SCMI SUPERSET XL Installation guide

USO E MANUTENZIONE

OPERATION AND MAINTENANCE

FONCTIONNEMENT ET ENTRETIEN

BETRIEBS- UND WARTUNGSANLEITUNG

USO Y MANTENIMIENTO

SUPERSET XL

SCORNICIASCORNICIA

SCORNICIASCORNICIA

SCORNICIATRICE ATRICE A

TRICE ATRICE A

TRICE AUTUT

UTUT

UTOMAOMA

OMAOMA

OMATICATICA

TICATICA

TICA

AUTOMATIC PLANING AND MOLDING MACHINE

MOULURIERE AMOULURIERE A

MOULURIERE AMOULURIERE A

MOULURIERE AUTUT

UTUT

UTOMAOMA

OMAOMA

OMATIQTIQ

TIQTIQ

TIQUEUE

UEUE

UE

PRPR

PRPR

PROFILFRÄSAOFILFRÄSA

OFILFRÄSAOFILFRÄSA

OFILFRÄSAUTUT

UTUT

UTOMAOMA

OMAOMA

OMATT

TT

T

MOLDURERA AMOLDURERA A

MOLDURERA AMOLDURERA A

MOLDURERA AUTUT

UTUT

UTOMAOMA

OMAOMA

OMATICATICA

TICATICA

TICA

(USA)(USA)

(USA)(USA)

(USA)

Questo manuale è da conservare per futuri riferimenti e dovrà sempre seguire la macchina

This manual is to be kept for future reference and must always accompany the machine.

Ce manuel doit être conservé pour de futures références et devra toujours suivre la machine.

Das Handbuch ist für künftigen Gebrauch aufzubewahren und muß stets die Maschine begleiten.

Este manual tiene que conservarse para futuras referencias y tiene que estar junto con la máquina.

0000571057C 1-1

1.1

SUPERSET XL CNusa1

GENERAL INFORMATION

PagineTotalicompresacopertrinaeretroN°105

Data

N°Bolla

Firma N° Modifica N°Bolla

Data N°

LIBRETTOUSOeMANUTENZIONE

SUPERSET XL

SCMIcannotbeheldresponsiblefordamagesresultingfromusenotdescribedinthismanualorfromimproper

maintenance.

Contactyourlocaldealerforanyrequirementsoradviceonuse.

MACHINE OPERATORS

Personnel who will be working on the machine must, apart from being professionally trained for the job, read

the manuals paying particular attention to the safety regulations and the paragraphs relative to his area of

competence.

The machine operators are identified as follows:

PRODUCTION OPERATOR - responsible for production

EXPERT OPERATOR - responsible for machine tooling and set-up

MAINTENANCE OPERATOR - responsible for machine maintenance

B11331

01/10/99

12/01/99

0000571057C

S.I.T./R.L.(05)

1.2 CNusa1 SUPERSET XL

GENERAL INFORMATION

çThese paragraphs address:

XXX

XX

XX

XX

XXX

XXX

XXX

XX

XX

XX

XXX

XX

XX

XX

X

X

X

XXX

XXX

XXX

XXX

XXX

XX

X

X

X

X

X

X

X

X

X

GENERAL INFORMATION...............................................SECTION 1

Machineoperators ........................................................................................... 1.1

1-1 CORRESPONDENCE .................................................................................... 1.4

1-2 RECOMMENDATIONS ................................................................................. 1.4

1-3 MACHINE IDENTIFICATION ....................................................................... 1.5

1-4 CONDITIONS OF USE AND CONTRAINDICATIONS .............................. 1.5

1-5 CONCEPTS OF USE RELATED TO THE OPERATOR ................................. 1.6

1-6 SAFETYWARNINGS..................................................................................... 1.7

1-7 TECHNICALCHARACTERISTICS............................................................... 1.9

1-8 NOISE LEVEL ................................................................................................ 1.12

1-9 OVERALL DIMENSIONS.............................................................................. 1.13

1-10 WORK AREAS AND STATIONING.............................................................. 1.14

INSTALLATION................................................................... SECTION 2

2-1 MACHINEUNLOADING .............................................................................. 2.2

2-2 POSITIONING................................................................................................ 2.2

2-3 LEVELLING .................................................................................................... 2.2

2-4 ELECTRICAL CONNECTION ANDEARTHING......................................... 2.4

2-5 CONNECTION TO SUCTION SYSTEM...................................................... 2.6

2-6 PNEUMATIC CONNECTION ....................................................................... 2.8

2.7 SAFETYDEVICES USED .............................................................................. 2.10

USE AND ADJUSTMENTS................................................ SECTION 3

3-1 CONTROL PANEL ......................................................................................... 3.2

3-2 STARTING THEMACHINE ........................................................................... 3.11

3-3 STOPPING THE MACHINE .......................................................................... 3.11

3-4 EMERGENCYSTOP ...................................................................................... 3.11

3-5 AUTO-BRAKINGMOTOR............................................................................ 3.12

OPERATING UNITS ..............................................................SECTION 4

4.1 TOOL ADJUSTMENT AND LOCKING ON SPINDLES ........................... 4.2

4.2 OPERATING UNITS ..................................................................................... 4.6

4.2.1 BOTTOM HORIZONTAL SPINDLE.................................................................... 4.6

4.2.2 RIGHT VERTICAL SPINDLE .............................................................................. 4.8

4.2.3 LEFT VERTICAL SPINDLE................................................................................. 4.10

4.2.5 TOP HORIZONTAL SPINDLE ............................................................................. 4.12

4.2.6 SECOND BOTTOM HORIZONTAL SPINDLE................................................... 4.14

4.3 TOP MOBILE UNIT...................................................................................... 4.16

4.4 INLETGUIDEAND TABLE .......................................................................... 4.18

4.5 UNIVERSAL SPINDLE UNIT..........................................................................4.20

1.3

SUPERSET XL CNusa1

GENERAL INFORMATION

çThese paragraphs address:

