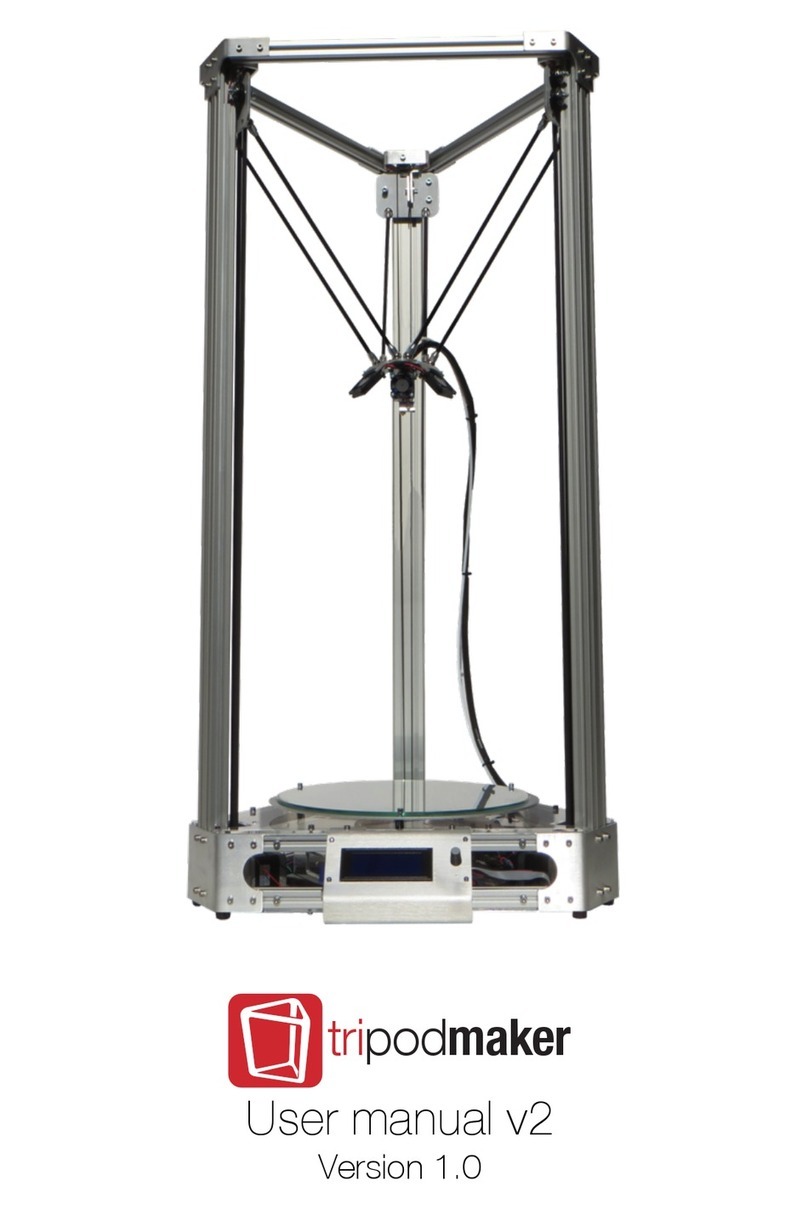

Tripodmaker Black Edition User manual

TRIPODMAKER BLACK EDITION

USER MANUAL

2 3

TABLE OF CONTENT

Specicaons and box content

1. Specicaons of the Tripodmaker..................................................................4

2. Box content.......................................................................................................5

3. Terminology........................................................................................................6

4. Aenons and warnings................................................................................8

Unboxing

1. Preparaons.....................................................................................................10

2. Load lament....................................................................................................11

3. Calibraon........................................................................................................12

4. Plexi covers......................................................................................................15

Menu

1. Info screen.......................................................................................................16

2. Quick sengs...................................................................................................18

3. Print le.............................................................................................................19

4. Extruder............................................................................................................20

5. SD card.............................................................................................................21

6. Conguraon...................................................................................................22

MAINTENANCE & TROUBLESHOOTING

1. General..............................................................................................................24

2. Extruder drive cleaning...................................................................................26

3. Cart alignment..................................................................................................28

4. Clogged nozzle - Cold pull ................................................................................34

5. Troubleshoong and easy xes.....................................................................36

THANK YOU

for your purchasing a Tripodmaker!

