TRONXY X6-2E User manual

Model name:X6-2E

Instructions

深圳市创星元科技有限公司

SHENZHEN TRONXY TECHNOLOG CO.,LTD

j. Cannot provide Valid documents or Beyond the warranty period.

Precautions for use

Before using this machine, please carefully read this manual and the following notes:

1. Keep children away from the machine when using the machine. Children are

forbidden to touch the machine in use.

2. Please put the machine on a stable surface before using the machine.

3. Please keep this manual for future reference.

4.The open hole of the housing is strictly prohibited to cover, which is used for

ventilation and heat dissipation of the machine to avoid overheating.

5.Please pay attention to the notice and warning posted on the machine to

avoid danger or injury.

6.It is strictly forbidden to use the machine in the environment of inflammable

and explosive substances.

7.It is strictly forbidden to pour any liquid or dust into the machine, or it will

damage the machine or even cause a dangerous accident.

8.Please do not disassemble or repair the machine without permission. In

addition to normal quick assembly steps and common problems, please ask a

professional to help.

9.Do not use the machine under high temperature (above 85 ° C) environment,

otherwise may damage to the machine.

11.For use of the machine, the following is not covered by warranty:

a.Due to abnormal external forces (such as fall, extrusion, knock against,

impact) caused by the damage of products;

b.Product damage caused by violation of product operation manual;

c.Product damage caused by using materials that are not compatible with or

have not been recognized by relevant national standards;

d.Beyond use under the conditions of use (such as the mainboard working

environment for 5 to 40 ℃, customers in the above 40 ℃ or below 5 ℃ when

used under the condition of damage).

g.Damage caused by irresistible external factors.

h.Normal consumption of parts, such as printing plateform, nozzle and other

accessories.

i. Damage by Pure artificial condition

10.When unattended, it is recommended not to run the printer.

e.Damage caused by privately modifying firmware and appearance structure.

f.Damage caused by improper storage (such as dampness, mildew, etc.).

Print size

Power

input

Pocision

Power

Print

Certificate

Nozzle

size

Connectio

n

Print color

Hotbed

Material

Nozzle

Display

Ambient

temperat

Print

ambient

Machine

material

slicing

software

Machine

weight

files

format

Packing

weight

operation

software

Packing

size

Operaton

system

Machine

Power

110V/220V AC,50/60Hz

DC 12V 20A

CE FCC

USB interface.TF card

PLA.ABS

0.1mm-0.4mm optional

Aluminium profiles,sheet

metal

≈10.1kg

220*220*210

X/Y0.0125mm,Z0.02mm

20-100mm/s(advise 60mm/s)

