Trojan Leisure Radiant Pools Metric Series User manual

Installation Manual

Metric Series Residential Swimming Pool

WARNING: DO NOT DIVE OR JUMP. IT IS NOT DESIGNED FOR DIVING OR

JUMPING. YOUR POOL IS APPROXIMATELY 4’ DEEP. IF YOU DIVE OR JUMP

INTO YOUR POOL YOU RUN THE RISK OF PERMANENT INJURY OR DEATH.

Enclosed in the liner box is the safety envelope. The safety stickers must be installed as per instructions. Failure

to properly install warning labels will void warranty. Alert all visitors and family of the risks associated with jumping

and/or diving and point out all warning labels supplied. Failure to mount these safety labels may subject you to

substantial liability in case of injury.

Your pool is designed for years of pleasurable, safe family fun. But when used incorrectly, a swimming pool can be

dangerous. To insure your pool is used safely you must observe the following safety precautions:

1. Do not dive, do not jump, no rough play, no running or pushing.

2. Do not walk on the top rail. It can be slippery and is not a walkway.

3. Be sure to install all safety labels provided with your pool according to the safety instructions.

4. Keep a 50’ safety rope with a flotation buoy with an outside diameter of 15” accessible in a prominent area

by your pool.

5. Post near all entrances to the pool area a list of telephone numbers for the following:

a. Local police

b. Local fire department

c. Local rescue unit

d. Local ambulance service

e. Local hospital

f. 911 emergency number, if available

6. Provide fencing or an enclosure which is independent of the house as a closure around the entire pool

area. The fencing must be made of durable material, a minimum of 4’ high from ground level and with

closures with self-latching locks to make the pool inaccessible to toddlers and uninvited guests. Make sure

the gate is always closed. Be sure to follow local building code requirements for load capacity and fencing

if using an aftermarket or homebuilt deck.

7. Check with your local town or municipality in regard to obtaining a building permit and/or an electrical

permit. The installer shall follow the regulations for set backs, barriers, devices and other conditions.

8. All electrical outlet connections should be a minimum of 5’ from the outside perimeter of the wall of the

pool. From 5’-10’ there should be either a fixed connection (outlet box) or twist lock connection with a

GFCI. Connect power cords to a 3-wire grounding-type outlet only.

9. Severe electrical shock could result if you install your pump or filter on a deck. They could fall into the

water causing severe shock or electrocution. Do not install on a deck or other surface at, above or slightly

below the top ledge of the pool, within 5 feet of pool water edge.

10. Do not sit, stand or climb on the pump and filter or any part of the pool structure. Components such as the

filtration system, pumps and heater must be positioned so as to prevent their being used as a means of

access to the pool by young children.

11. Never drink alcoholic beverages or use any intoxicants which could hinder your judgment and reflexes.

12. Never use the pool alone. All children must be supervised continuously.

13. Do not use pool if bottom is not clearly visible. At night, sufficient lighting must be available. It is the pool

owners’ sole responsibility to provide adequate lighting for the pool bottom, safety signs and walkways,

which exceeds minimum standards of the IES of North America.

14. Be sure that all toys, chairs and tables or similar objects that a young child could climb on be at least 4’

from the pool.

15. Do not use pool during electrical or rain storms.

16. See available Association of Spa and Pool Professionals (APSP) publications for more tips on pool safety.

IMPORTANT SAFETY INFORMATION

INTRODUCTION

Installation of the Metric Series above ground pool is not extremely hard or confusing. The

installation of an average size aboveground pool (18’-33’ diameter) will usually require 2-3 people

to help set it up. The secret to installing a pool so that it will give you years of enjoyment is to take

the time to follow the step-by-step instructions. It is very important to follow the instructions in the

sequence laid out in this manual. Included in this manual is an assortment of tools and materials

which you will need for preparing the ground, checking the levelness and setting up the pool.

Failure to follow instructions exactly will void all warranties. Read all instructions for related

accessories such as pumps, filters, etc. prior to starting.

Before you start, check your packing list to confirm that you have the correct number of parts and

components. The manufacturer reserves the right to revise, change or modify construction of its

pools. See proceeding page for Metric Series Pool Components chart. If there are any missing

or damaged components, please contact your retailer for replacement.

Even though all Radiant pools are designed to meet or exceed industry recommended safety

standards, special attention must be paid to all installation procedures that the installer performs

and controls. Spend time to assure that the entire pool framework is perfectly level. Unlevel pools

place extreme pressures on the pool walls. An earth mound or pool cove must also be installed.

This keeps the pool liner from creeping out from under the pool wall. Be sure to follow these

instructions. Improperly installed pools can rupture, allowing thousands of gallons of water to rush

out causing extensive property damage and injury to anyone in its path. As with any major home

project, a homeowner is responsible for following all local laws, ordinances and codes. Electrical

grounding of swimming pool is required. National and local codes must be followed. A checklist is

provided below as a guide for these considerations.

simply brilliant.

