Tristarbot M1 User manual

find more information on www.tristarbot.com

1

M1 User Manual

WARNINGS /Safety Information ................................................................................................2

Your first print..........................................................................................................................3

Print via Graphic LCD controller.................................................................................................3

Layer height......................................................................................................................8

wall thickness....................................................................................................................8

Infill..................................................................................................................................9

Print Speed.......................................................................................................................9

Cooling .............................................................................................................................9

Support. ...........................................................................................................................9

Platform adhesion.............................................................................................................9

Print via USB cable..................................................................................................................11

Pause or stop printing.............................................................................................................14

Change Filament.....................................................................................................................14

Recommended setting for different filaments..........................................................................15

find more information on www.tristarbot.com

2

WARNINGS /Safety Information

Hazards and Warnings

This M1 3D printer has motorized and heated parts. Always

be aware of possible hazards when the printer is operational.

Electric Shock Hazard

Never open the electronics case when the printer is powered on. Before

removing the electronics case cover, always power down the printer and

completely turn off and unplug the printer. Allow the printer to discharge

for at least one minute.

Burn Hazard

Never touch the hot end nozzle or heater block without first turning off the

hot end and allowing it to completely cool down. The hot end can take up

to 20 minutes to completely cool. Never touch recently extruded plastic.

The plastic can stick to your skin and cause burns. The print surface can

reach high temperatures that are capable of causing burns.

Fire Hazard

Never place flammable materials or liquids on or near the printer when it

is powered on or operational. Liquid acetone, alcohol, or other chemicals

may release vapors that are extremely flammable.

Pinch Hazard

When the printer is operational take care to never put your fingers near

find more information on www.tristarbot.com

3

any moving parts including belts, pulleys, or gears. Tie back long hair or

clothing that can get caught in the moving parts of the printer.

Age Warning

For users under the age of 18, adult supervision is recommended. Beware

of choking hazards around small children.

Your first print

Print via Graphic LCD controller

Before you make the first printing, you need a GCODE file

which could be read by the machine.There are files in the SD

memory coming along in the package, which are ready to print,

but if you want to make your own file, you need slicer software to

process your STL/OBJ files into GCODE files before printing. The

slicer we recommend is Cura, a free software which you can get

from

https://ultimaker.com/en/products/cura-software

The latest version is Cura 2.3.1,but Cura 2.1.2 is much more

stable for most computer.

Download the software and install it. When you run Cura at the

first time, you need to set up your printer as the picture

find more information on www.tristarbot.com

4

Choose other, and then prusa i3,then finish.

Load a STL files, which you can get from

http://thingiverse.com/ ,http://pinshape.com/ or some other 3d models web

find more information on www.tristarbot.com

5

sites, or you can make your own designs with CAD soft, and save as STL files.

After you load it, you can click on the model, and the buttons on the

right-top will be active, you can use them to scale, rotate, mirror the model, and

in the view mode button, you can view the model in Solid, X ray, and Layer

Mode.

On the right side of Cura, you can find the material choice, and simple/

advance setup, you can choose the simple one and have a try, or we make the

advance setup as following.

Click advance setup, and click on each feature to show the detail.

find more information on www.tristarbot.com

6

You can see the default setting, we need to change them for better printing.

find more information on www.tristarbot.com

7

Go to the drop down menu printer->manage printers, find setting on the

window.

Check the Machine->Nozzle Diameter, then you will find this feature on the

set up tab, you can try other options.

find more information on www.tristarbot.com

8

Make the nozzle diameter 0.4mm

The setting here is for PLA filament, if you print with other filament, you need

to set it up accordingly.

Layer height

The layer height mean how height the Z axis move for each layer, if this

number is small, the wall of the print will be very smooth, you even could not

recognize the layers, but small height means there are much more layers to go,

and that means much more time. So we 0.2mm is recommended, you can try

0.1mm for better printing, and 0.3mm for fast printing, please do not make it

more then 0.3mm, unless you get a nozzle bigger then 0.4mm.

wall thickness

The number is normally times of the nozzle diameter, minimum is one time of

find more information on www.tristarbot.com

9

the nozzle diameter, here 0.4mm, normally make it two or three times unless you

make a single wall printing.