0.2mm,0.3mm,0.4mm

optional

Dual color

≈12.3kg

500*530*220mm

470*445*407

1. Product parameters

3.5 inches full color touch

screen

8-40°C

support

Maxium260°C

20-80%

Repetier-Host.Cura

WinXP/Win7/MacOS

support

TRONXY exclusive slice

software

STL.OBJ.DAE.AMF.G-Code

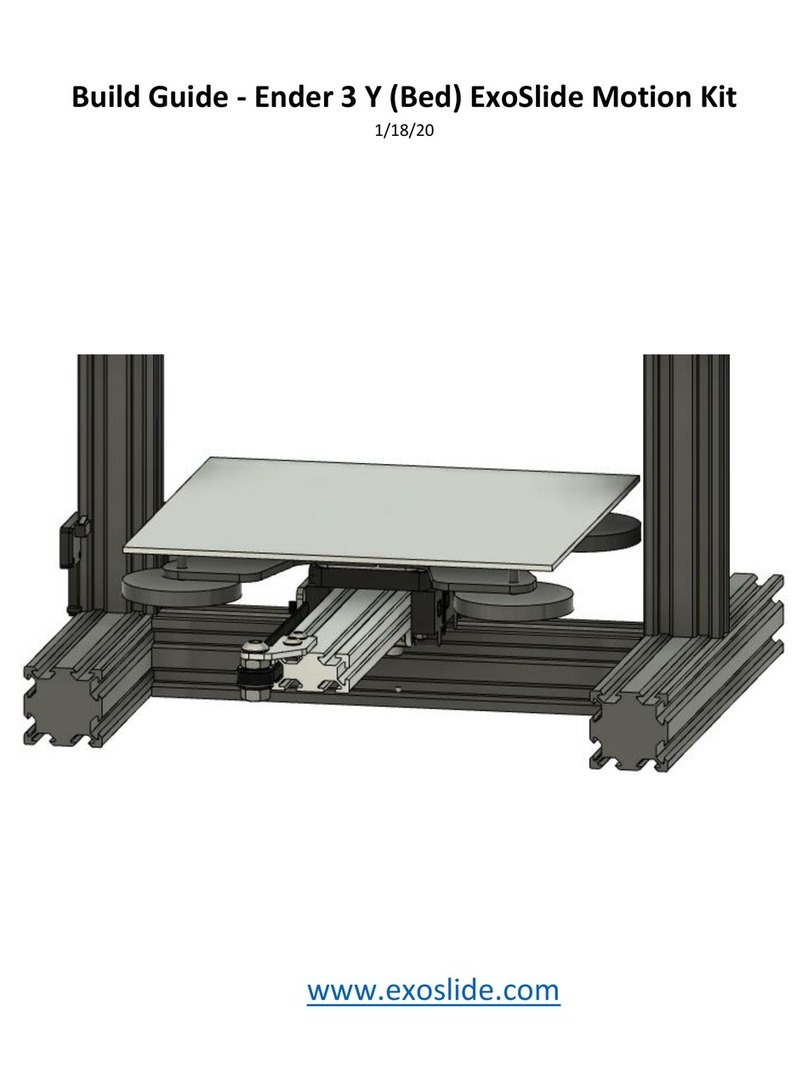

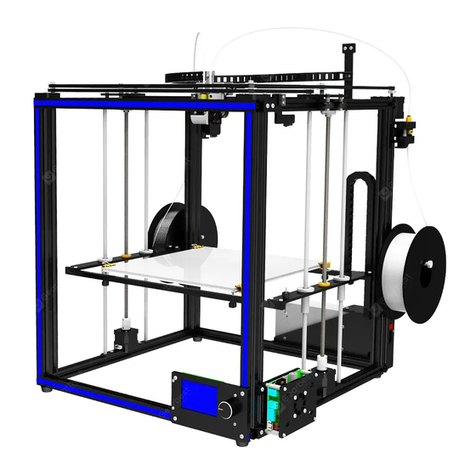

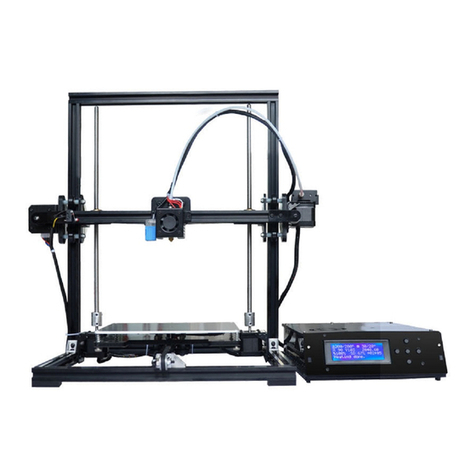

Gantry bracket The base X axis platform