With proper installation and care and

maintenance, this Metric Series Residential

Swimming Pool from Radiant Pools will

provide a lifetime of fun and relaxation for

you and your family and friends.

Radiant Pools offers a, non-prorated,

lifetime warranty on the entire pool

against manufacturing defects. Walls

panels, and aluminum components are

warranteed against factory defects due

to faulty workmanship or defects due to

manufacturing for as long as you own your

pool. Compare our warranty with any other

pool manufactured. Engineering, innovation

and efficiency make the difference.

It’s simply brilliant.

Obtain building permit if required.

Local building and zoning requirements

Electrical and Grounding requirements

Proper Backfill and Drainage

Fencing requirements

Backwash (waste water) requirements

Check availability of utilities.

Call before you dig (www.digsafe.com)

HOMEOWNER CHECKLIST

✓

1

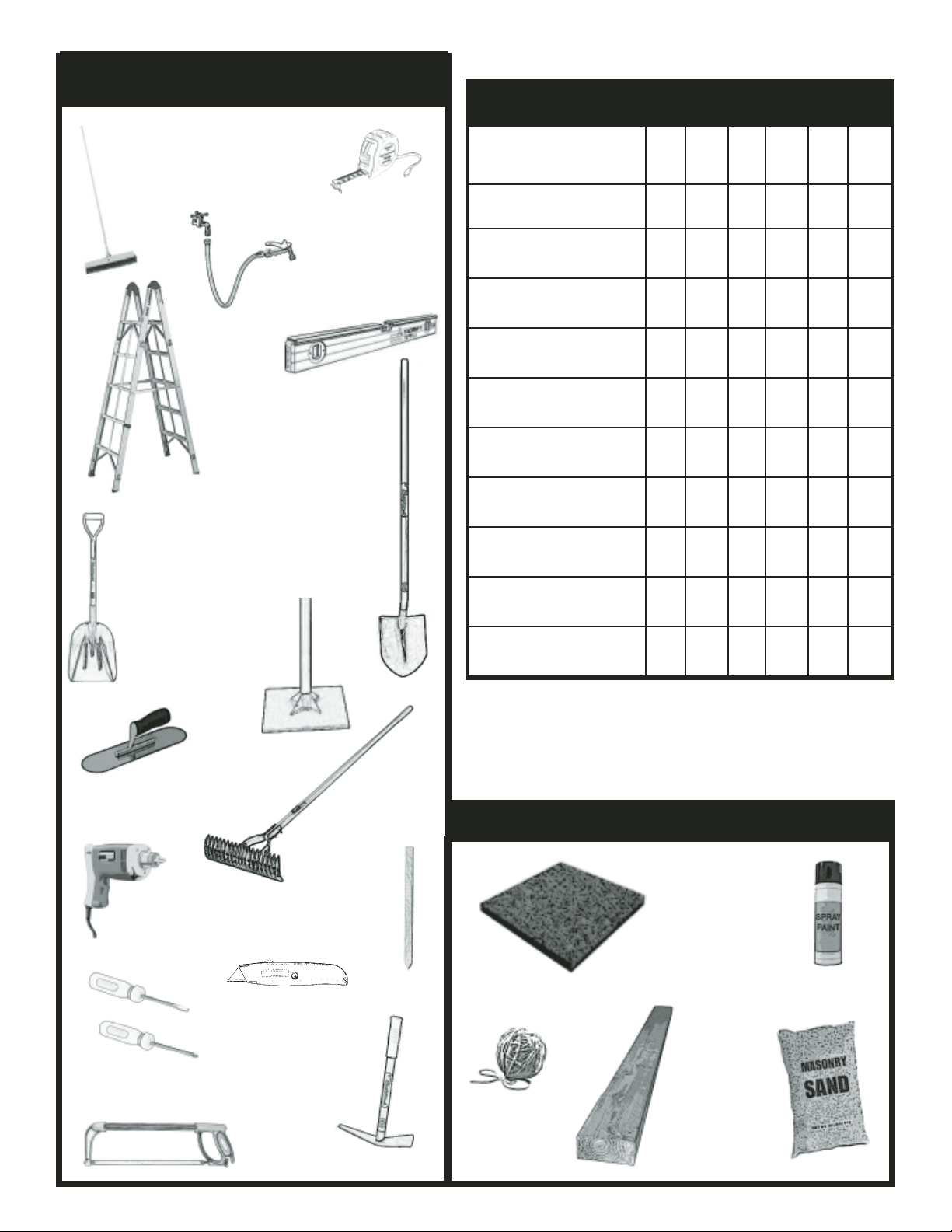

TOOLS NEEDED

MATERIALS NEEDED

Tape measure, 50ft.

