Trinity Highway SST User manual

SST

®

is a registered trademark of Energy Absorption Systems, Inc. Part No. 115313

© 2019 Trinity Highway Products, LLC

TrinityHighway.com 1 Revision J January 2020

SST

®

Trailer

The SST

®

Trailer (“SST

®

”) has been tested pursuant to National Cooperative Highway Research

Program (“NCHRP”) Report 350 specifications. The SST

®

has been deemed eligible for federal-aid

reimbursement on the National Highway System by the Federal Highway Administration (“FHWA”).

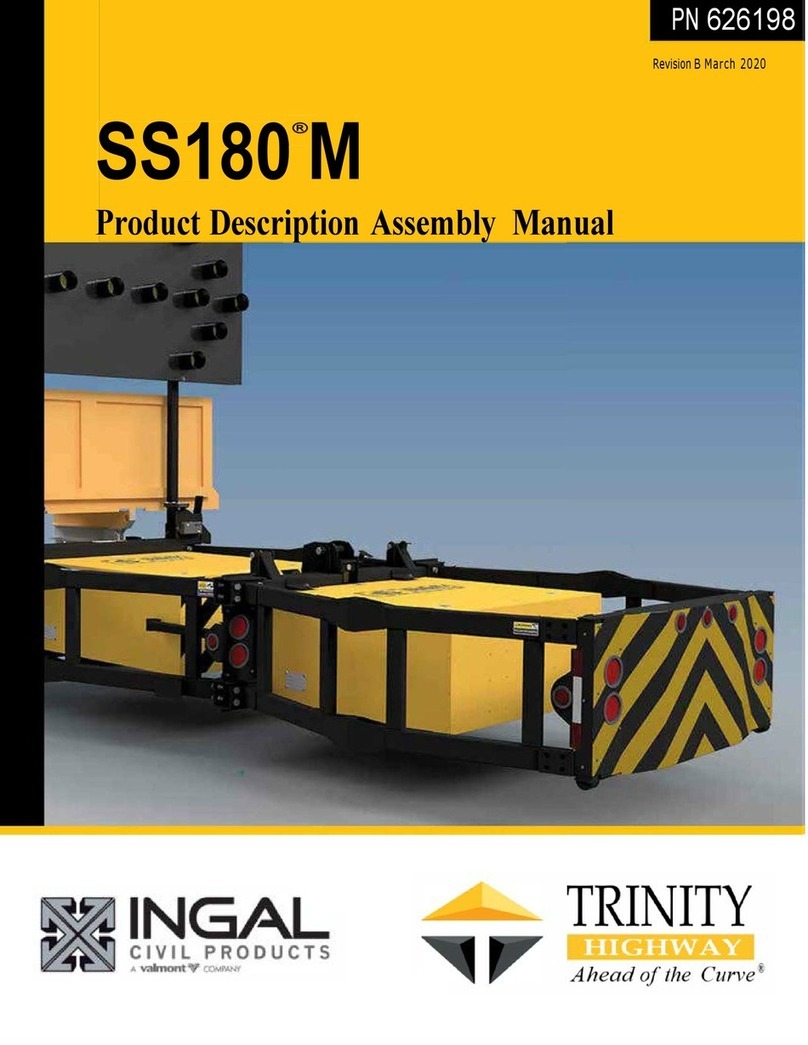

Product Description

Assembly Manual

2525 N. Stemmons Freeway

Dallas, Texas 75207

Warning:

The local highway authority, distributors, owners, contractors,

lessors, and lessees are RESPONSIBLE for the assembly, maintenance, and

repair of the SST

®

. Failure to fulfill these RESPONSIBILITIES with respect to

the assembly, maintenance, and repair of the SST

®

could result in serious

injury or death.

Important:

These instructions are for standard assembly specified by the

appropriate highway authority. In the event the specified system assembly,

maintenance, or repair would require a deviation from standard assembly

parameters, contact a Trinity Highway representative.

This manual must be available to the worker overseeing and/or assembling the product at

all times. For additional copies, contact Trinity Highway at (888) 323-6374 or visit

TrinityHighway.com.

The instructions contained in this manual supersede all previous information and manuals. All

information, illustrations, and specifications in this manual are based on the latest SST

®

information available to Trinity Highway at the time of printing. We reserve the right to make

changes at any time. Please contact Trinity Highway to confirm that you are referring to the most

current instructions.