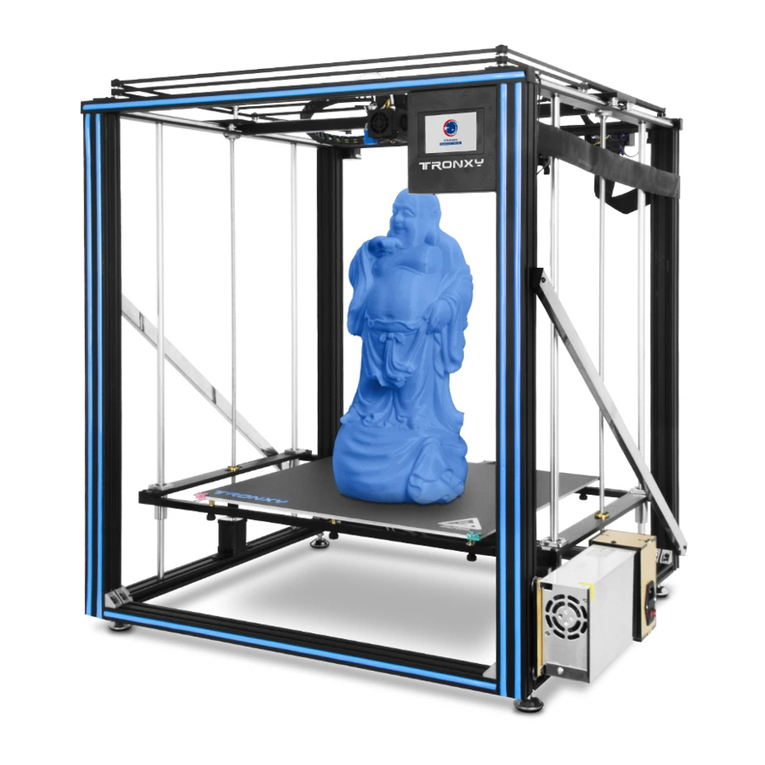

2. Machine Introduction

Touch screen

1.Front view

FT card slot, USB Y polished rod Right feeder

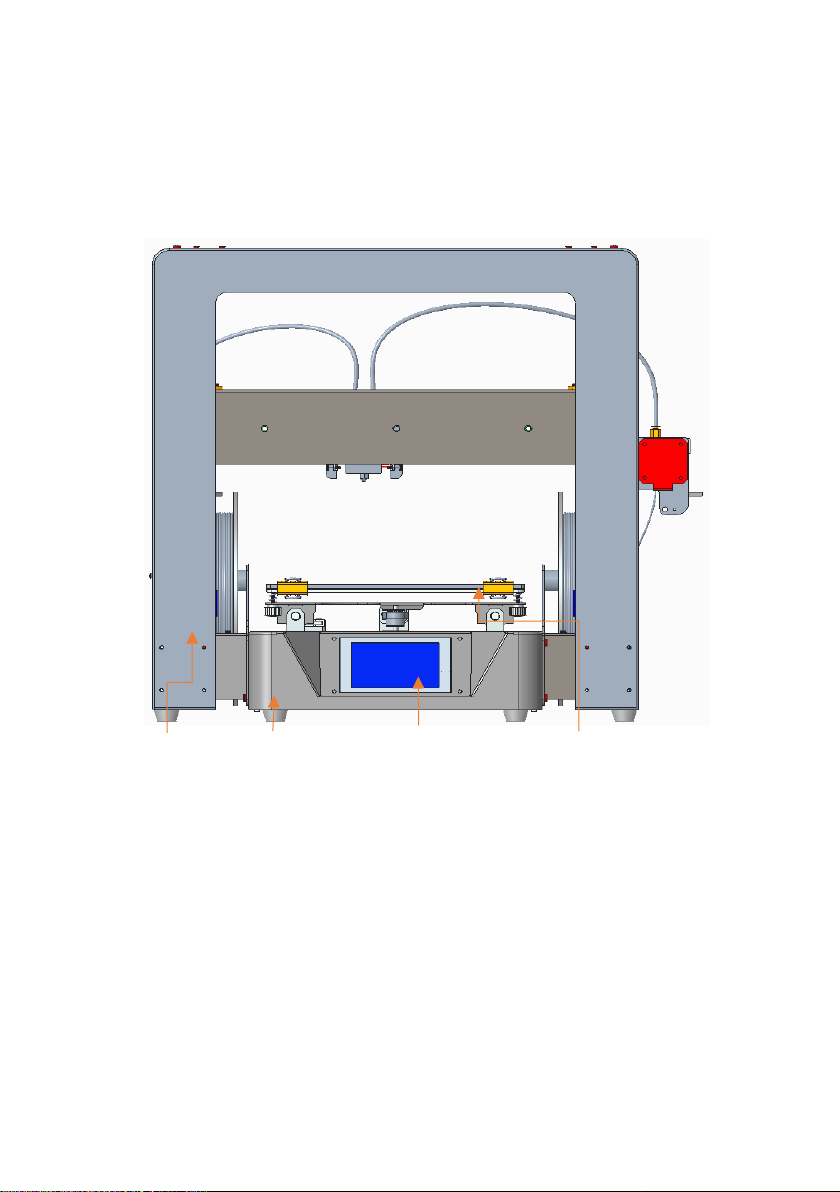

2.Right view

The right material shelf

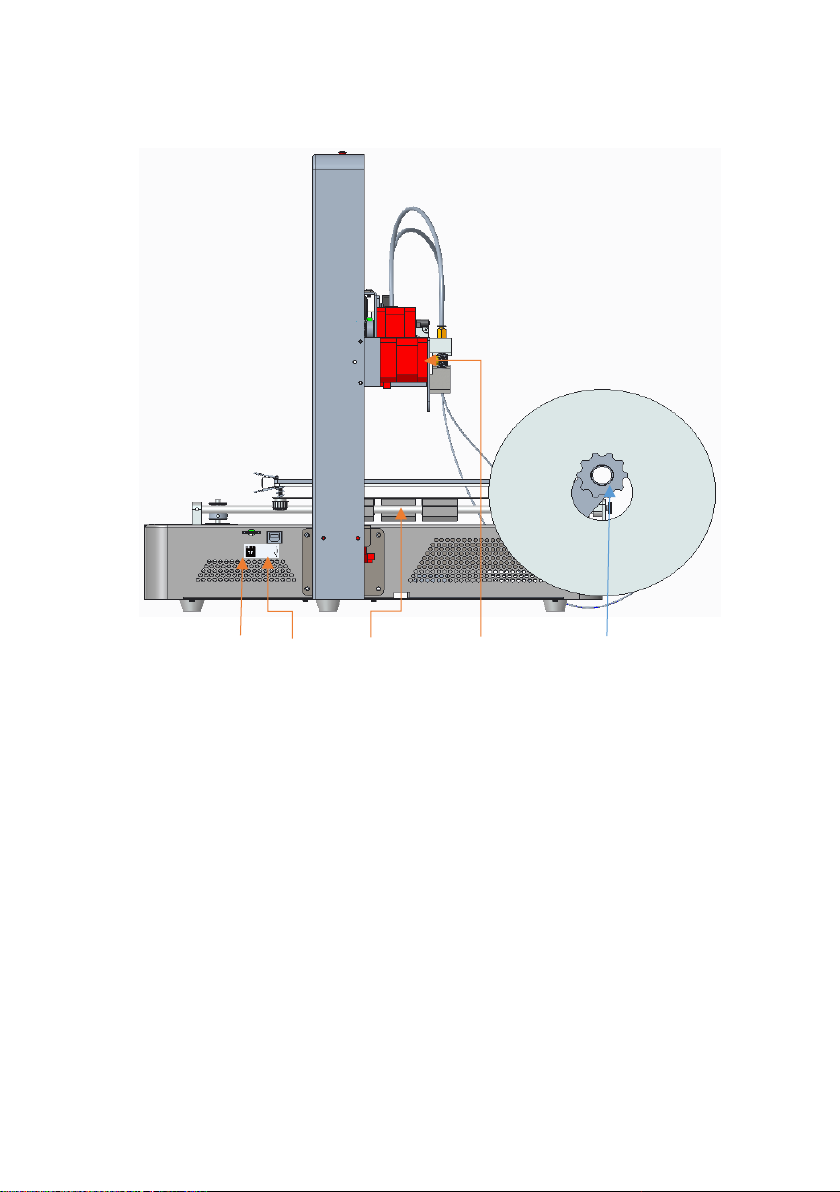

the left material shelf

Adjusting nut left feeder

3. Left view

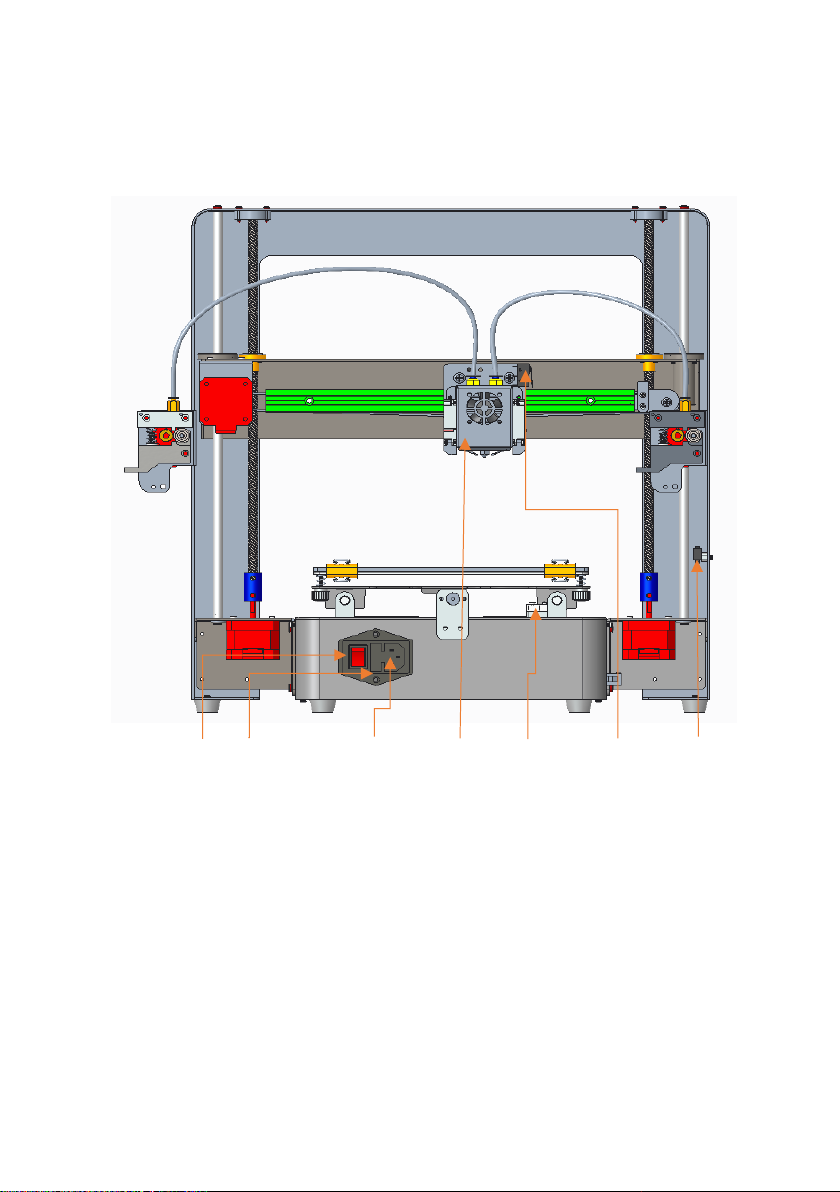

110V/220V selection port

4.Back view