This is the user manual for your Tripodmaker Black Edion. In this manual, you will

be guided through the prinng process. Read this manual carefully and take the

needed me to get familiar with your new product. This is a manufacturing device

that requires thorough understanding. If for any reason something would be unclear

or wrong, feel free to contact us at: info@tripodmaker.com

4 5

SPECIFICATIONS OF THE TRIPODMAKER

HARDWARE

technology FDM (Fused Deposion modeling)

dimensions 42 cm x 53 cm x 101 cm

shipping dimensions 45 cm x 55 cm x 110 cm

weight 23 kg

shipping weight 25 kg

print area Ø 30 cm x 45 cm

nozzle Ø 0.4 mm; full metal - up to 295°C

heated bed up to 95°C

power 88 - 264 V; 47 - 63 Hz; 5A

connecvity Stand alone prinng from SD card

casing plexi cover (oponal)

MATERIALS

diameter 1.75 mm

plascs PLA; PETG; HIPS; ABS; Polycarbonate

SOFTWARE

soware PRISMA cloud plaorm

printable les .STL

supported Chrome - Safari - Firefox

PERFORMANCE

bed leveling full automac / manual screw assisted

layer thickness / resoluon 75 micron - 300 micron

machine tolerance 0.1 mm

BOX CONTENT

Next to your Tripodmaker, which had the SD-card inserted, there are other

components in the box. Here the list:

1X Filament spool

(can be in any color)

1X Power cable

1X Power source

2X Spool holders

1X USB cable

1X Filament guidance

tube

1X Blue tape

1X Test print

1X User manual

Tripodmaker // Specicaons Tripodmaker // Specicaons

6 7

TERMINOLOGY

PRINT HEAD / HOT-END

1. Display

2. SD-card slot

3. Push and rotate buon

4. USB Socket

5. Build plate

6. Spool holder

mount locaon

7. Filament guide tube

8. Print head cables

9. Filament driver

10. Rods

11. Carts (wheels or linear sliders)

12. Vercal slides

1

1

2

3

7

8

9

6

3

4

5

10

12

11

2

1. Nozzle

2. Probe

3. Cooling fans

Tripodmaker // Specicaons Tripodmaker // Specicaons

8 9

ATTENTIONS AND WARNINGS

Please read this aenons carefully and keep them in mind while unboxing and

operang the device.

ATTENTION! Make sure your power

switch is in the OFF

[o] posion before you aach or

detach the power cable.

ATTENTION! Turning the

-Tripodmaker ON lights up the LCD

screen and the LED lights.

-Switching OFF can be done at any

me, however it is recommended

to only turn it of when not in use.

-Turning the Tripodmaker OFF

exnguishes the LCD screen.

ATTENTION! Using a glass or

wooden sheet to cover the original

aluminum build plate will make the

nozzle crash. The sensor is

unable to sense the aluminum

through these sheets of glass or

wood.

ATTENTION! make sure your plate is

free of objects.

ATTENTION! When storing your

spool, make sure your lament

doesn’t get tangled as this might

block the unwinding of the spool in a

next print

The TripodMaker is an electrical device and contains motors and hot elements.

During operaon of the printer, be always aware of possible hazards.

WARNING! Age Warning

User under the age of 18 are recommended adult supervision. The printer

includes small parts that can lead to choking.

WARNING! Burn Hazard

The extruder nozzle or heated building plaorm might be hot during operaon.

Never touch these before they cooled down. This can take more than 20 minutes.

Also the extruded plasc is hot and should not be touched.

WARNING! Electric Shock Hazard

When the printer powered, touching the electronics may result in an electric

shock. Make sure you disconnected the power source and power supply when

opening the electronics. Wait at least one minute before opening the box to allow

the power supply to discharge.

WARNING! Fire Hazard

Keep ammable liquids and/or materials away from the printer when powered or

in operaon.

WARNING! Pinch Hazard

During operaon, keep ngers, hair and loose clothing away from moving parts

like belts, pulleys, gears or fans.

WARNING! Stac Charge

Ground yourself before touching the printer electronics. Electrostac charge can

damage electronic components. Ground yourself by touching a grounded source.

ATTENTION! During the prinng

process, the hot-end and print bed

can get hot. Do not touch these unl

prinng is done.

Tripodmaker // Aenons and warnings Tripodmaker // Aenons and warnings

10 11

UNBOXING

Go to prisma.tripodmaker.com and enter your device ID. The setup process will

guide you with a series of instrucon videos unl your rst test print.

