Trimteck Optimux HPP5500 Series User manual

SMART POSITIONER PRODUCT MANUAL

HPP5500 SERIES

VERSION 1.00

2 HPP5500 series

Contents

1. Introduction …………………………………………………………………………………………… 4

1.1 General information for the users ………………………………………………………………. 4

1.2 Manufacturer Warranty …………………………………………………………………………… 4

2. Product Description ………………………………………………………………………………….. 5

2.1 General …………………………………………………………………………………………….. 5

2.2 Main Features and Functions ……………………………………………………………………. 5

2.3 Label Description ………………………………………………………………………………….. 5

2.4 Product Number …………………………………………………………………………………… 6

2.5 Product Specification ……………………………………………………………………………… 7

2.6 Parts and Assembly ……………………………………………………………………………….. 8

2.7 Product Dimension ………………………………………………………………………………… 8

2.7.1 HPP5500L ……………………………………………………………………………… 8

2.7.2 HPP5500R ……………………………………………………………………………… 9

3. Installation ………………………………………………………………………………………………. 10

3.1 Safety ……………………………………………………………………………………………….. 10

3.2 HPP5500L Installation …………………………………………………………………………… 10

3.2.1 Installation Steps ………………………………………………………………………... 11

3.3 HPP5500L Direct-Mounting Installation ……………………………………………………….. 13

3.3.1 Installation Steps ………………………………………………………………………... 13

3.4 HPP5500R Installation …………………………………………………………………………… 14

3.4.1 Bracket Information ……………………………………………………………………... 14

4. Connections …………………………………………………………………………………………….. 15

4.1 Safety ……………………………………………………………………………………………….. 15

4.2 Supply Pressure Condition ……………………………………………………………………….. 15

4.3 Piping Condition ……………………………………………………………………………………. 15

4.4 Connection – Actuator ……………………………………………………………………………...15

4.4.1 Single acting actuator ……………………………………………………………………15

4.4.2 Double acting actuator ………………………………………………………………….. 16

4.5 Connection – Power ……………………………………………………………………………….. 16

4.5.1 Safety ……………………………………………………………………………………...16

4.5.2 Terminal Overview ………………………………………………………………………. 17

4.5.2.1 Limit Switch Terminal-Mechanical Type ……………………………………. 17

4.5.2.2 Limit Switch Terminal-Proximity Type ……….……………………………… 18

4.5.2.3 Ground ………………………………………………………………………….18

5. Adjustment ……………………………………………………………………………………………….18

5.1 Limit Switch Adjustment …………………………………………………………………………… 18

5.2 Auto/Manual Switch (A/M Switch)………………………………………………………………. 19

5.3 Option PCB Adjustment ………………………………………………………………………… 19

3 HPP5500 series

6. Operation …………………………………………………………………………………………………20

6.1 Safety ………………………………………………………………………………………………. 20

6.2 Button Description ………………………………………………………………………………… 20

6.3 Run Mode (RUN) ………………………………………………………………………………….. 20

6.3.1 Auto Calibration (AUTO CAL) …………………………………………………………. 21

6.3.1.1 AUTO1 Calibration (AUTO1) ……………………………………………….. 21

6.3.1.2 AUTO2 Calibration (AUTO2) ……………………………………………….. 21

6.3.1.3 AUTO3 Calibration (AUTO3) ……………………………………………….. 22

6.3.2 Manual Mode (MANUAL) ……………………………………………………………… 22

6.3.3 Parameter Mode (PARAM) ……………………………………………………………. 22

6.3.3.1 Dead-Zone (dEAdZONE) …………………………………………………… 22

6.3.3.2 P Value (KP) …………………………………………………………………. 23

6.3.3.3 D Value (Kd) …………………………………………………………………. 23

6.3.3.4 I Value (KI) ……………………………………………………………………. 24

6.3.3.5 P_(KP_), D_(Kd_), I_(KI_) values…………………………………………… 24

6.3.4 Hand Calibration Mode (HAND CAL) …………………………………………………. 24

6.3.4.1 Zero-Point (PV_ZERO) and End-Point (PV_END) for Valves …………… 24

6.3.4.2 Zero-Point (TR_ZERO) and End-Point (TR_END) for Transmitter …….. 25

6.3.4.3 End-Point Ratio for Valve (PE_TRIM) ……………………………………… 25

6.3.4.4 Normal / Reverse Feedback Signal (TR_NORM / REV) ………………… 25

6.3.4.5 Normal / Reverse HART Signal (HT_NORM / REVS) …………………… 26

6.3.5 Valve Mode (VALVE) ……………………………………………………………………. 26

6.3.5.1 Acting Adjustment (ACT) …………………………………………………….. 26

6.3.5.2 Characteristic Adjustment (CHAR) …………………………………………. 27

6.3.5.3 User Characteristics (USER SET) ………………………………………….. 27

