ADCA FLT User manual

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

FLT

INSTALLATION AND MAINTENANCE INSTRUCTIONS

FLOAT AND THERMOSTATIC

STEAM TRAPS

ADCA

We reserve the right to change the design and material of this product without notice.

FLT20 / FLT21 / FLT25

FLT30 / FLT31 / FLT35

FLT40 / FLT41 / FLT45

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

GENERAL INFORMATION

• These instructions must be carefully read before performing any work involving

VALSTEAM ADCA products. Failure to observe these instructions may result in

hazardous situations.

• These instructions describe the entire life cycle of the product. Keep them in a

location that is accessible to every user and make these instructions available to

every new owner of the product.

• Current regional and plant safety regulations must be considered and followed

during installation, operation, and maintenance work.

• The images shown in these instructions are for illustration purposes only.

• For the problems that cannot be solved with the help of these instructions, please

contact VALSTEAM ADCA or its representative.

VALSTEAM ADCA ENGINEERING S.A

Zona Ind.da Guia

Pav.14 - Brejo

3105-467 Guia, Pombal

PORTUGAL

We reserve the right to change the design and material of this product without notice.

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

CONTENT

1. SAFETY INFORMATION 5

1.1. Explanation of symbols 5

1.2. Intended use 5

1.3. Qualication of personnel 6

1.4. Personal protective equipment 6

1.5. The system 6

1.6. ATEX 7

1.7. General safety notes 7

2. PRODUCT INFORMATION 9

2.1. Principle of operation 9

2.2. Certication 10

2.3. Product identication 11

2.4. Technical data 11

3. TRANSPORT, STORAGE AND PACKAGING 12

4. INSTALLATION 13

4.1. Preparation for installation 13

4.2. Changing ow direction 15

4.3. Installation procedure 17

5. START-UP 17

5.1. Preparation for start-up 17

5.2. Start-up procedure 18

6. OPERATION 19

6.1. Operating the BDV and HVV units 19

6.2. Operating the FLL 19

7. SHUTDOWN 20

7.1. Shutdown procedure 20

8. PARTS LIST 21

9. MAINTENANCE 23

9.1. Maintenance procedure 23

9.2. Cleaning/replacing the mechanism assembly 23

9.3. Replacing the oat 24

9.4. Fitting the retrot BDV, HVV, AFZ and VB21M units 25

9.5. Replacing the FLL oat lifting lever 25

9.6. Tightening torques 26

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

CONTENT

10. TROUBLESHOOTING 26

11. DISPOSAL 27

12. RETURNING PRODUCTS 27

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

5

1. SAFETY INFORMATION

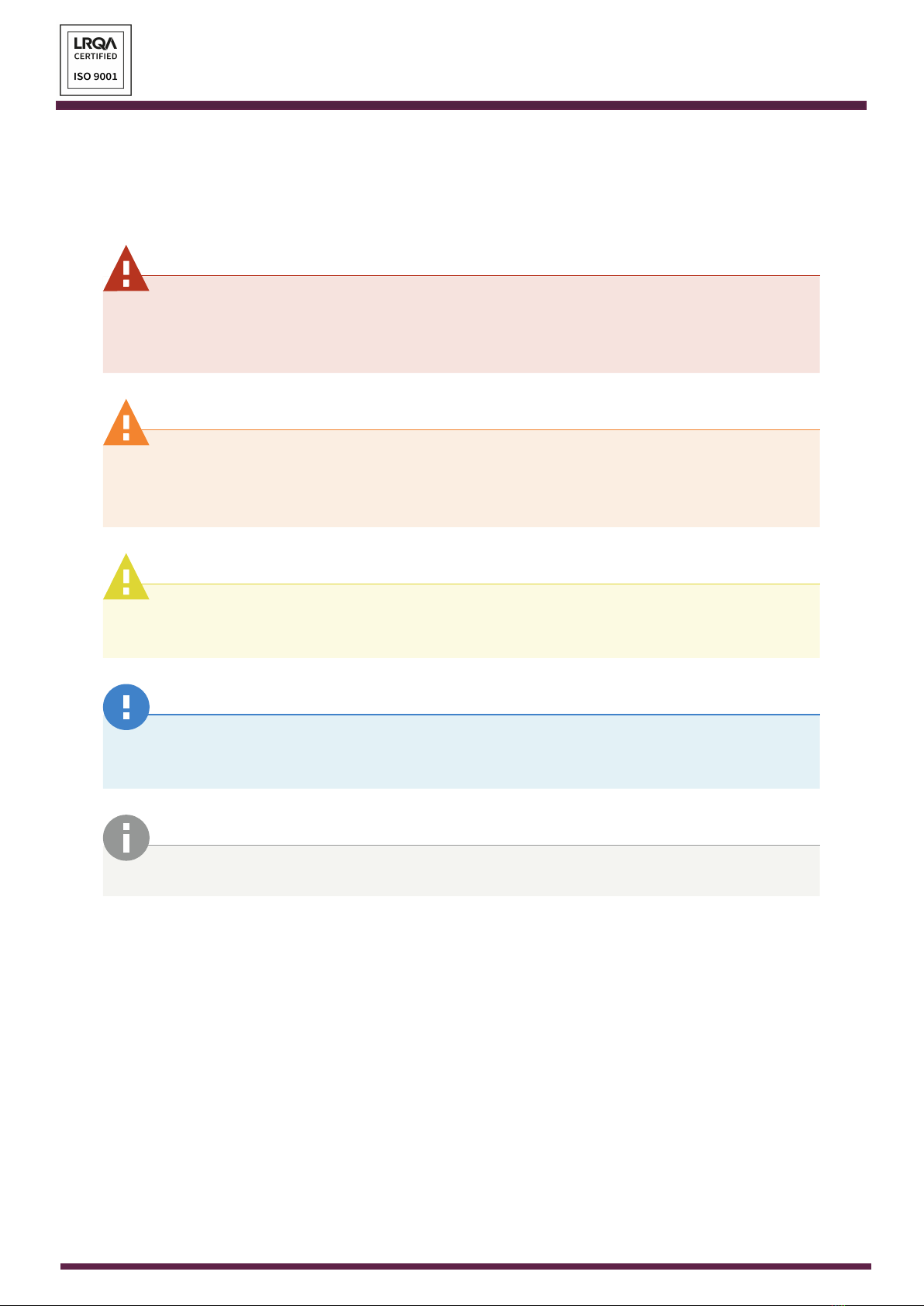

1.1. Explanation of symbols

Hazardous situation which, if not avoided by applying the correct preventive

measures, will result in fatal or serious injury and/or considerable damage to

property.

DANGER

Hazardous situation which, if not avoided by applying the correct preventive

measures, could result in fatal or serious injury and/or considerable damage

to property.

WARNING

