.com 1 │8 LTB011EN │2016.04

LTB011EN

Operating Instruction

Trimod Besta Level Switch – type B…5

for use in potentially explosive atmospheres acc. to IECEx scheme

Subject to technical modification

Bachofen AG | Ackerstrasse 42 | CH-8610 Uster | Switzerland

Phone +41 44 944 11 11 | Fax +41 44 944 12 33

www.trimodbesta.com 2 │8 LTB011EN │2016.04

Contents

2.

Conformity of standards..............................................................................................................................3

3.

Technical Data............................................................................................................................................3

4.

Installation and initial start-up.....................................................................................................................4

5.

Maintenance ...............................................................................................................................................5

6.

Replacement of the switch module.............................................................................................................6

7.

Fire protection.............................................................................................................................................6

8.

Disposal......................................................................................................................................................7

9.

IECEx - Certificate of Conformity................................................................................................................7

Legend

Information: Application hints and important information. To be followed for optimal function.

Attention:Requirements and prohibitions to prevent damages, especially to material and the environment.

Danger: Dangerous situation that can lead to injury and death if instructions are not followed.

www.trimodbesta.com 3 │8 LTB011EN │2016.04

1.

Safety Instructions

The operating manual must be read and understood before installation. If you are uncertain on any

point, please contact Bachofen AG, Switzerland.

The electrical connection may only be carried out by qualified personnel who have been authorised by

the operator.

All attached cables and cable bushings must comply with the requirements of IEC 60079-0 Appendix

A – explosion-proof cables and cable entries.

The supply voltage may only be applied after the cover has been closed. Please ensure that you

always observe the special regulations concerning work on explosion-proof devices and during work in

potentially explosive atmospheres at the operators site.

Every Trimod Besta level switch must be selected by qualified, trained personnel in accordance with

the specifications stipulated by the customer. These specifications must be kept by the operator in a

safe place, together with the operating instruction, the customer-specific designation and the type

number (see type plate). In the event of any deviation of the physical quantities (pressure,

temperature, density, etc.) from the original specification, the suitability of the level switch must be

checked again by qualified, trained personnel or by the manufacturer, with regard to the new

specifications.

If the device is mounted in a partition wall, which separates zones from one another, and if category 1

or 2 equipment is necessary, an equipotential bond must be made (contact resistance ≤MΩ) between

the metal housing of the level switch and the wall of the container.

The float and flange module must be included in the regular plant pressure tests.

Process vessels / float chambers must be brought to atmospheric pressure before work is carried

out and must be appropriately vented.

The devices may, under no circumstances, be used as a support aid or as a security fixture for

equipment structures or for persons.

When you are using a Trimod Besta level switch in a safety application according to

IEC 61508 and IEC 61511, the safety manual must be taken into consideration before

installing and commissioning the switch. The safety manual lists the restrictions and limitations of the

IEC 61508 certification of the Besta Trimod level switch. The safety manual can be downloaded from

http://www.trimodbesta.com/en/downloads/approvals/sil.html

2. Conformity of standards

Trimod Besta level switches type B…8 conform with the requirements of:

EN 60079-0, EN 60079-11, EN 60079-26

IEC 61508:2010 (Safety Integrity Level)

3. Technical Data

Ex-protection-data

Explosion protection Ex ia IIC T6 Ga/Gb

IECEx Certification of Conformity IECEx EPS 15.0038 X

Safety Integrity Level (SIL)

Type B…5 SIL 1 (SIL 3 capable)

Type BB…5 SIL 2 (SIL 3 capable)

Electrical connection

The electrical connection should be carried out in accordance with the regulations for explosion proof

devices.

Not suitable for the switching of motor loads and incandescent lamp loads. The device is not protected

against excess current.

www.trimodbesta.com 4 │8 LTB011EN │2016.04

Supply voltage For use in intrinsically-safe circuits only!

Maximum values I

i

= 0.5 A

C

i

, L

i

≈0 nF, 0 µH

The product of current and voltage should not exceed 0.12 VA, otherwise the gold contacts could be

permanently damaged.