Hose with spray nozzle

Level

Step Ladder

Long handled

pointed shovel

Short handle square shovel

Pick or mattock

Garden rake

Stake

Power Drill

Tamper,

10 or 12 in. Square

Hacksaw

Razor knife

Pool trowel

Screwdrivers,

Flathead and Phillips

String

2x4

Masonry

Sand

Spray Paint

Soft bristle broom

Patio Blocks

(2”x8”x16”)

POOL COMPONENTS CHECKLIST

*included for inground installation only.

IMPORTANT NOTE: DO NOT ALLOW SPLINES OR

COMPRESSION SEAMS TO COME IN CONTACT

WITH SAND OR OTHER DEBRIS AS THIS WILL

CAUSE DIFFICULTY IN INSTALLATION

Component 18’ 21’ 24’ 27’ 30’ 33’

Panels 8 10 10 10 12 14

Rebar 8 10 10 10 12 14

Anchor Plates 8 10 10 10 12 14

Coping 8 8 10 10 12 14

White Cap Screws 50 50 50 50 100 100

Coping Clips 8 10 10 10 12 14

Splines 16 20 20 20 24 28

Bolts (3/8”x2 1/4”)* 16 20 20 20 24 28

Skimmer Kit 1 1 1 1 1 1

Return Fitting 1 1 1 1 1 1

Vinyl Liner 1 1 1 1 1 1

2

IMPORTANT: BEFORE YOU BEGIN

The selection and preparation of the pool site is your responsibility. The manufacturer can

only suggest the proper techniques, indicate the important considerations and emphasize the

precautions and cannot be held responsible for damages to your pool that may result from

failure to carefully follow all pool specifications.

All Radiant Pool components are engineered to provide a precise fit. It is very important to

handle all components with care. Prior to assembly, all pool components should be free of

sand, mud, dirt and debris of any kind.

Do not allow splines or compressions seams to come in contact with sand or other

debris as this will casue difficulty with installation. We recommend a small dust broom

or damp cloth be available in the event that any dirt or debris finds its way to these

parts.

3

STEP 1: SELECTING POOL LOCATION

The selection and preparation of the pool site is your responsibility. The manufacturer can only suggest the

proper techniques, indicate the important considerations and emphasize the precautions and cannot be held

responsible for damages to your pool that may result from failure to carefully follow all pool specifications.

1. The surface on which your pool will stand must be absolutely level and solid. This condition should

extend 1foot beyond the actual pool area all around. The best surface is bare solid earth free from

stones, roots and other sharp objects.

Fill

2. Allow plenty of play area around the pool. Fit the location into your landscaping plans.

3. The pool site must be accessible to electrical and water supply and should allow for disposal of great

quantities of water when the pool is drained. All electric outlets within 10’ must be GFI protected.

5. Do not set up your pool in hilly areas or areas with poor drainage.

For Semi-Inground and Inground Installations:

The site of installation must accomodate an efficient

drainage system to minimize the impact of heavy rain

and high ground water conditions.

4. When installing your pool on a solid level surface, it is imperative that you protect your pool and liner

from chemicals and other foreign matter contained in the surface. Do not install your pool on peat

moss, tar paper, roots, sticks, gravel or chemically treated or contaminated soil not approved for pool

use. Any or all of these surfaces can ruin your pool and liner and will void your warranty. To prevent

stones or other foreign material from damaging the liner it is recommended to build a 2” to 3” base of

clean washed masonry sand or other suitable base material inside the entire pool.

5. If ants or termites are prevalent in your area, have soil treated with insecticides and allow sufficient

time for them to dissipate before continuing with pool installation.

6. Do not set up your pool under trees or under overhead wires.

7. Do not set up your pool near any existing structure such as

your house, garage, etc., as this condition may compel diving

or jumping into your pool which could result in permanent injury or

death. You must check with your local municipality for all appropriate

ordinances and regulations.

8. Do not set up your pool on or near any septic system or underground

utilities.

NO

NO

NO

NO

CORRECT

4

Once the ground is prepared, begin installing

2”x8”x16” patio blocks. (fig.C) The patio

blocks should be installed at the perimeter line

of the pool (1/2 the pool size from the center

stake) and at intervals corresponding to the

number of panels associated with the size of

the pool. Please see chart for appropriate

spacing.

Sink each patio block into the prepared ground

making sure that each block is level in all

directions (side to side as well as front to

back). Repeat this step around the perimeter

of the pool area making the tops of all blocks

level with the ground. Do not install the blocks

on loose sifted soil or sand. All patio blocks

must be flush with the ground, solid and level

with each other in all directions. Once all of

the patio blocks are installed, place a joiner

plate on each patio block. (fig.E) The joiner

plates will be used to provide a level platform

for wall installation.