Hazardous situation which, if not avoided by applying the correct preventive

measures, could result in moderately severe or minor injury.

CAUTION

Situation which, if not avoided, can result in property damage or product

malfunction.

NOTICE

Indicates additional information, tips and recommendations.

NOTE

1.2. Intended use

Refer to the markings on the device, such as nameplate and laser markings, Information

Sheet (IS) and these Installation and Maintenance Instructions (IMI) to check that the

product was designed for the intended use and meets the specications used for sizing

and selection. This includes checking application, material suitability, process medium,

pressure and temperature as well as their respective limiting values.

VALSTEAM ADCA does not assume any responsibility for damage resulting from

inappropriate use of the product, damage caused by external stresses or any other

external factors. Correct installation of the product is the full responsibility of the contractor.

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

6

Inappropriate use of the product is any use other than the one described in this chapter.

Inappropriate use also includes:

• Use of spare parts which are not genuine;

• Performance of maintenance work not described in these instructions;

• Use outside the limits dened by the accessories connected to the product.

• Unauthorized modications to the product.

If the product is to be used for an application or with a uid other than the one it was

designed for, contact VALSTEAM ADCA.

1.3. Qualication of personnel

Handling, installation, operation and maintenance work must be carried out by fully

trained and qualied personnel, capable of judging the work which they are assigned

to perform and recognizing potentially hazardous situations. They should be trained to

properly use this product according to these Installation and Maintenance Instructions.

Where a formal “Permits to Work” system is implemented in the plant it must be complied

with.

1.4. Personal protective equipment

Personal protective equipment should always be worn during work in order to protect

against hazards posed by e.g. the process medium, dangerous temperatures, noise,

falling or projected objects, working at height. These equipment includes a helmet, safety

glasses, safety harness, protective clothes, safety shoes, hearing protection, etc.

Always assess whether you or others in your vicinity require any protective

equipment. When in doubt check with the plant’s health & safety responsible

personnel for details on required protective equipment.

NOTE

1.5. The system

The complete system should be assessed as well as every action (e.g. closing of shut-

o valves, disconnection of the power supply) to ensure this will not bring additional risk

to personnel or property.

Dangerous actions that can result in a hazardous situation include isolation of protective

devices such as safety valve, vents, vacuum relief valves, disconnection of electric safety

devices, sensors and alarms.