Infill

If you want to print toys or other non-mechanical items,10% to 20% will be

fine. If you want to make some mechanical components, 30% or more is better.

Printing temperature for PLA, about 190 to 220 is fine, and bed temperature

is around 60 to 80.

Print Speed

This printer is pretty stable, you can try 90mm/s, 80mm/s for PLA, or 70mm/s

and 60mm/s for better result, but if you print with high temperature filament,

such as ABS, PC, Nylon ect, you need to slow down the speed, and for small print,

maybe even to the minimum speed, 25mm/s.

Cooling

Always check the Enable Cooling Fans for PLA but never check it for high

temperature filament.

Support.

Check the enable support when there is possibility to collapse, otherwise do

not enable it.

Platform adhesion

This feature is used to avoid warping .If you print with PLA, Skirt will be fine,

find more information on www.tristarbot.com

10

or you can use raft so you get a perfect leveling printing surface. Brim, it’s pretty

difficult to clear if you print a complicated item.

If you print with ABS, PC, Nylon, raft is preferred, but you may also need other

ways to avoid the warping. Glue, acetone , kapton tape, PEI surface, find more

information about how to avoid warping of different filaments.

Others just as default

When you finish the setting, the slicing should be finished, you then just plug

the SD memory to you computer and click Save to Removable Drive. And now

your file is ready.

Plug the SD memory into the SD slot on the right side of the LCD controller.

find more information on www.tristarbot.com

11

The files list should appear automatically when you plug the SD memory, now

choose the file and click the knob, and the machine will be heating up, when the

temperature reach, it will start to print. If the files list do not appear, put out the

SD card and plug it in again, or go to menu->Print file, or Menu->SD

card->Print file to find out your files list.

You can always turn off the machine if any unexpected issues appear.

Print via USB cable

First connect the machine with your computer via the USB cable coming

along. Then you need to install some software on your computer, we

recommend this free software repetier host, you can download it here

https://www.repetier.com/download-now/

find more information on www.tristarbot.com

12

Just go down to the bottom and click Download without donation

Or you can use the Simplify3D,which you can buy from

https://www.simplify3d.com/buy-now/

Now install the repetier host and run it.

