Trion Air Boss 38 Series Instruction manual

TRION®| www.trioniaq.com

Air Boss®Model 38 Series

Industrial Mist Precipitator

READ AND SAVE THESE INSTRUCTIONS

Installation

Operation

Maintenance

Parts

Manual

Model 38 Series

Installation, Operation, & Maintenance Manual

2www.trioniaq.com

INDUSTRIAL MIST PRECIPITATOR

TYPE IMP

AIR BOSS®MODEL 38 SERIES

TABLE OF CONTENTS

I. Principle of Operation and General Description ..................................................................................3

II. Installation ...........................................................................................................................................4

A. Unpack ..........................................................................................................................................4

B. Select Mounting Location..............................................................................................................4

C. Installation of Precipitator..............................................................................................................4

D. Wiring............................................................................................................................................4

III. Operation..............................................................................................................................................4

IV. Maintenance.........................................................................................................................................5

V. Troubleshooting....................................................................................................................................5

VI. Recommended Spare Parts.................................................................................................................6

VII. Outline Drawings

150 CFM Parts ...................................................................................................................................7

150 CFM - Outline Drawing with Inlet Flange or Pipe (424396).........................................................8

150 CFM - Outline Drawing with Inlet & Outlet Flange or Pipe (424397)...........................................9

300 CFM Parts ..................................................................................................................................10

300 CFM - Outline Drawing with Inlet Flange or Pipe (424399)........................................................ 11

300 CFM - Outline Drawing with Inlet & Outlet Flange or Pipe (424398)..........................................12

600 CFM Parts ..................................................................................................................................13

600 CFM - Outline Drawing (429436)................................................................................................14

VIII. Electrical Schematic (150, 300, 600 CFM).........................................................................................15

IV. Electrical Parts List (150, 300, 600 CFM)...........................................................................................16

V. Diagram..............................................................................................................................................17

