Trinity Highway INGAL SS180 M User manual

PN

626198

Revision

B March 2020

SS180

SS180

M

Product Description Assembly Manual

TRINITY

HIGHWAY

Ahead

of the

Curve

®

trinityhighway.com

1

Revision ANovember 2019

SS180®

M

The SS180®MTruck Mounted Attenuator (“TMA”) has been tested pursuant to American

Association of State Highway and Transportation Officials (“AASHTO”) Manual for Assessing

Safety Hardware(“MASH”) specifications.

Product

Description

Assembly

Manual

2525 N. Stemmons

Freeway

Dallas, Texas

75207

Warning:The local distributors, owners, contractors, lessors, and lessees

are RESPONSIBLE fortheassembly,maintenance,andrepair of the SS180®

M. Failure to fulfill these RESPONSIBILITIES withrespect to the

assembly, maintenance, and repair of the SS180®Mcouldresult in

serious injury or death.

Important: These instructions are for standard assembly specified by the

appropriate highway authority. In the event the specified system assembly,

maintenance, or repair would require adeviation from standard assembly

parameters, contact aTrinity Highway representative.

This manual must be available to the worker overseeing and/or assembling the product at

all times. For additional copies, contact Ingal Civil Products directly at 1800-803-795 or visit

www.ingalcivil.com.au.

The instructions contained in this manual supersede all previous information and manuals. All

information, illustrations, and specifications in this manual are based on the latest SS180®M

information available to Trinity Highway at the time of printing. We reserve the right to make

changes at any time. Please contact Ingal Civil Products to confirm that you are referring to the

most current instructions.

Part No.

626198

©2019 Trinity Highway Products, LLC

trinityhighway.com

2

Revision ANovember 2019

Table of Contents

Customer Service

Contacts.........................................................................................................

3

Important Introductory

Notes

...................................................................................................... 3

System

Overview

........................................................................................................................ 4

Safety

Symbols

........................................................................................................................... 4

Safety Rules for Assembly......................................................................................................... 4

Limitations and

Warnings

...........................................................................................................

..

5

Know Your SS180®MSystem ................................................................................................... 6

Assembly

...................................................................................................................................11

Recommended Tools ..........................................................................................................11

Preparation

..........................................................................................................................12

Operation Instructions.............................................................................................................. 20

Folding and Unfolding the

System.......................................................................................

20

Maintenance

..............................................................................................................................21

Routine

Maintenance...........................................................................................................

21

Detaching and Attaching the System ..................................................................................22

Lubrication

...........................................................................................................................24

Technical

Specifications

......................................................................................................

25

Repair

Instructions

.....................................................................................................................26

Post

Impact

..........................................................................................................................26

TroubleshootingGuide..............................................................................................................28

Hydraulic

Fluid

.....................................................................................................................29

Hydraulic System Check .....................................................................................................30

Pressure Relief

Valve

..........................................................................................................

32

CounterbalanceValve.........................................................................................................33

Hydraulic Cylinder ...............................................................................................................34

Hydraulic System Priming ...................................................................................................35

Reservoir.............................................................................................................................35

Electrical

Problems

..............................................................................................................36

TroubleshootingDecision Trees and System

Drawings............................................................

.

38

SS180®M............................................................................................................................40

Support Frame

Assembly

....................................................................................................41

Cartridge A..........................................................................................................................44

Cartridge B..........................................................................................................................45

Miscellaneous Part

Assembly..............................................................................................

46

Impact Face Assembly........................................................................................................47

Hydraulic Control Assembly ................................................................................................48

Hydraulic Cylinder

Assembly

...............................................................................................51

Pump

Assembly

...................................................................................................................52

Electrical Box,

Hydraulic

......................................................................................................53

LED Lighting Assembly .......................................................................................................57

Underride Assembly............................................................................................................60

Attachment

Assembly

..........................................................................................................61

trinityhighway.com

3

Revision ANovember 2019

Customer Service Contacts

Trinity Highway is committed to the highest level of customer service. Feedback regarding the

SS180®Msystem, its assembly procedures, supporting documentation, and performance is

always welcome. Additional information can be obtained from the contact information below:

TrinityHighway:

Telephone: (888) 323-6374 (USA)

+1 (214) 589-8140 (International)

Contact:

TrinityHighway.com/Contact

Website

trinityhighway.com

Important Introductory Notes

Proper assembly, deployment and future maintenance of the SS180®Mare critical to achieve

tested performance under accepted MASH criteria. Take the time to review this manual thoroughly

before performing all necessary work. These instructions should be read in their entirety and

understood before assembling the TMA. These instructions are to be used only in conjunction with

the assembly of the SS180®Msystem and are for standard assemblies only as specified by the

applicable highway authority.

In the event your system assembly requires or involves deviation from standard parameters or,

duringtheassemblyprocessaquestionarises,pleasecontact Trinity Highway customer service.

