Trio Motion PC-MCAT 64 User manual

QUICK START GUIDE

TECHNOLOGY

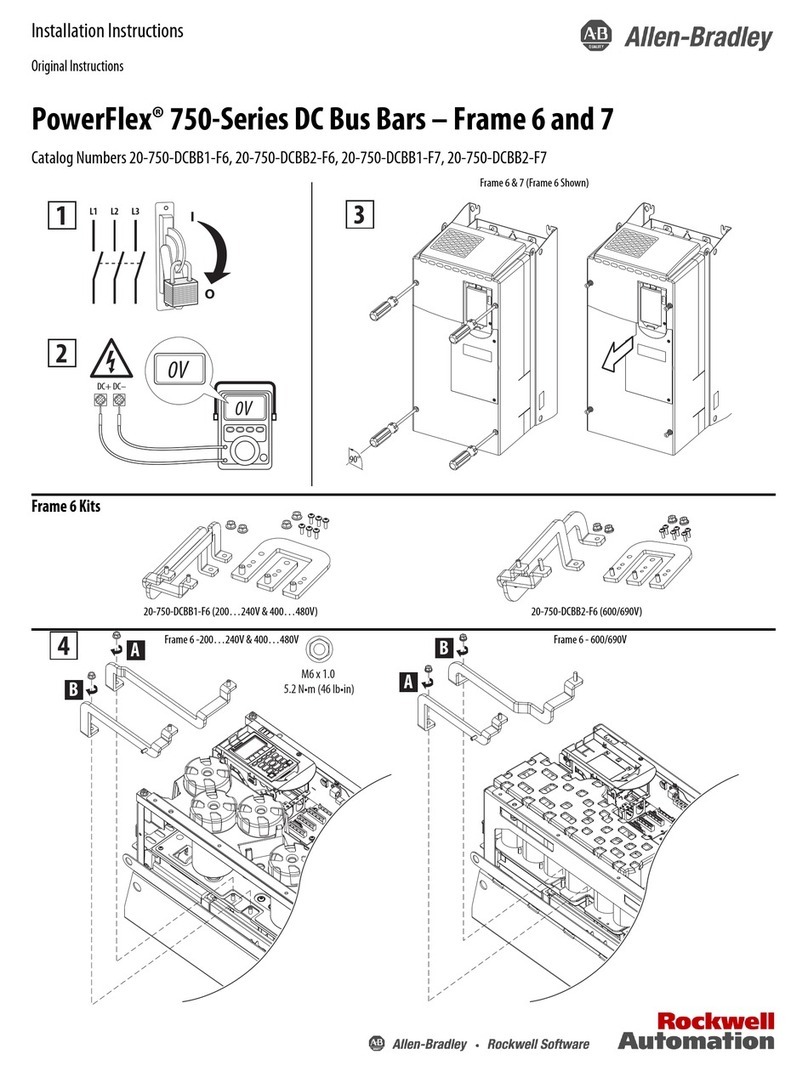

STATUS LED’S

ETHERCAT 100 BASE-T

USB (X4)

ETHERNET (GIG-E)

DUAL INPUT, POWER

HDMI OUTPUT CHASSIS EARTH

SCREW

TITLE

P# | P# |

PC-MCAT 64

P760

2

INTRODUCTION

The PC-MCAT combines a Windows® PC with the familiar and

powerful Trio Motion Coordinator core software. Using a

Quad Core ARM processor, the Motion Coordinator rmware

runs in real time with performance that is at least double that

of the equivalent MC4N-ECAT EtherCAT stand-alone Motion

Coordinator. This guide will take the user from initial power

up to programming and setup of the PC-MCAT in a typical

application.

It is assumed that the reader has some experience

with Windows and the Motion Perfect V4

programming application from Trio Motion

Technology.