X

X

X

X

X

X

X

X

X

X

X

X

XXX

X

X

XX

XX

XX

XX

XX

XX

XXX

XX

XXX

XX

ADJUSTMENT AND USE OF OPTIONAL UNITS ......SECTION 10

10.1 KNIFE ADJUSTMENTDEVICE ................................................................. 10.2

10.2 TANDEM FEED UNIT IN FRONT OF RIGHT VERTICALSPINDLE ...... 10.2

10.3 VERTICALPRESSER .................................................................................. 10.4

10.4 ADDITIONALEQUIPMENT FOR NARROW PIECES ............................. 10.4

10.5 MANUALLYOPERATEDTABLE LUBRICATIONPUMP......................... 10.6

10-6 AUTOMATICTABLE LUBRICATIONPUMP ............................................ 10.6

10-7 METRECOUNTER...................................................................................... 10.8

10-8 HOURCOUNTER ....................................................................................... 10.8

10-9 TW0-SECTORPRESSURE SHOE POSITIONED AFTER THE UNIT ...... 10.10

AUTO-BRAKING MOTOR.................................................SECTION 19

19-1 AUTO-BRAKING MOTOR...................................................................... 19.2

19-2 “ELETTRO ADDA” AUTO-BRAKING MOTOR ................................. 19.4

19-3 “LAFERT” AUTO-BRAKING MOTOR.................................................. 19.6

MAINTENANCE ..................................................................SECTION 20

20-1 MACHINE CLEANING .............................................................................. 20.2

20-2 PERIODIC LUBRICATION ........................................................................ 20.2

20-3 PNEUMATIC SYSTEM .............................................................................. 20.4

20-4 BOTTOM HORIZONTAL OPERATING UNIT BELT TENSIONING ..... 20.6

20-5 TOP HORIZONTAL OPERATING UNIT BELT TENSIONING .............. 20.6

20-6 RIGHT VERTICAL OPERATING UNIT BELT TENSIONING ............... 20.6

20-7 LEFT VERTICAL OPERATING UNIT BELT TENSIONING .................. 20.8

20-8 OPERATING UNIT BELT REPLACEMENT ............................................ 20.8

20-9 VARIATOR TIMING BELT REPLACEMENT .......................................... 20.10

20-10 INSPECTION OF SAFETY DEVICES ...................................................... 20.10

20-11 REMOVAL - STORAGE - DEMOLITION ................................................ 20.11

20-12 EMERGENCY CONDITIONS ................................................................... 20.11

20-13 TROUBLESHOOTING ............................................................................... 20.12

1.4 CNusa1 SUPERSET XL

GENERAL INFORMATION

1-1 CORRESPONDENCE

WhenwritingorphoningthedealerorSCMIforanyreasonconcerningthemachine,alwayssupplythefollowing

information:

1) Machinemodel

2) Serialnumber

3) Voltage and frquency

4) Date of purchase

5) Name of dealer where the machine was purchased

6) Detailed description of any faults found

7) Detailed description concerning the specific machining to be carried out

8) Period of use - number of hours of operation

Manufacturer’saddress

SCM GROUP USA INC.

SCM I DIVISION

2475SatelliteBlvd

SuiteB

Duluth,GA30136

Tel. 001-770-8138818 - Fax. 001-770-8138819

E-mail:[email protected]

1-2 RECOMMENDATIONS

Indrawingupthismanualalltheoperationsrelativetoregularmaintenancehavebeentakenintoconsideration.

It is recommended not to carry out any operation not described in this manual.

All operations requiring assembly or disassembly of parts must be carried out by authorised technicians.

The machine may only be used by trained personnel aware of the risks connected with its use.

Observetheaccident-preventionregulationsandtherulesofsafety andindustrialmedicineinforceinthecountry

where the machine is used.

Note:

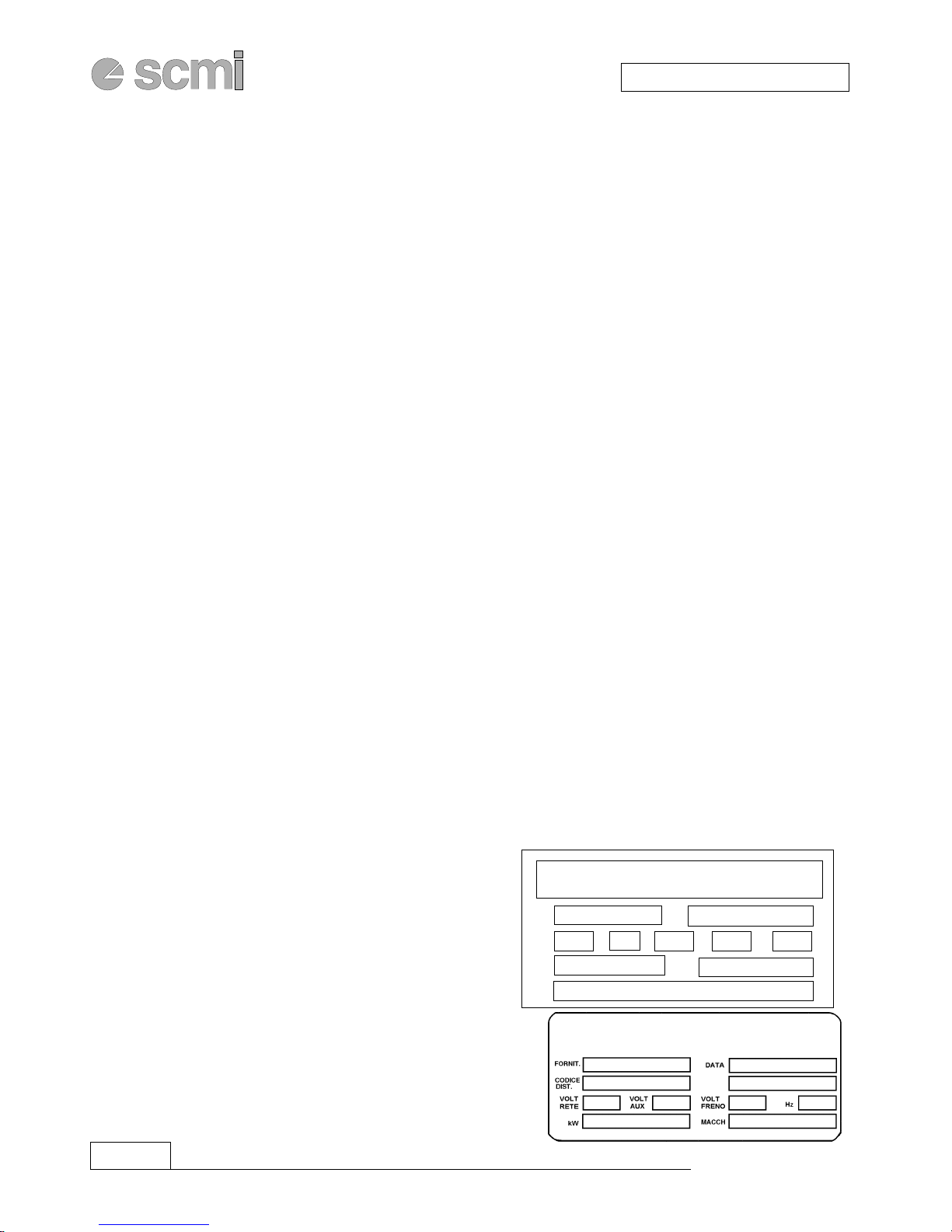

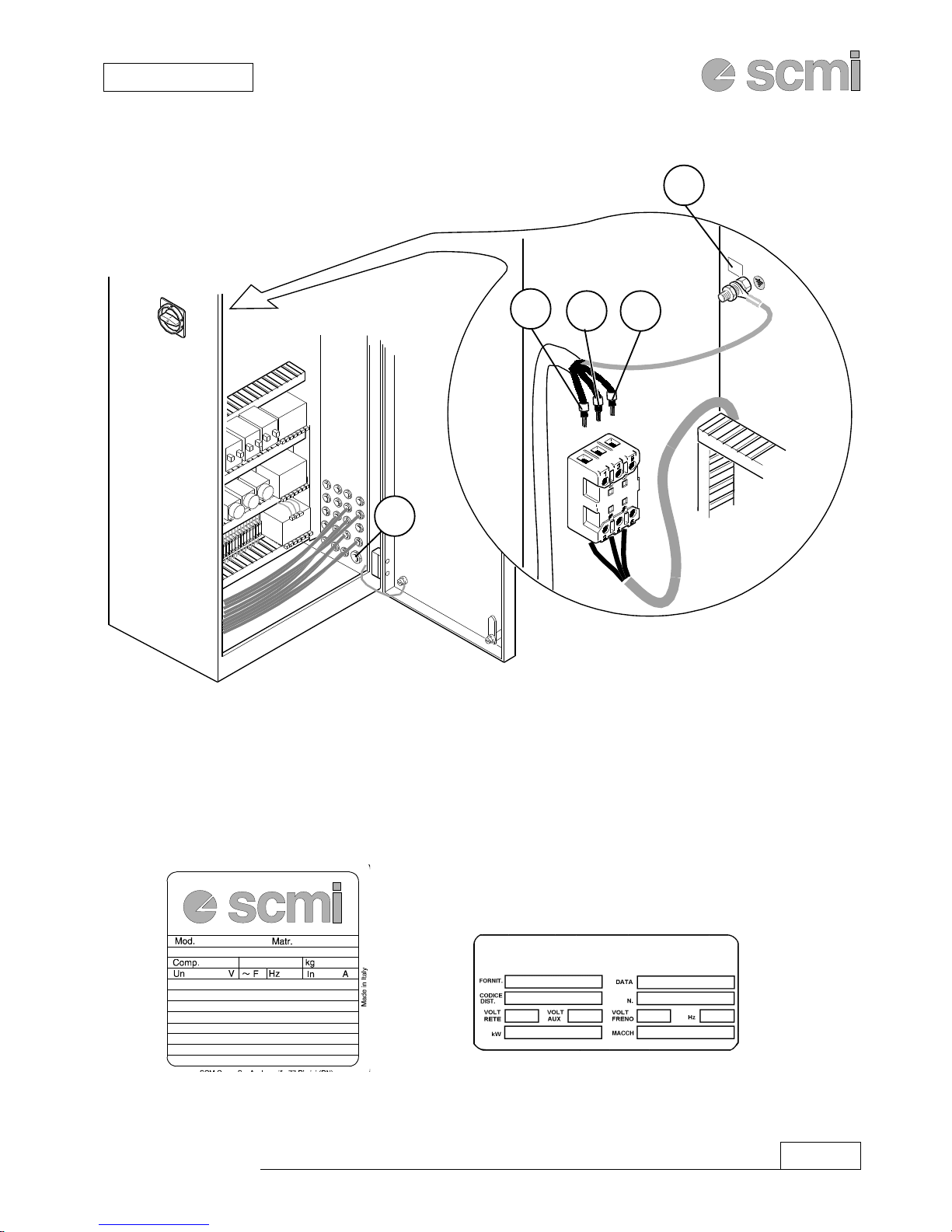

- Torequestinformationconcerningtheelectricalsystem,providethedatalistedontheplatebelow,locatedon

theinsideoftheaccessdoortotheelectriccompartment.

FORNIT. Company which has executed the electrical system

DATA Dateofconstructionofelectriccontrolunit

CODICEDISTINTA Electricalcomponentlistnumber

N. Wiringdiagramnumber

VOLT RETE Machinepower supplymainsvoltage(V)

VOLTAUX Auxiliarycircuitspowersupplyvoltage(V)

VOLTFRENO Motorbrakepower supplyvoltage(V)

Hz Electrical frequency in Hz

FASE Number of power supply phases

MACCH. / TIPO Machine type CODICE

SCHEMA

FORNIT.

TIPO DATA

VOLT

RETE Hz kW FASI

DIS. CODICE

A

1.5

SUPERSET XL CNusa1

GENERAL INFORMATION

1-3 MACHINE IDENTIFICATION

The machine is identified by the punched text on the metallic plate located on the side of the base.

1.2

Ref.

Mod. Machine model

Matr. Serial number

Ref. Internal reference

Comp. No. of machine composition

N Gross weight expressed in Newton

kg Weight

Un Nominal electric voltage expressed in Volt

~ F Number of phases

Hz Electrical frequency in Hz

In Rated current in Amperes

1-4 CONDITIONS OF USE AND CONTRAINDICATIONS

Thismachinemustonlybeusedforcuttingofwoodorsimilarmaterials.“Similarmaterials”meansmaterialswith

technological and physical characteristics similar to those of wood for which the machining mechanism and

shavingremovalissimilar.

Materials different from those quoted above, not being assimilated with wood, are consequently excluded.

