Trion Modular Filterpac Media Air Cleaner User manual

Other Trion Air Cleaner manuals

Trion

Trion M1100 User manual

Trion

Trion CA3000C User manual

Trion

Trion Air Boss M2500M User manual

Trion

Trion Port-A-Cart User manual

Trion

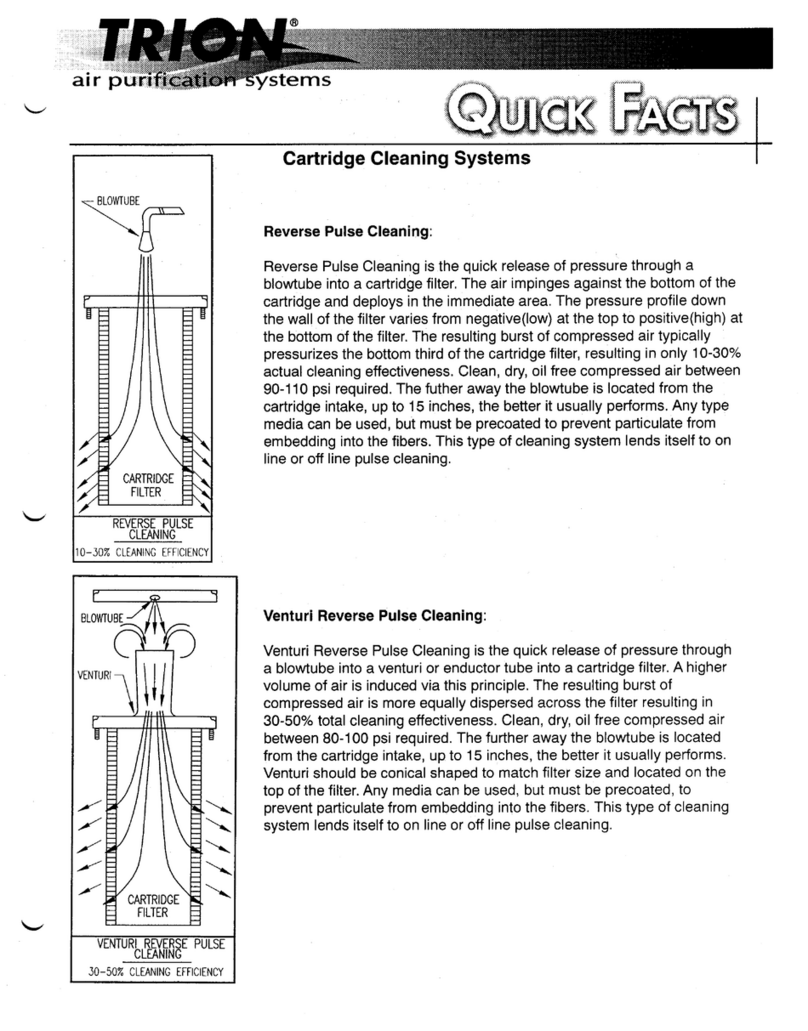

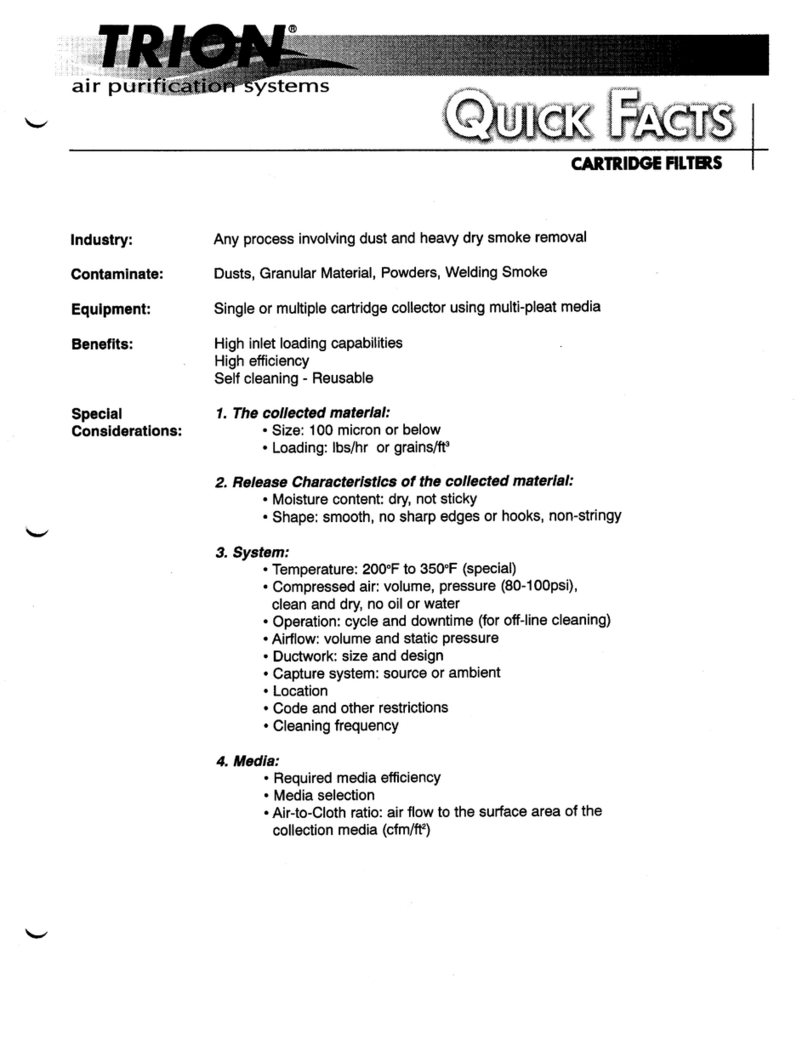

Trion Cartridge Filters User manual

Trion

Trion 73 Series Manual

Trion

Trion Air Boss T Series User manual

Trion

Trion T-ABS-1008 User manual

Trion

Trion TGM 2 1000 User manual

Trion

Trion Air Bear Right Angle Supreme MERV 8 User manual

Trion

Trion FM 1000 Operation manual

Trion

Trion ComfortBreeze UV360-1 User manual

Trion

Trion Air Boss M-Series User manual