Power switch Power fuse Power cord connector Two-color extruder Y shaft switch X shaft switch Z shaft switch

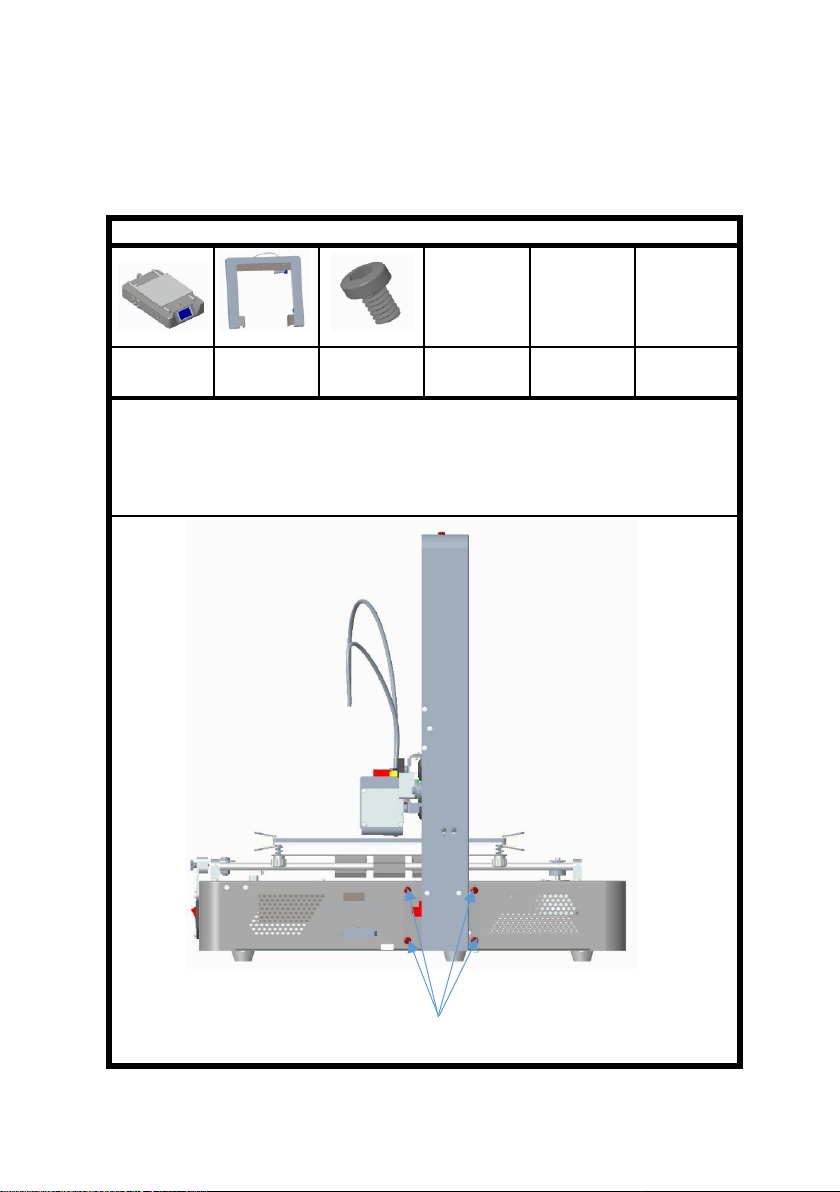

3. Product assembly

Step 1: assemble the base and the rack (take care to avoid scratching

parts when taking and assembling).

Assembly parts:

The base

1pcs

shelves

1pcs

screwPM4*6

8个

PM4*6 screws

to pass through the hole in the position as shown in the figure, and lock it with

the M4 tooth hole on the base.

