Trion Mini M.E. Instruction manual

TRION®| www.trioniaq.com

Mini M.E.

Mini Mist Eliminator

Industrial Applications

READ AND SAVE THESE INSTRUCTIONS

www.trioniaq.com Mini M.E.

1

Installation, Operation, & Maintenance Manual

Mini Mist Eliminator for Industrial Applications

Mini M.E.

Table of Contents

Inspection...........................................................................................................................................2

SafetyInformation..............................................................................................................................2

Introduction.........................................................................................................................................2

Pre-InstallationConsiderations..........................................................................................................2

Hood and Duct Design..................................................................................................................2

UnitLocation......................................................................................................................................3

Installation.........................................................................................................................................3

Location and Mounting.................................................................................................................3

Ductwork......................................................................................................................................3

DrainPiping..................................................................................................................................3

Operation...........................................................................................................................................3

InitialStart-Up...............................................................................................................................3

IndicatingLight..............................................................................................................................4

Care and Maintenance.......................................................................................................................4

General.........................................................................................................................................4

Cleaning........................................................................................................................................4

Blower/Motor Assembly................................................................................................................5

Troubleshooting..................................................................................................................................5

Diagrams/Exploded View Figures......................................................................................................7

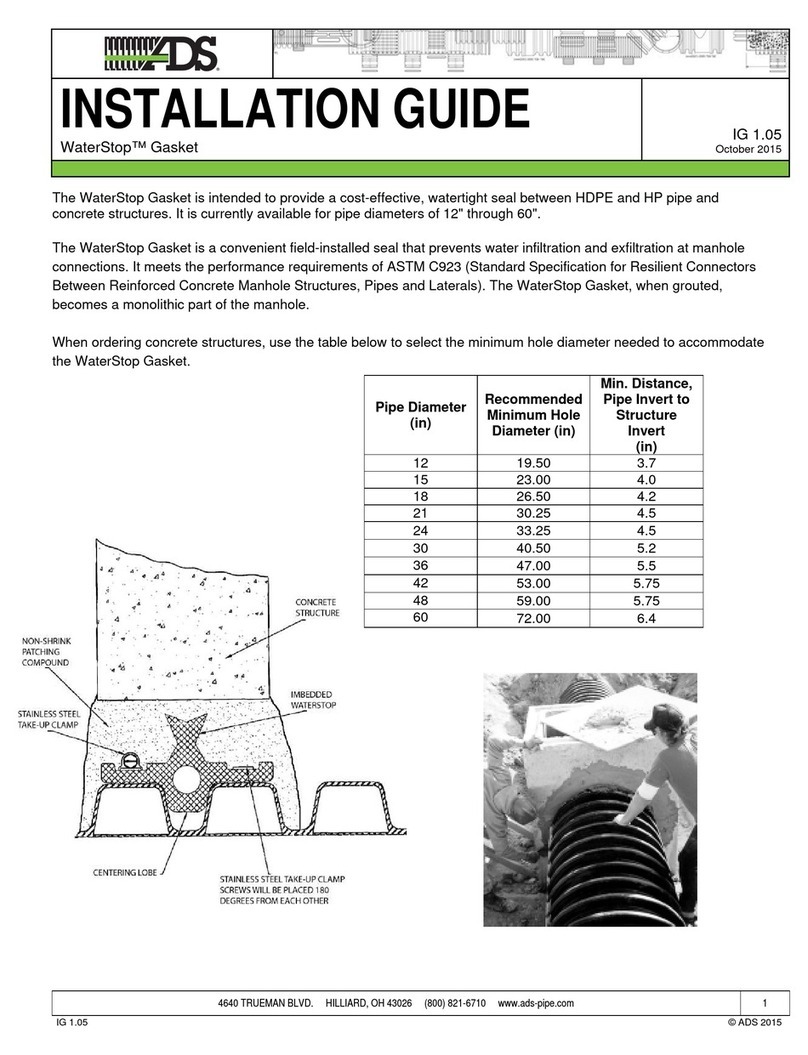

Figure 1 - Drawing with Drain Line..............................................................................................7

Figure 2 - Replacement Parts.......................................................................................................8

Figure 3 - Base Unit Outline Drawing...........................................................................................9

Figure 4 - Outline Drawing with Optional Accessories...............................................................10

Figure 5 - Blower Curves............................................................................................................11

Figure 6 - Wiring Diagram..........................................................................................................12

Limited Warranty..............................................................................................................................12

Please read these instructions carefully for trouble free operation

and to get the most out of your purchase. For further information

concerning this project, contact your local TRION representative.

www.trioniaq.com

Upon receipt, the unit(s) should be inspected for any

damage incurred in shipping. Damage should be noted

and a claim immediately led with the carrier at the

receiving end. Contact your TRION Representative or

the factory for authorization and instructions prior to

the return of any equipment.