6.3.5.4 Tight Shut Open (TSHUT OP) ………………………………………………. 27

6.3.5.5 Tight Shut Close (TSHUT CL) ………………………………………………. 28

6.3.5.6 Split Range Mode (SPLIT) ……………………………………………………28

6.3.5.7 Custom Zero Setting Mode (CST ZERO) ………………………………….. 28

6.3.5.8 Custom End Setting Mode (CST ENd) …………………………………….. 29

6.3.5.9 Interpolation Mode (ITP OFF / ON) ………………………………………….29

6.3.6 View Mode (VIEW) ……………………………………………………………………….29

7. Error and Warning Code ……………………………………………………………………………….30

7.1 Error Code ………………………………………………………………………………………….. 30

7.2 Warning Code ……………………………………………………………………………………… 31

8. Main Software Map …………………………………………………………………………………….. 32

4 HPP5500 series

1. Introduction

1.1 General Information for the users

Thank you for purchasing TRIMTECK products. Each product has been fully inspected

after its production to offer you the highest quality and reliable performance. Please read

the product manual carefully prior to installing and commission the product.

For the safety, it is important to follow the instructions in the manual.

TRIMTECK will not be responsible for any damages caused by user’s negligence.

The manual should be provided to the end-user.

Any modifications or repairs to the product may only be performed if expressed in this

manual.

The manual can be altered or revised without any prior notice. Any changes in

product’s specification, design, and/or any components may not be printed immediately

but until the following revision of the manual.

The manual should not be duplicated or reproduced for any purpose without prior

approval from TRIMTECK.

1.2 Manufacturer Warranty

For the safety, it is important to follow the instructions in the manual. Manufacturer will

not be responsible for any damages caused by user’s negligence.

Manufacturer will not be responsible for any damages or accidents as a result of any

alteration or modification of the product and its parts. If any alteration or modifications

are necessary, please contact TRIMTECK directly.

Manufacturer warrants the product from the date of original purchase of the product for

one (1) year, except as otherwise stated.

Manufacturer warranty will not cover products that have been subjected to abuse,

accidents, alterations, modifications, tampering, negligence, misuse, faulty installation,

lack of reasonable care, repair or service in any way that is not contemplated in the

documentation for the product, or if the model or serial number has been altered,

tampered with, defaced or removed; damages that occurs in shipment, due to act of

God, failure due to power surge, or cosmetic damage. Improper or incorrectly

performed maintenance will void this limited warranty.

For detailed warranty information, please contact TRIMTECK.

5 HPP5500 series

2. Product Description

2.1 General

HPP5500 series Smart Valve Positioner accurately controls valve stroke in response to an

input signal of 4-20mA from the controller. Built-in micro-processor optimizes the

positioner’s performance and provides unique functions such as Auto-Calibration, PID

Control, Alarms, and HART Protocol Communications.

2.2 Main Features and Functions

LCD display enables users to monitor the positioner status.

Positioner operates normally during sudden changes in supply pressure and / or high

vibration environment.

Low air consumption level and low voltage use (8.5 V) yield to lower plant operating

costs. HPP5500 series is compatible with most of controllers.

Variable orifice can be used to minimize the hunting occurrence and optimize operating

conditions.

Valve system feedback is greatly improved by the accuracy and fast response of the

HPP5500.

Different valve characteristics can be adjusted – Linear, Quick Open, Equal Percentage,

and Custom which user can make 16 points characterizations.

Tight Shut – Close and Shut - Open can be set.