TrinityHighway.com 2 Revision J January 2020

Table of Contents

Customer Service Contacts .......................................................................................................... 3

Important Introductory Notes ........................................................................................................ 3

Safety Symbols ............................................................................................................................. 4

Safety Rules for Assembly............................................................................................................ 4

Limitations and Warnings.............................................................................................................. 5

Trailer Description......................................................................................................................... 6

Trailer Safety Instructions ........................................................................................................... 10

Electric Brakes Safety Instruction ............................................................................................... 11

Tires & Axle................................................................................................................................. 12

Controlling Skid Distance and Roll-Ahead .................................................................................. 13

Assembly .................................................................................................................................... 14

Preparation............................................................................................................................ 15

Welding Procedures.............................................................................................................. 15

Bolt-on Procedures ............................................................................................................... 16

Assembly Checklist (Complete and File) .................................................................................... 28

Trailer Operations ....................................................................................................................... 29

Attaching the TMA ...................................................................................................................... 31

Trip Preparation Checklist........................................................................................................... 32

Detaching TMA ........................................................................................................................... 32

Inspection Schedule.................................................................................................................... 33

Routine Maintenance .................................................................................................................. 34

Lubrication............................................................................................................................. 34

Brakes................................................................................................................................... 34

Electrical................................................................................................................................ 36

Tires & Wheels...................................................................................................................... 36

Wheel Attachment................................................................................................................. 36

Axle ....................................................................................................................................... 37

Storage.................................................................................................................................. 38

Technical Specifications ............................................................................................................. 39

Repair Instructions ...................................................................................................................... 40

Troubleshooting Guide................................................................................................................ 45

Electrical Problems ............................................................................................................... 49

Quick Reference Troubleshooting Guide.................................................................................... 50

TMA....................................................................................................................................... 53

Support Frame Assembly

...................................................................................................... 55

Hydraulic Assembly............................................................................................................... 57

Misc. Hardware ..................................................................................................................... 59

Lighting Assembly................................................................................................................. 62

TrinityHighway.com 3 Revision J January 2020

Customer Service Contacts

Trinity Highway is committed to the highest level of customer service. Feedback regarding the

SST

®

, its assembly procedures, supporting documentation, and performance is always welcome.

Additional information can be obtained from the contact information below:

Trinity Highway

Telephone (888) 323-6374 (USA)

+1 312 467 6750 (International)

E-mail TrinityHighway.com/Contact

Website TrinityHighway.com

Important Introductory Notes

Proper assembly, deployment, and future maintenance of the SST

®

is critical to achieve

performance of the system that has been evaluated and deemed eligible for reimbursement by

the FHWA per NCHRP Report 350. These instructions should be read in their entirety and

understood before assembling the SST

®

. These instructions are to be used only in conjunction

with the assembly of the SST

®

and are for standard assemblies only as specified by the applicable

highway authority. If you need additional information, or have questions about the SST

®

system,

please contact the highway authority that has planned and specified this assembly and, if needed,

contact Trinity Highway’s Customer Service Department. This product must be deployed in the

location specified by the appropriate highway authority. If there are deviations, alterations, or

departures from the assembly instructions specified in this manual, then the device may not

perform as tested.

Important:

DO NOT use any component part that has not been specifically

specified herein for this system during assembly or repair.

This product has been specified for use by the appropriate highway authority and has been

provided to that user who has unique knowledge of how this system is to be assembled. No

person should be permitted to assemble, maintain, or repair this system that does not possess

the unique knowledge described above. These instructions are intended for an individual qualified

to both read and accurately interpret them as written. These instructions are intended only for an

individual experienced and skilled in the assembly of highway products that are specified and

selected by the highway authority.

A manufacturer’s drawing package will be supplied by Trinity Highway upon request. Details

contained in the drawing package must be studied thoroughly by a qualified individual who is

skilled in interpreting them before the start of any product assembly.

TrinityHighway.com 4 Revision J January 2020

Safety Symbols

This section describes safety symbols that may appear in the

SST

®

manual. Read the manual for

complete safety, assembly, operating, maintenance, repair, and service information.

Symbol Meaning

Safety Alert Symbol:

Indicates Danger, Warning, Caution, or Important. Failure

to read and follow the Danger, Warning, Caution, or Important indicators could

result in serious injury or death to the workers and/or bystanders.

Warning:

Read safety instructions thoroughly and follow the suggested safe

practices before assembling, maintaining, or repairing the SST

®

. Failure to follow

this warning can result in serious injury or death in the event of a vehicle impact

with a system.

Important:

Please keep up-to-date instructions for later use and reference by

anyone involved in the assembly of the product.

Safety Rules for Assembly

* Important Safety Instructions *

This manual must be kept in a location where it is readily available to persons who are skilled and

experienced in the assembly, maintenance, or repair of the SST

®

. Additional copies of this manual

are immediately available from Trinity Highway by calling (888) 323-6374 or by email at

TrinityHighway.com/Contact. Please contact Trinity Highway if you have any questions

concerning the information in this manual or about the SST

®

.

Important:

It is the responsibility of the installer to use proper safety precautions

when operating power equipment and when moving heavy equipment or SST

®

components. Hand, eye, foot, and back protection shall be used.

Warning:

Safety measures incorporating appropriate traffic control devices

specified by the highway authority must be used to protect all personnel while the

TMA is in use. The traffic control plan established by the highway authority must

always be observed when deploying this product.