1. Please read and understand this manual before

installing and operating the equipment.

2. The equipment location, installation and operation

should comply with the National Electrical Code

and local building and re codes. When in doubt,

consult the proper authorities.

3. Disconnect, lockout and tag the electrical power

while performing service work within the unit

cabinet.

4. All mounting arrangements used in the installation

must be able to support the weight of the unit plus

the weight of added accessories, options, and

collected contaminant.

5. The TRION MINI M.E. weighs 104 lbs. (47 kg.).

This manual should be carefully read before starting

the preparation and installation of the air cleaner.

The installation should conform to all local ordinances

associated with building codes and electrical codes

required for the unit. Authorities having jurisdiction

should be consulted before installation is made.

If there are no local codes, the installation should

conform to the National Electrical Code.

The TRION MINI M.E. is designed primarily for

the ltration of mist and smoke from metalworking

processes. The mist and smoke may be created from

oil-based, synthetic, semi-synthetic, or water-based

Mini M.E. 2

Installation, Operation, & Maintenance Manual

coolants like those used in cutting and grinding

operations.

The unit, arranged vertically for upward airow,

provides collecting efciency up to 95% and consists

of up to four ltration stages (as described below) and

a motor/blower. An optional inlet plenum is available

for ductwork connection.

The rst stage of ltration consists of two aluminum

mesh prelters in series to remove larger mist droplets.

The second stage – electrostatic precipitator – is the

primary ltration method and consists of two Ionizing/

Collecting Cells in series to charge and collect up to

95% of mist and smoke.

The third stage is either an aluminum mesh lter or an

optional charcoal lter for odor control.

The optional fourth stage is a 99.97% HEPA lter that

is mounted externally on top of the unit discharge grille.

In application, the contaminated air is captured at its

source from a machine enclosure or via a hood and

is transported to the unit through ducting furnished by

others. The contaminated air is then pulled upward

through the various stages of ltration and the cleaned

air is exhausted from the top of the cabinet through a

discharge grille. The unit should be located in the vertical

position and as close to the source of contaminant as

practical to minimize the length of ducting.

Hood and Duct Design

The effectiveness of the installation is dependent upon

the efcient capture and transport of the contaminant

at its source to the unit for collection.

In cases where adequate hooding is not provided

by the basic machine or the process creating the

contaminant, the design of the pick-up hood and the

transport ducting should not be oversimplied. Due to

the wide variety of applications, this subject warrants

a great deal more consideration than can be given

here. It is recommended that a recognized text be

consulted, such as Industrial Ventilation – A Manual of

Recommended Practice, available from:

WARNING!

Do not install this equipment in an area where

combustible vapors or gases exist. Do not use

this equipment for the collection of any materials

where there is a risk of re or explosion.

Inspection

Safety Information

Introduction Pre-Installation Considerations

www.trioniaq.com Mini M.E.

3

Installation, Operation, & Maintenance Manual

American Conference of Governmental Industrial Hygienist

6500 Glenway Avenue, Building D-7

Cincinnati, OH 45211-4438 U.S.A.

(Library of Congress Catalog Card #62-12929)

The duct between the pick-up hood and the unit

should be as short as possible and of adequate cross

sectional area to provide a transport velocity of 1500-

2000 feet per 3 minute (7.6-10.2 m/sec.). If the optional

inlet plenum is furnished, one 6” (152 mm) diameter

air inlet collar is provided. The ductwork should be A)

sloped to prevent the pooling of liquids, and B) sealed

to prevent leakage.

When ducting is utilized, the static pressure created

by the ductwork must be considered in conjunction

with the pressure that will be created by the build-up

of contaminant on the lters. Refer to the (System

Performance) Blower Curves of this manual.