PID parameters can be adjusted in the field without any additional communicator.

A/M switch can be used to direct supply air to the actuator or to manually operate the

positioner or valve.

Split range 4-12mA or 12-20mA can be set.

Operating temperature is -30 to + 85’C.

Manual Operation allows the user to operate the valve manually.

2.3 Label Description

Fig. 1: HPP5500 Label

A. Model Number: Indicates the model number of the positioner.

B. Explosion Proof: Indicates certified explosion proof grade.

C. Input Signal: Indicates input signal range.

D. Operating Temp.: Indicates the allowable operating temperature.

E. Ambient Temp.: Indicates ambient temperature for explosion proof.

F. Supply Pressure: Indicates the supply pressure range.

6 HPP5500 series

2.4 Product Number

** HPP5500 series can be used for direct-mounting application.

7 HPP5500 series

2.5 Product Specification

Model HPP5500L HPP5500R

Acting Type Single Double Single Double

Input Signal 4~20mA DC

Minimum Current Signal 3.2mA(Standard), 3.8mA(Hart Included)

Supply Pressure 0.14~0.7 MPa (1.4~7 bar)

Stroke 10~150 mm 0~120°

Impedance Max.500Ω@ 20mA DC

Air Connection PT, NPT 1/4

Gauge Connection PT, NPT 1/8

Conduit Entry PF(G) 1/2

Protection Grade IP66

Explosion Proof Ex ia IIC T5 / T6, Ex iaD IIIC T100℃/T85℃

Ambient Temperature T5 : -40℃to +60℃

T6 : -40℃to +40℃

Linearity ±0.5% F.S.

Hysteresis 0.5% F.S.

Sensitivity ±0.2% F.S

Repeatability ±0.3% F.S.

Flow Capacity 70 LPM (Sup.=0.14 MPa)

Air Consumption Below 2 LPM (sup = 0.14 MPa), Below 3 LPM (sup = 0.7MPa)

Output Characteristic Linear, Quick Open, EQ%, User Set (16 point)

V

ibration No Resonance upto 100Hz @ 6G

Humidity 5-95% RH @ 40℃

Communication (Option) HART Communication

Feedback Signal (Option) 4~20mA (DC 10~30V)

Material Aluminum Diecasting

Weight 2.0kg

Painting Epoxy Polyestere Powder Coating

Tested under ambient temperature of 20’C, absolute pressure of 760mmHg, and humidity of 65%. Please contact TRIMTECK for detailed testing specification.

* Explosion proof certification is in progress.

8 HPP5500 series

2.6 Parts and Assembly

Fig. 2. HPP5500L series exploded view Fig. 3. HPP5500R+LS series exploded view

2

9 HPP5500 series

2.7 Product Dimension

2.7.1 HPP5500L

2.7.2 HPP5500R

2.7.2.1 HPP5500R standard

10 HPP5500 series

2.7.2.2 HPP5500R with L/S option

3. Installation

3.1 Safety

When installing a positioner, please ensure to read and follow safety instructions.

Any input or supply pressures to valve, actuator, and / or to other related devices must

be turned off.

Use bypass valve or other supportive equipment to avoid entire system “shut down”.

Ensure there is no remaining pressure in the actuator.

3.2 HPP5500L Installation

HPP5500L should be installed on linear motion valves such as globe or gate type which uses

spring return type diaphragm or piston actuators. Before proceeding with the installation,

ensure following components are available.

Positioner unit

Feedback lever and lever spring

Flange nut (bottom side of YT-3400L)

4 pcs x hexagonal headed bolts (M8 x 1.25P)

4 pcs x M8 plate washer

11 HPP5500 series

3.2.1 Installation Steps

1. Proper bracket must be made in order to adapt the positioner on the actuator yoke.

Please consider following important points when a bracket is being designed.

Positioner’s feedback lever must be parallel to the ground at 50% of the valve stroke.

Feedback lever connection with the pin of the actuator clamp should be installed in

such a way that the valve stroke length coincides with the corresponding figure in

“mm” marked on the feedback lever. Improper setting may cause poor linearity and

may create unnecessary hunting during the operation.