These instructions are intended for an individual who is qualified to both read and accurately

interpret them as written. They are intended for the individual who is experienced and skilled in the

assembly of highway products which are specified and selected by the highway authority.

If additional information is required, please contact Trinity Highway Customer Service. If there are

deviations, alterations, or departures from the assemblyprotocolspecifiedin thismanual,the

SS180®Mmany not perform as tested.

Important: It is the responsibility of the installer to maintain asafe work area

including the use of standard work zone safety equipment &PPE: gloves, safety-

toe shoes, and eye /ear protection.

Important: DO NOT use any component part that has not been specificallycrash

tested and/or approved for this system during assembly or repair.

trinityhighway.com

4

Revision ANovember 2019

System Overview

The SS180®Msystem has shown to reduce the risk of injury to passengers of an errant vehicle

and to the driver of the truck to which the system is attached when the system is impacted within

the applicable MASH criteria. The system mounts on the rear of atruck and may be used in

stationary applications (e.g. as atruck block in awork zone) and mobile operations (e.g. striping,

sweeping, plowing, etc.).

Safety Symbols

This section describes safety symbols that may appear in the SS180®Mmanual. Read this

manual for complete safety, assembly, operating, maintenance, repair, and service information.

Symbol

Meaning

SafetyAlertSymbol:Indicates Danger, Warning, or Caution. Failure to read

and follow the Danger, Warning, Caution, or Important statements could result in

serious injury or death to workers and bystanders.

Warning: Read safety instructions thoroughly and follow the assembly directions

and suggested safe practices before assembling, maintaining, or repairing the

SS180®M. Failure to follow this warning can result in serious injury or death to the

worker and/or bystanders.

Important: Please keep up-to-date instructions for later use and reference by

anyone involved with this product.

Safety Rules for Assembly

*Important Safety Instructions *

This manual must be kept in alocation where it is readily available to persons who assemble,

maintain, or repair the SS180®M. Additional copies of this manual are available from Trinity

Highway by calling (888) 323-6374 or contact us using TrinityHighway.com/Contact.Please

contact Trinity Highway if you have any questions concerningthe information in this manual.

Important: It is the responsibility of the installer to use proper safety precautions

when operating power equipment, mixing chemicals, and when moving heavy

equipment or SS180®Mcomponents.Theinstalleris responsibleforproperuse

of hand, eye, foot, and back protection.

Warning: Safety measures incorporating appropriate traffic control devices

specifiedby thehighwayauthoritymustbe usedto protectallpersonnelwhilethe

TMA is in use. The traffic control plan established by the highway authority must

always be observed when utilizing this product.

trinityhighway.com

5

Revision ANovember 2019

Limitations and Warnings

Trinity Highway, in compliance with MASH “Recommended Procedures for the Safety

Performance of Highway Safety Features”, contracts with FHWA approved testing facilities to

perform crash tests, evaluation of tests, and submittal of results to the FHWA for review.

The SS180®Mwas tested to meet the impact criteria, requirements, and guidelines of MASH.

These tests, specificallyset forth by the FHWA, evaluate product performanceby simulating those

impacts outlined by MASH involving atypical range of vehicles on our roadways, from lightweight

cars (approx. 2420 lb. [1100kg]) to full size pickup trucks (approx. 5000 lb. [2270 kg]) as specified

by the FHWA. Aproduct can be certified for multiple Test Levels. The SS180®Mis certified to the

Test Level as shown below:

Test Level 3: 62 mph [100 km/h]

These FHWA directed tests are not intended to represent the performance of systems when

impactedby every vehicletype or everyimpactconditionexistingon theroadway. This

system is tested only to the test matrix criteria of MASH as approved by the FHWA.

Trinity Highway expressly disclaims any warranty or liability for injury or damage to persons or

property resulting from any impact, collision or harmful contact with products, other vehicles, or

nearby hazards or objects by any vehicle, object or person, whether or not the products were

assembled in consultation with Trinity Highway or by third parties.

The SS180®Mis intended to be assembled, delineated, and maintained within specific state and

federal guidelines.It is important for the highway authority specifying the use of ahighway product

to select the most appropriate product configuration for its sitespecifications. The customer should

be careful to properly select, assemble, and maintain the product. Careful evaluation of the site

lay out, vehicle population type; speed, traffic direction, and visibility are some of the elements that

require evaluation in the selection of ahighway product.

After an impact occurs, the debris from the impact should be removed from the area immediately

and the product should be evaluated and restored to its original specified condition or replaced

as soonas possible.Allcomponentsandassembliesshould be inspected andanypartsthatare

damaged should be replaced with original Trinity Highway replacement parts. Contact the

Customer Service Department prior to repair if you have any questions (p. 3).

Warning: It is the responsibility of the installer to ensure that the SS180®Mand

delineation used meet all federal, state, specifying agency, and local specifications.

Warning: It is the responsibility of the installer to ensure that your assembly

meets all appropriate Manual on Uniform Traffic Control Devices (MUTCD) and

localstandards.