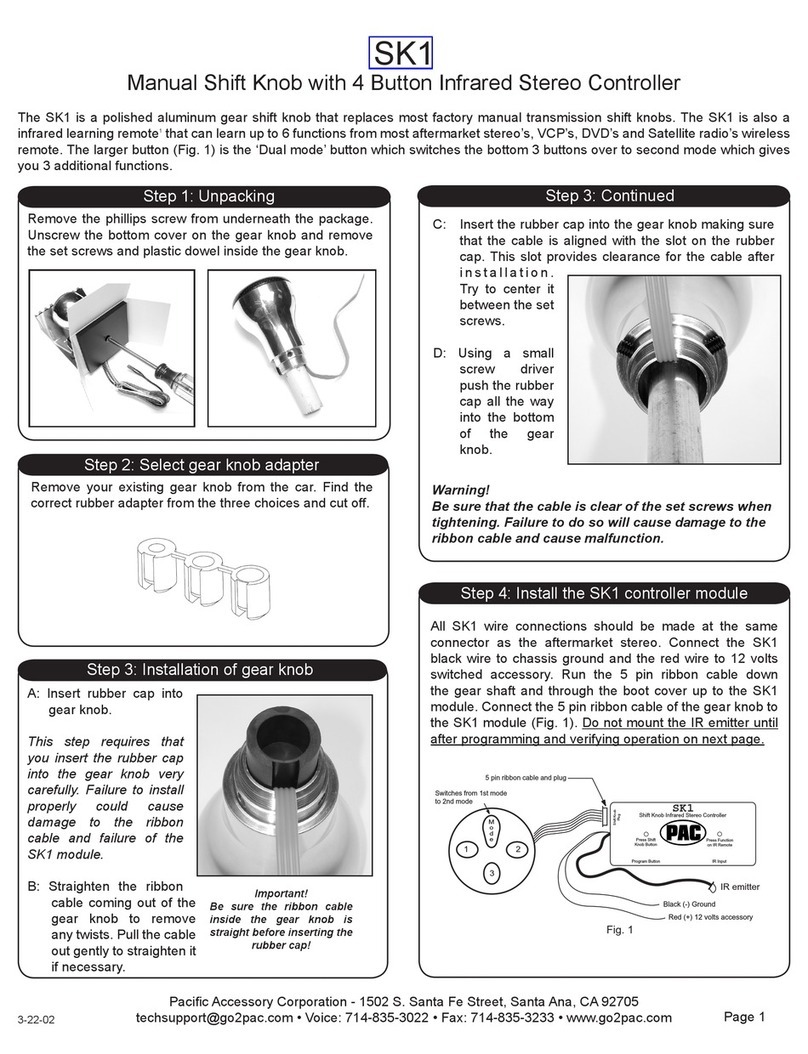

EQUIPMENT

In addition to the PC-MCAT, the user will need the following;

• USB keyboard.

• USB mouse or trackball.

• An HDMI monitor and HDMI connecting cable.

• A 24V d.c. power supply rated at 2 Amps.

INITIAL CONNECTIONS

Plug the HDMI lead into the HDMI socket on the front face of

the PC-MCAT. Connect the other end to a suitable monitor

display.

Plug the Keyboard into any of the available 4 USB sockets on

the front of the PC-MCAT.

Plug the mouse into one of the USB sockets on the front of

the PC-MCAT.

Do not connect peripheral devices to the USB socket on the

upper face of the PC-MCAT.

INTERNAL BATTERY

A PLC type battery is provided inside the top cover of the

PC-MCAT 64. This battery powers the Real Time Clock and

holds the PC’s bios settings. The battery lasts approximately

8 years and can be replaced while the PC-MCAT is powered to

preserve the settings.

0 SAFETY WARNING

During the installation or use of control systems, users of Trio products must ensure that there is no possibility of injury to any

person or damage to machinery.

Control systems, especially during installation, can malfunction or behave unexpectedly. Bearing this in mind, users must

ensure that even in the event of a malfunction or unexpected behaviour, the safety of an operator or programmer is never

compromised.

3

BATTERY REPLACEMENT

1. Obtain replacement battery from Trio

2. Insert at bladed screwdriver to cut-out shown in image 1

3. Compress the “lug” on the battery cover

4. Gently lever the battery cover up and forward

5. Lift away the cover taking care not to damage the wiring or case shown in image 2

6. Remove 2 pin connector from the PCB in the PC-MCAT

7. Remove battery from the battery cover

8. Reassembly is the reverse of the procedure

If the battery is disconnected at any time when the PC-MCAT is unpowered it is essential to reset the clock and bios.