Special conditions for safe use

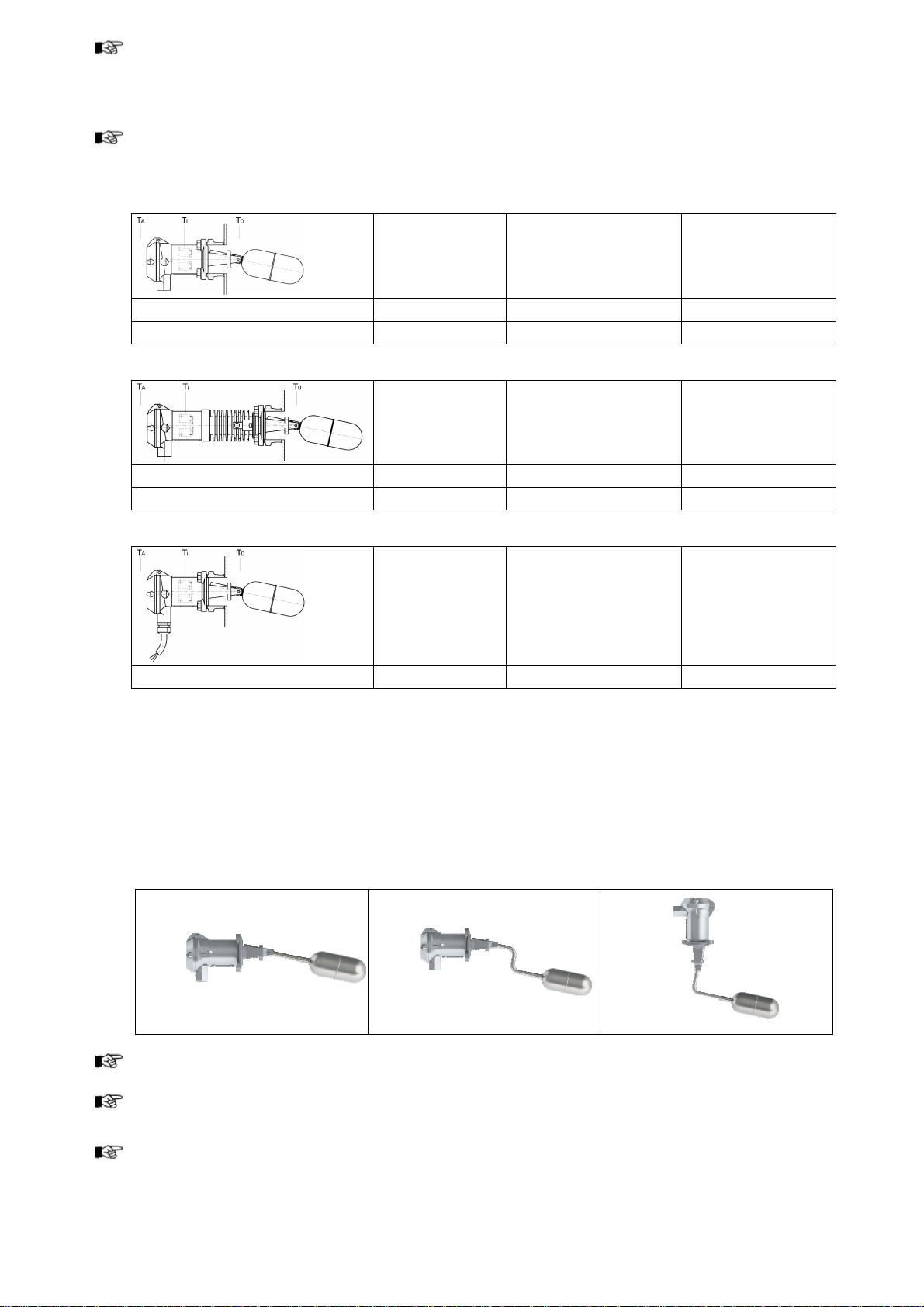

Level switch without heat exchanger

Limits

microswitch

T

i

Ambient temperature

(acc. to EN 60079-0

-20°C to 60°C)

T

A

Operating

temperature

T

0

B…5 -40°C to 150°C 0°C to 70°C 0°C to 330°C

DB…5 -40°C to 150°C -30°C to 120°C -30°C to 120°C

Level switch with heat exchanger for very high or very low operating temperatures

Limits

microswitch

T

i

Ambient temperature

(acc. to EN 60079-0

-20°C to 60°C)

T

A

Operating

temperature

T

0

HB…5, HBB…5 -40°C to 150°C 0°C to 135°C 0°C to 400°C

TDB…5, TDBB…5 -40°C to 150°C -10°C to 80°C -196°C to 270°C

Level switch for submersible application

Limits

microswitch

T

i

Ambient temperature

(acc. to EN 60079-0

-20°C to 60°C)

T

A

Operating

temperature

T

0

U…B…5, U…BB…5 -40°C to 150°C -30°C to 80°C -30°C to 80°C

The rated cross-section of the conductor to be considered here must be at least 0,5 mm².

Connection cables may not be bared for a distance of more than 3 mm from the terminal screw.

Wire end ferrules must always be used.

4. Installation and initial start-up

During installation, the correct operating position must be observed.

For side mounting, observe the “Top” arrow on the type plate.

The float must be able to move freely over the whole range of movement and must not be restricted by

the tanks walls or by fittings in the tank.