TrinityHighway.com 5 Revision J January 2020

Limitations and Warnings

Trinity Highway contracts with FHWA approved testing facilities to perform crash tests, evaluation

of tests, and submit of the results to the FHWA for review.

The SST

®

was tested to meet the impact criteria, requirements and guidelines of NCHRP Report

350. These tests are designed to evaluate product performance by simulating those impacts

outlined by involving a typical range of vehicles on roadways, from lightweight cars (approx. 1800

lb. [820kg]) to full size pickup trucks (approx. 4400 lb. [2000 kg]).. The SST

®

is certified to the

Test Level(s) shown below:

Test Level 3: 62 mph [100 kph]

These FHWA directed tests are not intended to represent the performance of systems

when impacted by every vehicle type or every impact condition existing on the roadway.

This system is tested to the test matrix criteria of NCHRP Report 350 as approved by

FHWA.

Trinity Highway expressly disclaims any warranty or liability for injury or damage to persons or

property resulting from any impact, collision or harmful contact with products, other vehicles, or

nearby

hazards or objects by any vehicle, object or person, whether or not the products were

assembled in consultation with Trinity Highway or by third parties.

The SST

®

is intended to be assembled, delineated, and maintained within specific state and

federal guidelines. It is important for the highway authority specifying the use of a highway product

to select the most appropriate product configuration for its site specifications. The customer

should be careful to properly select, assemble, and maintain the product. Site lay out, vehicle

population type; speed, traffic direction, and visibility are important elements that require

evaluation in the selection of a highway product.

After an impact occurs, the product must be repaired to its original condition as soon as possible.

When a safety product is impacted, it is mandatory that the highway authority inspect all the

components for damage and repair and/or replace components as necessary. If the system is not

repairable, a complete system replacement is required.

Warning:

Do not assemble, maintain, or repair the SST

®

until you have read this

manual thoroughly and completely understand it. Ensure that all Danger, Warning,

Caution, and Important statements within the manual are completely followed.

Please call Trinity Highway Customer Service if you do not understand these

instructions (p. 3).

TrinityHighway.com 6 Revision J January 2020

Trailer Description

The SST

®

has been shown to reduce the risk of injury to passengers of an errant vehicle and to

the driver of the truck to which the system is attached when it is impacted within the applicable

NCHRP Report 350 criteria. The system attaches to the rear of a truck and may be used in

stationary applications, such as a truck blocking a work zone or mobile operations, such as

striping, sweeping, plowing, etc.

The SST

®

consists of the following basic components: A collapsible frame assembly, two

crushable cartridges, an impact face, cylinder hitch assembly, intermediate frame suspension,

wheels and tires (Figures 1 and 2).

Definitions:

The BARRIER VEHICLE is the truck on which a TMA is mounted, while positioned upstream

(towards the direction that traffic is approaching) of a work zone.

The SHADOW VEHICLE is the truck on which a TMA is mounted, which is following behind a

moving operation such as striping, spraying, etc.

Figure 1

Figure 2

CARTRIDGE B CARTRIDGE A

IMPACT FACE

TRUCK

PINTLE HOOK

CYLINDER ASSEMBLY

SUSPENSION, AXLE, WHEELS

TrinityHighway.com 7 Revision J January 2020

Warning: Ensure that no one is near or behind the SST®when in operation.

Warning: Do not operate the SST®while wearing loose fitting clothing which may

become entangled during operation.

Warning: Deploy appropriate traffic-control devices while the SST®is in

operation.

1. It is the operator’s responsibility to ensure hydraulic cylinders are attached to the truck

hydraulic brackets and locked in place with the hairpin cotter pins when the SST®is in the

work zone or being used for protection (Figure 3)

.

*Trinity Highway recommends the use of a pintle hook with a rating of 20 tons (40,000 lbs.) or

greater.

Important: Check for signs of wear at the Pintle Hook and Receiver as part of

normal vehicle maintenance procedures.

REAR OF SUPPORT TRUCK

TRUCK MOUNTING PLATE

(ATTACHED DIRECTLY TO TRUCK FRAME RAILS)

HYDRAULIC CYLINDER

TRUCK PINTLE HOOK (*20 TON OR GREATER CAPACITY)

TRUCK CYLINDER MOUNT

(SUPPLIED WITH TRAILER)

Figure 3

TrinityHighway.com 8 Revision J January 2020

2. The TMA should be securely fastened to the truck. In the horizontal position on level

ground, the bottom of the TMA should be 12” ± 2” [305 mm ± 50 mm] from the ground and

level (Figure 4).

3. Make sure all twenty-four (24) pivot pins are in position and that all retaining pins are

assembled correctly (Figure 5).

4. The SST

®

is designed to absorb a crash and

to support its own weight if impacted within

the applicable NCHRP Report 350 criteria. Do

not drag the TMA or place anything on its top:

damage may result (Figures 6 and 7).