Trion

Trion MAX 5 2000 User manual

Trion

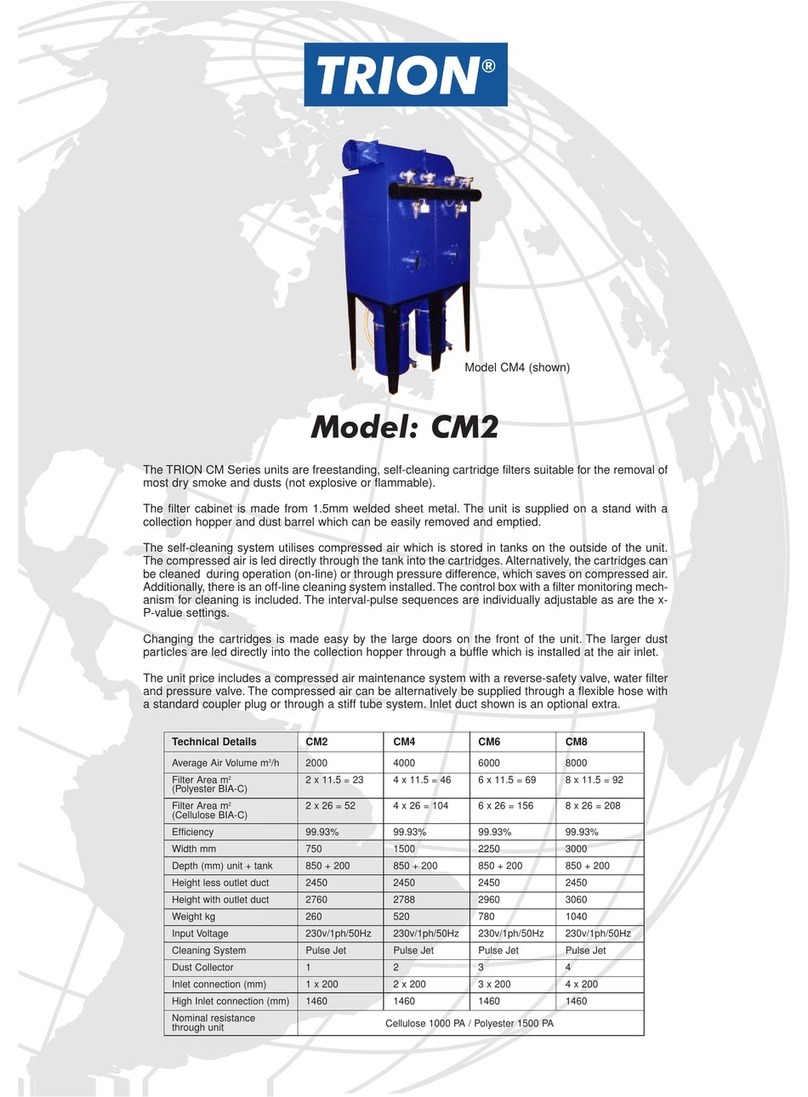

Trion CM2 User manual

Trion

Trion Console 250 442857-001 User manual

Trion

Trion FM 1000E User manual

Trion

Trion CM Series User manual

Trion

Trion 60 Series User manual

Trion

Trion Air Boss 75 Guide

Popular Air Cleaner manuals by other brands

Heaven Fresh

Heaven Fresh naturopure HF 290 instruction manual

AllerAir

AllerAir 8000 D Vocarb Specification sheet

Fellowes

Fellowes AeraMax PRO AM IVS manual

Envirco

Envirco Hospi-Gard IsoClean 800 Installation, operation and maintenance manual

Sharp

Sharp Plasmacluster KC-C100U Operation manual

LG

LG PS-S200WC owner's manual