Wood or similar materials must be without foreign bodies (e.g. nails, stones, etc.).

Any damage caused by machining them shall be the sole responsibility of the user.

DIMENSIONSOFTHEPIECETOBEMACHINED

Themaximumdimensionsofthemachinedpiecesare: ................................... height120(*) mmxwidth230(**)mm

Consideringthatthemaximumremovalis10mm,themaximumdimensionofthepiecestobemachinedmaybe:

height 140mmxwidth250mm

With the option to remove from 10 mm to 0.1 mm, the minimum dimension of the machined piece

maybe: ................................................................................................... height6(1) mmxwidth25(2) mm

Theminimumlengthofthepiecewithsinglefeedis: .............................................................................. 620(3) mm

(*) with 145 mm ø tool mounted on the top horizontal unit

(**) with 145 mm ø tool mounted on the left vertical unit

with 125 mm ø tool mounted on the left vertical unit of machine with electronic control (optional).

(1) with positioning through electronic control (optional).........................................minimum height10mm

(2) with relevant optional (kit for minimum working width) ..................................... minimum width15mm

(3) with relevant optional (reduction of traction distance between centres) ............minimumlength450mm

USABLE TOOLS

Themachinehasbeendesignedforexclusiveuseoftoolsinconformitytosafetycurrentstandardsofthecountryinwhich

theywillbeused,suitableforthetypeofmaterialtobemachined.

ThelinkbetweenthetooldiameterandthetoolheightatparityofrotationspeedisdefinedinthetableinChapter4.1.

ENVIRONMENT

Themachinemaybeoperatedinthefollowingambientconditions:

Humidity: max. 90%

Temperature: min. +1°C max. +40°C

Altitude: max. 1,000 m above sea level (over this level consult the manufacturer)

The machine may only be operated in closed environments.

The machine may not be operated in explosive environments.

N

1.6 CNusa1 SUPERSET XL

GENERAL INFORMATION

PROHIBITIONSOFUSE

It is prohibited to:

- use the machine in a way different from that specified;

- use the machine without the protections provided for each machining operation, or with only part of them;

- use rotating operating units to assist piece feed;

- use materials different in type and dimensions from those already stated;

- usetoolsnotinconformitytosafetycurrentstandardsofthecountryinwhichtheywillbeused,orwithincompatible

dimensions(seetableinChapter4.1);

- make modifications to the machine.

Any damage deriving from improper use is the sole responsibility of the user.

RESIDUAL RISKS

Despiteobservance of thesafety regulations and use according to the rulesdescribed in thismanual, the

following residual risks may still be present:

- With the machine in manual mode, some of the protections are necessarily lacking, e.g. the

horizontally-pivoted protection open, to allow tooling and machine set-up (expert operator task).

- Possible collision of tools with other machine parts during adjustment (expert operator task).

- Contact with the tool

-Contactwithrotatingelements,suchasbelts,toolspindles,pulleys,tractionandmotiontransmission

devices.

-Danger of generating sparks in case of contact between rotating tools and foreign bodies.

- Hazard due to inhalation of dust in case of working with inadequate aspiration.

- Hazard due to exposure to noise.

- Danger of electric shock from live elements.

- Piece recoil at inlet until it is dragged by the traction wheels.

- Possible risk of getting trapped and/or sheared if the user adds conveyors or sliding tables at the

machine outlet.

1-5 CONCEPTS OF USE RELATED TO THE OPERATOR

On the control panel there is one or more key selectors.

These selectors enable use of the machine according to precise settings and safe operating logic.

Only the expert operator may drive these selectors; improper use may cause precarious conditions of use and

dangerous situations.

On completion of the necessary adjustment and set-up operations to which the selectors give access, the

expertoperatormustextractthekeysfromthecontrolpanelandauthorisetheproductionoperatortouse

themachine.

Itisalsoindispensabletohave2suitablepadlocksavailabletolockthemainswitchoftheelectricalpowersupply

and the main valve of the pneumatic system (if present).

The door of the electric box is closed with one or more locks. The key to open the box is provided with the

machine. In normal operating and maintenance conditions the door must always be closed.

Theexpertoperatorisresponsibleforandcustodianofallthekeys.

1.7

SUPERSET XL CNusa1

GENERAL INFORMATION

1-6 SAFETY WARNINGS

Carefully read this instruction manual before starting the machine.

Observe all the instructions, warnings and danger signs affixed to the machine and check that these are always

maintainedintactandperfectlylegible.

Thismachinehasbeenconstructedtooffermaximumsafety,distinguishedatthetimeofitsconstruction,together

with best performance.

Arbitrarymodificationsmadetothemachineshallrelievethemanufacturerofanyliabilityfordamages

which may derive from it.

PROCEDURES FOR WORKING SAFELY

- Aclearworkingareaaroundthemachineisfundamentalforsafety:thefloormustbeflat,well-keptandfree

of material, e.g. shavings, scraps, etc.

- Sufficient lighting must be provided, general or localised at the workstation, min. 300 LUX.

- Be careful with objects which may cause accidents: take off rings, watches, bracelets and ties, tie sleeves

around the wrists and tie up hair.

- Wear clothing in conformity with the safety regulations including:

- suitable shoes as per the safety regulations;

- hearing protection;

- respiratory tract protection;

- protective glasses or screens;

- gloves to handle tools and raw materials;

- The operator must never leave the machine unattended during operation.

- Duringcleaning, maintenance, identification and correction of faults,thesafety procedures provided must

beapplied.

- The Use-Maintenance manual must be kept near the machine so that it may be consulted at any time.

FOR ALL TOOL CHANGE, CLEANING OR MAINTENANCE OPERATIONS, SET ALL THE

SWITCHES TO ZERO AND PADLOCK THEM.

OPERATOR TRAINING

It is important that all the operators receive adequate training, which includes information relative to the

dangers associated with use of the machine and the precautions to take. In particular:

- themachine operatingprinciples, properuse, correctuseof theprotections whichmust periodicallybe

checked.

- how to handle the pieces at the time of use;

- the position of the hands before, during and after machining.

The operators must furthermore be trained for firefighting operations.

GUARDS

The machine must not be used if all the guards and other safety devices necessary for machining are not in

position, in good operating condition and have not undergone proper maintenance.