18’ 6’ 10 5/8” 8

21’ 6’ 5 7/8” 10

24’ 7’ 5” 10

27’ 8’ 4 1/8” 10

30’ 7’ 9 1/8” 12

33’ 7’ 4 1/8” 14

Patio Block

Intervals

Pool

Size

Qty

Needed

Once you have chosen an appropriate location

for your pool based on the criteria specified

above, determine the pool circumference by

putting a stake in the ground at the center of the

location desired and with a line equal in length

to the radius of the pool (1/2 the pool size plus

12”), mark off the circumference with a sharp

object, lawn edger, spray paint, etc. (fig.A)

After all of the sod has been removed,

you must make the pool area absolutely

level as measured by a transit or level.

Find the lowest spot within the pool area and

level the ground to that lowest spot. (fig.B)

Do not add dirt to the low areas. It is the high

areas that must be dug away. The perimeter

of the pool must be a solid foundation to prevent

the pool from settling into dirt that is loosened

by rain and water splashing over the side.

Once again, clean the area of all sharp objects,

including roots and rocks that could later effect

your swimming pool.

For Site Preparation insstructions for

Inground installation, see page 12.

STEP 2: PREPARING THE POOL SITE

STEP 3: PATIO BLOCK INSTALLATION

D.

Patio

Block

B.

C.

Patio Block

Pool

Radius

A.

Pool

Radius + 12”

5

Compression Seam

Anchor Plate

Patio Block

Compression

Seam

Spline

E.

Locate the wall section that is cut for the

installation of both the skimmer and return

fitting. The location for this panel should be

adjacent to the electrical supply and provide

ease of access once the pool is installed.

Place the 2 wall sections so that the panels

meet on center of a patio block. At the end of

each wall panel is a compression seam for the

spline assembly. Place an anchor plate on patio

block, centered under compression seams of

meeting panels. Attach wall sections using the

provided splines. Please be aware that each

compression seam should be flush before

attempting to insert the splines. (fig.G) Splines

are designed to slide freely into place when

inserted properly into leveled panels.

NOTE: When inserting each spline, please be

aware that the outside spline should be

inserted completely before inserting the

inside spline.

Duplicate this process with the remaining wall

panels stopping before installing the final wall

panel. At this time, you need to bring in the

sand through this opening to prepare the bottom

of the pool.

12" max.

STEP 4: WALL INSTALLATION

Dished bottom option

Skimmer

Return Fitting

Wall Section

G.

Pool Exterior

Pool Exterior

Bring the required amount of clean and washed

masonry sand into the interior of pool area

Refer to the chart below for the required

amount. Once the sand has been placed inside

the pool, install the remaining wall panel.

STEP 5: SAND REQUIREMENTS

(1 yard masonry sand = appx 1.5 tons)

18’ 2

21’ 3

24’ 3.5

27’ 4.5

30’ 5.5

33’ 6.5

Sand Amt

(cubic yds)

Pool

Size

6

Install rubber gasket on the mounting plate,

making sure the gasket straddles both sides of

the mounting plate. (fig.H)

Slide skimmer face through pre-cut skimmer

opening, keeping skimmer body on outside of

pool wall. Attach gray plastic mounting plate

tightly to skimmer face using panhead screws

into each side center holes as shown circled.

(fig.I)

Fasten assembly by inserting 2” countersunk

bolts through corner holes in mounting plate,

through pre-cut holes in pool wall and

through corner holes in plastic backup

plates securing with T-nuts.

Hand tighten only.

Finish securing backup plates with

4 sheet metal screws per diagram.

The skimmer faceplate is attached

after the liner is installed.

For Skimmer Assembly instructions for

Inground installation, see page 15.

The return fitting is comprised of 3 pieces:

inlet fitting, SP 1091Z10 and back nut. (fig. J)

In geographic areas of deep winter ground

freezing, an inlet plate (#3185) is

recommended.

Install the return fitting by threading the

SP 1091Z10 into the inlet fitting. Place the

assembly into the pre-cut hole, slide the inlet

plate over the exposed threads and then

thread the back nut onto the SP 1091Z10

fitting. All threaded connections should be

prepared using a combination of Teflon tape

and marine grade silicone. The return faceplate

is attached after the liner is installed.

STEP 6: SKIMMER ASSEMBLY

I.

Gray Plastic Skimmer

Mounting Plate w/gasket (1)

2” countersunk bolts (4)

Sheet metal

screws (4)

Skimmer

Pre-cut Skimmer

Mounting holes (4)

Plastic Backup Plates (2)

SP 1091Z10

Back Nut

Inlet Fitting

STEP 7: RETURN FITTING ASSSEMBLY

J.

Inlet Plate

H.