Host Vehicle Tare Weights should be between 6150kg and 11,000kg.

Warning: Roll-ahead distance is 6.4m. Plan your TMA deployment accordingly.

trinityhighway.com

6

Revision ANovember 2019

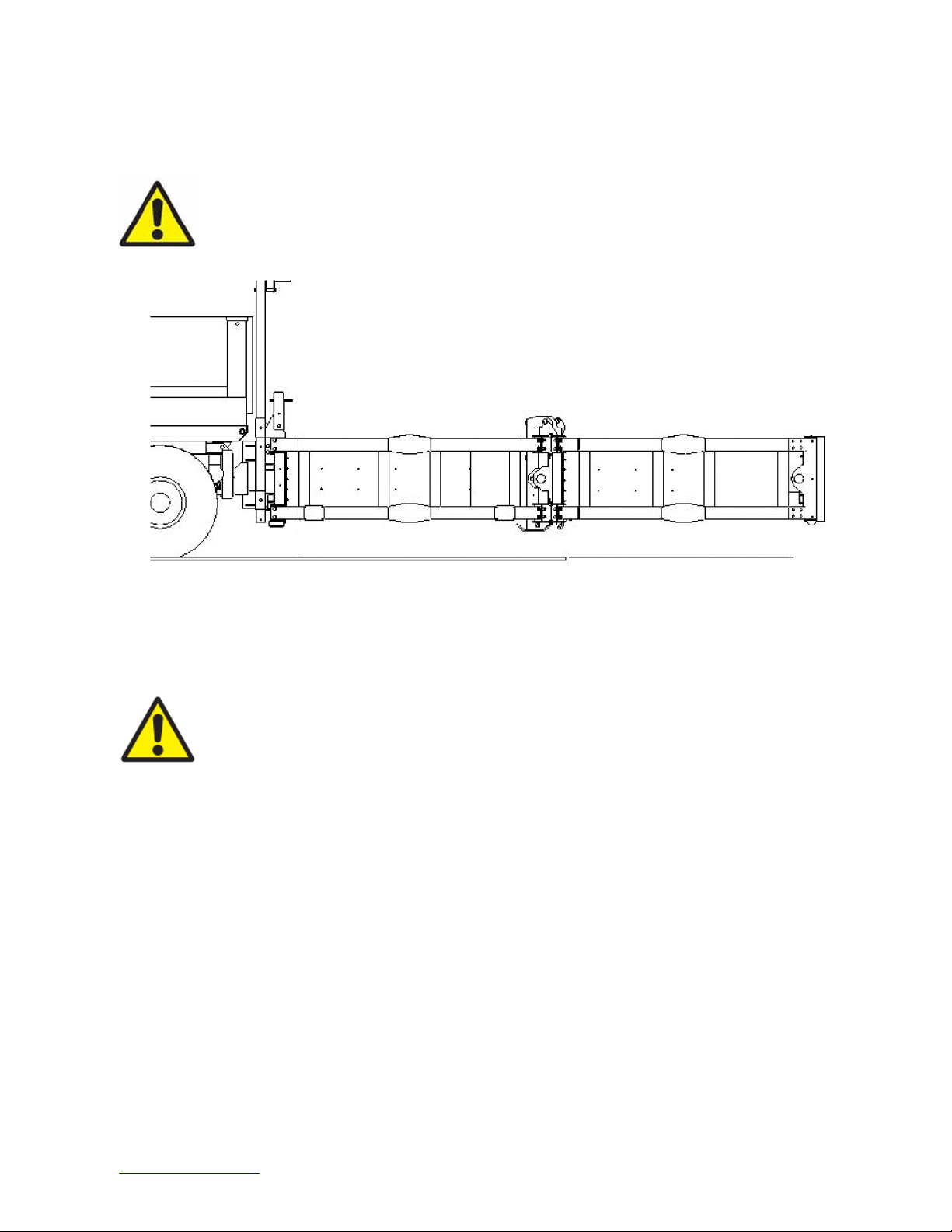

Know Your SS180®M System

For the safety of the operator, the operator shall stand at the rear of the truck, on the curb side,

(Figure 2). When tilting the TMA, care shall be taken to stay clear of all moving parts.

TYPE B CARTRIDGE TYPE A CARTRIDGE

SOCKET HITCH UNDERRIDE

SUPPORT STRUCTURE

Figure 1

STAND HERE

(FOR

CONTROLS ON

RIGHT

SIDE OF

TRUCK)

CONTROLS LOCATED

ON

EITHER SIDE OF

TRUCK

CONTROLS RHS

CARTRIDGE BCARTRIDGE A

TRUCK

STAND HERE

(FOR

CONTROLS ON LEFT

S

I

DE

OF TRUCK)

CONTROLS

LOCATED ON

EITHER

SIDE OF

TRUCK

CONTROLS LHS

Figure 2

trinityhighway.com

7

Revision ANovember 2019

1. TheSS180®Mshallbe rigidlyfastened to thetruck.In thehorizontalposition,thebottom

of the TMA shall be 11" to 13" [280 to 330 mm] from the ground to the bottom of the Rear

Impact Face (Figure 3).