The clock and date must be set to the correct values. These are used during RTX operation so must be correct.

4

BIOS SETTING

• Under “Setup Utility” -> ”Thermal Conguration” set Critical Trip Point and Passive Trip Points to <Disabled>. This is because

the processor temperature is monitored by the real time Motion Coordinator.

Thermal conguration Parameters

Critical Trip Points <Disabled>

Passive Trip Points <Disabled>

Active Trip Points <Disabled>

Dynamic Platform & Thermal Framework

DTPF Featire <Disabled>

CPU Sensors

Critical <70 ºC>

Passive <60 ºC>

Ambient Sensor Participants

Critical <60 ºC>

Passive <43 ºC>

• Under “Setup Utility” -> ”Boot Conguration” set Numlock to <O>. This is because setting to On can aect the entry of

Windows user passwords on small keyboards.

5

CONNECTORS

Dual Input / Power connector:

Note: Use ferrules on all wires for best connection.

1. Connection: Push wire into hole of connector. Tighten

screw. Insert connector into PC-MCAT.

2. Removal: Reverse the procedure.

POWER CONNECTOR

The 24V Main connection, pin

2, is the primary supply to

the PC-MCAT. The 24V Main

connection is monitored and

when it drops below 18V, IN(0)

is set to ON. This can be used

as a trigger to run a controlled

shutdown of the PC-MCAT.

If a controlled shutdown is

required, then the Aux (pin 1) must be connected to a battery

or other maintained source that lasts for the length of time

needed to complete the shutdown.

The Aux power input can be between 12 - 24V

POWER UP SEQUENCE

The PC-MCAT 64 will automatically boot into Windows

Embedded with RTX real time running. The default password

“trio” for default user “Trio” needs to be entered.

The Motion Coordinator program will be run as a service using

the RTX real time executive automatically.

If the RTX is not required the boot sequence must be altered

to bypass running RTX during the startup sequence.

POWER DOWN SEQUENCE

A controlled power down sequence should be used to avoid

damaging Windows and to allow the machine to complete a

cycle.

Windows should be shutdown using the command EX(2) inside

a Motion Coordinator program. Alternatively EX(3) can be

used to re-start Windows. Using EX(2) allows the Motion

Coordinator service to be closed then Windows to shutdown.

This process takes about 30 seconds.

Input 0 can be used to detect the main 24v power supply

rail if an auxiliary power supply (12-24v) is provided from a

battery or UPS.

Input 1 is used by Windows to indicate to the Motion

Coordinator that a Windows shutdown has been requested.

USB PORT (X4)

The USB ports on the front panel are for use

with standard Windows peripheral devices.

If a keyboard and mouse are used, connect

them to 2 of these ports.

HDMI PORT

The HDMI port allows cthe PC-MCAT to drive high

resolution screens.

Aux 12 - 24V

Main 24V

0V

0V

6

ETHERCAT PORT

The PC-MCAT acts as an EtherCAT master.

EtherCAT drives and I/O devices are normally

connected in a chain.

ETHERCAT OPERATION

All motion and Input/Output physical connections are via the

EtherCAT port on the PC-MCAT. There is no local I/O but the

Inputs 0 to 15 and Outputs 8 to 15 are reserved for internal

use by the PC-MCAT system. This means the external I/O

aligns with other Motion Coordinators that do have their own

I/O.

PLUG AND PLAY

The PC-MCAT comes with an internal database of EtherCAT

slave denitions. This allows many well-known devices to be

connected and automatically congured by the PC-MCAT on

startup.

NETWORK TOPOLOGY

EtherCAT networks are logically one string of devices.

Connect the Master to the rst slave IN connection, then the

OUT of the rst to the IN on the second and so on. There is

no return cable, the last slave device automatically sets its

OUT socked to be a terminator.

Star and branch topology is possible using an approved

EtherCAT hub.

0 STANDARD ETHERNET HUBS AND SWITCHES DO NOT

WORK WITHIN AN ETHERCAT NETWORK.

The EtherCAT port is automatically congured for use by the

Motion Coordinator when it starts up. It can be viewed from

the Windows Network “Change Adapter Settings” window.

In Windows, the EtherCAT port is shown as Disabled. This is

correct and must not be changed.