Mounting Plate

Gasket

7

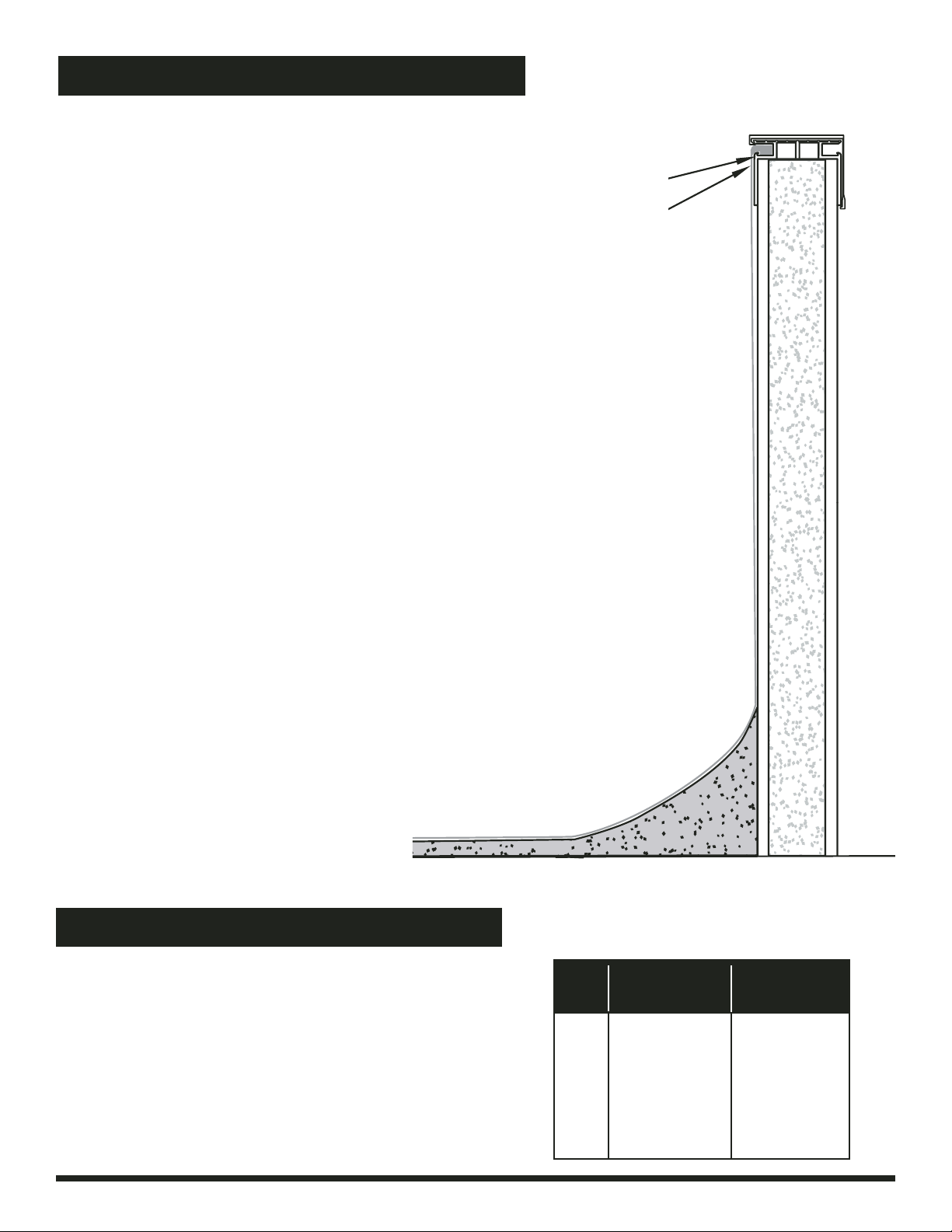

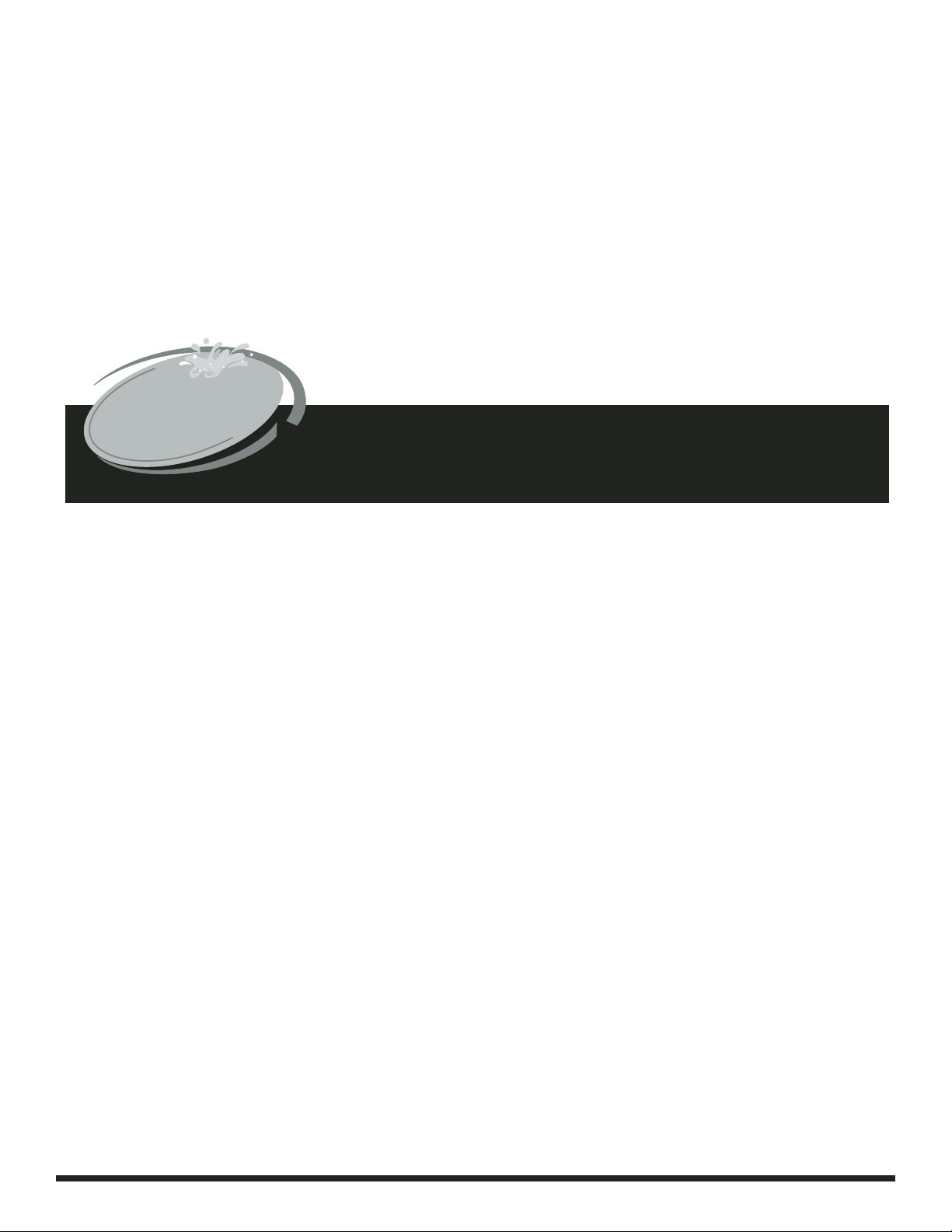

2" EPS FOAM

INSULATION

ACRYLIC COATED

ALUMINUM WALL

BEADED VINYL LINER

DURABLE PVC COPING

PVC COPING CLIP

The plastic coping is attached by simply snapping

over the pool wall. Each coping joint should be offset

from a wall joint. (fig. L) You need to leave a 1” gap

between lengths of coping. Once all of the coping

has been placed, secure the coping to the pool wall

with the white cap screws provided. Using a 3/32”

drill bit, drill through the plastic coping and

EXTERIOR pool wall while pressing down firmly

on the coping on top of pool wall. Using a Phillips

screw driver, hand tighten each screw. DO NOT

OVERTIGHTEN.

Note: Plastic coping on the interior side of the

pool wall will be held in place by the weight of

the water on the beaded vinyl liner.

For the 18’ pool, the screw spacing should be

approximately 24” beginning with the first screw

approximately 2”-3” over from a compression seam.

For all other pool sizes, the screw spacing should

be approximately 29” beginning with the first screw

approximately 2”-3” over from a panel joint. The

beaded vinyl liner with the weight of the pool water

will draw coping into place and level on the interior

of the pool wall.

Install coping clips by snapping over gaps between

coping lengths.

For CP2 coping installation instructions for Inground

installation, see page 15.

STEP 9: INSTALLING PLASTIC COPING

STEP 8: PREPARING POOL COVE

Pool Cove

Interior

Pool Wall

K.

Using the masonry sand, build a pool cove

6” to 8” high inside the wall along the entire

circumference of the pool.(fig. K) This will

prevent the liner from creeping under the wall.

This step is not optional and must be done.

Spread the remaining sand equally across the

bottom of the pool. This will give you a 2” to 3”

sand base. After the cove and base are in place,

dampen, rake and tamp the entire pool area.

Make sure that no sand is allowed to

remain on the wall above the cove.

This could cause pinholes in your liner.

Pool

Exterior

Wall Joint

Pool Base

Coping Clip

L.