2. Assemble the positioner with the bracket made in

previous step by fastening the bolts. Please

refer to the backside of the positioner for size of

the bolts. The standard bolt size is M8 x 1.25P.

Please contact TRIMTECK for other bolt sizes.

3. Attach the positioner with bracket to the actuator

yoke – DO NOT TIGHTEN POSITIONER

COMPLETELY.

4. Connect positioner’s feedback lever to the actuator clamp. The hole gap on the

feedback lever is 6.5mm. The connection pin’s outer diameter should be less than

6.3mm.

5. Connect supply pressure to the actuator temporarily. Supply enough supply pressure to

the actuator in order to position the actuator clamp at 50% of the total valve stroke.

6. Insert connection pin into the feedback lever. The pin should be inserted when the

actuator clamp is at 50% of the total valve stroke.

Proper way to connect feedback lever, connection pin, and lever spring

12 HPP5500 series

7. Check if feedback lever is parallel to the ground at 50% of the valve stroke. If it is not

parallel, adjust the bracket or feedback link bar to make parallel. Improper installation

may cause poor linearity and may create unnecessary hunting during the operation.

8. Check the valve stroke. The stroke marks are indicated on the feedback lever of the

positioner. Position the connection pin at the number on the feedback lever which

corresponds to the desired valve stroke. To adjust, move the bracket, the connection

pin or both.

Fig 3. Pin Insertion when valve stroke is 45mm (up) and is 75mm (bottom)

9. After installing the positioner, operate the valve from 0% to 100% stroke by using direct

air to the actuator (manual position). On both 0% and 100%, the feedback lever should

not touch the lever stopper, which is located on the backside of the positioner. If the

feedback lever touches the stopper, the positioner should be installed further away from

the yoke.

Fig. 4. Feedback lever should not touch lever stopper 0% ~ 100% valve stroke.

10. After the installation, tighten all of the bolts on the bracket, the feedback lever, and the

connection pin.

13 HPP5500 series

3.3 HPP5500L Direct-Mounting Installation

HPP5500L can be installed on direct-mounting / tube-less type actuator.

3.3.1 Installation Steps

1. Please remove the plug which blocks OUT port on the back of the HPP5500 unit.

OUT ports on the side of the positioner should be blocked by plugs.

2. Mount HPP5500L onto actuator’s yoke by using 2 bolts. As you mount the positioner,

please be careful not to lose o-rings from the air channel. Please ensure that the lever

adapter connection has been properly installed onto actuator’s stem before tightly

fastened.

Remove

Block

14 HPP5500 series

3.4 HPP5500R Installation

HPP5500R should be installed on rotary motion valve such as ball or butterfly type which

uses rack and pinion, scotch yoke or other type of actuators which stem rotates 90 degrees.

Before proceeding with the installation, ensure following components are available.

Positioner unit

Fork lever and lever spring

Standard rotary bracket (included with the positioner)

4 pcs x hexagonal headed bolts (M8 x 1.25P)

4 pcs x M8 plate washer

3.4.1 Bracket information

Standard bracket (included with the positioner) contains two components. The bracket is

designed to fit onto the actuator with 20mm stem height (H). If actuator’s stem height (H) is

30mm or 50mm, bracket must be adjusted. Please refer to below table how to adjust the

bracket.

Actuator stem

height (H)

Markings of bolt holes

A-L B-L A-R B-R

20mm H : 20 H : 20, 30 H : 20 H : 20, 30

30mm H : 30 H : 20, 30 H : 30 H : 20, 30

50mm H : 50 H : 50 H : 50 H : 50

15 HPP5500 series

4. Connections

4.1 Safety

Supply pressure should be clean and dry air – avoiding moisture, oil or dust.

Always recommended to use air filter regulator (i.e. YT-200 series).

TRIMTECK has not tested positioner’s operation with any other gases other than

clean air. Please contact TRIMTECK for any questions.

4.2 Supply Pressure Condition

Dry air with at least 10℃lower than ambient temperature.

Avoid from dusty air. Positioner’s inner filter can only filter 5 micron or larger.

Avoid oil.

Comply with ANSI/ISA-57.3 1975(R1981) or ISA S7.3-1975(R1981).