The unit should be mounted vertically with ample

space above the discharge grille (12” minimum,

305mm). Also, provide ample lter access in front of

the unit (24” minimum, 610mm) and ample service

access on the right-hand side. If one unit is to collect

the contaminant from two sources, the unit should

be located so that the ducting from each source is

identical in length and conguration. If this is not

practical, the ducting should be designed and sized

so that the static pressure created by each duct run

is identical, or so that adequate capture and transport

velocities from each source are assured.

Unit Location

Installation

WARNING: ELECTRICAL SHOCK HAZARD

This unit should only be installed by a qualied

HVAC technician in accordance with the

National Electrical Code (NEC) and local codes

and ordinances. Do not connect the unit to the

power source until installation is complete.

Improper electrical installation may damage

equipment, can create a hazard, cause personal

injury or death, and will void the warranty.

Location and Mounting

Review the Pre-Installation Considerations as found

on Page 3 and prepare the unit for installation in the

planned location as follows:

1. To reduce weight for ease in handling and to gain

access inside the cabinet, open the access door

and remove the ionizing/collecting cells, placing

them safely aside.

2. Next, locate, level and secure the unit in the

desired location, assuring that the weight of the

unit plus the weight of any accessories, collected

contaminant and any ducting are adequately

supported. See Safety Information on page 3 for

unit weight.

3. Replace the ionizing/collecting cells.

Ductwork

Connect the ductwork as described under Hood and

Duct Design on page 3, being sure it is sloped to

prevent the pooling of liquids and is sealed to prevent

leakage.

Drain Piping

The bottom of the unit is open to allow drainage back

into a machine enclosure. The optional inlet plenum is

provided with a ½” NPT (12 mm) female connection. If

the collected liquid drain-off is to be piped to a machine

sump or an oil recovery reservoir, the piping must be

adequately trapped to overcome the negative pressure

inside the unit cabinet and thereby prevent air being

drawn through the drain, refer to diagram on page 7.

Initial Start-Up

1. Double-check the unit for proper mounting

securement, ductwork, piping, and wiring

connections.

2. Open the access door and check the interior cabinet

for cleanliness and ensure that all of the ltration

stages are in place.

3. Close the access door and plug the MINI M.E. into

a standard 3-wire grounded wall receptacle using

WARNING!

Sharp edges may be located on metal ductwork.

Wear protective gloves when handling.

Operation

www.trioniaq.com

Mini M.E. 4

Installation, Operation, & Maintenance Manual

the power cord provided.

4. Turn the variable speed control switch from the

“Off” position to initiate the blower. Air should blow

out of the discharge grille located on top of the unit.

Adjust airow as required.

Indicating Light

The LED light on the front panel provides an indication

of the electrical operation of the electronic air cleaner.

Constant illumination indicates correct operation of the

power supplies and power to the ionizing/collecting

cells. If the LED is continuously ickering, or fails to

glow, it is an indicator of potential problems. Refer to

the Troubleshooting diagram to correct the problem.

General

Care and maintenance includes the periodic cleaning

and replacement of the various ltration components,

and servicing the blower/motor assembly.

The frequency for routine cleaning and/or replacement

of the lters after initial start-up is dependent upon the

nature and amount of contaminant being collected.

Relatively clean mist particles that coalesce into larger

droplets when collected tend to drain from the collecting

surfaces in a “self-cleaning” action. Mist mixed with

semi-solids, smoke, dust, and other solids do not drain

SAFETY NOTE

Factory designed access to all electrically

charged high voltage components contain

electrical interlocks for the safety of operating

personnel. Any additional access that may be

provided in the system, where there is access

to high voltage, must be equipped with such

interlocks. Interlocks are readily available from

the factory.

Care and Maintenance

WARNING: ELECTRICAL SHOCK HAZARD

Before cleaning or servicing this unit it is

recommended that this unit be disconnected

from any electrical supply outlet. Failure to follow

these precautions could result in electrical shock,

re, death or serious personal injury.

as readily and therefore require more frequent manual

cleaning. As the make-up and quantity of contaminants

vary from application to application, practical

maintenance time schedules are best established by

several visual examinations of the ltration components

after the unit is placed into operation.Also, observing the

contaminant pick-up at the hood is a good indicator of

the lter condition. Any depreciation in the effectiveness

of pick-up indicates a drop off in capture velocity, which

is usually attributed to clogged lters.