8

18’ 6335 6963

21’ 8622 9477

24’ 11,262 12,378

27’ 14,254 15,666

30’ 17,645 19,388

33’ 21,293 23,403

BEADED VINYL LINER

BEAD RECEIVER

STEP 11: FILLING YOUR POOL

Whether you are filling the pool with your own

home water source or through a water-fill service,

please use the chart at right to determine the water

volume requirements for your particular size pool.

Please see your pool professional for instructions

on proper water testing and balancing.

48” Pool Wall

(40” of water)

Pool

Size

52” Pool Wall

(44” of water)

Water Gallonage per Pool Size

STEP 10: INSTALLING LINER

TIP: To help in removing stubborn wrinkles,

a shop vacuum may be used to suck the

air out from behind the liner.. Attach shop vac

to skimmer outlet and seal with duct tape. Seal

all other openings with duct tape as well. Turn on

vac and run till wrinkles are removed. Once the

wrinkles are gone, begin filling with water. After 6”

of water is in the pool, turn off and remove the

shop vac.

BEADED VINYL LINER

BEAD RECEIVER

Clear all sticks and sharp objects from an area near

the pool that is as large as the pool itself. Remove

the liner from its carton and unfold and open the

liner. Refold the liner so that it can easily be carried

to the pool and unfold from the outside of the pool.

Check to make sure the sand in the pool is level

and that there are no sharp objects in the pool.

Place the liner into the pool while holding onto the

top of the wall section of the liner. Snap the bead

of the liner into the bead receiver around the entire

pool. Gently pull on the liner and use a soft bristle

broom to remove as many wrinkles as possible on

the bottom of the pool. Start filling the pool slowly

with water. Continue pulling gently and working the

liner with a broom as needed. Some wrinkling of

the liner may be evident and in no way affects the

structural strength of your pool.You can continue

to work out the wrinkles as needed by pulling

gently on the liner or by using a broom.