Caution:

Do not sit, stand or lean on any part of the TMA.

Figure 6

Figure 7

Figure 4

12” ± 2” [305mm ± 50 mm]

Figure 5

PIVOT PIN

RETAINING PIN

TrinityHighway.com 9 Revision J January 2020

5. Ballast and other heavy objects MUST BE ADEQUATELY ANCHORED to the truck to

prevent shifting during an impact. The force on the tie-down straps could be 20 times the

weight of the ballast (Figure 8).

6. The agency or highway authority responsible for the truck should inspect it for adequate

operator safety equipment (e.g., seat belts, head rests, etc.).

7. Make certain that the applicable highway authority’s current specifications as to TMA

reflectivity are evaluated and complied with. It is the operator’s responsibility to make sure

that all applicable reflectivity standards are met and the appropriate taping of indicators is

placed on the TMA before use on the highways.

8. Make sure that the performance and safety of the SST

®

is not impaired by damage or

corrosion.

Warning:

Failure to comply with these instructions can result in improper TMA

performance and possible personal injury. This TMA is intended to be used as an

impact attenuator on the rear of trucks which meet the minimum requirements for

this system (p. 13).

9. Regular maintenance of the SST

®

is important for safe use. Refer to the Routine

Maintenance section of this manual for additional information (p. 33).

a. Regular inspection of frame members, cartridges, and pins is necessary to ensure

proper system performance.

b. Regular inspection of hoses, cylinders, and tires is important. A broken or damaged

hose or cylinder will cause the system to function improperly. Low tire pressure could

cause a blowout.

c. Keep electrical connections clean to prevent arcing. Clean any hydraulic spills or

leakage to prevent bodily injury, fire, etc.

10. This system is a crash cushion and is therefore used in high traffic areas as directed by

the appropriate highway authority. Stay clear of traffic whenever possible. If an accident

is to occur, even during an NCHRP Report 350 criteria impact, there may be fragments

from the truck or impacting vehicle that could cause injury.

11. Do not use any part of the TMA for towing or hauling a load.

12. Ensure your truck is appropriate for attaching an SST

®

. See the Assembly section on page

14 for further details.

13. Mindfulness when moving hydraulic cylinders is encouraged so as not to pinch hands or

drop cylinders on your feet.

14. When cylinders are not in use, make sure they are stored on the cylinder storage pins with

the lynch pins fastened to keep the cylinders secure.

15. Periodically check the hydraulic fluid level.

Figure 8

TrinityHighway.com 10 Revision J January 2020

Trailer Safety Instructions

Caution: Noncompliance with these instructions can lead to damage of the SST®

components or render the SST®unfit for protection.

1. The Jack is used to support the TMA when it is detached from the truck. When the TMA

is attached to the truck, the Jack must be fully rotated 90 degrees to the travel position.

2. The driver should be extra cautious while backing the truck with the SST®so that injury

and/or damage will not result.

3. Periodically check and correct tire pressure to recommended pressure noted in this

manual. Never exceed the maximum pressure listed on the tire side wall.

4. Make sure the wheel lug nuts/bolts on the SST®are tightened to the correct torque as

recommended in the Maintenance section.

5. Be sure the pintle hook and pintle eye are connected and properly tightened and adjusted.

6. Make sure all lights are working correctly.

7. On a regular basis per maintenance schedule, verify that the breakaway brakes are

functioning properly.

8. Avoid sudden stops and starts that can cause loss of vehicle control.

9. Avoid sudden steering maneuvers that might create sway or undue side force on the

SST®.

10. Slow down when traveling over bumpy roads, railroad crossings and ditches.

11. Make wider turns at curves and corners.

12. When uncoupling the SST®, place blocks or wheel chocks at the front and rear of the trailer

tires to ensure that the trailer does not roll away when the coupling is released.

13. Lightly coat all electrical terminal connections periodically with non-conducting (dielectric),

light waterproof grease.

14. Periodically check axle bearings. Maintain per maintenance schedule (p. 33).

15. Always use safety chains when towing to prevent runaway trailer in case of system

detachment.

16. Cross safety chains under coupling to prevent tongue from dropping to ground in case of

connection failure.

17. Allow only enough slack for tight turns.

18. Do not let safety chains drag on the ground.

19. Twist safety chains equally from hook ends to take up slack.

20. The truck operator is completely responsible for monitoring the condition of the trailer

components as they relate to safe highway transit of their vehicle.

TrinityHighway.com 11 Revision J January 2020

21. Check that the wiring is properly connected and not touching the road, but loose enough

to make turns without disconnecting or damaging the wires.

Caution: Trailer towing can be hazardous.

22. Do not modify or change the trailer in any way.

23. Never weld, bolt or modify anything on the trailer. The added weight could affect impact

performance.