Model 38 Series

Installation, Operation, & Maintenance Manual

3

www.trioniaq.com

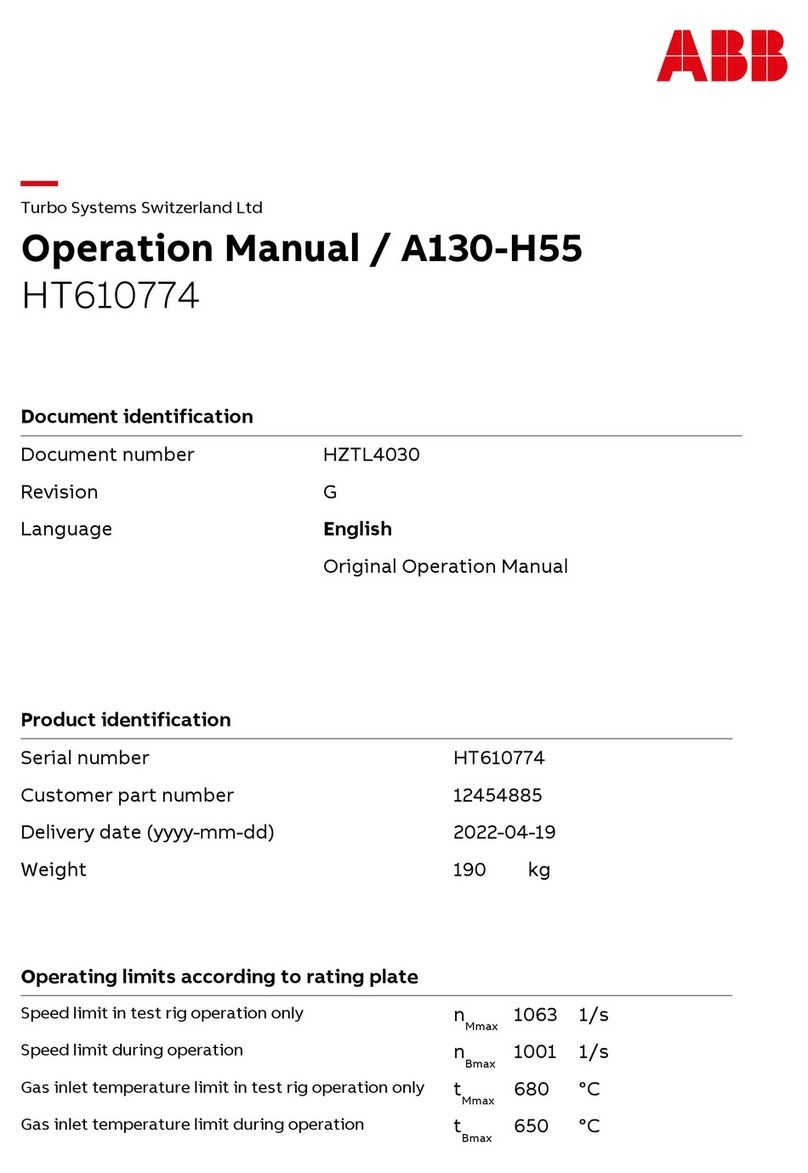

I. PRINCIPLE OF OPERATION & GENERAL

DESCRIPTION

The TRION Industrial Precipitator is a two-stage, dual

voltage, electronic air cleaner designed to remove

particulate matter from gas.

In the rst stage of operation, the particles to be collected

pass through an ionizer where they are electrically

charged, by a corona discharge, regardless of their size.

In the second stage of operation, these charged particles

pass into a collector where they are electrically attracted

and collected.

The ionizer consists of electrically charged, 24 Ga.

stainless steel spiked blades supported between

grounded electrodes. The collector consists of a series

of parallel plates arranged so that each alternate plate is

electrically grounded. The charged plates are of the same

polarity as the ionizing bladed and charged particles so

that they repel, while grounded plates, being of opposite

polarity, attract.