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

7

1.6. ATEX

If the product is in the scope of the ATEX 2014/34/EU directive and as such bears the Ex

marking, consult its specic Additional Instructions for use in Potentially Explosive Areas

(IMI EX). In such cases, handling, installation, operation and maintenance work must

only be performed by personnel qualied and authorized to work in potentially explosive

areas.

1.7. General safety notes

RISK OF BURSTING IN PRESSURE EQUIPMENT

Valves, ancillaries and pipelines are pressure equipment. Working above

their operating limits or improper opening can lead to component bursting.

• Observe the maximum operating limits of the product and check if they are

lower than those of the system in which it is being installed. Check the product

Information Sheet (IS).

• Install a safety device.

• Before starting any work on the product, depressurize it and cool or heat it up

to ambient temperature. This also applies to the line in which it is tted.

• Drain the process medium from the product and all the relevant plant sections.

DANGER

RISK OF BURNS

Depending on the operating conditions, products and pipelines may get very

hot or cold and cause burn injuries.

• Do not touch the product while it is hot or cold, allowing it rstly to cool down

or heat up.

• Wear protective clothing and safety gloves during working operation.

• Thermally insulate tubes and product’s as a preventive measure.

RISK OF INJURY CAUSED BY FLUID ATTACK ON PRODUCTS

MATERIALS

The product must only be used with mediums that do not attack the materials

of the product (body, gaskets, seals). Otherwise, leaks may occur, and hot

and/or hazardous uid can escape.

• Do not use the product with mediums other than the ones it was designed for.

Check section 1.2 - Intended Use.

• Prevent medium contamination.

WARNING

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

8

RISK OF INJURY CAUSED BY UNDER TIGHTENED PRODUCT OR

ITS COMPONENTS

Excessively low tightening torques may cause medium to escape or and/or

components to be projected at high speed which may result in a hazardous

situation depending on the medium, chemical properties and/or its operating

conditions.

• Do not loosen any screw while the equipment is pressurized.

• Observe the specied tightening torques on these Installation and Maintenance

Instructions. If the relevant torque value is not mentioned contact VALSTEAM

ADCA.

RISK OF HEARING LOSS

Depending on the operating conditions, the product may generate loud

noises.

• Wear hearing protection when in the vicinity of the product.

RISK OF INJURY AS A RESULT OF ILLEGIBLE INFORMATION

Important information written in the product nameplate, markings and warning

signs may wear overtime or get illegible due to e.g. dirt accumulation, resulting

in hazardous situations and personal injury or property damage.

• Keep nameplates, markings and warning signs in a legible state, replacing

when illegible, missing or damaged.

WARNING

RISK OF INJURY DUE TO RESIDUAL PROCESS MEDIUM

Direct contact with dangerous process medium may lead to personal injury,

e.g. smoke inhalation and chemical burns.

• Drain the process medium from the product and all the relevant plant sections.

• Wear protective clothing, safety gloves, mask, and eye protection.

RISK OF INJURY DUE TO IMPROPER HANDLING

Manual handling (e.g. lifting, carrying, pushing, pulling) of large and/or heavy

products may result in personal injury.

• Assess the risk associated with the handling task.

• Use adequate handling methods and appropriate auxiliary handling equipment.

CAUTION

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

9

RISK OF PRODUCT DAMAGE DUE TO EXCESSIVELY HIGH

TIGHTENING TORQUES

High tightening torques may lead to premature wearing of product components.

• Observe the specied tightening torques on these Installation and Maintenance

Instructions. If the relevant torque value is not mentioned contact VALSTEAM

ADCA.

NOTICE

2. PRODUCT INFORMATION

The ADCA FLT20, FLT21 and FLT25 (SG iron), FLT30, FLT31 and FLT35 (carbon steel)

and FLT40, FLT41 and FLT45 (stainless steel) are oat and thermostatic steam traps

with integral air vent designed for modulating discharge of condensate and air venting,

ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and

other applications where continuous discharge is essential.

These steam traps can be installed in horizontal or vertical pipelines and are available

with inline or angled variants to suit system design.