The steps are also covered in this manual.

STEP 1. PREPERATIONS

Place the Tripodmaker box on a

stable surface with great access on

all sides.

Open the top and take out all

accessories (Spool/cables/etc)

Now lt the box on its side and open

the boom

Tilt the box back in it’s upright

posion.

Now you can li the box while the

printer remains on the oor.

Posion your Tripodmaker on a

sturdy table.

Now cut the zipes around the 3

belts so the catridges can move

freely.

Plug it in the electrical outlet and

turn your device on.

Make sure the fan on the back of the

printhead is on.

Tripodmaker // Unboxing

Put blue tape on the printbed.

Install the spoolholders. Note that

some forces might be needed.

STEP 2. LOAD FILAMENT

Navigate to the change lament

menu quick sengs/change lament

Wait for the printer to heat up and

stop retracng. An insert lament

message will appear

Cut the lament to have a sharp p

Push the lament through the small

bowden tube

Place the spool on top of the printer

like in the picture

Push down the extruder drive screw

and insert the lament.

The lament should be visible in the

bowden tube for 1 cm.

Tripodmaker // Unboxing

12 13

Iniate the lament loading by

rotang the buon.

Aer the lament stops loading,

rotate the buon unll laments

starts oozing out of the nozzle.

Click when done.

Push the short bowden tube in the

frame.

A correct installed lament spool

looks like this

STEP 3. CALIBRATION

This will make sure the printer is

completely level aer transport.

Before proceeding remove any

remaining lament from the nozzle

Navigate to the Set probe oset

menu item and iniate it:

Conguraon/Set probe oset

Turn the knob to move the nozzle

towards the printbed unl it touches

the blue tape.

Now click to save and start the

calibraon. Wait for the calibraon to

complete.

You are now ready to print

Tripodmaker // Unboxing Tripodmaker // Unboxing

STEP 4. (OPTIONAL)

MANUAL CALIBRATION

In case there are sll dicules

with your print adhesion in some

areas you can perform a manual

calibraon.

First perform the Home all step

to make sure the printer is homed

correctly.

NOTE: make sure the printbed is

covered with blue tape except for

the 3 screws

Now execute the Front le tower

command. The print head will move

to the front le tower.

Now perorm the set Nozzle Height

step from the menu.

Similar to the rst step in auto

calibraon you have to bring the

nozzle down to the buildplate unl it

touches the blie tape.

Click to save

NOTE: This will erase the auto

calibraon results

14 15

STEP 5. (OPTIONAL)

INSTALL PLEXI COVERS

If you gor you Tripodmaker Black

Edion with plexi covers follow the

diagram to install the covers.

Install the lock on the le side when

facing the front of the printer.

Connect bolts as in the picture

Repeat this for each door.

Connue by performing this same

procedure on the front right tower.

Connue by performing this same

procedure on the back tower.

Adjust the screw with a size 3 allen

wrench unl the nozzle touches the

blue tape on the printbed.

You are now ready to print

Tripodmaker // Unboxing Tripodmaker // Unboxing

16 17

MENU

The menu on you Tripodmaker Black Edion can be navigated through the push and

rotate buon next to the display. Aer turning your Tripodmaker on the info screen

will appear. You can scroll through 4 secons by rotang the buon.

Tripodmaker // Menu Tripodmaker // Menu

>secon 1: Temperature nozzle /

B= Temperature bed

Z= Current print height

Buf: Buer value

Mul: Speed mulplier 100% by default

E= Extruded lenght

NOTE: values will change during print

>secon 2: XYZ coordinates

NOTE: values will change during print

>secon 3: Extruder and bed

temperature

NOTE: values will change during print

>secon 4: Prinng me and

lament printed in meters.

Access the main menu by pushing

the buon

18 19

> Quick sengs >Home all

This wil home the printhead to the

top of the printer.

Navigate by rotang the buon.

Click to access

> Quick sengs

> Quick sengs >Z babystep:

Adjust the z height of the print-

head. Do not perform this seng

unless you suer from bad bed

adhesion.

> Quick sengs >Lights:

Turn the led lights on or o

> Quick sengs > Change lament:

Use this funcon to load or unload

lament.

Tripodmaker // Menu

> Quick sengs > Preheat PLA/ABS:

This seng will preheat the nozzle and

buildplate to the right temperatures for

PLA and ABS. Prints will start imidiately

with a pre-heated printer.