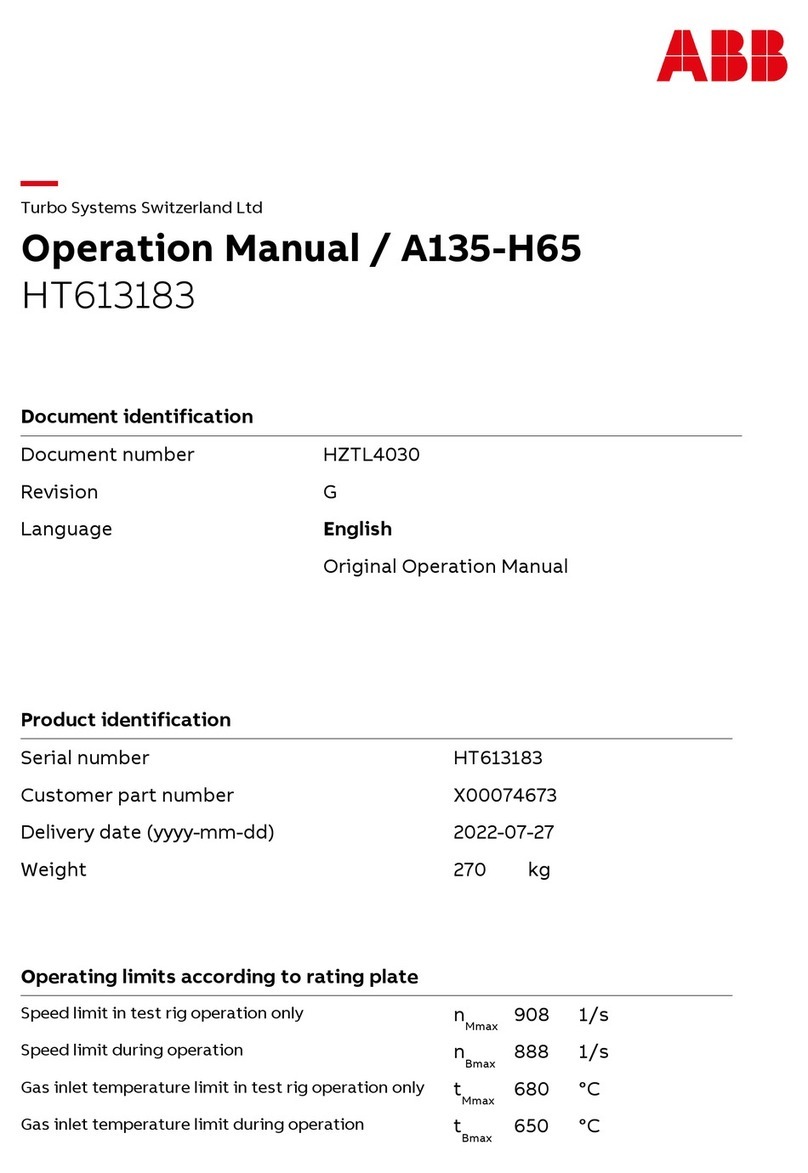

Three distinct functional components comprise the

complete cleaner:

1. An ionizer to ionize the particulate matter in the gas.

2. A collector to collect the ionized particles.

3. A power supply to furnish the high voltage direct

current required by the ionizer and collector.

Usually, this particular model series is applied to collect

particulate matter in the form of mist. When collected, the

particles coalesce into liquid droplets of adequate weight

causing them to roll off the vertically positioned collector

plates where they drain away to a predesignated location.

The ionizing and collecting sections are primarily

constructed of aluminum, can be easily handled, and

slide into the cabinet like drawers. A perforated steel

bafe, located on the discharge side of the collector

section, provides protection especially on units installed

with an open discharge. The bafe also slides into the

cabinet like a drawer. All three of these components are

accessible through a single, side mounted, access panel.

Internally, the following materials are exposed and

subjected to the gas ow through the cabinet:

• Aluminum

• Stainless Steel

• Mild Steel

• Silicone Rubber

• Nylon

• Glass Fiber Reinforced Polyester

The steel cabinet contains two pre-drilled mounting bars.

Depending on the specications, the cabinet is provided

with pipe anges, both on the inlet and the outlet for “in-

line” installation or with a pipe ange on the inlet and an

open outlet for free discharge installation. The inlet ange

contains a ame arrestor which serves as a strainer as

well as protection against any possible aming caused by

arc over in the collector. The ame arrestor is required

on all applications using the Model 38. Appropriate

location placement for the piping/threaded lter type must

be included for system protection. This arrestor must be

ordered separately.

The power supply is contained on the unit access panel

in a weatherproof enclosure. It converts the alternating

current input into the high voltage direct current necessary

to energize the ionizing and collecting sections. Supply

line power is connected to the unit in a weatherproof

junction box (IP-54) and is delivered to the transformer

primary through an oil proof cable connected to the

enclosure through a quick connect tting. In addition to

the necessary high voltage components, the secondary

contains a pilot light to indicate proper operating voltages.

For 220-240 VAC units, a 1.2 Amp fuse is installed for

added protection in the terminal block in the eld wiring

junction box. The TRION part number for the 5 mm x 20

mm fuse is 151678-001.

Clean Air

Dirty Air

Prelter Ionizer Collection

Plates

Power

Supply

Model 38 Series

Installation, Operation, & Maintenance Manual

4www.trioniaq.com

II. INSTALLATION

A. UNPACK

Normally, the shipment is packaged in one container

including the entire unit, completely assembled and with

instructions. Any shipping damage noted upon receipt

should be immediately referred directly to the carrier and

a claim led. When receipt has been cleared, all crating

and blocking used in shipment should be carefully

removed.

B. SELECT MOUNTING LOCATION

Consideration must be given to three main points when

selecting the mounting location.

i. Temperature

The temperature of the gas ow through the precipitator

must not exceed +160 degrees F and also be low enough

so that all vapors and/or mists have fully condensed into

particulate matter prior to entering the unit. The purpose

may be defeated if warm materials pass through the

unit in a gaseous state, then condense into mist down

stream from the collector element. Adequate duct runs

between the contaminate and the precipitator, or a chill

means, must be provided to lower the gas temperature

to a satisfactory point. The minimum temperature to

which the unit should be exposed is +20 degrees F.

ii. Positioning

Although the unit will operate in any position, it is primarily

designed for vertical upow. The important factor to keep

in mind when positioning is the adequate drainage of

collected materials and with the unit in the vertical upow

position, this feature is best facilitated.

iii. Service Access:

Adequate space should be provided in front of the access

panel for ease in access panel and internal component

removal.