Guide for Recommended Cleaning Frequency

Light loading 4-6 months

Medium loading 2-4 months

Heavy loading 1-2 months

Very heavy loading 2 weeks-1 month

Cleaning

The aluminum mesh lters and ionizing/collecting

cells require periodic cleaning. Hot water, 140-1600

F (60-710 C), and a good non-foaming, non-corrosive

detergent (safe for use on aluminum) should be used.

TRION’s Tridex APS liquid detergent, formulated

specically for this purpose, is available through your

TRION Representative.

The lter components should rst be rinsed in warm

water, and then soaked in a detergent water solution.

When the contaminant loosens or dissolves, the lters

should then be thoroughly rinsed and dried prior to

placing them back into service. When cleaning the

components, it is not necessary to “make them shine.”

Cleaning is to remove the accumulated dirt build-up.

Dirt stains do not impair efciency.

WARNING!

Do not allow debris or foreign objects to

become lodged between the cell plates. This

will cause shorting and damage the cells and/

or the power supply.

CAUTION!

Do not use steam cleaners to wash the cells.

The high temperatures may cause the cell plates

to warp or create other damage to the cell.

www.trioniaq.com Mini M.E.

5

Installation, Operation, and Maintenance Manual

If a scheduled maintenance time for lter component

cleaning is at a premium, it may be advantageous to

maintain a clean, spare set of lter components so

that service to the dirty components can be completed

within a few minutes.

Blower/Motor Assembly

After 1,000 hours of operation, remove the blower

access panel on top of the unit. Check and correct the

following, if necessary:

1. Securement of fasteners.

2. Blower wheel and compartment for excess dirt

buildup.

NOTE: Blower and motor bearings are sealed and

require no lubrication.

WARNING!

Factory designed access to all electrically

charged high voltage components contain

electrical interlocks for the safety of operating

personnel. Always unplug the unit while

performing service within the cabinet.

WARNING: RISK OF ELECTRIC SHOCK

These maintenance and service instructions

are for use by qualied personnel only.

To reduce the risk of electric shock, do

not perform any servicing other than that

contained in the operating instructions unless

you are qualied to do so.

All TRION Air Cleaners are manufactured to provide

continued, trouble-free service. However, as with all

mechanical equipment, breakdowns can occasionally

occur.