Take out the bottom rack from the packing box and put it on the shelf, as

shown in the figure. Align with the position as shown in the figure, and use 8

PM4*6 screws

Loose screw

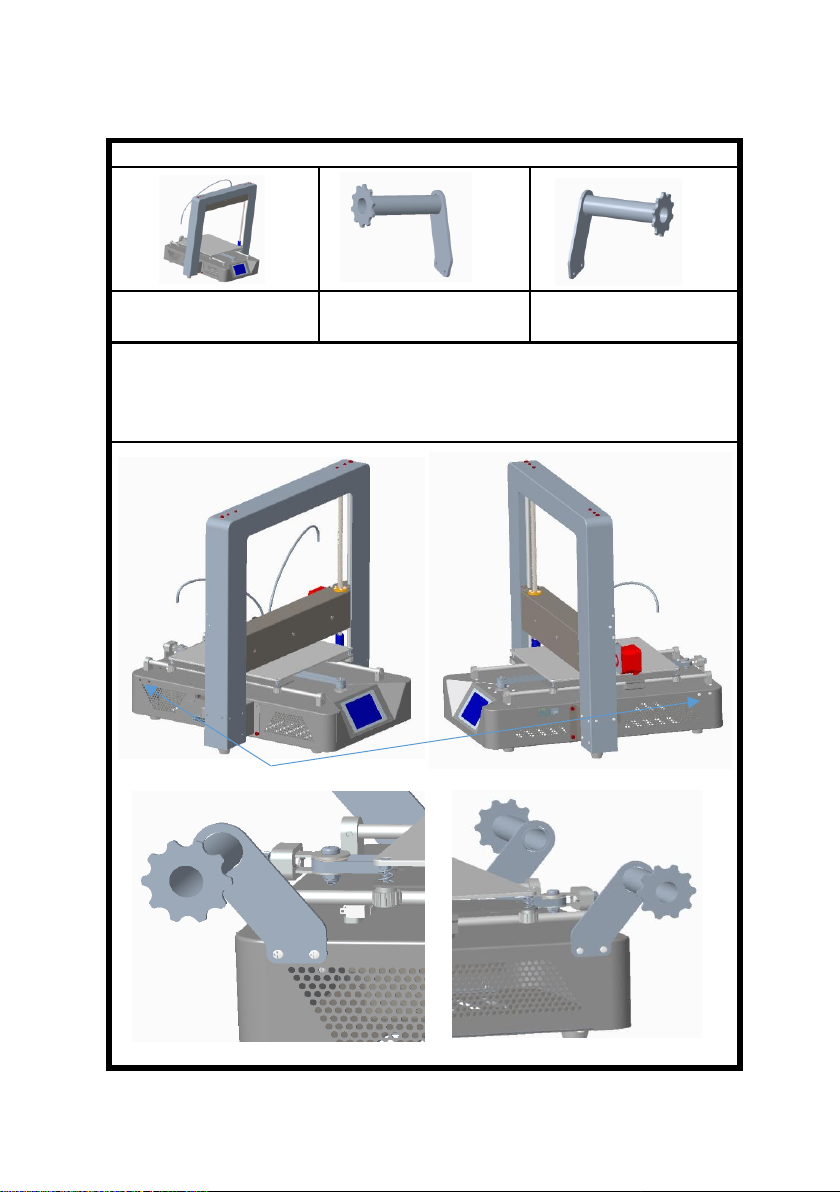

Loosen the 2 screws on the left and right sides of the cabinet, take 1 piece of

left and right material rack as shown in the figure,

place it according to the position shown, align the holes, and lock it with 2

screws.

printer 1pcs

left rack parts 1pcs

right rack parts 1pcs

Step 2: assemble the filament rack

Assembly parts:

screws PM3*4

feeder parts

2pcs

printer 1pcs

screws PM3*4

screws PM3*4 6pcs

Assembly parts:

Step 3: feeder assembly

2. Insert the material tube into the air nozzle hole of the feeder.

1. Screw through the machine sheet metal hole, align with the screw tooth hole

of the feeder component, and then lock it, as shown in the figure.

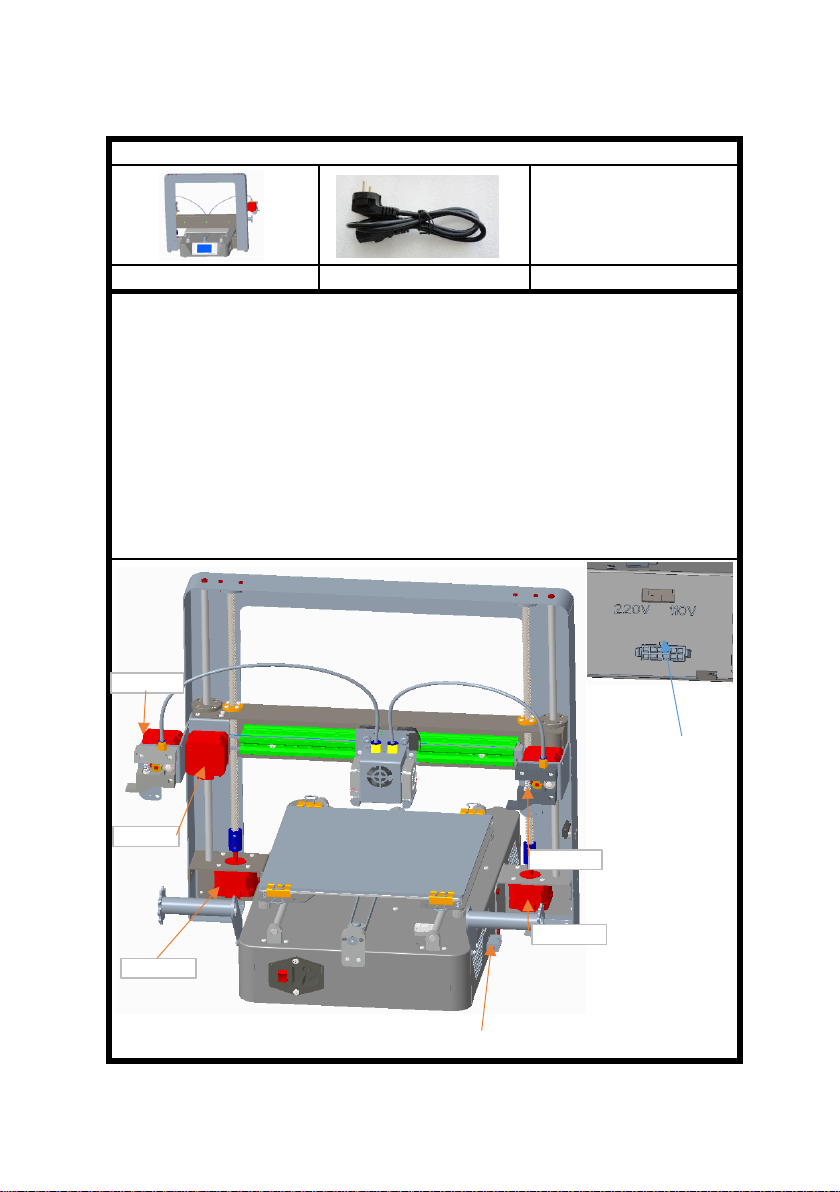

12 p female terminal

Assembly parts:

You can select 110V voltage.