C. INSTALLATION OF PRECIPITATOR

1. Disconnect primary cable from power pack.

2. Remove access panel hardware and panel. Place

in safe location being careful not to deform the high

voltage spring contacts in the under side.

3. Remove ame arrestor, ionizer, collector and outlet

bafe and place them aside with access panel if

ange type lter unit.

4. The internal surfaces of the cabinet are treated with

a light-weight oil to protect the unpainted metal from

rust and corrosion prior to packing for shipment. The

preserving oil should be thoroughly ushed away

with an adequate solvent prior to mounting.

a) Refer to Drawings for mounting bolt hole

dimensions.

b) Be sure ame arrestor is properly installed in inlet

ange before connecting the mating ange of the

adjoining duct run.

c) If a threaded/pipe type lter, install arrestor in inlet

piping where a ange connection exists to install/

access the inlet ducting.

5. Thoroughly clean all installation dirt from the cabinet,

then reinstall ionizer, collector and outlet bafe.

6. Reinstall and secure access panel.

D. WIRING

Connect alternating voltage as specied through a

service switch, to the connections provided in the

junction box located on the side of the unit. Refer to the

electrical parts list and schematic.

III. OPERATION

Energize the unit. The pilot light should glow, indicating

the ionizer and collector are correctly powered. Arcing

and cracking accompanied by a ickering of the pilot

light may be noted when the unit is rst energized. If

it occurs, it is probably due to some small amount of

foreign material in the system or collector and should

quickly subside. If the pilot light is dim, or does not glow,

when the unit is energized or prolonged, arcing occurs,

refer to Troubleshooting, page 5.

WARNING

THIS APPLIANCE MUST BE EARTHED.

WARNING

THIS UNIT IS INTENDED TO BE PERMANENTLY

CONNECTED TO FIXED WIRING. IT SHALL BE

PROVIDED WITH A MEANS OF DISCONNECTION

FROM THE SUPPLY HAVING A CONTACT

SEPARATION OF AT LEAST 3 MM IN ALL POLES.

THE MEANS OF CONNECTION IS NOT FURNISHED

WITH THE UNIT.

Model 38 Series

Installation, Operation, & Maintenance Manual

5

www.trioniaq.com

IV. MAINTENANCE

NOTE: EXERCISE THE NORMAL PRECAUTIONS

WHEN WORKING WITH HIGH VOLTAGE.

Theprecipitator,whenappliedtoliquidparticulatematter,is

self-cleaning to a degree. The continual run-off of collected

material provides a cleaning action. Periodically, however,

the components should be inspected and cleaned.

Depending on the type and amounts of materials collected,

the various components become dirty in different periods

of time. Frequent inspection after initial start-up is best

practical method to establish a routine maintenance

schedule for any given material being collected.

To remove components:

1. Disconnect primary cable at tting on power pack.

2. Remove access panel hardware and remove

access panel. When removing and placing it down,

be careful not to deform the high voltage contacts

located on the under side.

3. Pull components from cabinet. Place on smooth at

surface to avoid deforming.

Any coatings of contaminant build-up on ionizing blades can

normally be removed with a small amount of solvent applied

with a cloth. Exceptionally stubborn coatings on blades may

require removal with a very ne emery cloth, carefully used.

Use emery cloth on at surface of blade, not on points.

When necessary, after prolonged use, the complete

ionizer and collector plate sections may require a good

manual cleaning with warm water and a non-foaming,

non-corrosive detergent. Care should be taken in handling

throughout the operation. High pressure commercial

spray devices (such as a car wash) usually do a good job.

Periodically, the surfaces of the components within the

power pack should be wiped clean and the securement of

connections checked. Access to the power supply is gained

by removing the primary power cable and power pack cover.

V. TROUBLESHOOTING

NOTE: EXERCISE THE NORMAL PRECAUTIONS

WHEN WORKING WITH HIGH VOLTAGE.

A. PILOT LIGHT (LED) DIM:

1. Check to see that primary power is supplied to power

supply and that LED is good.