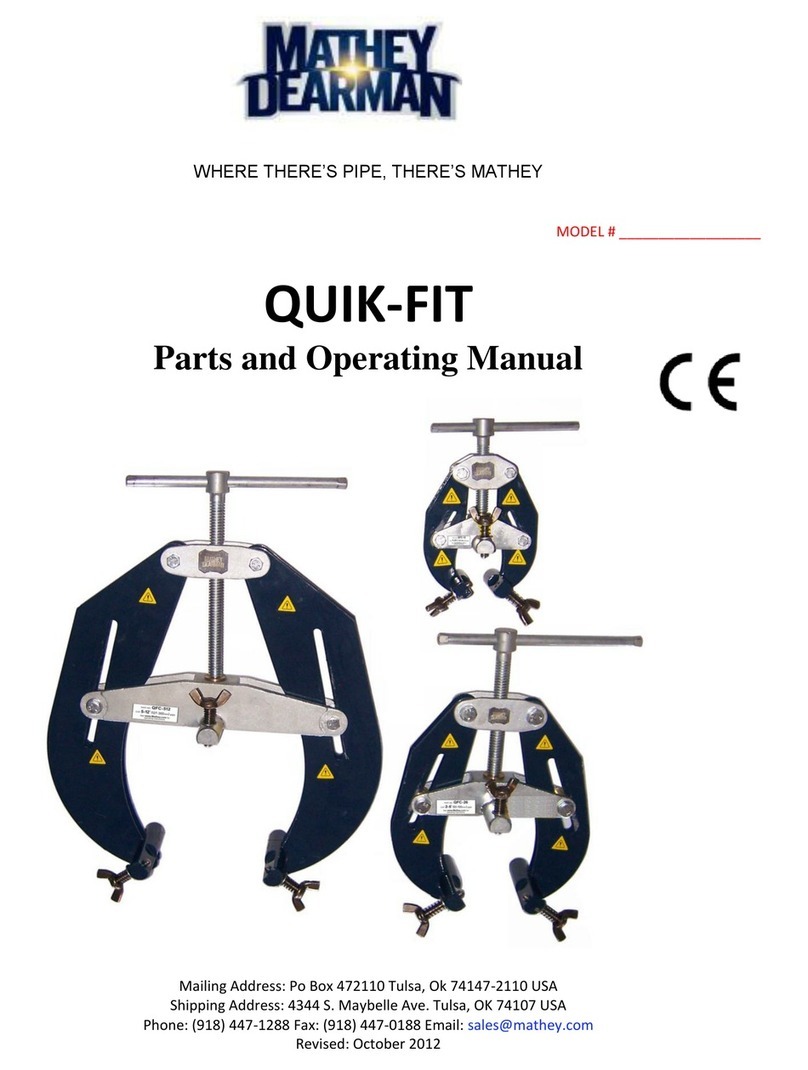

Refer to the Replacement Parts diagram for

replacement parts.

Before troubleshooting the unit, review the safety

information on Page 3, refer to the Wiring Diagram on

Page 12, check for proper wiring connections, and the

correct input line voltage.

Troubleshooting

www.trioniaq.com

Troubleshooting Procedure

Mini M.E. 6

Installation, Operation, and Maintenance Manual

Turn unit on.

Motor operates

properly. Power

supply light is on.

Yes Yes Yes Yes

Motor does

not operate at

all or operates

intermittently.

Power supply light

is on.

No No

Motor operates

properly.

Power supply

light operates

intermittently or

not at all.

No

Motor operates

with little or no

air volume from

the unit.

Check for:

1. Faulty control

switch

2. Motor turns

frequently

3. Faulty motor

capacitor

4. Loose wire

connection

or wire

disconnected

Check for:

1. Dirty Ionizer/

Collector cells

2. Faulty control

3. Failed

transformer

4. Failed power

supply

Check for:

1. Dirty or

clogged

lters

2. Inlet or

discharge

blocked

3. Blower

wheel dirty

4. Incorrect

line voltage

Repair completed. Contact your local

TRION distributor.

No

Yes

Unit operates

correctly.

www.trioniaq.com Mini M.E.

7

Installation, Operation, & Maintenance Manual

Figure 1 - Drawing with Drain Line

www.trioniaq.com

Mini M.E. 8

Installation, Operation, & Maintenance Manual

Figure 2 - Mini M.E. Replacement Parts

Item TRION Part No. Description

1 334562-005 Lift and Turn Latch

2357679-001 Motorized Impeller Assembly, 120V/60Hz

357679-002 Motorized Impeller Assembly, 230V/50-60Hz

3257680-001 Capacitor, 20µF, 120V

257680-002 Capacitor, 50µF, 230V

4239071-006 Transformer, 120V

239071-011 Transformer, 230V

5 356764-001 PCB Assembly

6 257544-001 HV Contact Board Assembly

7 132311-001 Interlock Switch

8235477-001 Speed Control, 120V/60Hz

235477-002 Speed Control, 230V/60Hz

9 139999-001 Speed Control Knob

10 141102-001 LED, Red

11 441729-201C Ionizer/Collector Cell

12 240550-013 Aluminum Mesh Filter

13 245395-007 Charcoal Filter (Optional)

14 220110-929 Ionizer Wire Assembly

www.trioniaq.com Mini M.E.