24. Use a correctly rated pintle hook (20 tons or greater).

Electric Brakes Safety Instruction

Caution: Noncompliance with these instructions can lead to damage of TMA

components or render the SST®unfit for protection.

1. In case of a connection failure, the SST®is equipped with a breakaway cable that activates

the electric brakes by pulling the breakaway pin mechanism.

2. It is the responsibility of the truck operator to set the attachment point of the breakaway

cable on the truck, so that the trailer brakes do not activate during normal towing.

3. If the truck operator connects the breakaway cable too tightly to the truck, the breakaway

mechanism will activate. The results of an improper connection can be catastrophic and

will result in damage to the trailer brakes and possibly the loss of tire and hub as bearings

are destroyed due to overheating.

TrinityHighway.com 12 Revision J January 2020

Tires & Axle

1. Periodically check and correct tire pressure. Inflate trailer tires to a minimum of 35 psi.

Never exceed the maximum pressure indicated on the tire side wall.

2. All trailer tires have a maximum speed rating of 65 mph [105 kph].

3. Three to five years is the projected life of a normal trailer tire.

4. The mileage expectation of a trailer tire is 5,000 - 12,000 miles [8,050 - 19,300 km].

Warning: Incorrect tire pressure can cause loss of control resulting in injury and

equipment damage.

5. Always replace trailer tires with (ST) Special Trailer tires.

6.

Wheels and tires offset is the distance from the mounting surface to the centerline of the

tire. The SST

®

axle bearing sets are designed for wheels with 0 to 1/2” [13 mm] offset.

Exceeding this offset will shorten bearing life and may lead to bearing failure.

7. Wheels and tires must be matched. The wheel will have a label stating its rim diameter,

width and contour. The tire selected must be approved by the Tire and Rim Association

for use on that particular size wheel.

8. When replacing tires, the tire capacity selected should not exceed the capacity rating of

the wheel.

9. When replacing tires, the tire inflation pressure must not exceed the pressure rating of the

wheel.

Warning: The use of tires that are not approved for use on a wheel could result

in explosive separation of the tire and wheel and could cause a serious accident.

10. Make sure the wheel lug nuts are tightened to the correct torque.

11. Do not jack up the trailer on the suspension components because of potential for damage.

Use the trailer frame when jacking up the trailer.

12. Never weld to the Torflex®axle. The Torflex®axle contains rubber cords to provide the

suspension system and can be damaged by heat generated from welding on the bracket

or tube.

13. Trailer wheels carry substantially more weight than truck wheels of the same size and

more disc flexing can occur due to side loading stresses. It is necessary to re-torque the

lug nuts several times until the wheels nut torque stabilizes.

Warning: Be careful to use only the recommended lug nut torque as specified

for that wheel and fastener. It is possible to permanently damage a wheel that has

been over torqued and may cause the loss of that wheel from the trailer.

Warning: Never use oil or grease on studs or nuts for wheels. Assembling wheels

without good metal to metal contact could cause loosening of the wheel nuts.

TrinityHighway.com 13 Revision J January 2020

Controlling Skid Distance and Roll-Ahead

The use of a SST®on the back of a truck will not:

Affect the skid (roll ahead) distance of an impacted truck. KEEP WORK CREWS CLEAR!

Controlling skid distance (roll ahead):

Skid distance is significantly increased and is less predictable for lightweight shadow vehicles.

Skid distance is reduced and is more consistent when heavier shadow vehicles are used.

Required truck weight: 9,920 lbs. [4,500 kg] or greater.

Roll-Ahead Distance for Shadow Vehicles

Weight of Shadow

Vehicle (Moving)

Prevailing Speed

mph [kph]

Weight of Impacting Vehicle to be Contained*

4,500 lbs

[2,040 kg]

10,000 lbs

[4,536 kg]

15,000 lbs

[6,804 kg]

24,000 lbs

[10,886 kg]

10,000 lbs

[4,536 kg]

60-65 [96-105] 100’ [30 m] 175’ [53 m] 225’ [69 m] 275’ [84 m]

50-55 [80-88] 100’ [30 m] 150’ [46 m] 175’ [53 m] 200’ [60 m]

45 [72] 75’ [23 m] 100’ [30 m] 125’ [38 m] 150’ [46 m]

15,000 lbs

[6,804 kg]

60-65 [96-105] 75’ [23 m] 150’ [46 m] 175’ [53 m] 225’ [69 m]

50-55 [80-88] 75’ [23 m] 125’ [38 m] 150’ [46 m] 175’ [53 m]

45 [72] 50’ [15 m] 100’ [30 m] 100’ [30 m] 100’ [30 m]

24,000 lbs

[10,886 kg]

60-65 [96-105] 75’ [23 m] 100’ [30 m] 150’ [46 m] 175’ [53 m]

50-55 [80-88] 50’ [15 m] 75’ [23 m] 100’ [30 m] 150’ [46 m]

45 [72] 50’ [15 m] 75’ [23 m] 75’ [23 m] 100’ [30 m]

Note: Distances are appropriate for shadow vehicle speeds up to 15 mph [25 kph].