Warning: TheSS180®Mcan only absorb the energy of an impacting vehicle

when in the unfolded position.

Figure

3

↑

12” ±1” [305 mm ±25 mm]

↓

2. Jacksshall be usedto supporttheSS180®Mwhen it is detached from the truck. The

Jacks must be stored while the TMA is attached to the truck.

Important: The SS180®Mmust be deployedin the unfoldedpositionat all times

while operating as either aBarrier Vehicle or Shadow Vehicle.

The SS180®Mcan be in the "unfolded" position when traveling short distances at low speed

(not greater than 40 km/h).

The SS180®Mmust be in the "folded" position whentravelinglongdistancesat ahigh

speed(greater than 40 km/h).

trinityhighway.com

8

Revision ANovember 2019

3. The SS180®Mis intended to support its own weight and dissipate the kinetic energy of

errant vehicles per MASH criteria. Do not drag the TMA or place anything on its top or

damage will result. Do not sit, stand, or lean on any part of the TMA (Figures 4&5).

Figure

4

Figure

5

4. Before raising or lowering the TMA, the operator shall be fully trained in its proper

operation. All operators are required to fully understand the contents of this manual prior

to operating the system. The operator should never stand under the TMA while it is being

raised or lowered.

5. Folding the TMA provides the best maneuverability and driving characteristics. The TMA

shall be inits foldedtransportposition while travellingbetween deployment locations.Refer

to local agency policies as required for additional guidance. Unfold the system before

entering ajob site or beginning shadow vehicle operations. The support vehicle must be

fully stopped before TMA folding and unfolding.

6. All persons shall stand clear before folding or unfolding the TMA. The system must be

stopped in full folded position before allowing anyone directly behind the folded system.

trinityhighway.com

9

Revision ANovember 2019

7. Ballast and other heavy objects MUST BE ADEQUATELY ANCHORED to the truck to

prevent shifting during an impact (Figure 6). The force exerted on the tie-down straps could

be 20 times the weight of the ballast.

Figure

6

8. The agency responsible for the truck shall inspect it for adequate operator safety

equipment (e.g., seat belts, head rests, etc.)

9. The SS180®Mcan only be mounted to trucks weighing between 6,120 -11,340

kg.

10. Make sure that the performance and safety of the TMA is not impaired by damage or

corrosion.

Warning:This TMA is intended to be used as an impact attenuator on the rear

of trucks weighing between 6,120 -11,340 kg. TheTMAshallnotbe used for

any other purpose.

11. Regular maintenance of the TMA is critical for proper operation. Refer to the maintenance

section of this manual for additional information.

a. Regular inspection of frame members, cartridges, and fasteners is necessary to

ensure proper system performance.

b. Regular inspectionof hydraulic hoses is critical. Abroken or damagedhose will cause

the system to operate uncontrollably.

c. Keep electrical connections at the Pump Motor/Solenoid clean. Clean any hydraulic

spills or leakage to prevent bodily injury, fire, etc.

12. The driver shall be cautiouswhile making turns with the TMA in the unfolded position. The

TMA extends beyond the end of the truck and will swing wide while turning.

13. This system is an impact attenuator and is therefore used in high risk areas. Stay clear of

trafficwhenever possible.

trinityhighway.com

10

Revision ANovember 2019

14. The Hydraulic Assembly was designed to fold and unfold the TMA. Any other use may be

hazardous to people or equipment.

a. Do not use the system to push aload.

b. Do not use the raised end of the system to support any load.

c. Do not use any part of the TMA for towing or hauling aload. This could cause the lift

mechanism to malfunction and permanently damage the system.

d. Do not use the TMA as aladder.

Warning: Do not leave the TMA raised, even slightly, when deployed.

BARRIER VEHICLE -Atruck on which aTMA is mounted, while positioned upstream (towards

the direction that traffic is approaching) of awork zone.

SHADOW VEHICLE -Atruck on which aTMA is mounted, which is following behind amoving

operation such as striping, spraying, etc.

THE USE OF ATMA ON THE BACK OF ATRUCK, WHEN IMPACTED WITHIN THE

APPLICABLE MASH CRITERIA, HAS BEEN SHOWN TO:

Reduce the severity of the impact

Help protect the occupants of the impacting vehicle

Help protect the barrier or shadow vehicle occupants

Help reduce damage to the barrier or shadow vehicle

HAS NOT BEEN SHOWN TO:

Affect the skid (roll ahead) distance of an impacted truck

CONTROLLING SKID DISTANCE (ROLL AHEAD):

• Skid distance is significantly increased and is less predictable for lightweight shadow

vehicles.