> Quick sengs > Fan speed:

Here you can turn the fans on or o.

> Quick sengs >Cooldown

This will boost all fans to cool the

print head rapidly.

> Quick sengs > Disable stepper

This will disable the stepper motors.

Now you can move the carts and the

print-head by hand.

> Print le

This will navigate to your SD card.

Now you can select the le you want

to print.

Tripodmaker // Menu

20 21

> Extruder > Bed temp:

Click to access and rotate to adjust

the bed temperature

> Extruder > Temp1:

Click to access and rotate to adjust

the nozzle temperature

> Extruder > Tuen extr. 1 o:

This will turn the nozzle o

Navigate by rotang the buon.

Click to access

> Extruder

> Extruder > Extr. posion

Access this menu to perform manual

extrusion of the lament.

> Extruder > Extr. posion

Rotate the buon clockwise to

push the lament through the

nozzle. NOTE: the nozzle must

be heated otherwise nothing will

happen.

> Extruder > Set Origin

This menu has to be executed if

instructed by our support team.

Tripodmaker // Menu

> SD card:

This menu gives access to your SD

card. While prinng this menu gives

access to the pause and resume

funcons.

> SD card > Print le:

This will navigate to the les on your

SD card.

Navigate by rotang the buon.

Click to access

> Conguraon

> Conguraon > language:

Printer menu language is available in

english only.

> Conguraon > Manual Calibraon:

This will enter the manual calibraon

menu. See page 13 step 4

Tripodmaker // Menu

22 23

> Conguraon > Manual Calibraon:

Set nozzle height - sets nozzle height

Note: this will erase results from auto

calibraon

Right/le/back tower - nozzle moves

to choosen tower

> Conguraon > Manual Calibraon:

home all - printer needs to be homed

before starng manual calibraon

> Conguraon > auto calibraon:

This will iniate the calibraon

program. See page 11 step 8

> Conguraon > Factory Reset

Please contact info@tripodmaker.

com for further troubleshoong.

If a factory reset is necessary our

support team will provide the reset

code.

> Conguraon > Factory Reset

Proceed with instrucons received

by our support team.

Tripodmaker // Menu Tripodmaker // Menu

YOU ARE ALL SET NOW!

Note that during the print the Tripodmaker shows the compleons percentage of

your print.

Menus that are accessible during print can be modied (ex. temperature/fans etc)

Use these features on your own risk during a print.

24 25

MAINTENANCE & TROUBLESHOOTING

1. EXTRUDER DRIVE

Check the extruder on a regular base for accumulated lament dust. We recommend

cleaning the extruder drive every 3 months or aer periods of intensive usage. How

to clean your extruder is explained from page 16 onwards.

Tripodmaker // Maintenance

2. MOVING PARTS

Check your carts on wobble aer a while. If the carts are loose on the track,

you can ghten the eccentric nut in order to remove the cart wobble. The carts

must run smooth. If you over ghten the eccentric nut, you will need to use

allot of force to move the cart and it will seem you have “hick-ups” during the

sliding maneuver. How to ghten your carts is explained on page 21 step 11.

3. NOZZLE AND HOT-END

Make sure that the nozzle and hot-end are cleaned when covered with plasc

residues. To clean of the nozzle, simply heat it unl the plasc gets scky, and

use a printed cube to peel of the scky plasc.

Tripodmaker // Maintenance

26 27

MAINTENANCE & TROUBLESHOOTING

1. EXTRUDER DRIVE CLEANING

Problem: Filament is slipping or extrusion problems.

Soluon: Clean the extruder drive

We recommend cleaning the

extruder drive every 3 months.

Remove the extruder drive tension

screw

Remove circlips that clamps the

tube holder

To remove the Nylon tube, push the

movable piece in the direcon of the

white arrow. Once squeezed inward,

the nylon tube can be retracted.

Tripodmaker // Maintenance

To remove the Nylon tube, push the

movable piece in the direcon of the

white arrow. Once squeezed inward,

the nylon tube can be retracted.

remove the two screws that hold the

extruder drive motor

remove the extruder drive from

the top frame through one of the

openings. Compress the spring

mechanism to squeeze it through.

Unplug the motor cable.

remove the extruder drive gear with

a small Allen wrench. In order to

remove the extruder drive gear from

the axe, squeeze the mechanism.

Clean the extruder drive gear with a

knife. The small blade ts inside the

slots of the extruder drive gear.