Roll-Ahead Distance for Barrier Vehicles

Weight of Barrier

Vehicle (Stationary)

Prevailing

Speed mph

[kph]

Weight of Impacting Vehicle to be Contained*

4,500 lbs

[2,040 kg]

10,000 lbs

[4,536 kg]

15,000 lbs

[6,804 kg]

24,000 lbs

[10,886 kg]

10,000 lbs [4,536 kg]

60-65 [96-105] 50’ [15 m] 100’ [30 m] 150’ [46 m] 200’ [60 m]

50-55 [80-88] 25’ [8 m] 75’ [23 m] 100’ [30 m] 150’ [46 m]

45 [72] 25’ [8 m] 50’ [15 m] 75’ [23 m] 100’ [30 m]

15,000 lbs [6,804 kg]

60-65 [96-105] 25’ [8 m] 75’ [23 m] 100’ [30 m] 150’ [46 m]

50-55 [80-88] 25’ [8 m] 50’ [15 m] 75’ [23 m] 100’ [30 m]

45 [72] 25’ [8 m] 25’ [8 m] 50’ [15 m] 75’ [23 m]

24,000 lbs [10,886 kg]

60-65 [96-105] 25’ [8 m] 50’ [15 m] 75’ [23 m] 100’ [30 m]

50-55 [80-88] 25’ [8 m] 25’ [8 m] 50’ [15 m] 75’ [23 m]

45 [72] 25’ [8 m] 25’ [8 m] 25’ [8 m] 50’ [15 m]

Shadow or Barrier Vehicle Recommended Weight

Recommended minimum Barrier/Shadow vehicle weight: 9,920 lbs [4,500 kg].

*Weights of Typical Vehicles:

Midsize automobile - 2,250 lbs [1,020 kg]

Full-size automobile - 3,500 lbs [1,500 kg]

Loaded 3/4-ton pickup truck - 6,000 lbs [2,750 kg]

Loaded 1-ton cargo truck - 10,000 lbs [4,500 kg]

Loaded 4-yard dump truck - 24,000 lbs [11,000 kg]

Source: "Use of Truck Mounted Attenuators in Work Zones" by T. Darcy Sullivan, P.E and

Jack B. Humphreys, P.E., University of Tennessee.

TrinityHighway.com 14 Revision J January 2020

Assembly

Read and understand all instructions before beginning assembly.

Important: The truck weight shall be 9,920 lbs [4500 kg] minimum.

The system must be attached to the truck by pintle hook and cylinder attachment brackets.

The truck frame must be suitable and accessible for mounting a TMA system. If there are any

questions regarding the suitability, contact the Customer Service Department for assistance.

1) Shipping list

Check the shipping list against the actual parts received to make sure all items were received.

Review the drawing package and familiarize yourself with the assembly and part numbers.

2) Recommended tools:

Welding equipment (for 1/2” [13 mm] plate) GMAW or SMAW

Cutting torch

Hammer

Drift pin or Alignment pin (12” [305 mm] long)

Tape measure

1/2” drive socket wrench with 6” extension

1/2" drive sockets (9/16”, 3/4”, 7/8”, 1-1/8” deep well)

Open end wrenches (9/16”, 1-1/8”)

12” crescent wrenches – (2) (optional)

Marking implement (pencil, soap stone)

Floor jack

Drill motor for 13/16” diameter bit

13/16” diameter bit and pilot drill for same

Center punch

Torque wrench – 90 ft lbf [120 N-m]

Torque wrench – 25 ft-lbf [34 N-m]

Forklift

Hydraulic fluid (Dexron®III fluid only) *Shipped with system

Vise Grips

Allen Wrench 5/32”

Phillips Screw Driver #2

Wire Cutters

Note: The above list of tools is a general recommendation and should not be considered

an extensive list. Depending on specific conditions and the complexity of the assembly

specified by the appropriate highway authority the required tools may vary. Decisions as

to what tools are needed to perform the job are entirely within the discretion of the

specifying highway authority and the authority’s selected contractor performing the

assembly of the system.

TrinityHighway.com 15 Revision J January 2020

Preparation

3A)Assembly must be performed on a level surface

The TMA framework is very heavy and pivots in several areas. Until the framework is secured

with the cables, it can swing out in an approximate 7’ [2 m] radius from either side of the trailer

axle. A level surface is required to maintain control of the framework when it is being extended

to its full length.

3B)Truck ballast

Use a bubble level to verify that the truck is parked on a level surface. The truck should be as

close to the final driving weight as possible. If ballast is needed to meet 9970lbs [4500kg]

minimum, add it at this time. Ballast must be properly anchored to the truck to keep it in place

during an impact. Ideally, an adequately sized truck that requires no ballast should be used.