ETHERCAT NETWORK DETECTION

EtherCAT Intelegent drives Window in Motion Perfect

7

NETWORK SETUP

If the PC-MCAT is connected to a network, its IP address may

be given by the network DHCP address server. Use the

windows command line to discover the IP address given, or

check the PC-MCAT tray application.

OTHER PORTS AVAILABLE

All communication with the Motion

Coordinator in the PC-MCAT is through the

given Windows IP address. There is no

function to set IP_ADDRESS on the PC-MCAT

Motion Coordinator. Any external device

that wants to open a Motion Coordinator

Server connection must do so using the

Windows IP address for the connection.

There are 2 Ethernet connections

available; each has its own IP address

conguration in Windows.

Ethernet Server connections on the Motion

Coordinator:

• Port 502 - Modbus TCP

• Port 2222 - Ethernet IP (ODVA Industrial Protocol) UDP

connection

• Port 44818 - EtherNet/IP explicit messaging

• Port 3240 – TrioPC Motion ActiveX

• Port 23 - Motion Perfect connection

Many Windows services provide server functions and have

port numbers allocated according to the Internet Assigned

Numbers Authority. (IANA) Clients that open connections to

these port numbers will be communicating with a Windows

Application and not the Motion Coordinator.

Any application running in the PC-MCAT itself must use the

internal IP address 127.0.0.1 to communicate with the Motion

Coordinator. For example a Modbus Client running in the PC-

MCAT will use 127.0.0.1 and not the IP address of either of the

physical Ethernet connections.

RUNNING MOTION PERFECT ON REMOTE PC

Connect the PC to the PC-MCAT Ethernet port, either directly

with a xed IP address on both the PC and the PC-MCAT, or

via a network with automatic IP address control.

Close the Motion Perfect v4 that is running in the PC-MCAT.

You can now use Motion Perfect v4 to on the remote PC to

connect to the Motion Coordinator in the PC-MCAT. Motion

Perfect version 4.2 or later is required.

8

PC-MCAT API

There is a shared memory API that allows Windows

programmes to interact with the PC-MCAT Motion

Coordinator.

The API is installed in C:\Program Files\TrioMotion\PC-MCAT.

The PCMCAT_ApiTest.exe application uses the API to talk to

the Motion Coordinator.

The pcmcat_api.h le contains denitions that should be

included into your MSVC C/C++ source code. The pcmcat_api.

dll and motion_api.dll contain the implementation.

CREATING AN EXAMPLE WINDOWS CONSOLE

APPLICATION

1. Open Visual Studio version 2012.

2. Create a new C++ Windows console application.

3. Copy the API to the solution directory.

9

4. Add in the references to the API le.

5. Add the PCMCAT API calls.

CHASSIS MOUNTING DIMENSIONS (LOOKING FROM

FRONT)

M4 screws should be used

in 2 places to mount the

PC-MCAT to an unpainted

metal panel.

The best EMC performance

is obtained when the PC-

MCAT is attached from the

shield screw (marked) using

a at braided conductor

with a cross section of

4mm x 1mm. Do NOT use

a circular section wire or

run the braid to a central

star point.

0 ENSURE THAT THE VENTILATION SLOTS AT THE TOP

AND BOTTOM OF THE PC-MCAT ARE KEPT CLEAR

TO ENSURE A FREE FLOW OF AIR THROUGH THE

MODULE.

38.6

19.3 19.3

4

145.8

4

4.5

4.5

Shield Screw

UK | USA | CHINA | INDIA

WWW.TRIOMOTION.COM

THE MOTION SPECIALIST

CAD data Drawings to aid packaging and mounting are available in various formats from the Trio web site. Products should be

wired by qualied persons.

Specications may change without notice. E & OE

Quick Start v1.1 March 2017

154mm

184mm

56mm

186mm

122mm

35mm

226mm

132mm

35mm 135mm

122mm

35mm

270.97mm

212.97mm

40mm

200.35mm

146.35mm

42.55mm

120mm

157mm

107mm

40mm

140mm

15mm 17mm

15mm15mm

120mm

157mm

40mm 120mm

157mm

40mm

170mm

129mm

25mm

130mm

26mm 85mm

This manual suits for next models

1

Table of contents