Tripodmaker // Maintenance

28 29

Remount the complete assembly. Pay

aenon that the extruder drive gear

is posioned ush with the front

of the black anodized components.

The screw rests on the at surface

of the motor axe. Pay aenon to

the orientaon of the extruder drive

gear!

Plug the cable and squeeze the

extruder drive back in its posion.

Make sure to plug the extruder drive

cable so the colors match when the

plug is plugged in!

Reghten the screws for

posioning the extruder drive

motor.

Insert the pneut coupling. Make

sure it is hand ght, do not over

ghten it!

Slide in the white tube and make

sure it is deep enough. Push-pull-

push-pull to be sure it is deep

enough.

Insert the extruder drive tension

screw and reghten it.

Done!

Tripodmaker // Maintenance

30 31

3. CLOGGED NOZZLE CLEANING

Problem: No lament is coming through the heated nozzle

Soluon: Clean the nozzle wiith the cold-pull method

1. Remove the lament from the

printer through thhe menu:

quick sengs>change lament

2. Remove bowden tube from the

print head by pushing the black clip

downards (with a screwdriver) and

pulling the tube out.

3. Heat up the print head

Go to Menu > Extruder > Temp.1

(click)

Set temperature to 180 degrees C

(click to conrm)

4. Insert (light preferably colored)

lament in the print head by

bypassing the bowden tube

Make sure lament oozes out of the

nozzle

Tripodmaker // Maintenance

5. Cool down the hot end

Go to Menu > Extruder > Temp.1

(click)

Set temperature to 0 degrees C (click

to conrm)

7. Check if black residue is stuck on

the outer end of the lament you

just pulled out of the hot-end

6. Wait unl hot-end temperature

is 110 degrees C and pull rmly the

lament back. You should hear a

“plopping” sound.

8. In case allot of residue was found,

go back to step 3 and repeat the

operaon.

Else, put back the bowden tube.

Make sure the bowden is inserted

deep enough unl the point it can’t

go any further.

Tripodmaker // Maintenance

32 33

TROUBLESHOOTING AND EASY FIXES

PRINT DOESN’T STICK TO THE PRINTER BED OR DETACHES ON CERTAIN

SPOTS.

Cause:

- Build plate is not leveled properly.

Soluon:

1. Try to use new tape

2. Try to level the build plate by re-calibrang the device

THE PRINT IS STUCK ON THE BUILD PLATE.

Cause:

This can happen with prints that have a large area touching the buildplate.

Soluon:

Use a puy knife to get the pieces from the build plate. WARNING! Make sure

your other hand is not in the path of the knife as the print migh come loose all of a

sudden.

CLOGGED NOZZLE

Soluon:

Try manually feeding the nozzle while seng the temperature on 245 degrees.

See on page 32 how to manually feed the nozzle. Try dierent temperatures

between 245 and 180 degrees. If no lament is geng through try the following:

1. Heat the extruder to 215 degrees. Take a short piece of clear/white PLA (1/2

meter) and push it in the nozzle from top like on page 32 of this manual. Push it

inside unl you can’t get any further. Then pull it out. Cut the dirty p o with pliers

and re-insert. Keep doing this unl the lament is clear and the clog is eventually gone.

2. To improve results with this process it might help to push a neelde of <0.4

(specialised 3D prinng needles or the classic needles from your local pharmacy)

in the boom of the nozzle and then pull it out

again. Perform step 1 again. Alternate step 1 and

2 a few mes unl the clog is gone.

In case this doens’t solve the problem, contact

support: info@tripodmaker.com.

Tripodmaker // Maintenance Tripodmaker // Maintenance

THE FILAMENT IS STUCK IN THE TUBE

Cause:

Filament is stuck in the nylon tube due to a blob that is retracted in the tube.

Soluon:

Remove the tube out of its couplings and remove the lament. The tube can be

removed by pushing in the couplings in the opposite direcon you want to pull out

the tube.

34 ©Tripodmaker

Table of contents

Other Tripodmaker 3D Printer manuals

Popular 3D Printer manuals by other brands

Creality

Creality CR-200B Pro quick start guide

Wuxi Tiertime Technology

Wuxi Tiertime Technology CETUS MKIII quick start guide

Creality

Creality Ender-3 V3 KE user manual

weistek

weistek IdeaWerk WT150 Product user manual

AIO ROBOTICS

AIO ROBOTICS ZEUS Quick start user guide

JGaurora

JGaurora A-8 Operation instructions