5.Remove the power cord and plug into the 3P port of the host power supply.

printer(included wiring) 1pcs

4.According to the local voltage, select the power supply voltage of the host. As

shown, the position shift is 220V, and the toggle switch is to the right.

The rest is plugged into e2-motor.

Step 4: wiring

Power supply

voltage

selection

Make sure the debugging is good.

1. Insert the male terminal of the shelf 12P wire into the female terminal of the

left rear side of the base.

2. 2Motor 6P terminals protruding from the left back side of base, short plug in

z1-motor, long plug in e1-motor.

3. 3 Motor 6P terminals protruding from the right rear side of the base are

inserted into z2-motor for short while x-motor for long.

Power line 1pcs

X-MOTOR

Z1-MOTOR

Z2-MOTOR

E1-MOTOR

E2-MOTOR

as shown in the figure.Basic functionality for displaying submenus.

2.Click the system menu and enter it into the system submenu, as shown

in the figure: click the return menu and return to the superior menu.

2.1Click the state, and the display is as shown in the figure: the machine

position state parameters are displayed.

Click back menu to return to the superior menu.

4. Operational guidelines

1.Enter the main screen of the startup, display the system, tools, and

print three main menus. Click on each of the three sub-menus,

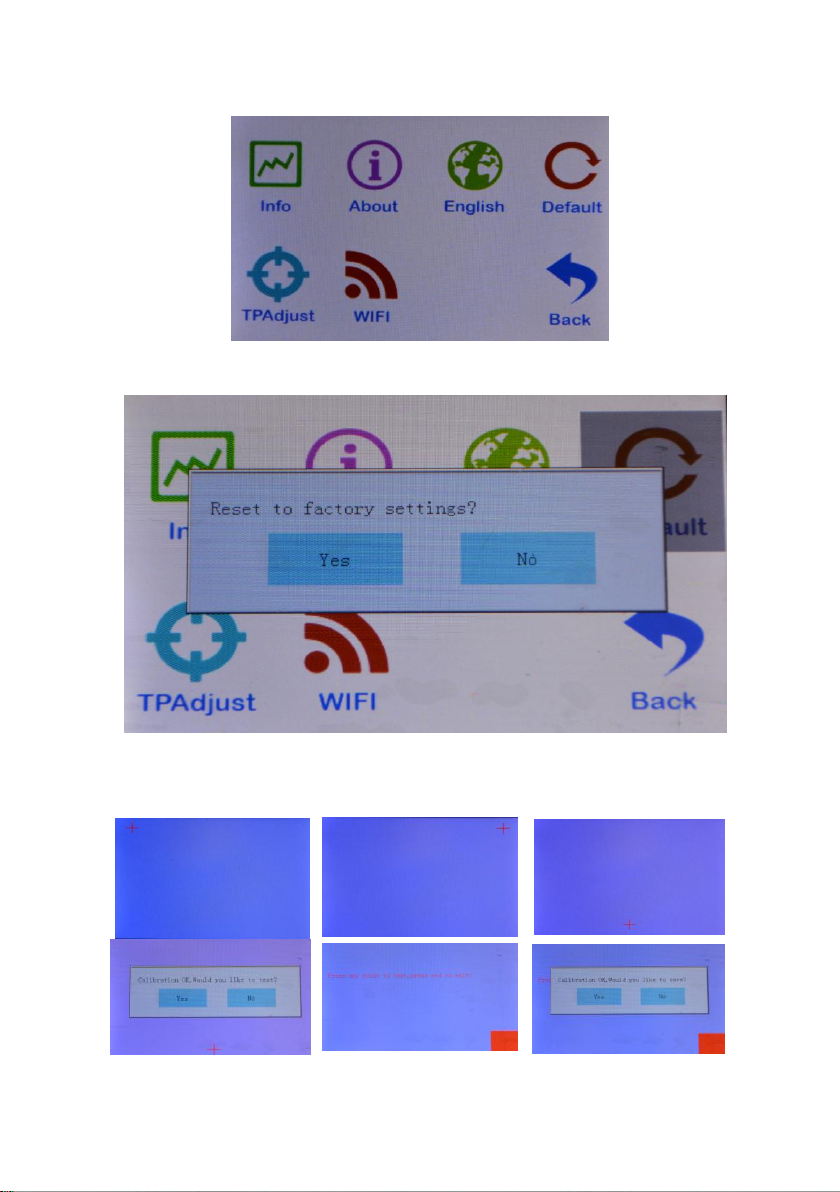

2.3Click the Chinese location menu to enter Chinese and English.Click back

menu to return to the superior menu.

2.2Click the machine information and the display is as shown in the

figure: the machine brand, ID, version and other information are

displayed.

Click back menu to return to the superior menu.

2.5Click the screen correction icon to enter the screen correction and

click the cross position for correction.

2.4Click the factory setting and ask if the factory setting is restored.Click

to return to restart and restore the factory Settings.

Adjust the screen when the menu is off, save it back.

2.6Click the WIFI menu to enter WIFI parameter setting.Save Settings click on

the icon to return.

3.Click the tools menu to enter the machine parameter setting

and adjustment.