Installation positions that are subject to turbulence impair the function and should always be avoided.

www.trimodbesta.com 5 │8 LTB011EN │2016.04

Process connection flange - Industrial range

For switches in the industrial range with flanges according to DIN, ANSI, etc., the seals

1)

and

connecting studs

1)

that are used must correspond to the industry standard for material, pressure

class and type of seal and must be tightened to the corresponding tightening torques.

1)

not a component of the supply.

In case of uncertainty on any point, refer to the corresponding standard or consult the manufacturer.

Process connection flange - Standard range

For switches of the standard range PN 25 (360 psi), corresponding seals are supplied with the unit.

Minimum tightening torques and tightening sequence:

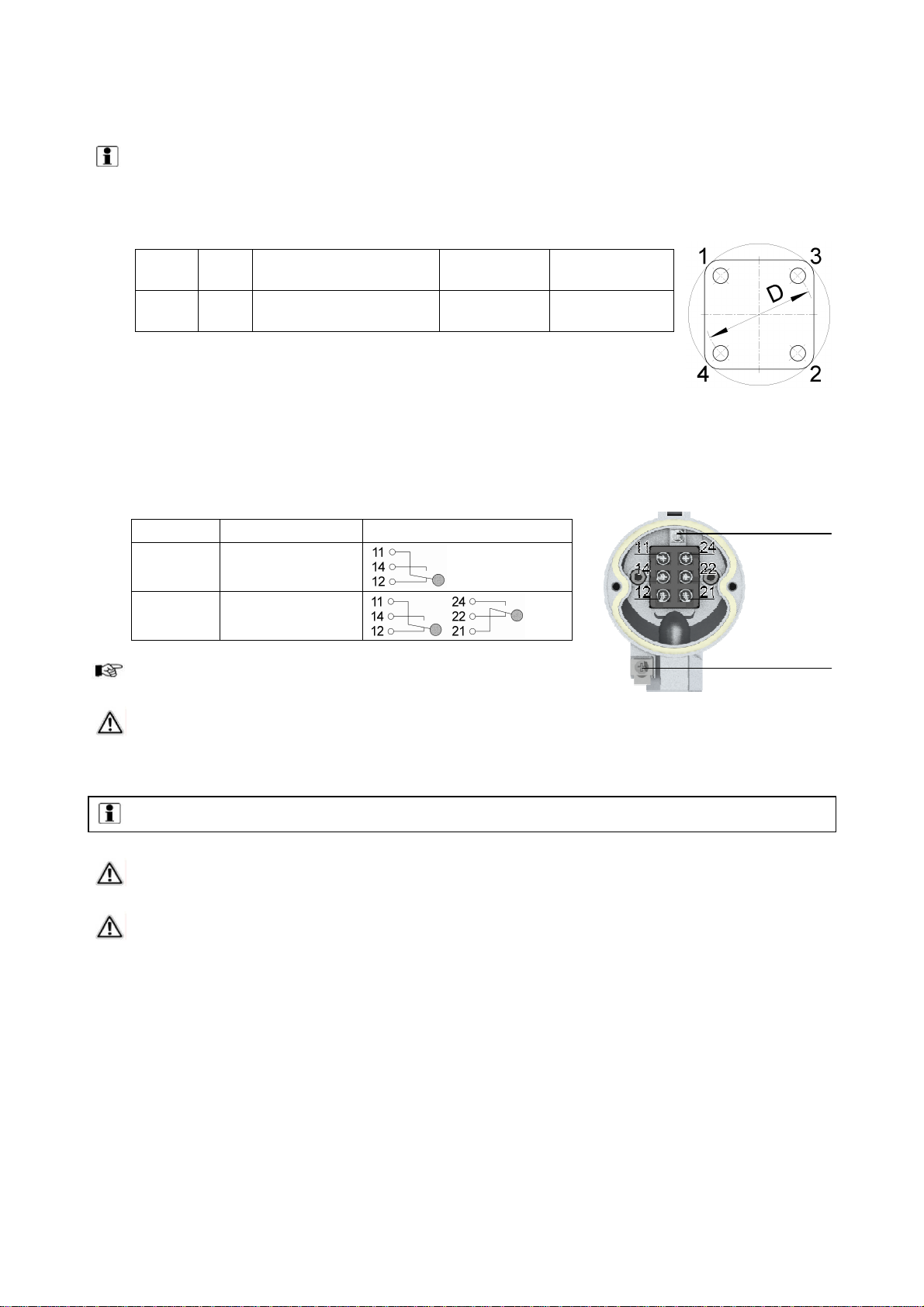

Flange

D

Seal

Stud

Carbon steel

Stud

Stainless steel

01 / 011

92 mm

Garlock Blue Gard 3000

Reinz Chemotherm

3)

18 Nm

2

)

22 Nm

2

)

2)

Data refer to lubricated studs

3)

High / low temperature application (graphite gasket)

Connecting

1. Loosen the cover screws, remove the protective plug from the cable entry and fit the cable gland.

2. Insert the cable and connect to the wires according to the connection diagram (see inside the

housing cover and instructions). All terminal connections are self-opening.