9

Installation, Operation, & Maintenance Manual

Figure 3 - Base Unit Outline Drawing

www.trioniaq.com

Mini M.E. 10

Installation, Operation, & Maintenance Manual

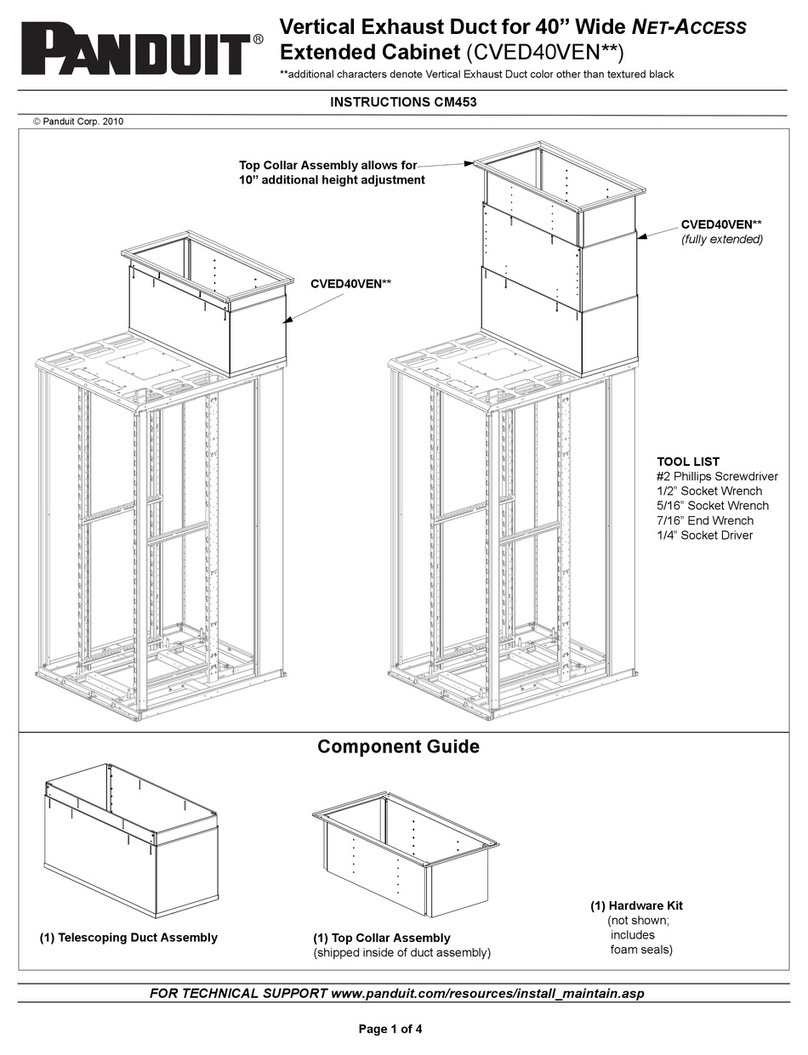

Figure 4 - Outline Drawing with Optional Accessories

www.trioniaq.com11 Mini M.E.