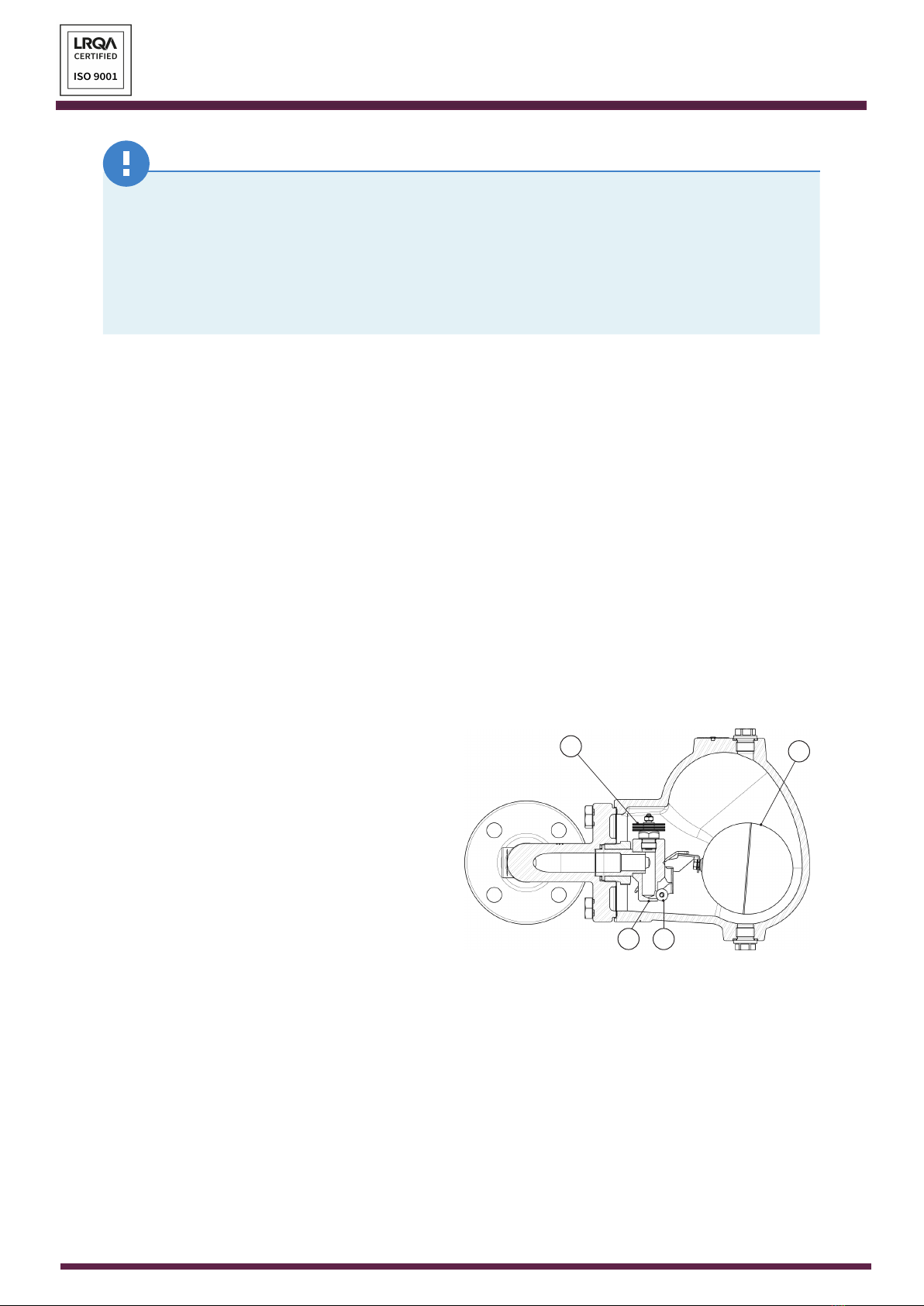

2.1. Principle of operation

A oat (8) opens or closes the valve seat

(4), by moving a ball (6) via a simple

lever mechanism according with the

condensate level inside the steam trap,

changing its position in relation to the

seat. Condensate discharge and opening

of the equipment is proportional to the

movement of the oat. As the oat rises,

so does the discharge capacity. Discharge

is modulating and does not interfere with

automatic controls, if tted.

Air venting is ensured by a thermostatic

air vent (9) located in the steam space above the condensate level. After releasing the

initial air, it remains closed until air and other non-condensable gases accumulate during

normal operation and cause it to open by reducing the temperature of the air/steam

mixture. The thermostatic air vent oers the added benet of increasing condensate

capacity on cold start-up.

The steam trap can be supplied without air vent.

9

4

Fig. 1

6

8

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

10

Thermostatic capsule air vents are available on request in alternative to the standard

bimetallic air vent.

The steam trap can be supplied with a variety of options, most of which can also be

retrotted in case the steam trap has been supplied with the optional top and bottom

cover connections.