NOISE

The operator must be informed concerning the noise levels which may be generated during normal use of

the machine and the factors which affect the exposure to noise. The factors include:

- correct tool selection;

- correct speed selection;

1.8 CNusa1 SUPERSET XL

GENERAL INFORMATION

- toolandmachinemaintenance;

- typeofmaterialmachined;

- importanceanduseofallthefencesprovided;

- properuseofpersonalprotection(headsets,earplugs,etc.).

DUST

Theoperatormustbeinformedconcerningtheriskscausedbyexposuretodustandthefactorswhichaffect

exposure. These factors include:

- tooland machinemaintenance;

- relation between cutting speed and feed speed;

- typeof materialmachined;

- importance of local aspiration on each operating unit (dust collection at source);

- proper adjustment of hoods, deflectors, hoppers;

- proper use of personal protection (masks, etc.).

The suction system must be connected to the machine and operational before starting machining.

DO NOT USE COMPRESSED AIR TO REMOVE DUST AND SHAVINGS.

MACHINE SAFETY

- The machine must not be used if the guards and safety devices are not active, in position, in good

conditionand properly maintained.

- Neverworkpiecesofdimensionsnotsuitedtothemachinecapacity(seedimensionsofmachinedpiece

in paragraph 1.4).

- Before mounting any tool, ensure that the mortising surfaces are well-cleaned and without dents.

SAFETY DURING MAINTENANCE

- UseonlyoriginalSCMIspareparts.

- When maintenance operations need to be carried out, stop the machine, set the main electrical and

pneumatic switches to zero and padlock them.

- Completelystopthemachineandensurethatthetoolsarestandingstillbeforeproceedingwithcleaning

or maintenance and before removing any protection for cleaning, inspection or maintenance.

- Carry out a routine check of the signalling devices of the electric panel: one by one switch on the tool

motor of each unit and check on the electric panel that the corresponding pilot light is on.

- Regularlyandsystematicallycheck theefficiency ofeach safetydevice.

TOOLS

- Exclusivelyusetoolsinconformitytosafetycurrentstandardsofthecountryinwhichtheywillbeused.

- Follow the instructions of the manufacturer for use, adjustment and repair of the tools.

- The speed limit (number of revolutions/min.) marked on the tool must not be exceeded.

- Ensure that the tools are perfectly balanced and sharpened and accurately splined and tightened.

- Never use cracked or deformed tools.

- Ensure that the spacing rings and the flanges are suitable for use as declared by the manufacturer.

1.9

SUPERSET XL CNusa1

GENERAL INFORMATION

1-7 TECHNICAL CHARACTERISTICS

Max. working width (finished section) ............................................... 230 mm(OPT 240 mm)

Min. working width (finished section) .................................................. 25 mm (OPT 15 mm)

Max. working height (finished section) ....................................................................... 120 mm

Min. workingheight (finishedsection) ........................................................................... 6 mm

Minimumlengthofsinglepiece ..............................................620 mm (OPT 450 mm)

Feed speed ....................................5÷25m/min(OPT6÷36m/min)

Spindle rotation speedi ..................................... 6000 RPM (OPT 8300 RPM)

Spindlediameter .................................. 40 mm (OPT 50mm o 1"13/16)

Usefullengthofvertical spindles ...............................................140 mm (OPT180 mm)

Usefullength ofhorizontal spindles ....................................................................... 250 mm

Universalspindlelength ....................................................................... 240 mm

Axialadjustment ofverticalspindles with

respect to the table ..................................................................... 0÷80 mm

Axialadjustment of horizontal spindles with

respect to the right guide ..................................................................... 0÷45 mm

Axial adjustment of the planer spindle ..................................................................... 0÷45 mm

Minimumand maximumdiameterof profilingtool ................................................................100-200 mm

Minimum and maximum diameter of tools

onplaner spindle ................................................................120-140 mm

Profile capacity on 2nd bottom horizontal unit

with 200 mm ø tool ......................................................................... 15 mm

Motor power of tool-holder spindles ........................................... 4 kW (OPT up to 15 kW)

Feed motor power .............................................................3 HP (2,2 kW)

Feed roller diameter ....................................................................... 140 mm

Inlet table length ........................................... 2000 mm(OPT 2500 mm)

Quick adjustment for inlet guide and table ......................................................................... 10 mm

Net weight composition 1 ....................................................................... 2200 kg

Netweightcomposition 5 ....................................................................... 2350 kg

Netweightcomposition 2 ....................................................................... 2900 kg

Netweightcomposition 6 ....................................................................... 3050 kg

1.10 CNusa1 SUPERSET XL

GENERAL INFORMATION

Optionals

Optionals for feed systemo

- Pneumatic cut-out from control panel for feed unit located before the planer spindle

- Horizontal presser before planer with pneumatic cut-out from control panel.

- Tandem feed unit in front of right vertical unit with rapid cut-off.

- Tandem feed unit in front of universal unit with rapid cut-off.

- Traction wheels flanged in correspondence to the left vertical unit with manual horizontal movement.

- Supplementary vertical roller presser

- Supplementary steel feed roller, 140 x 25 mm

- Supplementary flanged steel feed roller, 140 x 25 mm

- Supplementary rubber feed roller, 140 x 25 mm

- Supplementary flanged rubber feed roller, 140 x 25 mm

- Supplementary knurled feed roller, 140 x 25 mm

- Supplementary flanged knurled feed roller, 140 x 25 mm

Optionals for table and guides

- Hardened insert on inlet table

- Chrome-plated antiwear work tables

- Grooved tables

- Supplementary tables with Rexilon inserts

Optionals for universal spindle unit

- Front and rear pressure pads to be applied on the hood

- Vertical pad presser to use the universal spindle from underneath

- Fitting on supplementary hood for glass stop recovery on the left side

- Static inverter to machine with continuously variable rotation speed from 1000 to 6000 rpm.

- Supplementary suction hood for blade of max. 250 mm.

Various optionals

- “Control 10 Plus” microprocessor electronic control. Allows automatic positioning from the control panel of the left vertical and

the top horizontal units for the different work sections.

- Automatic adjustment device for left vertical spindle to machine pieces of different width in rapid succession.

- Micrometric horizontal adjustment of working width.

- Front presser on hood of top horizontal with parallelogram movement.

- Two-sector pressure shoe located after the top horizontal spindle.