• Skid distance is reduced and is more consistent when heavier shadow vehicles are used.

• Required Truck +TMA weight: 7,030 kg] up to 12,250 kg.

trinityhighway.com

11

Revision ANovember 2019

Assembly

Read and understand all instructions before beginning assembly.

Theweightof thevehicleshallbe between6,120kg and11,340kg fortested performance.

Refer to the Australian Design rules – Vehicle Standards Bulletin 6 (VSB6) for the Australian

regulations regarding chassis modifications and attachments. The system may be attached to the

truck by attaching parts to the vehicle frame, using specified hardware in the VSB6. Do not weld

any TMA components to the truck frame. It is recommended the use of side fishplate to mount the

unit to the chassis (as per page 13, figure 8). The addition of the side fishplates allows for the

removal and replacement of the mounting system, if the unit was to be damaged in a TMA impact.

Use certified or professional welders to ensure durable attachment of the TMA system.

Disconnect the truck battery before any welding on truck or TMA.

The truck frame must be suitable and accessible for mounting aTMA. If there are any questions

regarding the suitability, contact the Customer Service Department for input as to your

specific application.

Shipping list

Checkthe shipping list against the actual parts.

Recommended Tools

• Welding equipment

• Cutting torch

• Hammer

• Drift pin or alignment pin (300mm long)

• Tape measure

• 1/2” drive socket wrench w/150mm extension

• 1/2” drive sockets (9/16”, 1-1/8”, 1-1/2”, 9/16” deep well)

• Open end wrenches –(9/16”, 1-1/8”, 1-1/2”)

• 300mmcrescent wrenches –(2)

• Marking implement (pencil, soap stone)

• Drill for 13/16" diameter bit

• 13/16" diameter bit and pilot drill bit for same

• Center punch

• Torque wrench -120 N-m

• Hydraulic fluid (Dexron™ III fluid only) -Shipped with system

• Floorjackor Forklift

• Work gloves and other personal protection equipment as required

• Bubble level

Important: The above list of tools is ageneral recommendation. Depending

on specific site conditions and the complexity of the assembly specified by

the appropriate highway authority, additional or fewer tools may be required.

Decisions as to what tools are needed to perform the job are entirely the

responsibility of the specifying highway authority and the authority’s

selected contractor performing the assembly of the system at the authority’s

specifiedassemblysite.

trinityhighway.com

12

Revision ANovember 2019

Preparation

1A) Assembly Must Be Performed On Level Surface

The system’s framework is very heavy.

1B) Truck Ballast

Use abubble level to verify that the truck is parked on alevel surface. The truck shall be as close

to the final driving weight as possible. If ballast must be added to achieve the minimum weight, add

it at this time. Ballast must be properly anchored to the truck to keep it in place during an impact.

Ideally, an adequately sized truck, that requires no ballast, should be used. Because the 910

kg weight of the rearward protruding TMA is supported by the back of the shadow vehicle,

care must be taken not to exceed the manufacturer's published maximum axle loads. To ensure

that the driving characteristics of the vehicle are maintained, the manufacturer’s recommended

center-of-gravityzone shall be followed completely.

2) Interference Check

Before attempting to assemble the Underride, check for interference concerns.

The TMA folds so the Impact Face is very closeto themounting location(p. 24, Figure 25).If you

are not using astandard Socket Receiver Hitch Underride skip to Step 8.

Temporarily position the Underride Socket Receiver undertruckframe as shown(p.13,Figure8)

and check for interference concerns. Interference concerns with tail lights, springs, dump bodies

(in the folded or unfolded positions), etc., shall be corrected before proceeding.