The steam lock release (SLR) consists in a needle valve integrated in the steam trap

body. Its aperture is tunned manually, with a screwdriver, to allow constant bleeding of

steam, just enough to prevent steam locking. This option is not retrottable.

The oat lifting lever (FLL) is used to manually open the steam trap main valve, to drain

its content or to check the current oat position. This option is not retrottable.

The hand vent valve (HVV) is a retrottable option which can be installed on the top

cover connection. It is used for manual venting and/or depressurization.

The blowdown valve (BDV) is a retrottable option which can be installed on the bottom

cover connection. It is used as a manual drain and/or depressurization.

The anti-freeze device (AFZ) is a retrottable option which can be installed on the

bottom cover connection. It is used for automatic discharge of condensate after system

shutdown to prevent it from freezing inside the steam trap. The valve consists in a simple

mechanism with a spring and a stainless steel ball. The spring force keeps the valve

open as long as the medium pressure is below approximately 0,3 bar, at which point the

medium pressure pushes the ball against the seat and closes the valve.

The vacuum breaker (VB21M) is a retrottable option which can be installed on the

top cover connection. It is used to protect plant and process equipment, such as heat

exchangers, against vacuum condition. A stainless steel ball remains on the seat of the

vacuum breaker when the system is under positive pressure. The ball lifts o the seat in

case of vacuum formation, and air is drawn into the equipment “breaking” the vacuum.

2.2. Certication

This product has been specically designed for use with liquids and gases which are

in Group 2 of the European PED – 2014/68/EU Pressure Equipment Directive and it

complies with its requirements.

FLT20, FLT21 and FLT25 – CE MARKING – GROUP 2 (PED – European Directive)

PN 16 Category

All sizes SEP

FLT30, FLT31, FLT40 and FLT41 – CE MARKING – GROUP 2 (PED – European Directive)

PN 40 Category

All sizes SEP

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

11

FLT35 and FLT45 – CE MARKING – GROUP 2 (PED – European Directive)

CLASS 150 PN 40 Category

All sizes – SEP

– All sizes 1 (CE marked)

If the product falls within category SEP it must not be CE marked, unless

other directives are applicable.

NOTE

This product is not in the scope of the ATEX 2014/34/EU directive as it does not have its

own potential ignition source. Personnel responsible for the plant installation must assess

the risks caused by static electricity and take the necessary precautionary measures to

prevent static charge. These measures include e.g. connection of the product to the

equipotential bonding system.

2.3. Product identication

The following items are indicated on the product nameplate or directly on its body:

• Manufacturer

• Product model (e.g. FLT30)

• Pressure rating (e.g. PN 40)

• Nominal size (e.g. NPS 3/4")

• Max. dierential pressure (e.g. DP: 4,5 bar)

• Max. operating temperature (e.g. TMO: 250 ºC)

• Max. operating pressure (e.g. PMO: 32 bar)

• Min. admissible temperature (e.g. -10 ºC)

• Max. admissible temperature (e.g. TMA: 300 ºC @ 27,6 bar)

• Max. admissible pressure (e.g. PMA: 37,1 bar @ 100 ºC)

• Flow direction (indicated by an arrow)

• Serial number and year of manufacturing (e.g. Reg.:17483/19)

• CE Marking (when applicable – see section 2.2 – Certication)

• EX Marking (when applicable e.g. EX h IIB T6…T3 Gb – see section 2.2 –

Certication)

2.4. Technical data

For technical data including dimensions, materials, limiting conditions and versions refer

to the product respective Information Sheet (IS).

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

12

3. TRANSPORT, STORAGE AND PACKAGING

RISK DUE TO FALLING LOADS

Loads may tip or fall over resulting in demage to property, serious injury or

death.

• Use suitable equipment when moving or lifting suspended loads.

• Make sure no one is standing below the suspended load.

WARNING

RISK OF INJURY DUE TO IMPROPER HANDLING

Manual handling (e.g. lifting, carrying, pushing, pulling) of large and/or heavy

products may result in personal injury such as back injury.

• Assess the risk associated with the handling task.

• Use adequate handling methods and appropriate auxiliary handling equipment.

CAUTION

RISK OF PRODUCT DAMAGE DUE TO IMPROPER STORAGE

• Do not remove any packaging or protective covers until immediately before

installation at the site.

• Store the product in a solid base in a dry, cool and dust-free environment.

• Until its installation, protect it from the weather, dirt, corrosive atmospheres and

other harmful inuences.

RISK OF PRODUCT DAMAGE DUE TO LONG TERM STORAGE

Some product components may deteriorate with time (e.g. valve packings,

seals).