You need to set up the printer

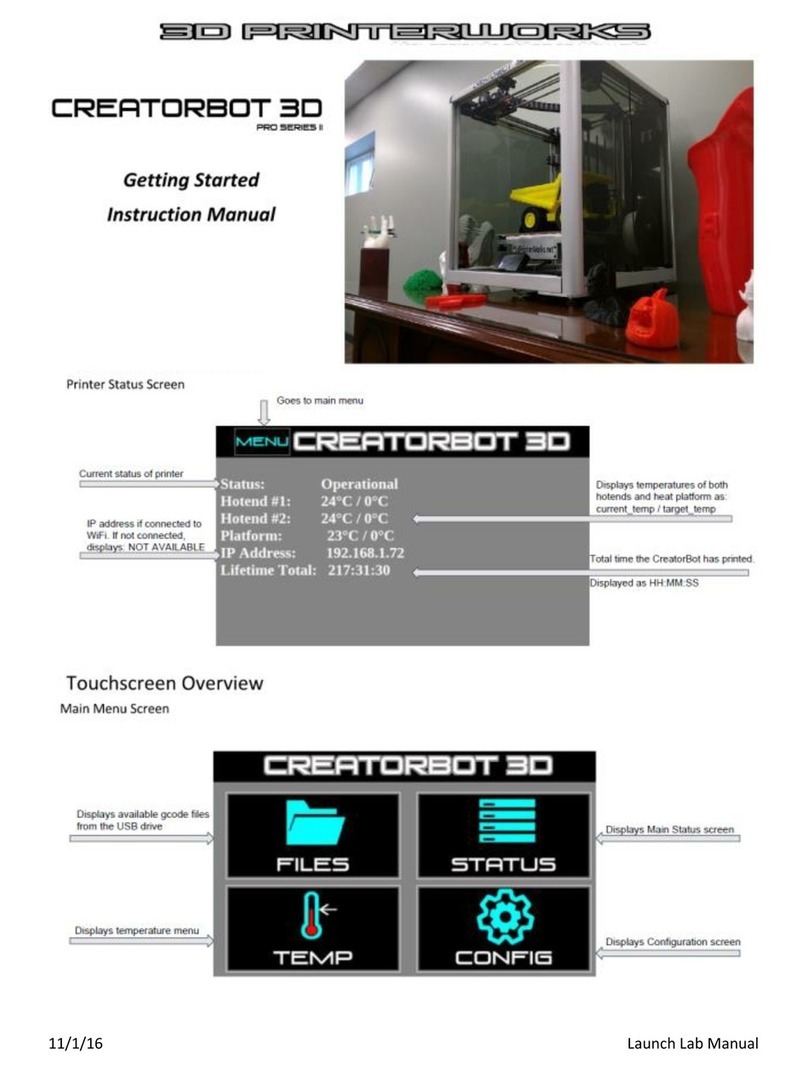

Go to the drop down menu config->printer setting

Connector as default serial connection

find more information on www.tristarbot.com

13

Port is normally COM something, please try it.

The Baud Rate for this printer is 115200

Keep others as default.

Now you can click the red Connect button with a white plug on the top-right

corner of the repetier host, and the button should be green, if not, choose other

Port on the last step, and try it again, till it turn green, and the printer is

connected with your computer.

About other setting of repetier host, please refer to

https://www.repetier.com/#documantation

find more information on www.tristarbot.com

14

Load Model file and slice it, repetier host use cura slicer too, so you can refer

to the cura slicing setting for detail.

When slicing is finished, click Start Print, the commands will then send to your

printer, temperatures will rise up, and then start to print.

Pause or stop printing

If you use graphic LCD controller to make the printing, go to menu->SD

card->Pause print/stop print to pause or stop the printing.

If you use repetier host or other software, there are buttons on it so you can

pause or stop print.

Change Filament

Heat up the nozzle first before you change filament. Go menu->Quick

setting->Preheat PLA/Preheat ABS or Menu->Extruder->Temp.1 and rotate

the knob to raise the temperature of the nozzle. When the temperature reach the

target, then go to menu->Quick setting->Change Filament. The filament then

will be pushed out, and you can load another filament.

IMPORTANT NOTICE: Please Change filament before you finish the last inch.

The extruder CAN NOT finish all the filament, so if it keep on extruding, the last

small piece will block the nozzle throat, and it’s pretty difficult to clean.

find more information on www.tristarbot.com

15

Recommended setting for different filaments

Filament type

Nozzle

Temp(°C )

Bed Temp

(°C )

Print Speed (maximum

in mm/s)

Cooling fan

PLA

190-220

70

80

Fan needed

ABS

245-250

100-110

50

Never

TPE (flexible filament)

245-250

80-100

30

Never

TPU(flexible filament)

200-220

70-80

30

Nylon

230-270

110-120

50

Never

HIPS

240-250

110

50

Never

NinjaFlex

210-225

20-50

30

PETG

230-250

60

50

Never

Polycarbonate(PC)

250-270

120-130

50

Soft PLA

210-220

60-100

10-20

If find nozzle jam or extruder motor knocking, please raise the nozzle temperature about 5 to

10 degree and try again. If you use glass on the bed, you may need to raise the bed temperature

about 5 degree then the recommended one. The faster you print, the higher temperature for the

nozzle. You can try faster speeds then the recommended ones above, and find whether you can

accept the quality.

For flexible filament, when you slice the file on slicer software, increase the retraction

distance.

Table of contents