STEPS 2&3

ATTACHMENT ASSEMBLY

STEP 5&

6

SUPPORT FRAME

UNDERRIDE

SOCKET

RECEIVER

SUPPORT MOUNT

STEP 4

Figure 7

trinityhighway.com

13

Revision ANovember 2019

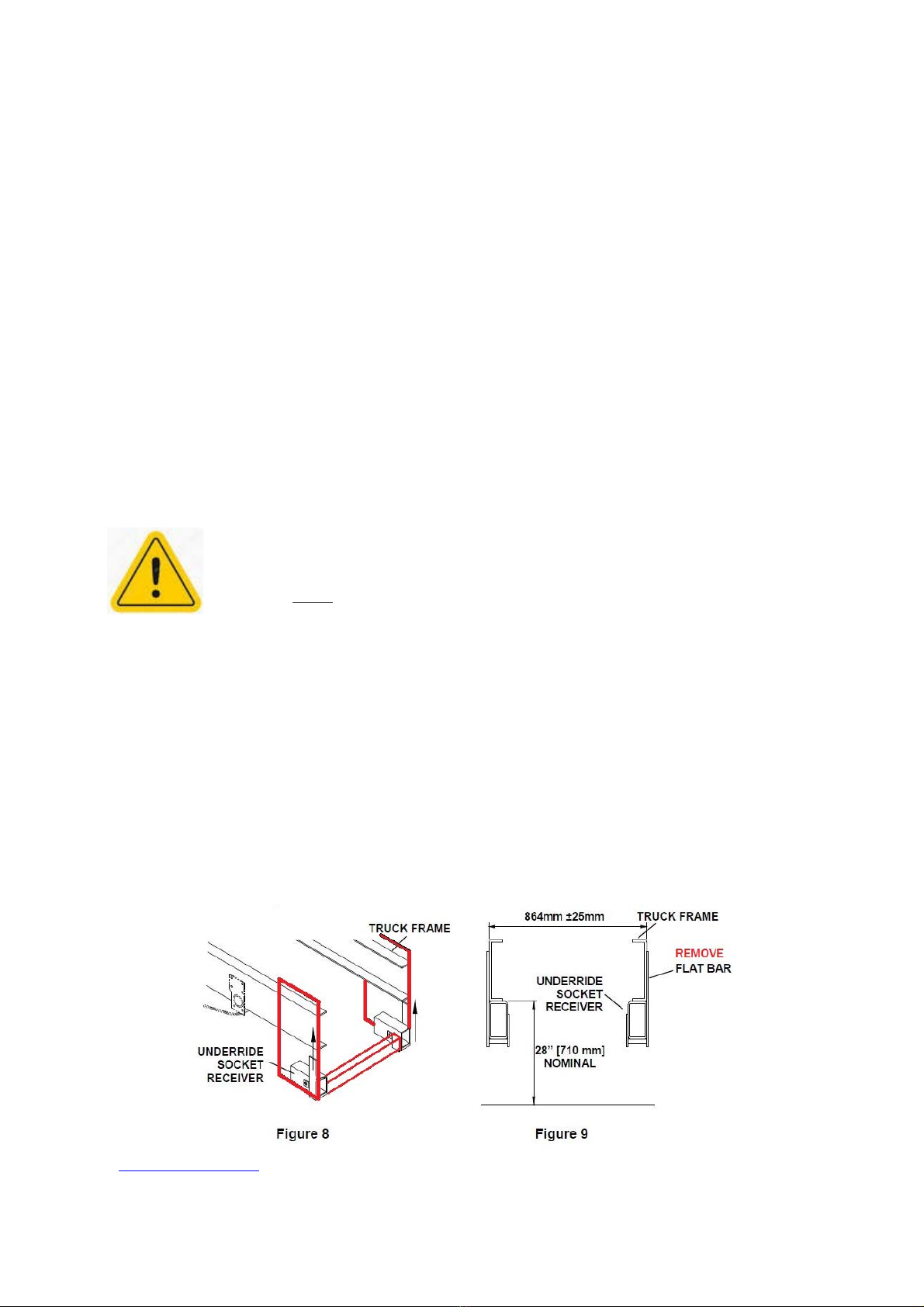

3) Underride Assembly

With the truck at its actual driving weight and parked on a level surface, measure the distance from

the ground to the bottom of the truck frame. A distance of 711mm ± 25 mm is required. Spacer

Tubes may be added to the bottom of the frame to achieve this height (p. 14, Figure 10).

Note: The truck’s springs may settle with the weight of the TMA, sometimes as much

as 50 mm. Adjust the height to compensate for anticipated settling.

Measure distance from the back end of the frame forward to the rear-most leaf spring hanger. Look

for any obstruction on the bottom of the frame that may interfere with the Socket Receiver. A

minimum of 305 mm is required (Underride Assembly drawing on p. 60).

It is important to check for obstructions before mounting the socket receivers. Position the Socket

Receiver at the rear end of the frame so that the 76 x 387 mm flat bar is along the outside of the

frame member and the Socket Receiver Assembly is flush with the end of frame. If spacers are

required, weld them to the Socket Receiver and lap the Spacer Splices (pieces of 10 x 51 x 103

mm flat bar) across the Socket Receiver and Spacer at the rear most location (p. 47). The top of

the Socket Receiver shall be 711mm ± 25 mm from the level ground for proper system height (p.

14, Figure 10).

Important: Welding must be performed by professional or certified welder.

All welds must be then primed and painted.

Australian chassis modification regulations may differ to that explained in this manual. It is always

recommend that you follow your local design rules when modifying the vehicle's chassis and

installing any TMA. Ensure that the vehicle and any modifications carried out meet the compliance

requirements for your region.

To provide addition strength to the rear of the chassis, it is recommend that the Underride Socket

Receivers have the flat mounting bar removed, then weld the Underride Socket Receivers to a large

16mm thick steel fishplate (similar as shown below in figure 8). Remember to position holes in the

fishplates for the pins to pass through the socket receiver. Then bolt the fishplates to the chassis and

if possible, also the tray sub frames. Once bolted on, install an extra cross-brace on the inside

between each Underride Socket Receiver. This will provide a rigid rear mount assembly (without

welding to the chassis), while allowing the removal and replacement of the receivers if damaged in

a TMA impact.

trinityhighway.com

14

Revision ANovember 2019

An example of modified Underride Socket Receiver mounts are shown below.They are a

suggested guide on how to install the Underride Socket Receivers without welding to the

vehicle chassis.