Connection diagram

Type

Function

Connection diagram

B…5 SPDT

BB…5 Dual SPDT

3. Connect grounding (inside housing) and equipotential bonding

screw (outside, beside cable entry)!

4. First close the cover and then apply the supply voltage!

5. Maintenance

Trimod Level switches must be periodically tested and cleaned, at least once annually.

Procedure:

1. Before opening the housing, disconnect the supply voltage; electric shocks can be life

threatening.

2. Process vessels / float chambers must be brought to atmospheric pressure before work is carried

out and must be appropriately vented. If necessary, lower the fill level. If the switch is mounted in

a chamber, close the corresponding shut-off valves and, depending on the requirement, empty or

vent the chamber.

3. Loosen the flange connection and remove the switch.

4. Check the float and mechanism for damage and contamination.

5. Remove deposits and metal particles by means of suitable and approved methods. Care must be

taken to ensure that no mechanical damage occurs as a result of the cleaning.

6. In the case of floats with protective bellows, the bellows must be removed before cleaning and

should be cleaned separately, both internally and externally.

7. Check the float and mechanism for complete deflection, as well as for smooth and unrestricted

operation.

Equipotential

bonding screw

Grounding

www.trimodbesta.com 6 │8 LTB011EN │2016.04

8. In the event that it becomes necessary to replace individual components, please note that only

original spare parts, split pins, float, switch module, etc. may be installed.

9. After completion of the cleaning / inspection work, the switch module must be checked for correct

function by means of an acoustic continuity tester or similar device with simultaneous deflection

of the float, followed by recording in the inspection log book.

10. In order to guarantee the absence of leaks between process vessel / float chamber, the flange

seal must be replaced after each dismantling.

11. After carrying out the inspection work, the device is re-fitted at the intended location.

6. Replacement of the switch module

Defective controller modules must be replaced with new, works-tested units. In order that the complete

type designation can be stamped on the type plate, the complete designation of the existing controller

must be specified at the time of ordering. If a complete identification of the controller is not possible,

then the manufacturer should be consulted before dispatching the complete device.

Example: Complete type number of the switch B5 01 04

Incomplete data of replacement switch module B5

Complete the type number with 01 04 ►B5 01 04

In the case of uncertainty on any point, please contact the local Trimod Besta agent or the

manufacturer.

Replacement of the switch module

The switch does not have to be removed from the process vessel in order to replace the switch

element.

1. Observe chapter 1 «Safety instructions».

2. Cut off power supply before opening enclosure cover! Be aware of the danger of hazardous

voltage!

3. Loosen 2 cover screws with screwdriver.

4. Check that terminals are not live.

5. Disconnect wires, including grounding and equipotential connection.

6. Loosen 2 Allan screws (Allan key 5 mm) on the side of the terminal block.

7. Unscrew switch module (together with intermediate temperature piece, for H… and TD… types)

from the flange module.

8. Make sure that the O-ring seals or flat gaskets fit properly.

9. Fit replacement module (together with intermediate temperature piece, for H… and TD… types)

and tighten 2 screws.

10. Re-connect wires including grounding- and equipotential bonding connection (see connection

diagram inside cover and attached switch operating instruction).

11. Energize power supply only when hinged cover is closed!

Follow the installation instruction LTI004X «Replacement of the switch module»

7. Fire protection

Trimod Besta level switches must be protected against external fires.

www.trimodbesta.com 7 │8 LTB011EN │2016.04

8. Disposal

Trimod Besta level switches are free of asbestos or otherwise hazardous materials (2011/65/EU - RoHS).

Disposal to be carried out according to environmental and local regulations.

9. IECEx - Certificate of Conformity

See http://iecex.com/

www.trimodbesta.com 8 │8 LTB011EN │2016.04

Subject to technical modification

Bachofen AG | Ackerstrasse 42 | CH-8610 Uster | Switzerland

Phone +41 44 944 11 11 | Fax +41 44 944 12 33

This manual suits for next models

9

Table of contents

Other Trimod Besta Switch manuals

Popular Switch manuals by other brands

Sun Oracle

Sun Oracle Sun Datacenter InfiniBand Switch 36 Hardware Security Guide

AVE

AVE 8PSWT specification

Micas

Micas M2-W6910-64C Hardware installation and reference guide

Siemens

Siemens RUGGEDCOM RX1500 user guide

NVT Phybridge

NVT Phybridge CLEER24 Quick install guide

HP

HP 6127XLG Blade Series Command reference