2. If power is supplied to the power supply, and the pilot

light is dim, it is an indication that there is a short

circuit, either in the power supply or the ionizing-

collecting elements. It can be isolated to one or the

other by energizing the power supply with the ionizer

and collector elements removed from the cabinet. If

the light glows bright with the elements removed

from the cabinet, the short is then in the ionizer or

the collector sections. It can be further isolated to

one or the other by energizing one at a time with the

other removed.

• Power Supply Shorts: Pilot light dim or out with

ionizing-collecting elements removed. Replace

power supply.

• Ionizer Shorts:

• Bent or deformed ionizer blades. Remove

and replace.

• Dirty insulators. Clean.

• Foreign objects between charged and

ground potentials. Remove.

• Collector Shorts:

• Foreign object between plates.

Remove.

• Bent or deformed plates. Straighten.

• Dirty insulators. Clean.

B. EXCESSIVE ARCING:

1. Loose or damaged ionizing blade. Replace.

2. Large particle of foreign material lodged between

the collector plates. Remove.

3. Bent collector plates. Straighten.

4. Loose high voltage connection or deformed high

voltage contact spring. Correct or replace as

necessary.

5. Ionizer and/or collector excessively dirty. Refer to IV.

Maintenance.

C. LOW OR REDUCED EFFICIENCY:

1. Dirty ionizing blades and/or collector components.

Refer to cleaning instructions under IV. Maintenance.

2. Increase in gas ow above the unit rating. Reduce

ow.

WARNING

HIGH VOLTAGE IS PRESENT INSIDE CABINET. DO

NOT DEFEAT COVER INTERLOCK ARRANGEMENT.

ALWAYS DISCONNECT FROM SUPPLY AND WAIT

ONE MINUTE BEFORE PERFORMING SERVICE

WITHIN THE CABINET.

Model 38 Series

Installation, Operation, & Maintenance Manual

6www.trioniaq.com

3. Increase in particulate concentration above unit

rating. Reduce concentrations.

4. Low secondary voltage. The ionizer voltage should

be -13 KVDC +/- 500 VDC. The collector voltage

should be -6.5 KVDC +/- 500 VDC. The ionizer

current should be between 0.5 and 1.5 mA.

5. Loose or faulty high voltage connection between

power supply and ionizer-collector elements. Check

secondary wiring from power supply to high voltage

contact springs. Check high voltage contacts to be

sure they are contacting both ionizer and collector.

VI. RECOMMENDED SPARE PARTS

ITEM DESCRIPTION PART NO. QTY SUGGESTED

AAll 120 VAC Input Power Supply 267232-120 1

All 240 VAC Input Power Supply 267232-240

BLED Assembly 241101-020 1

C Spring Contact 221952-001 1

Model 38 Series

Installation, Operation, & Maintenance Manual

7

www.trioniaq.com

TRION

Part Number

Weight

(lbs.)

Inlet

Connector

Outlet

Connector

Part Number

Flame Arrestor

Power Supply

120 240

VAC VAC

439057-001

-029 141 2” Flange _ 322792-001 1

0

0

1

-002

-030 145 3” Flange _ 322792-002 1

0

0

1

-003

-031 150 4” Flange _ 322791-002 1

0

0

1

-008

-036 147 2” Flange 2” Flange 322792-001 1

0

0

1

-009

-037 155 3” Flange 3” Flange 322792-002 1

0

0

1

-010

-038 165 4” Flange 4” Flange 322791-002 1

0

0

1

-015

-043 138 2” Pipe _ 322792-001 1

0

0

1

-016

-044 141 3” Pipe _ 322792-002 1

0

0

1

-017

-045 143 4” Pipe _ 322791-002 1

0

0

1

-022

-050 141 2” Pipe 2” Pipe 322792-001 1

0

0

1

-023

-051 147 3” Pipe 3” Pipe 322792-002 1

0

0

1

-024

-052 151 4” Pipe 4” Pipe 322791-002 1

0

0

1

-061

-062 159 6” Flange _ 322791-001 1

0

0

1

-060

-059 183 6” Flange 6” Flange 322791-001 1

0

0

1

150 CFM PARTS

NOTES:

1. The part number for the Ionizer Cell for all units on this page is 422728-011. Only one required.

2. The part number for the Collector Cell for all units on this page is 422729-003. Only one required.

3. Flame arrestor not supplied but required in pipe inlet applications.

VII. OUTLINE DRAWINGS

OUTLINE DRAWINGS (SUBSEQUENT PAGES)

The “weatherproof power pack” and “weatherproof junction box” are designed to offer protection to IP-54. The junction

box for 220-240 VAC models is furnished with a terminal block for connection of eld installed supply power wiring.