Because the tongue weight of the Trailer TMA is supported by the back of the vehicle, be sure

not to exceed the manufacturer's published maximum axle loads.

Important: It is the responsibility of the TMA operator to ensure the truck

manufacturer's center-of-gravity zone is known and applied when adding ballast.

4) Check for interference

Before attempting to assemble the cylinder brackets and pintle hook, check for interference

problems.

Temporarily position the cylinder brackets and pintle hook on the truck frame and check for

interference problems (p. 17). Interference problems with tail lights, springs, dump bodies (in

the up or down positions), etc., shall be corrected before proceeding.

Prepare the truck for the cylinder brackets and pintle hook. The truck frame shall be two C-

channels spread 34" ± 1" apart. Most trucks have a 1/2" plate welded across the back frame

members and a pintle hook. If not, start by making sure the frame is square by measuring

back from the spring shackles. Cut the frame square first if needed. Once the frame is

squared, the plate can be welded or bolted on.

Welding Procedures

a. Start by grinding the inside and outside of the frame ends to prepare for the weld

(Figure 9).

b. The plate needs to be a minimum of 1/2" thick and wider than 36" (Figure 10).

c. Grind the plate in the locations where the frame is to be welded.

d. Tack the plate into position and make sure that the rear plate is positioned correctly.

e. Continue welding the inside and outside frame to the plate.

Figure 10

Figure 9

TRUCK FRAME

GRIND THIS

EDGE

34” ±1”

CENTER PLATE ON TRUCK FRAME

TACK WELD

MIN. 1/2” THICK PLATE

GRIND PAINT OFF

BACK OF PLATE

4” MAX. OR

ADD GUSSET

FROM PLATE

TO THE FRAME.

TrinityHighway.com 16 Revision J January 2020

Bolt-on Procedures

a. Start by cutting two (2) 4" x 4" x 1/2" steel angle the height of the C channel.

b. Measure and mark the angle for four (4) 1-1/16” holes (Figure 11). The spacing needs to

be equal distances vertical and horizontal. Make sure the holes are spaced at least 2-

1/16” apart.

c. Drill holes in the angle.

d. Use the angle as a template for marking and drilling holes in the truck frame (Figure 12).

e. Bolt the angle in place using two (2) 1" diameter (grade 5) bolts on each side.

f. The plate needs to be a minimum of 1/2" thick and wider than 36" (Figure 13).

g. Drill matching holes in the plate.

h. Mount plate using four (4) 1" diameter (grade 5) bolts. If the plate is greater than 4” below

the C channel frame, you must gusset from the plate to the frame.

Figure 11

Figure 12

Figure 13

CENTERLINE OF

ANGLE FACE

2 1/16” MIN.

1 1/16” DIA. HOLE

(4 PLACES)

4” X 4” X 1/2”

ANGLE

1” HEX NUT

(4 PLACES)

1” GRADE 5 HEX

BOLT (4 PLACES)

1” HEX NUT (4 PLACES)

1” HEX NUT (4 PLACES)

CENTER PLATE ON

TRUCK FRAME

MIN. 1/2” THICK PLATE

4” MAX. OR ADD GUSSET

FROM PLATE TO FRAME

1” GRADE 5 HEX BOLT

(4 PLACES)