Supply pressure range is 0.14 ~0. 7MPa (1.4~-7 bar)

Set air filter regulator’s pressure level 10% higher than actuator’s spring range pressure.

4.3 Piping Condition

Ensure inside of pipe is clean of obstructions.

Do not use pipeline that is squeezed or shows any type of damamges.

Pipeline should have more than 6mm of inner diameter (10mm outer diameter) to

maintain flow rate.

The length of pipeline system should not be extremely long. Longer pipeline system

may affect flow rate due to the friction inside of the pipeline.

4.4 Connection – Actuator

4.4.1 Single acting actuator

Singe acting type positioner is set to use OUT1 port. OUT1 port should be connected with

supply pressure port from actuator when using single acting type of spring return actuator.

Fig. 7: Singe acting linear (left) and rotary (right) type actuator

16 HPP5500 series

4.4.2 Double acting actuator

Double acting type positioner is set to use OUT1 and OUT2 port. As input signal increases,

the supply pressure will be supplied through OUT1 port.

Fig. 8: Double acting linear (left) and rotary (right) type actuator

4.5 Connection – Power

4.5.1 Safety

When installing in hazardous and explosive gas area, conduit tube or pressure-proof

packing union must be used. The compound charging box should be the flameproof

type and must be sealed completely.

Conduit entry connection tap is PF 1/2 or G 1/2.

Before connecting terminal, ensure that the power is off completely. Do not open the

cover when the power is still alive.

Please use ring-type rug to protect against vibration or any other external impact.

Positioner with PTM options must be supplied 10~28V DC separately. For L/S option,

separate 12-24V DC must be supplied. For both options, it should not exceed 30V

DC.

Positioner should be grounded.

Please use twisted cable with conductor section are 1.25mm2and that is suitable for

600V (complying to the conductor table of NEC Article 310.) The outer diameter of the

cable should be between 6.35 ~ 10mm. Use shield wire to protect against electro-

magnetic field and noise.

Please do not install the cable near high noise equipments, such as high-capacity

transformer or motor.

17 HPP5500 series

4.5.2 Terminal

Overview

Fig. 9: Positioner Terminal

IN +: Input Signal (+)

IN -: Input Signal (-)

FG: Ground

OUT+: Feedback Signal (+)

OUT-: Feedback Signal (-)

4.5.2.1 Limit Switch Terminal – Mechanical Type

18 HPP5500 series

4.5.2.2 Limit Switch Terminal – Proximity Type

4.5.2.3 Ground

1. Ground must be done before operating the positioner.

2. Open terminal cover and locate ground terminal plate on the right hand bottom side of

the terminal plate. The outer cable entry is located at outside of the terminal. Please

make sure that the resistance is less than 100ohm.

3. When using external ground, use (+) screw driver to unscrew the ground bolts. Insert

outside ground bolts and spring washer into ring type terminal of the ground cables and

tighten them with bolts.

4. When using inside ground, use 3mm wrench to loosen locking bolts of the terminal box

cover.

5. Adjustments

5.1 Limit Switch Adjustment

HPP5500 series can have limit switch option. If user wants to adjust the position, please

loosen cam bolts and adjust cam.

Mechanical Type Proximity Type

19 HPP5500 series

5.2 Auto/Manual Switch (A/M Switch)

Auto/Manual Switch allows the positioner to be functioned as by-pass. If switch is set as

Auto, the positioner will operate per input signal. If switch is set as Manual, the positioner

will send supply pressure directly to the actuator.

5.3 Option PCB adjustment

5.3.1 By adding option sub-pcb, the positioner can have options. There are 3 types of sub-pcb’s

HART only PTM only PTM + HART

5.3.2 Installation Steps

1. Open the cover and remove the main PCB from the positioner.

2. Mount support PCB and plug sub-PCB into main PCB connector.

.

Option Jumper

20 HPP5500 series

** Option Jumper must be removed, when HART option included sub-PCB is being mounted.

6. Operation

6.1 Safety

Following process will operate valve and actuator. Before proceed with any AUTO

Calibration, please separate valve from the entire system, so AUTO Calibration will

affect entire valve process.