Installation of the Underride Socket Receivers may vary on each vehicle due

to chassis, suspension and body variations. You should allow seek the

direction of a engineer as to the best installation for your selected vehilce,

prior to beginning installation.

A

B

A

B

trinityhighway.com

15

Revision ANovember 2019

762 ±25 mm

711 ±25 mm

711 ±25 mm

Important: Left and right Underride Socket Receivers must be parallel and

level with each other.

TRUCK FRAME TRUCK FRAME

SPACER TUBES

FLUSH

WITH

FRAME

END

UNDERRIDE SOCKET

RECEIVER UNDERRIDE

SOCKET

RECEIVER

WITH SPACERS WITHOUT SPACERS

Figure 10 –Socket Hitch

Left Side

Shown

4) -Socket Hitch Assembly

Insert the Socket Hitches and pin them into place using the 1” x 6 3/4” Hitch Pins and

Retainer Pins shipped with the system.

RIGHT SOCKET

HITCH

LEFT SOCKET HITCH

HITCH &RETAINER PINS

Figure

11

B

A

trinityhighway.com

16

Revision ANovember 2019

5) Mount the Support Brackets to Socket Receivers

Mount the Support Brackets to the Socket Hitches as shown in Figure 12. Shims are used to level

the system. It is recommended that two (2) 1/4" Shims per side be used initially. This may be

adjusted once the system is assembled.

2 1/2” X 3 1/4/”

BAR WASHER

TRUCK FRAME

SOCKET

HITCH

3 1/4”X3 1/4”

BAR WASHER

SUPPORT

BRACKET

1” HEX NUT

1” LOCK WASHER

1” FLAT

WASHER

12GA

SHIM

Figure 12

1/4” SHIMS (TWO PER SIDE

RECOMMENDED AT INITIAL SETUP.

LEVEL THE TMA BY ADJUSTING

THE NUMBER OF SHIMS

1” FLAT WASHER

1X3 1/2” HEX BOLT

6) Attach the Support Frame /Backup to the Attachment Assembly

Move the system to the truck and pin the Support Frame/Backup Assembly to the Support Brackets

(Figure 13). The system is to be assembled as a whole unit. Use forklift slings to support the system.

Use the upper set of mounting holes for the attachment.

UPPER

MOUNTING

HOLES SUPPORT FRAME /

BACKUP ASSEMBLY

1-1/4 X7” HITCH PIN

Figure

13

ADD SHIMS TO LEVEL

SYSTEM (STEP 7)

trinityhighway.com

17

Revision ANovember 2019

7) Adjust the Height of the System Frame

Verify that the system frame is 305mm ±25 mm from the ground at the rear of the system.

It may

be necessary to add shims to the Socket Hitch in order to level the Frame (Figures 3 & 12).

8) Connect the Lights and Controls

Locate the female TMA Socket Connector in aconvenient location on the truck so that lifting or

lowering the TMA will not damage the electrical cable. Make sure that the electrical cord on the

TMA can reach this location.

For support vehicles with combined tail and clearancelights, connect a jumperbetweenpins 2 and

6on the backside of the male TMA plug connector (VIEW A-A and Figure 14). Connect the

7-pinplugtothesocket on thetruck.

The truck battery must be of the proper voltage. The SS180®Mis available in 12 and 24 volt

versions. Be sure the system and truck are compatible. Use standard safety practices when

attaching the battery cables. Attach positive terminal first when connecting and remove the

negative cable first when disconnecting the battery. Do not run the battery cables around sharp

corners, metal work, or in other areas that could pinch or cut the cables. Connect the battery cable

to the pump motor. Consult the Hydraulic Assembly drawing package.

Caution: For over-current protection, the positive cable lead coming off the

truck battery should be protected with a70 amp fuse or circuit breaker within

450mm of the truck battery.

The controls at the rear of the truck are mounted to bothsides of theSupportFrame.Securely

fasten cable ties to secure any loose wiring to the SS180®Mframe. Mount the cab switch box

inside the cab within easy reach of the driver and plug in the cabswitch box at the mating connector

of the TMA.

VIEW A-A

A

A

Figure

14

trinityhighway.com

18

Revision ANovember 2019

9) Check the Hydraulic System

TheHydraulic Assemblyis pre-assembledandtestedforoperationandleaksbeforeshipping.The

pump is wired as shown on the Hydraulic Assembly drawing (pp. 53-56). Before operating the

system, check to see if the reservoir has adequate fluid. The fluid level of afolded system should

beapproximately half full. Add onlyDexron™ III ATF fluid.Do notoverfill or fluid may leak out when

un-folded. Replace the cap in the fill port.