• Do not store the product for more than 12 months.

• If for any reason the product must be stored for longer periods of time contact

VALSTEAM ADCA.

NOTICE

Products are individually wrapped in plastic lm, thermo shrinkable plastic and/or stored

in a cardboard box as they leave VALSTEAM ADCA. Avoid removing packaging and any

protective cover until immediately before installing the product at the site.

If the transport packaging has any shipping damage contact VALSTEAM

ADCA or its representative.

NOTE

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

13

Before storing and transporting the product protect it from impacts and mechanical

damage, paying special care with sealing surfaces and other fragile parts.

If the corrosion protection (paint and other surface coatings) of the product is

damaged during transport or other handling procedures repair it immediately.

NOTE

4. INSTALLATION

Before performing any installation work, refer to section 1 – Safety information.

RISK OF INJURY DUE TO INSUFFICIENT SUPPORT

DURING INSTALLATION

Insucient support of the product during installation may cause it to fall and

cause personal injury.

• Ensure the product is safely held in place during installation.

• Wear protective safety shoes.

WARNING

RISK OF PRODUCT DAMAGE DUE TO STRESS

The product is not intended to withstand external stresses that may be

inducted by the system to which it is being connected to.

• Make sure that the connected pipe does not subject the body to any stress

(forces or torques) during installation and operation.

• Do not use the product as an elevation point.

NOTICE

4.1. Preparation for installation

Before installation, make sure the following conditions are met:

• The installation area has easy access and the product is to be installed in a position

where operation and maintenance work can be performed safely.

• The product will be installed with proper support and free of any stresses that can

be induced by the system due to e.g. pipe expansions. The necessary precautions

are recommended during system design.

• The pipeline where the product will be installed is designed in such a way that it

takes into account the weight of the product. The pipeline may require support on

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

14

both sides next to the product, particularly if its size and weight are considerable

and especially if vibrations are to be expected in the system.

• The product is not damaged.

• Make sure all the necessary materials and tools are readily available during

installation work.

• Referring to this Installation and Maintenance Instructions (IMI), Information Sheet

(IS) and nameplate, check that the product is suitable for the intended installation:

temperature, medium, pressure, temperature, etc. – see section 1.2 – Intended

use.

• Check that there are no foreign bodies inside the pipelines and ancillaries, ushing

may be necessary. These should be thoroughly cleaned.

• Check any mounted pressure gauges and make sure these function properly.

• An additional ADCA pipeline strainer or lter may be necessary to install upstream

of the steam trap in some applications, preventing solid particles in the process

medium from damaging it.

• A balance pipe can be connected to the optional top cover connection. This is

useful in some applications, particularly when the steam trap is not tted with an air

vent. The cross section of the balance pipe must be at least DN 8 - 1/4".

• The pipelines are layed out with a gradient so that condensate is free to fall towards

the steam trap.

Assembly Drawings (AD) with assembly details and parts lists are available

on request.