6.2 Button Description

Positioner has 4 buttons, and they enable to perform various functions.

Fig. 11: <ENTER>: Enter to main and sub menus, and save

<ESC>: Return to previous menu

<UP> & <DOWN>: Move to next menu, and adjust.

6.3 Run Mode (RUN)

After power connection to the positioner, Run Mode will be

appeared on positioner’s LCD screen within 6 seconds. “RUN”

indicates that the positioner adjusts the valve stroke according to

the receiving signal. There are six types of display message in

“RUN” Mode.

1. Run PV: Process Value - valve stroke %

2. Run SV %: Set Value – input signal 0~100%

3. Run SV mA: Set Value – input signal 4~20mA

4. Run MV: Manipulate Valve – Motor Manipulate Value (digit)

5. Run Vel: Velocity – Current valve stem’s velocity (digit)

6. Run Err: Error – Difference between SV and PV (%)

To change display, push <ESC> + <UP> buttons at the same time. The display will change

in the order indicated above. If <ESC> + <DOWN> pushed, the order will be appeared in

This manual suits for next models

2

Table of contents

Popular Valve Positioner manuals by other brands

VRG Controls

VRG Controls VGP Series instruction manual

CONFLOW

CONFLOW Power Genex PPR Series Installation and maintenance manual

Siemens

Siemens SIPART Series operating instructions

SMAR

SMAR FY301 Instruction, operations & maintenance manual

SMC Networks

SMC Networks IP6000 user manual

KAUP

KAUP T 163SN operating manual

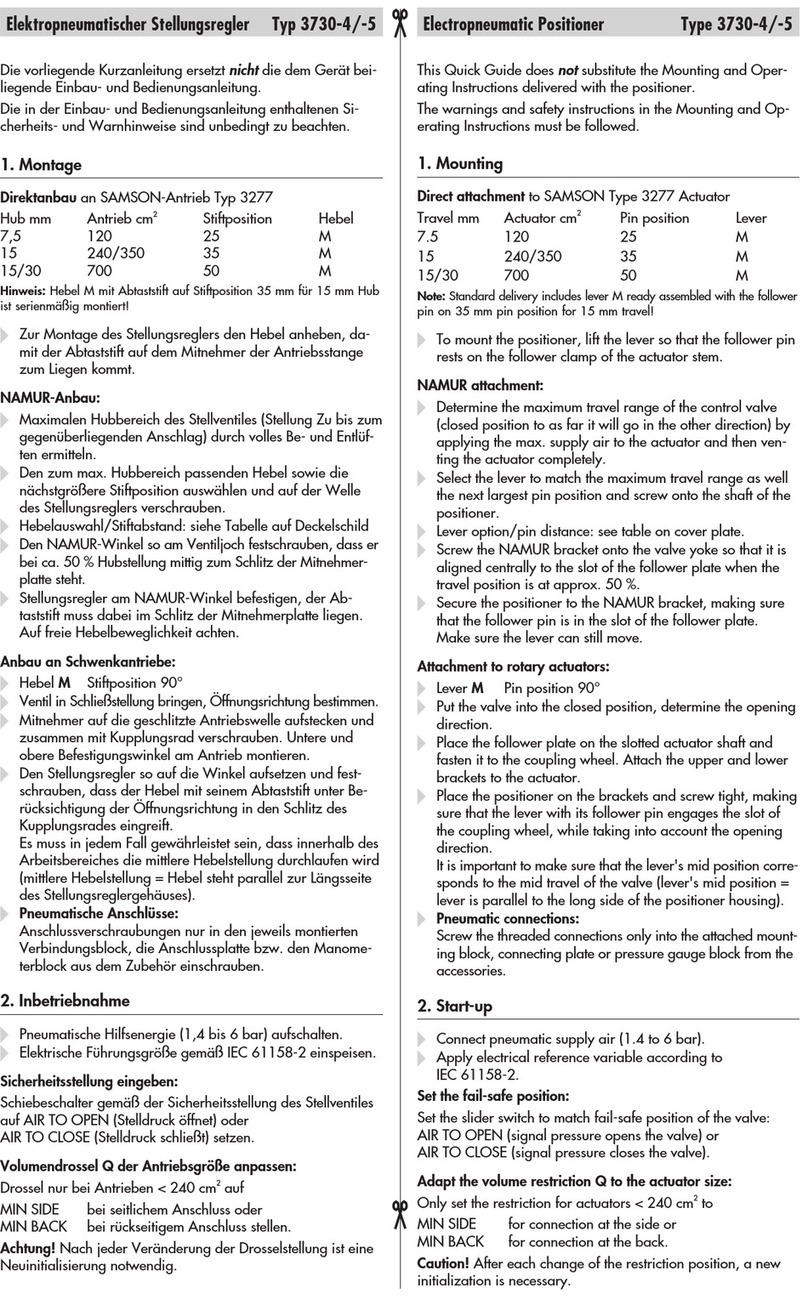

Samson

Samson 3730-4 quick guide

Flowserve

Flowserve Logix 3200MD Installation, operation and maintenance

Vector

Vector TCY-MZ manual

RTK

RTK SR-3300 Installation and operating instructions

halstrup-walcher

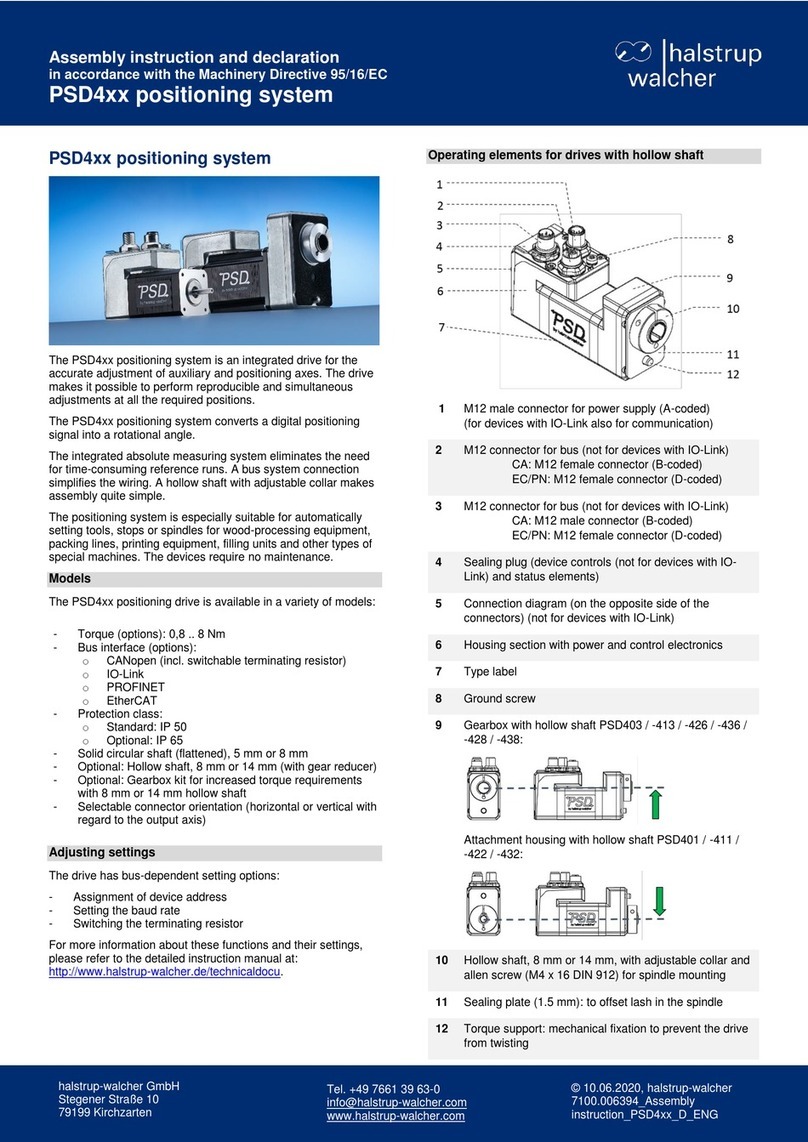

halstrup-walcher PSD4 Series Assembly instruction and declaration

Baker Hughes

Baker Hughes Masoneilan 51 Series instruction manual