Read Operation Instructions (p.19;Folding andUnfoldingthe System). To ensure all electricaland

hydraulic lines will not be damaged, use the switch at the rear of the truck to fold and unfold the

system twice. Cycling the SS180®Mwill purge excess air from hydraulic lines and confirm its

operational status.

Important: Cycle the system using the cab switches to test controller operation.

OPERATION SWITCH

RESERVOIR CAP

APPROXIMATE FLUID LEVEL

W/SYSTEM UN-FOLDED

APPROXIMATE FLUID LEVEL

W/SYSTEM FOLDED

Figure

15

Note: Continuous operation may run down truck battery and/or damage pump.

Important: Ensure both positive and ground cables are connected directly from

pump to battery. DO NOT rely on chassis or frame for proper grounding.

trinityhighway.com

19

Revision ANovember 2019

10) Store the Jacks

The Jacks are provided to facilitate the attachment and removal of afolded SS180®Mfrom the

truck. Retrieve Jacks set aside earlier and place them in astorage location (Figure 16).

Figure

16

Important:Unbolt, remove, and store Jacks when the TMA is in service.

11) Verify the Position of the Hydraulic/Electrical Lines

Check the location of all the hydraulic and electrical lines to be sure they will not be damaged

whilefoldingandunfolding thesystem.

12) Final Check of System

Double check the height and levelness of the system.

13) Ready to Use

The SS180®Msystemis nowreadyforuse.To ensureproper andsafeoperation,allSS180®M

users shall be given operating and safety training from this manual and as specified by the owner

andlocalregulations.

Table of contents

Other Trinity Highway Control Unit manuals

Popular Control Unit manuals by other brands

Siemens

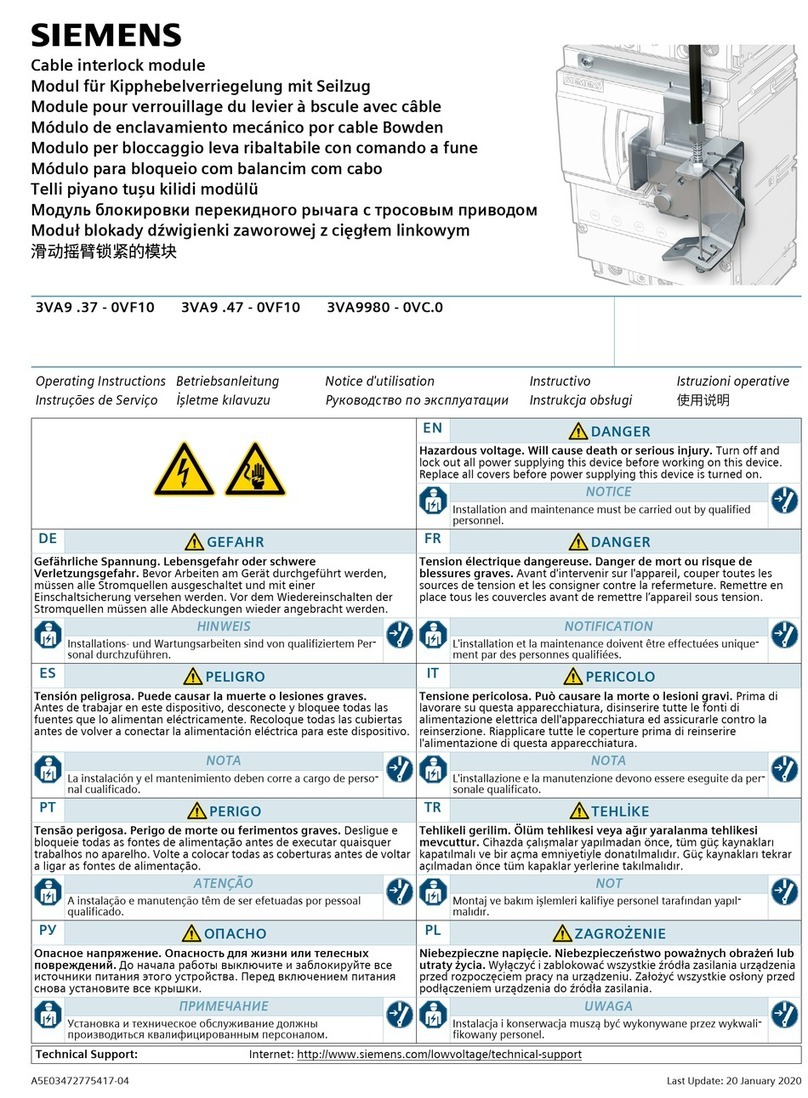

Siemens 3VA9.37-0VF10 quick start guide

Conrad

Conrad BRC36 operating instructions

Viessmann

Viessmann vitotronic 200-h Installation and service instructions

Elster

Elster Kromschroder VMF Series technical information

Elko

Elko EST3 quick start guide

Grundfos

Grundfos CIM 260 Functional profile and user manual