NOTE

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

15

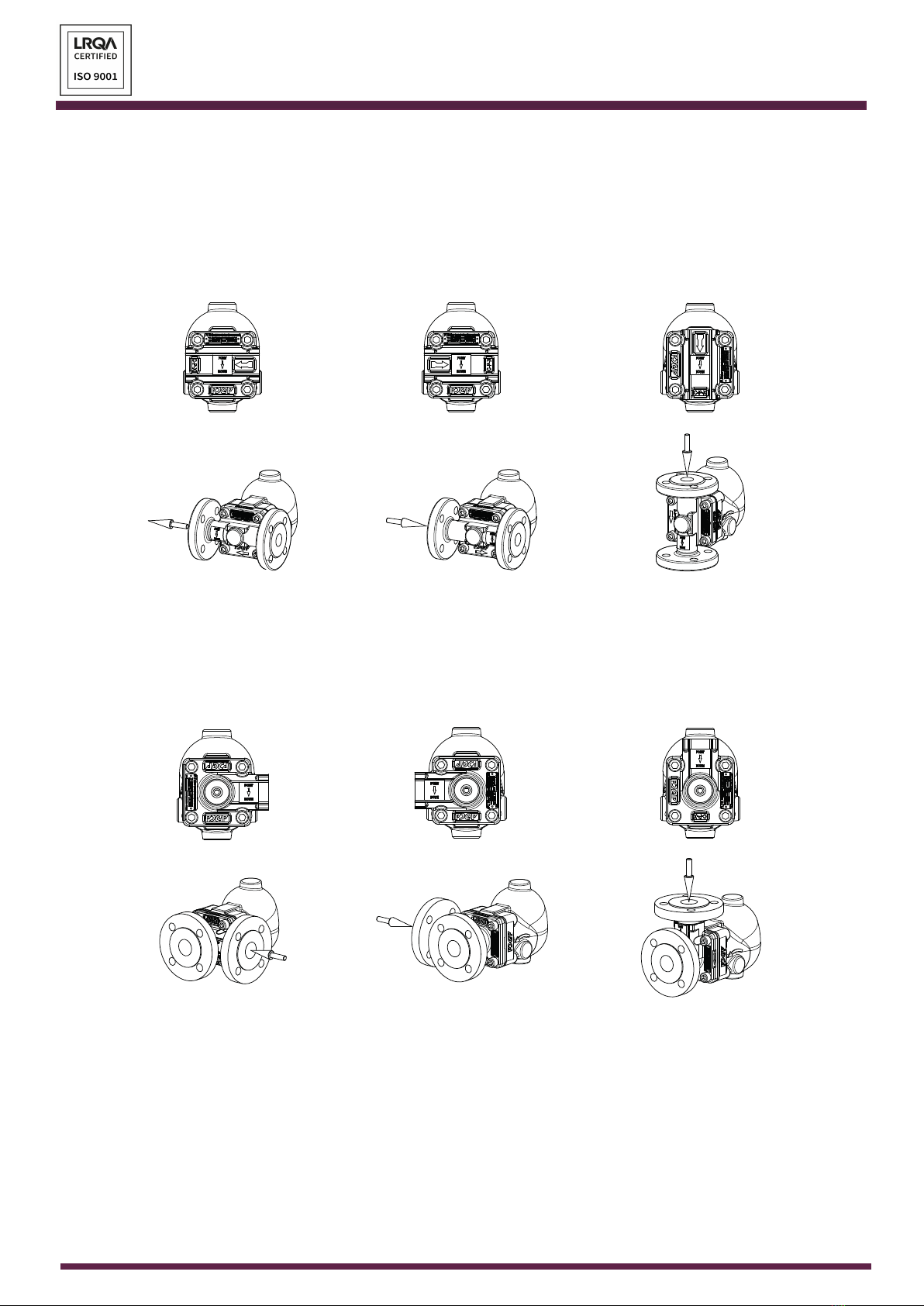

4.2. Changing ow direction

The steam trap ow direction can be easily changed by repositioning the body (1) in

relation to the mechanism (4, 6, 7, 8, 9) and cover (2).

The following ow directions are possible for steam traps with inline connections:

Fig. 2 - Flow direction options for steam traps with inline connections.

IR - Horizontal from right to left IL - Horizontal from left to right IT - Vertical from top to bottom

The following ow directions are possible for steam traps with angled connections:

Fig. 3 - Flow direction options for steam traps with angled connections.

AR - Angled from right to front AL - Angled from left to front AT - Angled from top to front

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

16

To change ow direction proceed according to the following steps:

Fig. 4 - Flow direction change.

9 8

64

7

53110

24A

1. Undo the bolts (10) gradually in a crisscross pattern and separate the cover (2)

from the body (1).

2. Remove the body gasket (3) and clean surfaces thoroughly, leaving no remaining

graphite leftovers.

3. Unscrew the seat nut (4A), inspect the gasket (5) and replace if necessary.

4. Screw the seat nut (4A) loosely once again.

5. Rotate the body (1) to meet the desired ow direction according to Fig. 2 and Fig.

3, keeping the mechanism assembly (4, 6, 7, 8, 9) with the automatic air vent (9)

pointing upwards. Replace the "POINT DOWN" sticker accordingly.

6. Secure the seat (4) and tighten the seat nut (4A) with the recommended torque –

see section 9.6 – Tightening torques.

7. Fit a new body gasket (3) and install the cover (2) with the protruding section

pointing upwards.

8. Apply a suitable lubricant to the threads of the bolts (10), and tighten gradually in

a crisscross pattern until the recommended torque is acheived – see section 9.6 –

Tightening torques.

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

17

4.3. Installation procedure

1. Remove plastic lm and other packaging, as well as the protective covers which

are placed on anges or connection ends. Make sure the steam trap is free from

foreign matter.

2. The steam trap can be installed in any of the positions shown in Fig. 2 and Fig. 3.

3. The steam trap has an arrow or inlet/outlet designations, be sure that it is installed

in the appropriate direction according to uid ow. The "POINT DOWN" sticker

must have the arrow pointing downwards.

4. Take care with jointing materials and sealing compounds to ensure that none may

be permitted to block or enter the steam trap causing malfunction. In case of anged

connections use appropriate ange gaskets.