Installation, Operation, & Maintenance Manual

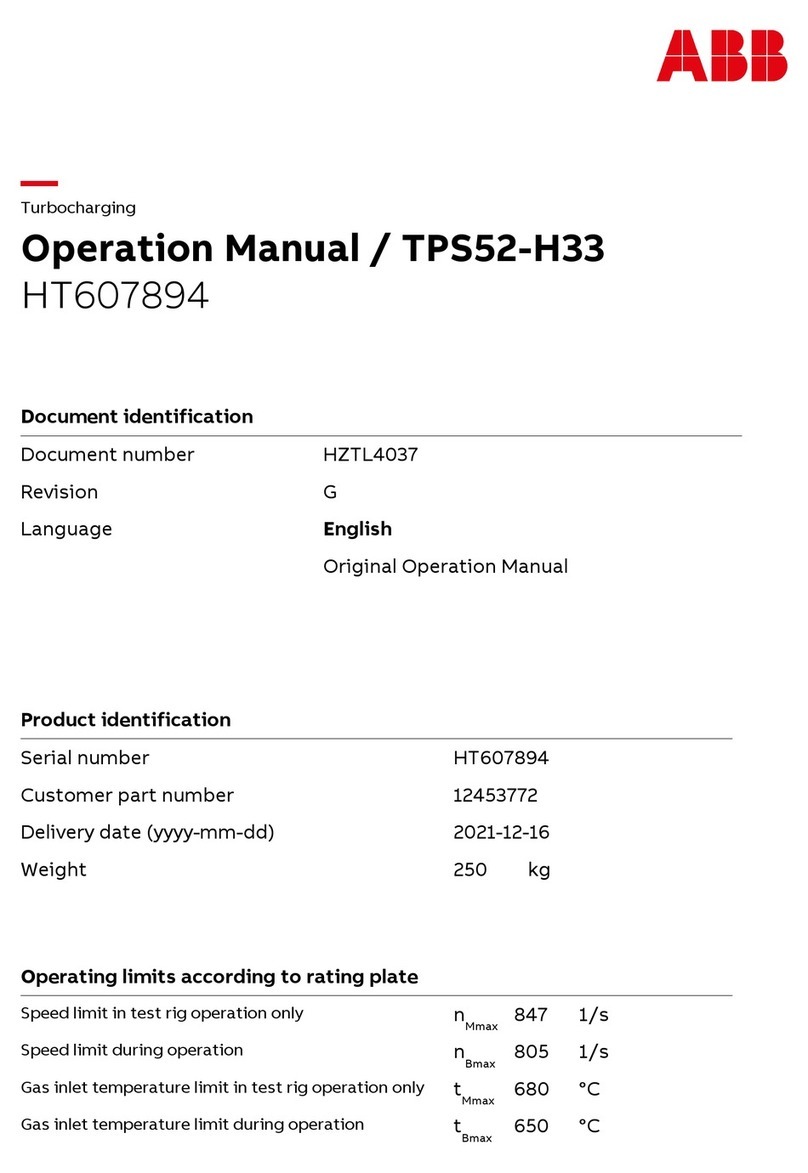

Figure 5 - Blower Curves

Mini M.E. EAC, 120V - 230V/60Hz

0

0.5

1

1.5

2

2.5

0100 200 300 400 500 600 700

CFM

In H

2

O

(3) 2" Alum. Mesh

(2) 2" Alum & Carbon

(3) Alum & HEPA

(2) Alum & Carbon & HEPA

Mini M.E. EAC, 240V/50Hz

0

0.5

1

1.5

2

0100 200 300 400 500 600

CFM

In H2O

(3) 2" Alum. Mesh

(2) 2" Alum & Carbon

(3) Alum & HEPA

(2) Alum & Carbon & HEPA

www.trioniaq.com 12

Mini M.E.

Installation, Operation, & Maintenance Manual

Figure 6 - Wiring Diagram

Limited Warranty

Seller warrants the equipment of its manufacture to be free from defects in workmanship and material for a period of three (3)

years after shipment or if applicable – three (3) years after initial startup of equipment, whichever occurs rst. This warranty

is limited, however, to the repair or replacement of defective equipment, which is returned, freight prepaid, to Seller’s factory.

This limited warranty does not apply to any part or component that is damaged in transit or when handling, has been subject

to misuse, negligence or accident, has not been installed, operated or serviced according to Seller’s instructions, or has

been operated beyond the factory-rated capacity or has been altered in any way.

Seller’s liability is limited to replacement of defective parts or components and does not include any cost of labor (including,

but not limited to, labor required to remove and/or reinstall any defective part) other than TRION factory labor.

TRION shall not be responsible for loss of use of any product, loss of time, inconvenience, or damage to other equipment or any

other indirect or consequential damage with respect to property whether as a result of breach of warranty, neglect or otherwise.

THE WARRANTIES AND LIABILITIES SET FORTHABOVE ARE IN LIEU OF ALL OTHER WARRANTIESAND LIABILITIES,

EXPRESSED OR IMPLIED, IN LAW OR IN FACT, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE.

The foregoing shall constitute the total liability of Seller in the case of defective performance of all or any of the equipment

or services provided to Buyer. Buyer agrees to accept and herby accepts the foregoing as the sole and exclusive remedy

for any breach or alleged breach of warranty by Seller.

TRION®

101 McNeill Rd. | Sanford, NC 27330

© TRION 2015. All Rights Reserved.Form No. 157550-001 Rev. 11/15

Table of contents

Other Trion Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Baileigh Industrial

Baileigh Industrial DDTM-8052-HD Operator's manual

CKD

CKD ESM Series manual

Siemens

Siemens SIMOVERT MASTERDRIVES 6SE7021-6CS87-2DA0 operating instructions

SMW Autoblok

SMW Autoblok Mario Pinto LT Use and maintenance instructions

Dodge

Dodge USN 500 Series instruction manual

Burkert

Burkert 6519 operating instructions