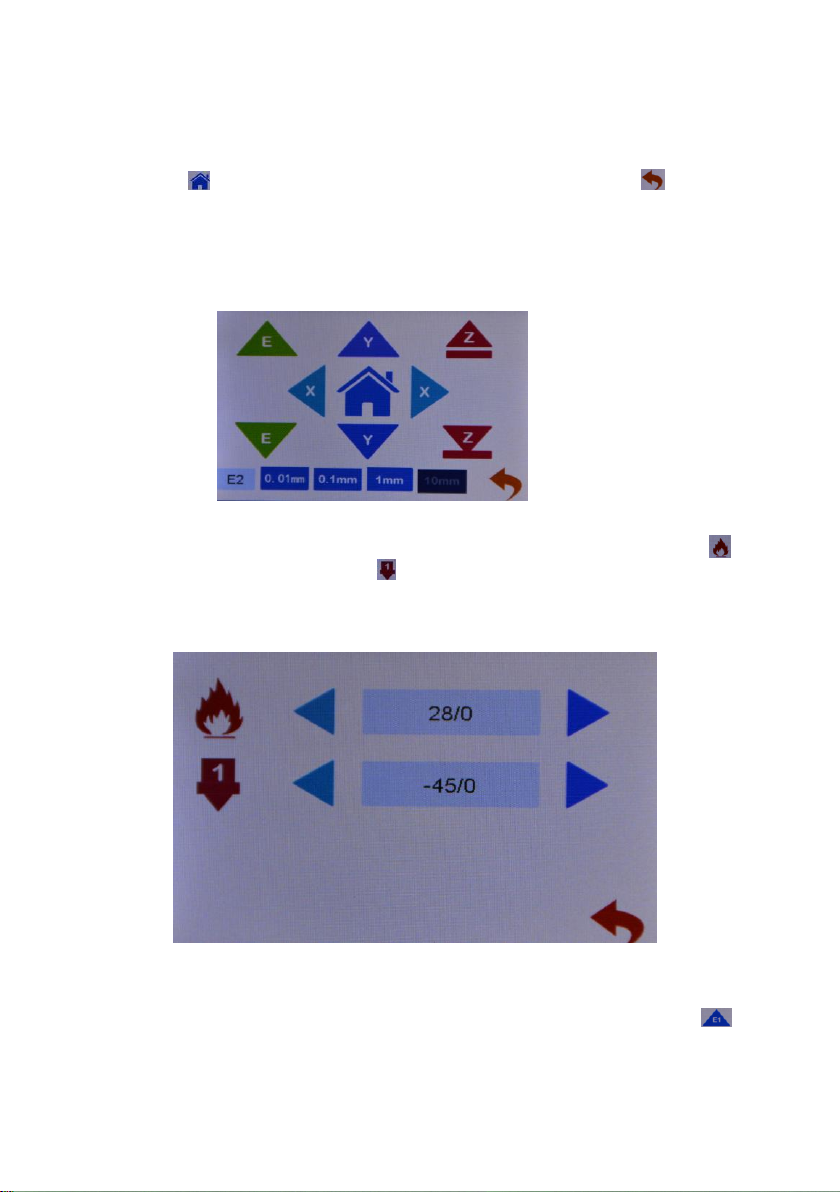

3.1.1 Click the manual menu to enter the manual adjustment

mode.Adjust the motor rotation, E extruder feeding/discharging, XYZ

shaft motor moving.ICONS 0.01mm, 0.1mm, 1mm, 10mm,

3.1.2 Click on the E1 icon, and the E1 icon changes to show E2. Click on

the E2 icon againto show E1, as shown in figure E1E2. Click on the

switch state.When displaying E1,click icon E to start extruder 1; when

displaying E2, click icon E to start extruder 2.

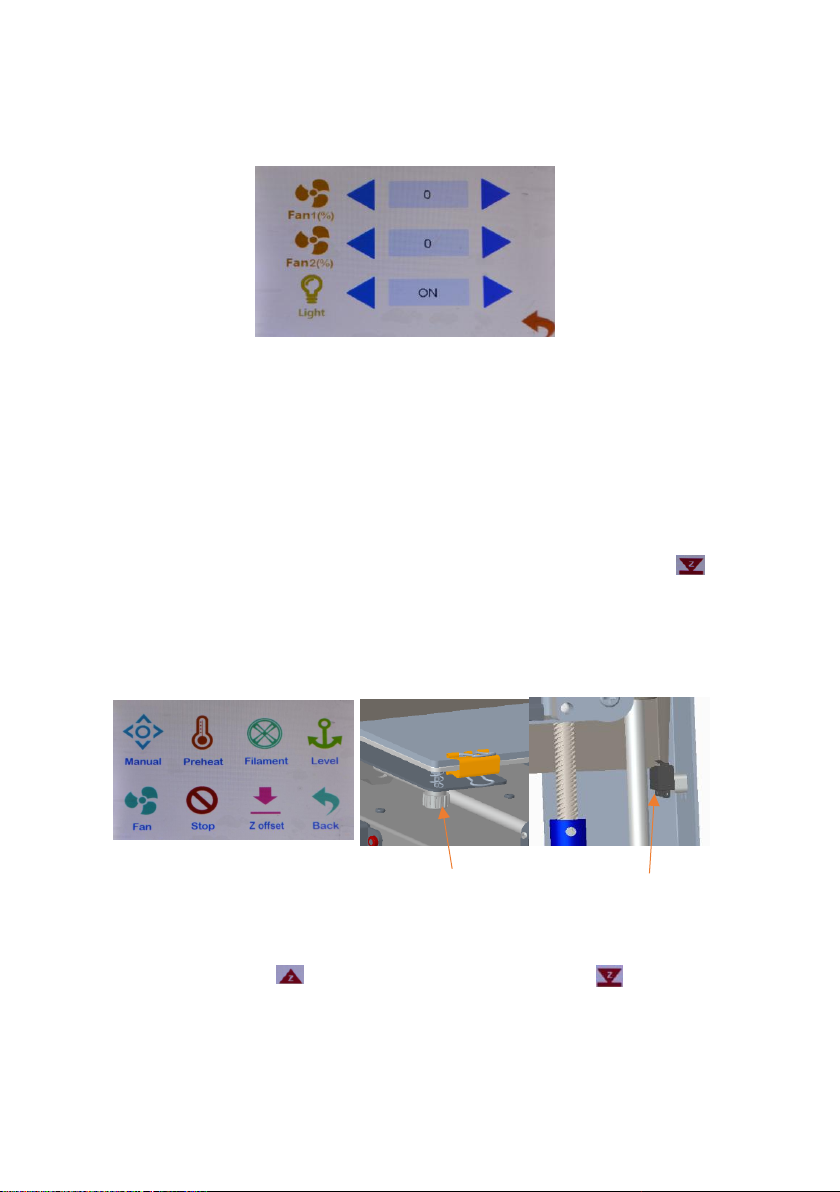

3.2Click the preheat icon, as shown in the figure, to set the heating

temperature of the machine extrusion head and the hot bed, the icon

hot bed heating and the icon hot head heating, and click the icon

on the right and left direction to adjust the setting temperature heating.