The terminal block is earthed to the junction box through the earth terminal (PE) and includes a 1.2 Amp fuse for the

line connection (L). A third unfused terminal is included for the neutral (N) supply wire. A strain relief connector for

connecting a supply cable to the junction box, suitable for cable diameters of 4.8 to 7.9 mm, is furnished. It is packaged

with the junction box.

Model 38 Series

Installation, Operation, & Maintenance Manual

8www.trioniaq.com

150 CFM - Outline Drawing with Inlet Flange or Pipe (424396)

Model 38 Series

Installation, Operation, & Maintenance Manual

9

www.trioniaq.com

150 CFM - Outline Drawing with Inlet & Outlet Flange or Pipe (424397)

Model 38 Series

Installation, Operation, & Maintenance Manual

10 www.trioniaq.com

TRION

Part Number

Weight

(lbs.)

Inlet

Connector

Outlet

Connector

Part Number

Flame Arrestor

Power Supply

120 240

VAC VAC

439057-004

-032 156 2” Flange _ 322792-001 1

0

0

1

-005

-033 160 3” Flange _ 322792-002 1

0

0

1

-006

-034 165 4” Flange _ 322791-002 1

0

0

1

-007

-035 174 6” Flange _ 322791-001 1

0

0

1

-011

-039 162 2” Flange 2” Flange 322792-001 1

0

0

1

-012

-040 170 3” Flange 3” Flange 322792-002 1

0

0

1

-013

-041 180 4” Flange 4” Flange 322791-002 1

0

0

1

-014

-042 198 6” Flange 6” Flange 322791-001 1

0

0

1

-018

-046 153 2” Pipe _ 322792-001 1

0

0

1

-019

-047 156 3” Pipe _ 322792-002 1

0

0

1

-020

-048 158 4” Pipe _ 322791-002 1

0

0

1

-021

-049 164 6” Pipe _ 322790-001 1

0

0

1

-025

-053 156 2” Pipe 2” Pipe 322792-001 1

0

0

1

-026

-054 162 3” Pipe 3” Pipe 322792-002 1

0

0

1

-027

-055 168 4” Pipe 4” Pipe 322791-002 1

0

0

1

-028

-056 178 6” Pipe 6” Pipe 322791-001 1

0

0

1

-057 179 4” Flange 6” Flange 322791-001 1 0

-065* 162 3” Pipe 3” Pipe 322792-002 1 0

300 CFM PARTS

NOTE:

1. The part number for the Ionizer Cell for all units on this page is 422728-012. Only one required.

2. The part number for the Collector Cell for all units on this page is 422729-002. Only one required.

3. Flame arrestor not supplied but required on pipe inlet applications.

* Stainless Steel Ionizer & Collector Cell

• Ionizer Part No. 431318-001

• Collector Cell Part No. 431319-001

Model 38 Series

Installation, Operation, & Maintenance Manual

11

www.trioniaq.com

300 CFM - Outline Drawing with Inlet Flange or Pipe (424399)

Model 38 Series

Installation, Operation, & Maintenance Manual

12 www.trioniaq.com

300 CFM - Outline Drawing with Inlet & Outlet Flange or Pipe (424398)

Model 38 Series

Installation, Operation, & Maintenance Manual

13

www.trioniaq.com

TRION

Part Number

Weight

(lbs.)