- Kit for glass stop cutting on right side by means of top horizontal spindle.

- Fitting for vertical cut with several blades with second bottom horizontal unit

- Safety device by means of anti-return breaker arms located at the machine inlet.

- 25 HP (18.5 kW) motor for second bottom horizontal unit.

- Inlet guide with bearings for automatic feeders.

- Electrical fitting for use of automatic loaders.

- Pump for work table lubrication with manual drive.

- Pump for work table lubrication with automatic drive.

- Manual centralised lubrication.

- Hour counter for hours of service.

- Metre counter with reset.

- Lighting inside the horizontally-pivoted protection.

-Auto-brakingmotor

1.11

SUPERSET XL CNusa1

GENERAL INFORMATION

COMPOSITIONS

Legend:

Bottom horizontal (planer) Top horizontal

Right vertical Left vertical Universal unit

Composition 1

Composition 2

Composition 5

Composition 6

1.12 CNusa1 SUPERSET XL

GENERAL INFORMATION

1-8 NOISE LEVEL

WARNING

The noise values are emission levels and not necessarily safe working levels. Although there is a correlation

betweentheemissionlevelsandtheexposurelevels,itcannotreliablybeusedtodeterminewhetherornotfurther

precautions are required. The factors affecting the real exposure level include the duration of exposure, the

ambientcharacteristics,othersourcesofemission,suchasthenumberofmachinesandotheradjacentmachining

operations.

The exposure levels may also vary from country to country.

However, this information allows the user of the machine to make a better evaluation of the dangers and risks.

Some factors which reduce exposure to noise are:

- Correct tool selection

- Correct speed selection

- Tooland machine maintenance

- Use of the anti-noise covers and protections supplied

- Proper use of hearing protection

Planing and profiling machine model: SUPERSET XL

As per test report: CSR No. 99033

Operating conditions: Planing

Reference norm: ISO 3746/79

Other reference regulations: ISO 7960/95 Annex H UNI EN ISO 11201-97

In idle without suction Running

Sound power

level emitted

dB W (A) [mW (A)] 88.4 [ 0.69 ] 101.5 [ 14.19 ]

Sound pressure level

at operator work

station inlet

dB (A) [dB max]

76.5 90.5 [ 101.1]

Sound pressure level at

operator work station

outlet

dB (A) [dB max]

68.6 84.4 [ 94.8 ]

Constant K = 2 [dB] according to prEN 12750

The above values are referenced to "free range" conditions in compliance with the

test methods as provided by the reference norm.

1.13

SUPERSET XL CNusa1

GENERAL INFORMATION

1615

3496 (*)

866 (*)

900

1600

57

1615

1600

4296 (*)

57

866 (*)

1145

1145

900

900

1-9 OVERALL DIMENSIONS

COMPOSITIONS1AND5

(*)+500mmwithoptional2500mminlettable

COMPOSITIONS2AND6

(*)+500mmwithoptional2500mminlettable

1.14 CNusa1 SUPERSET XL

GENERAL INFORMATION

A

BC

C

*

*

min. 1000 mm

min. 1000 mm

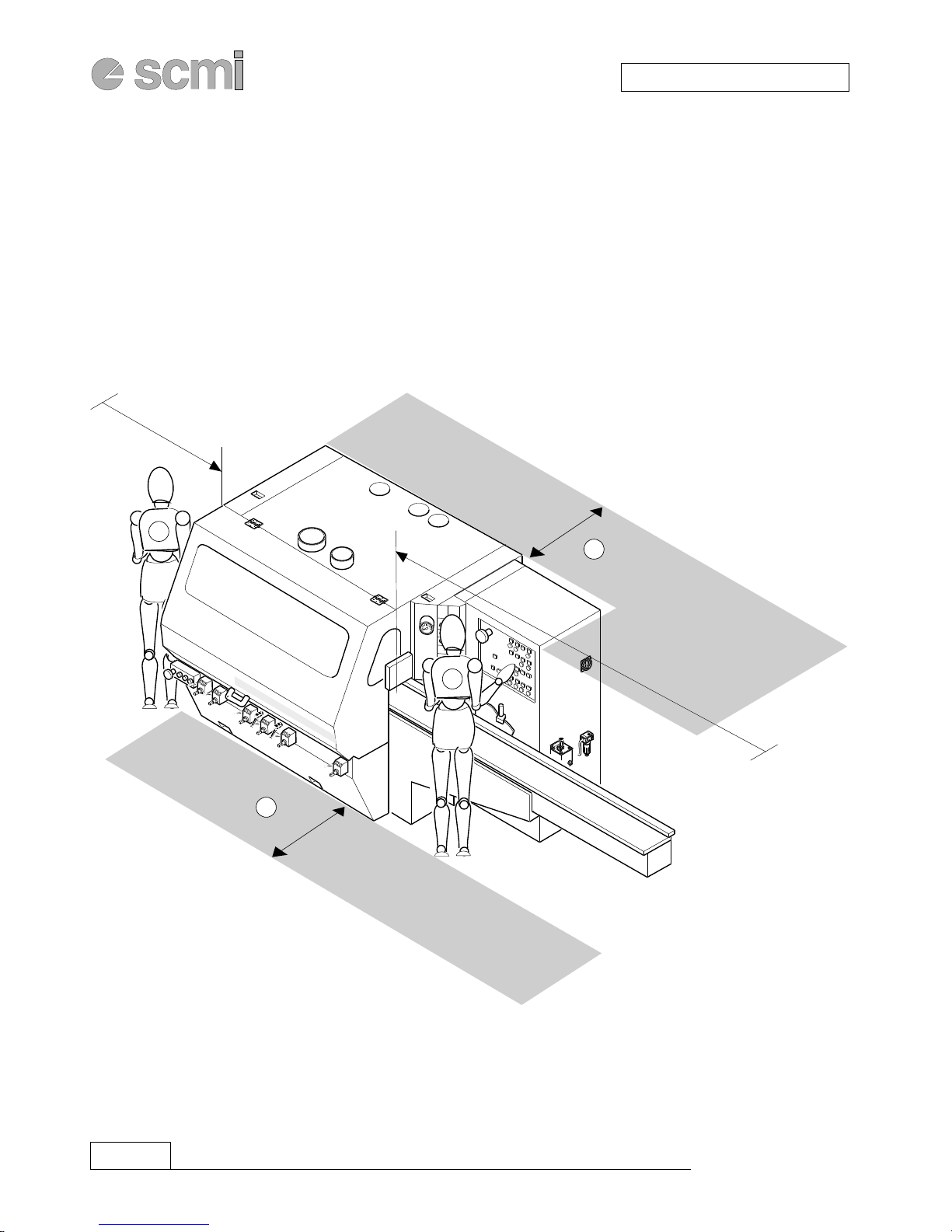

1-10WORK AREAS AND STATIONING

Legend:

A-Controlstationandinsertionofmaterialtobemachined

B-Machinedmaterialunloadingstation

C-Outercontrolareaorpedestrianpassage

NOTE:Thedistance*mustbe800mmlongerthanthelongestpiecetobemachined

CAUTION: Failingtorespecttheminimumfreespacesmaycreatedangerousconditionsfortheoperatorandthe

personnelaroundthemachine.Donotdepositgoodsofanykindwithinthezonelimits.

2.1

SUPERSET XL

INSTALLATION

cnusa2

SECTION2

INSTALLATION

2-1 MACHINEUNLOADING ............................................................................................................... 2.2

2-2 POSITIONING................................................................................................................................. 2.2

2-3 LEVELLING ..................................................................................................................................... 2.2

2-4 ELECTRICAL CONNECTIONANDEARTHING.......................................................................... 2.4

2-5 CONNECTION TO SUCTION SYSTEM....................................................................................... 2.6

2-6 PNEUMATIC CONNECTION ........................................................................................................ 2.8

2.7 SAFETYDEVICES USED ............................................................................................................. 2.10

2.2 cnusa2 SUPERSET XL

INSTALLATION

2-1 MACHINE UNLOADING

Before unloading the machine, remove all the parts used for transport or packaging.

Lift the machine with a crane or other hoisting means, hooking the cables fitted with hooks in the special

attachments(Bfig.2.1).Intheabsenceofsuitablehooks,cableswithslotmayalsobeusedforlifting;inthiscase

thehorizontally-pivotedprotectionmustbeopenedandthesplitpinsremovedfromthepivot.Removethepivots,

place the slots of the cables into position, re-insert the pivots and remount the split pins (C Fig. 2.1 – cable

attachmentsequence).

NOTE: Respect the cable lengths indicated in Fig. 2.1.

During lifting avoid tearing or sudden movements.

Asanalternativetotheinstructionsabove,themachinemayalsobeliftedwithaforklifttruckequippedwithforks

of suitable length, inserting the forks in the special openings indicated with plates (A Fig.2.1).

Adopteverycautiontoexcludeanypossibilityofthemachineturningover,securingitwithcablestothestructure

of the forklift truck.

Ensure that the crane, cables or lift truck have a capacity equal to or greater than the weight of the

machine.

Theweightisindicatedonthemachineidentificationplate (seepoint1-3).

2-2 POSITIONING

Selectthebestposition,withgoodlighting(500LUXminimumisrecommended),takingintoconsiderationthe

connectionstotheelectricline,thecompressedairsystem,thescrapsuctionsystem,andeasymaintenance.The

minimum free space around the perimeter of the machine must be 1000 mm, except in the operator zone for

starting and adjustments where it must be 1500 mm and at the operator work station at the outlet where the

distance must be equal to the maximum length of the machined piece plus 800 mm.

Checkthatthefloorsurfaceissolid(preferablyinnon-deformablematerial,acementfloorisrecommended),so

that the base may find a uniform support at the contact points.

Themachineisgreasedandoiledforreasonsoftransport.

Beforestartingwork,thoroughlyremovethegreasefromtheworkingareasandtheprotections.

Thebaseofthemachineisfittedwithspecialsupportfeetinsidewhichscrewsarefittedformachinelevelling.

2-3 LEVELLING

Position the machine as convenient, and rest a high-precision level (0.05 mm per meter) on the ground table in

correspondencetoeachspindle,firstlongitudinallythentransversally,makingpreliminarycorrectionsbyacting

on the screws (m12x25 hexagonal head in the accessory pack) which have been inserted under the feet. The

supportbosses(PFig.2.1)suppliedintheaccessorypackarepositionedbetweenthescrewsandthefloor.

Againadjustthescrews,simultaneouslycheckingthevariationsproduced.An0.1mmplanarityerroristolerableas

maximumvalueovertheentirelengthoftheworktables.

For transversal levelling place the level near the first spindle and move it by successive sections of 300 mm.

The inlet table must be perfectly aligned with the fixed table of the machine. Misalignment in both directions

between the two tables must not exceed 0.1 mm.

2.3

SUPERSET XL

INSTALLATION

cnusa2

max 90°

≥≥

≥≥

≥1200mm

≥≥

≥≥

≥1400mm

BC

A

P

2.1

2.4 cnusa2 SUPERSET XL

INSTALLATION

2-4 ELECTRICAL CONNECTION AND EARTHING

Theelectricalconnectionandthetestslistedbelowmustalwaysbecarriedoutbyaspecialisedelectrician.

Ensurethattheelectriclineofthefactoryissufficienttosupportthepowerofthemachineandcheckthatthemainsvoltage

correspondstothatofthemachine.

Note: Theidealoperatingconditionforthemachineistosupplytheexactvoltageshownontheidentification

plate in Fig. 2.2; (tolerance ± 5%).

Out of this range, adjust the power supply voltage.

On the machine identification plate, read the value of the total absorbed current (Amp).