TrinityHighway.com 17 Revision J January 2020

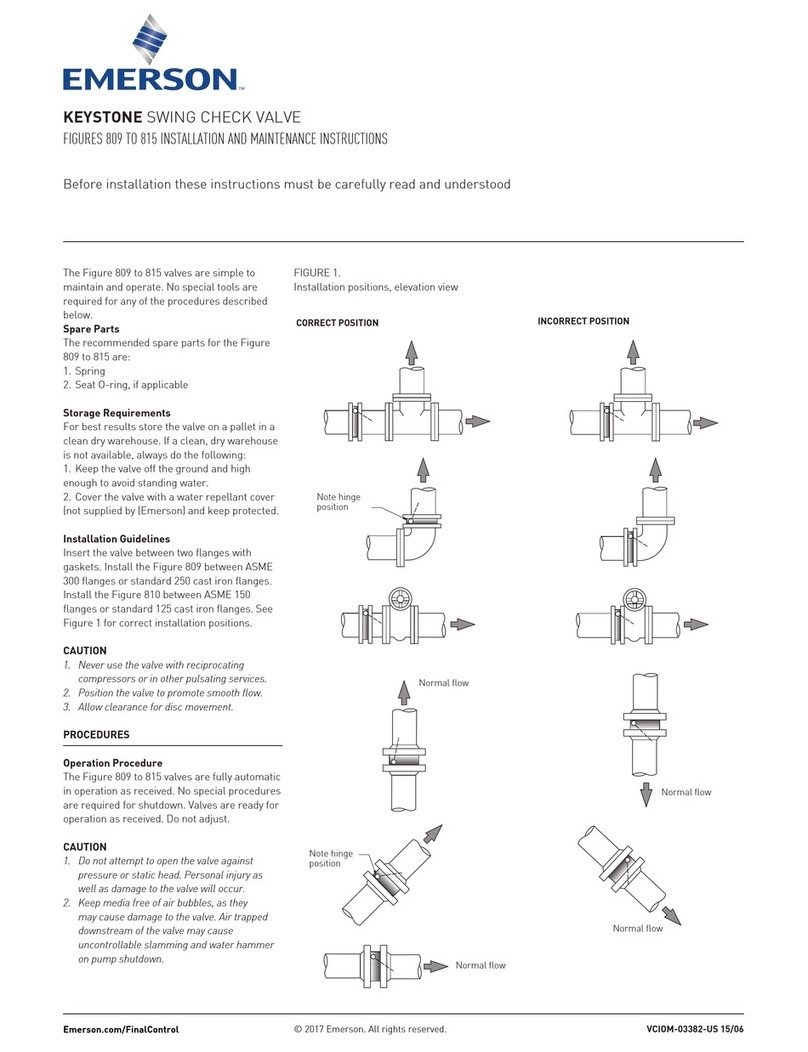

5) Underride Assembly

With the truck at its actual driving weight and parked on a level surface, measure the distance

from the ground to the pintle hook. Attach the pintle eye to the trailer at the same height with

the trailer frame at 12" ± 2" [305 ± 50 mm] above the ground, front and rear.

Note: The truck’s springs may settle with the weight of the TMA. Adjust the height to compensate

for anticipated settling.

Position the Cylinder Brackets in line horizontally with the pintle hook ±5” [127mm] and in line

vertically with the truck frame rails as shown below. Weld two opposing sides of each bracket

or bolt the brackets to the truck.

Caution: The truck frame is high carbon steel. Do not weld or apply excessive

heat to bottom flange forward of rear-most leaf spring hangers to avoid cracking.

Prime and paint all welded areas.

6a) If TMA is fully assembled; attach the TMA to the truck. Go to Step 23.

6b) Uncrate the TMA

See Uncrating Instructions, Part No. 616787B.

7) Extend the Support Frame

Slowly and evenly pull the frame out to its full extent.

Warning: Use extreme care. The frame can be unwieldy even when supported

by a forklift.

Figure 14

Rear of Support Truck

Note: Pintle hook cylinder

mount to be aligned on same

centerline ± 5” [127 mm]

PINTLE HOOK (20 TON OR

GREATER CAPACITY)

CYLINDER MOUNT

[560 to 760 mm]

CYLINDER MOUNTS TO BE ALIGNED WITH TRUCK

FRAME RAILS ± 2” [50 mm] – APPROX. 32”

[813 mm] CENTER TO CENTER

22” to 30”

TrinityHighway.com 18 Revision J January 2020

Warning:

Until the cables are attached, the system may shift to one side

(Figure 15).

8) Attach Fenders

Attach Fenders as shown below. Do not tighten bolts yet. Attach nylon ties through hole in

bracket to secure light cable.

Figure 15

Figure 16

Fender Assembly

ALIGNMENT CABLES

ALIGNMENT CABLES

3/8” HEX NUT

3/8” LOCK WASHER

3/8” FLAT WASHER

3/8” X 1” G5 HEX BOLT

HOLE IN BRACKET

FENDER

NYLON TIES

TrinityHighway.com 19 Revision J January 2020

9) Mount Wheels

Attach

wheels as shown below using the torque sequence and stages for tightening.

10) Align Fenders

Align Fenders and tighten bolts

.

11) Assemble Fender Clearance Lights

Attach Fender Clearance Lights. Use nylon zip tie straps as shown in Figure 16 to keep the

wire away from the tire (Figure 18).

Lug nut torque requirements:

A. Start all nuts by hand to prevent

cross threading.

B. Torque nuts in stages as follows:

1st stage 20-25 lbf-ft

2nd stage 35-40 lbf-ft

3rd stage 70±5 lbf-ft

C. Follow torque sequence in Figure 17.

Figure 17

Figure 18

Fender Clearance Light Assembly

LUG NUT

WHEEL

WITH TIRE

REMOVE DUST CAP

BEARING PROTECTOR

BEARING PROTECTOR BRA

GROMMET, LIGHT

3 1/4X1 15/16, RECT

LIGHT, SEALED CLEARANCE,

2 1/2X1 1/4, A, 12V

FENDER

Table of contents

Other Trinity Highway Control Unit manuals

Popular Control Unit manuals by other brands

Lumel

Lumel MR03 Series user manual

Rockwell Automation

Rockwell Automation Allen-Bradley 1769-BOOLEAN Reference manual

jbc

jbc UCR470-5A manual

Akron

Akron Style 6032 Installation, operation & maintenance manual

Robostar

Robostar N1 Series Option DeviceNet manual

Emerson

Emerson Keystone Installation and maintenance instructions