5. When a socket weld or butt weld version is being installed, the welding should

be carried out by qualifed personnel following an appropriate welding procedure.

Do not weld on top of the corrosion protection (paint, surface coatings). If there is

corrosion protection on the welding ends remove it before welding. After welding

the steam trap to the pipeline repair its corrosion protection.

6. When welding the steam trap to the pipeline make sure to restrict the heat-aected

area to the weld seam, if not possible remove the mechanism assembly (4, 6, 7, 8,

9) prior to welding – see section 9.2 – Cleaning/replacing the mechanism.

5. START-UP

Before performing the start-up procedure, refer to section 1 – Safety information.

The start-up procedure must be followed every time the product is put back into service.

5.1. Preparation for start-up

Before starting up, make sure the following conditions are met:

• All works on the system have been completed.

• All the necessary safety devices have been installed.

• When required, warning notices are used to alert others that the system is starting

up.

• The product is correctly installed – see section 4 – Installation.

• Referring to these Installation and Maintenance Instructions (IMI), Information Sheet

(IS) and nameplate, check that the product is suitable for the intended installation:

temperature, medium, pressure, temperature, etc. – see section 1.2 – Intended

use.

• A safety check was performed by qualied personnel. Checking for leaks, structural

damage and integrity of system components.

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

18

RISK OF PRODUCT DAMAGE DUE TO CONTAMINATION

The plant operator is responsible for cleaning the pipelines in the plant as

well as keeping the product well maintained. At start-up, the presence of

small particles in the medium (dirt, scale, weld splatters, etc.) may damage

the product or cause malfunction.

• Flush pipelines before start-up.

• Clean protection varnishes from pipes and anges, leftover paint, graphite,

grease, etc.

• Use a pipeline strainer or a lter.

NOTICE

5.2. Start-up procedure

1. Open shut-o valves slowly, until normal operating conditions are achieved.

2. Check for any leaks.

3. Check the steam trap to ensure it is operating correctly.

24 hours after system start-up, it is recommended to check pipe connection

for leaks and retighten when necessary. Clean strainers/lters to avoid

blocking.

NOTE

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

19

6. OPERATION

Before operating the product refer to section 1 – Safety information.

Immediately after completing the start-up procedure, the product is ready for operation.

6.1. Operating the BDV and HVV units

RISK OF BURNS FROM BDV AND HVV VALVE OPERATION

Operating the BDV and HVV valve discharges hot medium to the atmosphere

which may cause burn injuries.

• Wear protective clothing, safety glasses and heat-resistant gloves during

operation.

• When operating the valve stand to the side well clear of its outlet.

RISK OF INJURY DUE TO EXCESSIVELY LOOSENING THE BDV OR

HVV VALVE SCREW

Excessively loosening the valve screw while operating may cause the retainer

to break or come loose. This may result in the screw blowing o leading to

personal injury and product malfunction.

• Loosen the valve screw slowly and do not unscrew it excessively.

WARNING

1. Open the BDV or HVV by slowly unscrewing the valve screw. Be careful to avoid

contact with the hot medium which will be discharged trough the valve whole as it

opens.

2. Close the valve by tightening the valve screw to a torque of 20 to 25 Nm ensuring

that there is no leakage.

3. Periodical valve operation is recommended to ensure correct functioning.

6.2. Operating the FLL

1. Turn the lever (33) anticlockwise (viewing the lever from the front) to lift the oat

and open the valve seat.

2. Turn the lever (33) clockwise (viewing the lever from the front) to let the oat

drop and close the valve seat. If there is condensate inside the steam trap body

keeping the oat buoyant then the valve will only close once it has been discharged

independently if the lever (33) is turned clockwise or not.

VA L STEAM

ADCA

IMI FLT20.015 E 00.22

ADCA

20

7. SHUTDOWN

Before performing the shutdown procedure, refer to section 1 – Safety information.

7.1. Shutdown procedure

1. Switch o the system and secure it so it cannot be turned on by unauthorized

personnel.

2. Fully close the upstream shut-o valve, to stop the process medium from owing

through the steam trap.

3. Make sure the pipeline and the steam trap are not under pressure and are at a safe

temperature.

4. Allow medium to cool down and completely drain it from the pipeline and steam

trap.

5. Fully close the downstream shut-o valve.

6. If the steam trap is to be removed from the pipeline – see section 3 - Transport,

storage and packaging.

Other manuals for FLT

1

This manual suits for next models

9

Table of contents

Other ADCA Industrial Equipment manuals