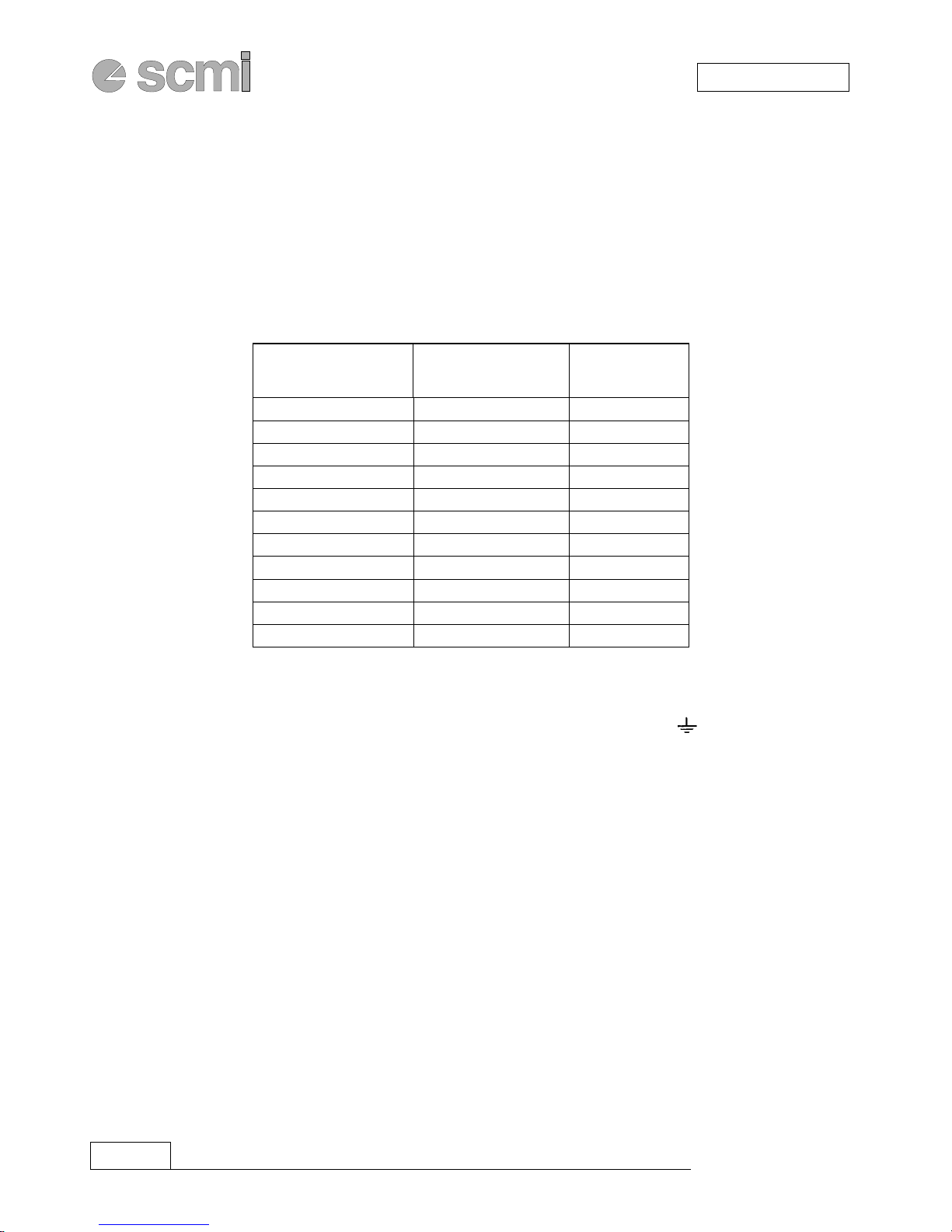

Then, referring to the table below select the cable cross-sections, and the fuses to install upstream of the

machine. The fuses are of the “DELAYED FUSE” (AM) type.

AMPERE ASSORBITI

ELECTRICAL INPUT (AMPERE)

AMPERES ABSORBES

STROMAUFNAHME (AMPERE)

AMPERE ABSORBIDOS

SEZIONE CAVI

CABLE SECTION

SECTION CABLE mm2

KABELQUERSCHNITT

SECCION CABLES

FUSIBILI AM

AM FUSE

FUSIBLE AM

SICHERUNGEN

FUSIBLES AM

fino a/up to/ jusqu'à /bis 10. 2.5 12 A AM

da/from/de/von 10 a/to/à/bis 14 4.0 16 A AM

da/from/de/von 14 a/to/à/bis 18 6.0 20 A AM

da/from/de/von 18 a/to/à/bis 22 6.0 25 A AM

da/from/de/von 22 a/to/à/bis 28 10.0 32 A AM

da/from/de/von 28 a/to/à/bis 36 10.0 40 A AM

da/from/de/von 36 a/to/à/bis 46 16.0 50 A AM

da/from/de/von 46 a/to/à/bis 54 16.0 63 A AM

da/from/de/von 54 a/to/à/bis 76 25.0 80 A AM

da/from/de/von 76 a/to/à/bis 92 35.0 100 A AM

da/from/de/von 92 a/to/à/bis 110 50.0 125 A AM

Electrically isolate the machine by setting the main switch to zero and connect the 3 electrical cables (phases)

to the terminals L1, L2, L3 as in Fig. 2.2.

Connecttheyellow-greencable(earth)totheterminal(PE)ormarkedwiththesymbol ,and theneutralcable,

if present, to the terminal (N).

Shouldthemachine beconnected toa mobilepower cable,use aflexible rubbercable markedwith thesymbols

H07RN-ForA07RN-Fhastobeinaccordancesafetycurrentstandardsofthecountryinwichitwillbeused.

The relevant coupling outlet must comply with the DIN 49463 regulation and the international regulations

IEC309-1andIEC309-2ortosafetycurrentstandardsofthecountryinwichitwillbeused.

Carefullylockthecableclamp(GFig.2.2). Checkthatthespindlerotationdirectioniscorrect(thespindlesmust

rotate in the opposite direction to the piece feed) by starting the machine as described further on.

If the spindles do not turn in the right direction:

- Disconnect the power

- Invert two phases on the terminal board

- Retest the rotation direction.

Warning!!!:In normal operating and maintenance conditions, the door of the electric box must always remain

closed. It may only be opened by a specialised electrician using the special key provided with the

machine and kept by the expert operator.

The complete wiring diagrams and certificates may be found in the accessory bag.

2.5

SUPERSET XL

INSTALLATION

cnusa2

L2 L3

L1

PE

Ref.

G

2.2

Table of contents

Other SCMI Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Henkel

Henkel BONDERITE C-AK 9045-6 AERO Technical bulletin

Omron

Omron SYSMAC NX series Startup guide

permaban

permaban AlphaJoint installation guide

Festo

Festo CRHD Series Repair instructions

MILLART MACHINE TOOLS

MILLART MACHINE TOOLS TB-12 Operation manual

Siemens

Siemens SIMATIC ET 200SP HA Equipment manual