Inlet

Connector

Outlet

Connector

Part Number

Flame Arrestor

Power Supply

120 240

VAC VAC

439057-063 355 8” Flange 8” Flange 322791-003 1 0

439057-064 355 8” Flange 8” Flange 322791-003 0 1

600 CFM PARTS

NOTE:

1. The part number for the Ionizer Cell for all units on this page is 422728-013. Two are required.

2. The part number for the Collector Cell for all units on this page is 422729-005. Two are required.

Model 38 Series

Installation, Operation, & Maintenance Manual

14 www.trioniaq.com

600 CFM - Outline Drawing (429436)

Model 38 Series

Installation, Operation, & Maintenance Manual

15

www.trioniaq.com

VIII. ELECTRICAL SCHEMATIC

GRN/YEL

BOX MOUNTING RECEPTACLE

PRIMARY LEAD AND PLUG ASSY

ENCLOSURE COVER

ELECTRICAL ENCLOSURE ASSY

GRN/YEL

267239-001 REV -

JUNCTION BOX ASSY

LED

GRN

COLLECTOR

C

A

BBLK

WHT

COLLECTOR IONIZER

BLK

WHT

IONIZER

BLK

GRN

WHT 120 V, 50-60 HZ, 1Ø

LINE

GROUND

NEUTRAL

BLK

RED

LED

120 VAC

CATHODE

ANODE

NEUT

GRD

POWER SUPPLY

RED

BLACK

BLK

WHT

BOX MOUNTING RECEPTACLE

PRIMARY LEAD AND PLUG ASSY

ENCLOSURE COVER

ELECTRICAL ENCLOSURE ASSY

LED

JUNCTION BOX ASSY

267239-002 REV -

COLLECTOR

CGRN/YEL

A

BBLK

WHT

COLLECTOR

BLK 1

BLK 2

GRN/YEL

1.2 A. FUSE L

WITH EARTH (GROUND)

220-240 V, 50-60 HZ, 1Ø

PE

N

IONIZER

GRN/YEL

BLK

WHT

IONIZER

BLK

RED

LED

240 VAC

CATHODE

ANODE

NEUT

GRD

POWER SUPPLY

RED

BLACK

GRN/YEL

BLK 1

BLK 2

120V

220-240V

Model 38 Series

Installation, Operation, & Maintenance Manual

16 www.trioniaq.com

IV. ELECTRICAL PARTS LIST

150 CFM

QTY

300 CFM

QTY

600 CFM

QTY Item TRION Part No. Description

1 1 1 1 267232-120 Power Supply - 120 VAC Input Voltage

267232-240 Power Supply - 240 VAC Input Voltage

1 1 -

2

268678-001 Primary Plug and Receptacle Assembly

120 VAC Input Voltage - 150 and 300 CFM

268678-003 Primary Plug and Receptacle Assembly

240 VAC Input Voltage - 150 and 300 CFM

- - 1

268678-002 Primary Plug and Receptacle Assembly

120 VAC Input Voltage - 600 CFM

268678-004 Primary Plug and Receptacle Assembly

240 VAC Input Voltage - 600 CFM

1 1 1 3 241101-020 LED Assembly

1 - -

4

422728-011

Ionizer Cell- 1 - 422728-012

- - 2 422728-013

1 - -

5

422729-003

Collector Cell

- 1 - 422729-002

- - 2 422729-005

4 4 4 6 122732-002 Insulator (HV Contact)

2 2 2 * 221952-001 HV Contact

2 4 8 * 242037-002 Spiked Ionizer Blade

2 2 4 * 220081-001 Insulator, Ionizer Cell

2 2 4 * 220146-001 Insulator, Collector Cell

Model 38 Series

Installation, Operation, & Maintenance Manual

17

www.trioniaq.com

V. DIAGRAM

3

6

5

1

4

2

Form No. 61-0184 Rev. 10/16 © TRION 2016. All Rights Reserved.

TRION®

101 McNeill Rd. | Sanford, NC 27330

Table of contents

Other Trion Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ProMinent

ProMinent CHLORINSITU IIa Series Maintenance instructions

ABB

ABB HT553703 Operation manual

ADCA

ADCA FLT Installation and maintenance instructions

Effer

Effer DMU 2000 Technical Assistance manual

Xylem

Xylem McDonnell & Miller PSE-800-M Application, Installation, Operation, and Maintenance Manual

Meritor

Meritor TM Series Service manual