Use the heating function when replacing filaments.Click the digital icon

to directly switch to the preset temperature.

Set the heating temperature, the temperature reached, click the icon

to return the material.When installing the consumables, insert the

consumables directly into the feeder hole

After clicking, the dark color is displayed, such as icon 10mm, indicating

that each click of motor stroke moves 10mm.

Click the icon and the machine returns to the origin.Click back

to the parent menu.

3.3Click the icon of loading and unloading filaments to indicate

preheating.Remove the filaments to warm up before pulling them out

and click the icon to send the materials to the nozzle to flow the

materials.Click the icon motor to stop.Single side feed can not be

too long,Avoid plugging the hot material into the cold end of E2.E2

motor filaments feed back and forth.changed to E2,click

filaments return,click filamenst in。

and press down the feeder pressing block. As shown in the figure, pass

the filaments through the feeder to the material pipe,

3.4Leveling menu, auto leveling function, click the icon to enter auto

leveling.The machine reads the parameters of the leveling point and

saves them.Automatic leveling function selection.This function is not

available on this machine.

Adjusting nut

3.6.1Click the emergency icon, the machine stops in the current state,

and the motor unlocks.When adjusting the gap between the printing

platform and the nozzle, use emergency stop to let the extruder slide

freely.Gap size, with a piece of A4 paper between the nozzle and the

platform sliding resistance, but do not tear the paper is appropriate.The

platform should be positioned near the support point of the

platform,The platform should be positioned near the support point of

the platform, but avoid screw holes. Adjust each support point.

3.6.2Will print platform of the first four adjusting nut is tightened, the

spring pressure in the shortest possible location, click on the icon ,

extrusion head down, run into the Z axis stop switch, adjust the position

of the switch, to squeeze head nozzle and the platform about 2-3 mm

apart, then loosen the adjusting nut, fine-tuning platform for extrusion

head nozzle and the mobile platform about 2-3 mm apart, Distance

from the nozzle to an A4 sheet of paper thickness.

3.7Click the Z offset icon to enter the Z axis position adjustment.The

function of automatic leveling is effective.Select the fine tuning 0.1mm

icon, click the icon Z axis to move up, and click the Z axis to

move down.djust the nozzle and platform to A4 paper thickness. Click

the icon set Z to zero and save the setting.

This function is automatically leveling Z axis compensation, with leveling

function used, leveling simple.This function is not available on this

machine.

The Z axis switch

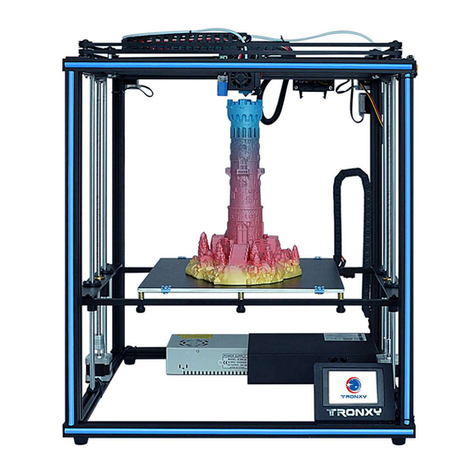

3.5Click the fan icon to enter the fan setting, and turn the fan value 0

OFF, 100 ON, light ON, and light OFF.

4.2Click on the file and select the file, which is sliced, to enter the file

screen.Click the icon to delete the file.Click the icon to enter

print mode.

Top left frame preview model;The right picture frame shows the status

parameters, the green hourglass shows the printing time,and the blue

hourglass shows the time needed after printing.Indicates the printing

speed by the number of the icon,the name of the printing file by the

icon, and the printing progress by the percentage.

4.1Click on the print icon to enter print.The screen displays the files in

the machine memory card.

Click the arrow to scroll up and down.Click the folder, open the folder,

and display the folder contents.

4.2.1Click the icon to stop printing and ask if the filaments should

be replaced.To replace the filaments,click YES to replace the filaments as

step 3.3 and return to continue printing.Click NO and go back to print.

4.2.2Click the icon to stop printing, and the machine asks if the state

is saved. Select "YES".The next printing will start from the current

state.Select NO, machine state reset.Click cancel to continue

printing.This function continues for breakpoint.After the model print

stops, the stop save state is shut down, and you can continue printing

after the next start.Boot prompt last print interrupt, select YES continue

last print.

Table of contents

Other TRONXY 3D Printer manuals

TRONXY

TRONXY X5SA User manual

TRONXY

TRONXY X5SA-400-2E User manual

TRONXY

TRONXY XY-3 User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY X5SA-500 User manual

TRONXY

TRONXY X5S User manual

TRONXY

TRONXY VEHO 600-2E User manual

TRONXY

TRONXY X1 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY VEHO600 User manual

TRONXY

TRONXY X6D User manual

TRONXY

TRONXY X5S 2E User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY X5SA-500-2E User manual

TRONXY

TRONXY XY-3 PRO V2 User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY XY-2 User manual

TRONXY

TRONXY X5 User manual

TRONXY

TRONXY X5SA-400-PRO User manual

TRONXY

TRONXY D01 User manual