9

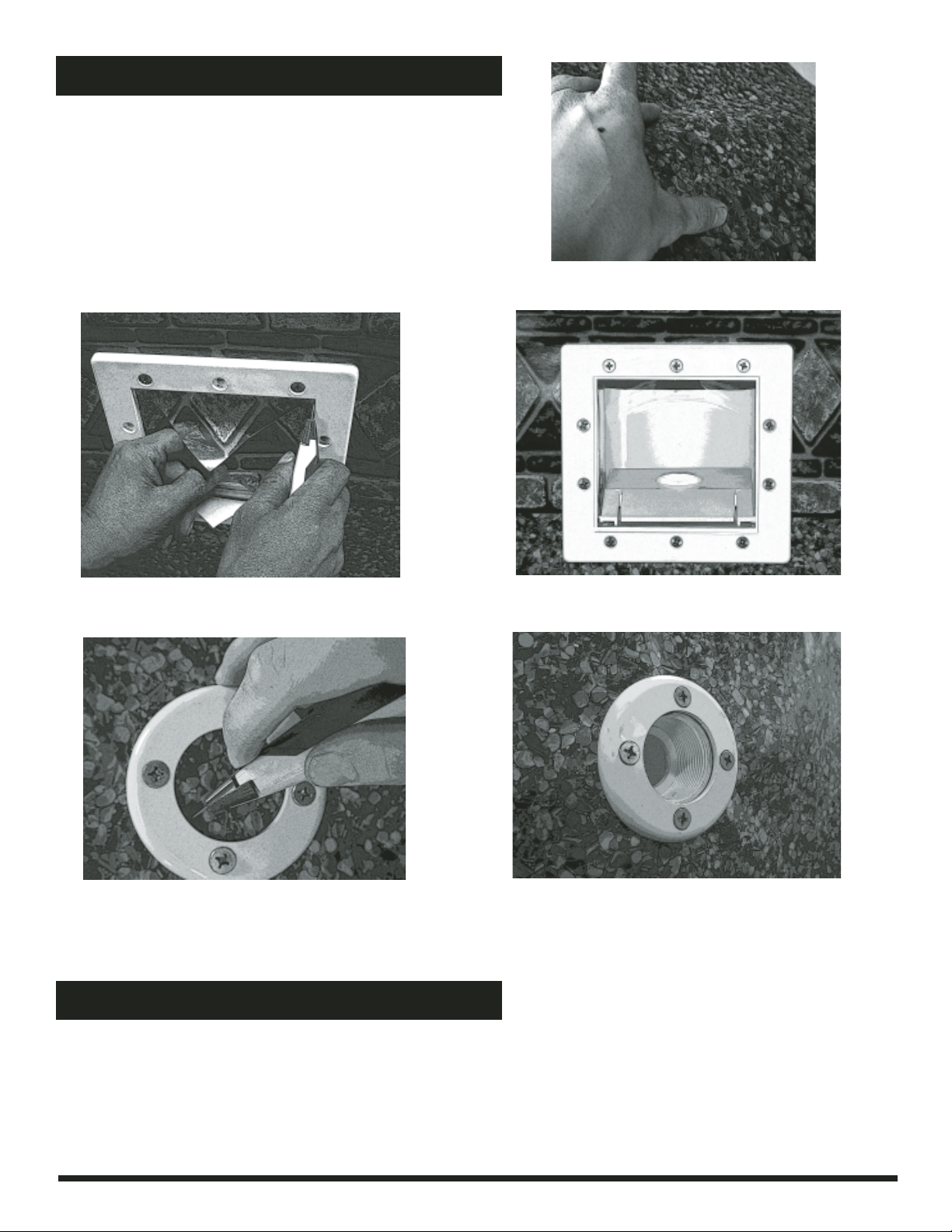

STEP 12: INSTALLING FACEPLATES

Once the water level reaches 2”-3” from the return

and skimmer, install the faceplates. Carefully locate

the screw holes in for each opening. Once located,

carefully puncture the liner with an icepick or nail.

Attach faceplate with 1” screws and hand tighten

evenly till snug. Using a razor knife, carefully trim the

liner out of the openings for the skimmer and return.

When done, install the eyeball into the return. Locate screw holes.

Trim liner from skimmer opening.

Trim liner from return opening.

Skimmer faceplate installed.

Return faceplate installed.

Please refer to pump and filter manufacturers’ installation instructions.

STEP 13: CONNECTING PLUMBING

10

Metric Inground Installation Instructions

11

With the shape of the pool excavation marked out, its height relative to the ground must be

determined. The pool should be set at a height so that rain and splash will drain away, rather than

towards the pool. It is best to use a building level, transit and a measuring stick to determine the

required depth of excavation. It is best to set up the transit in a location so that you can leave it in

the same place for the entire pool excavation. It is best to keep the top of the pool 2”-6” above the

ground at the highest point so that you are able to place your deck on undisturbed soil.

Since the excavation will be 2’ wider ( Recommended for the first time installations, even though a

1’ excavation is acceptable) all around than the actual pool dimension, it is important that the

excavator does not dig the 2’ ledge around the hopper too deep. A sturdier pool will result when

the pool rests on undisturbed earth. It is better to have to remove a inch or two by hand then to

have to build up after the excavator had gone too deep. Any voids beneath the wall panels cause

by large rock removal, etc., must be filled and properly compacted.

INGROUND: LEVELING THE EXCAVATION

TRANSIT

2" - 6" ABOVE HIGHEST GROUND OUTLINE OF POOL

MEASURING STICK

FLOOR OF EXCAVATION

SIDE VIEW OF EXCAVATION SITE

CORRECT INCORRECT

UNDISTURBED EARTH

CUT AWAY FILL IN

POOL WALL POOL WALL

If steps are going to be installed, excavate a 6 foot by 10 foot area where they are to be located on

the pool. Please see the dig specifications for locations of steps.

IMPORTANT NOTE: if installing steps with your Metric Inground installation, you

must begin the process at the step site. Wall panels must first be mounted to

the step and wall panel assembly continues from there.

PREPARING FOR WALK-IN STEP

12

Step Extension Plate

Female Stair Connector

T-Spline

Radius Wall Panel with

Compression Seam

Male Stair Connector

Stair Flange

Hex Bolt

Hex Nut

INGROUND: WALK-IN STEP INSTALLATION

Metric step installation components:

Pool wall height 52" / Step height 48"

• 4" step extension plate to close gap at bottom of step

• Radius step connector - 2 parts (both are 48" long):

- male portion attaches to the pool wall with splines

- female portion is bolted to the step flange

• Standard spline for interior side of pool

• Extended T spline for exterior side to connect A-frame

• Each pool will have 1 panel that is shorter in length,

except the 27' pool which will have 2 shorter panels

1. Position the step in the installation location. Level step,

establish pool height (pool height will be wall height plus

coping on top).

2. Align the female stair connector with the side flange of the

step as pictured. The ‘C’ receiver toward and flush with front

interior edge of the step. The top of the connector at finished

wall height

3. Clamp connector in place, drill step flange at holes in

connector with a 7/16 drill bit, bolt connector to the step,

do not tighten until all panels are completely connected.

4. Slide male step connector down female connector attached

to step.

5. Install standard spline on interior side of pool and extended

T spline on exterior side, connecting the step to the first panel.

6. Install A-frames at the 2 extended splines, check level of step,

tighten the step connector bolts.

7. Check panel joints for proper location-using the radius of pool

from the established center point of the pool.

8. Encase the base of the pool and step with a concrete collar.

See concrete requirements on next page.

9. Follow step Manufacturer’s instructions for installation of step

gasket and faceplate after the liner is installed.

18’ 8’ Radius

21’ 8’ Straight

24’ 8’ Straight

27’ 8’ Straight

30’ 8’ Straight

33’ 8’ Straight

Step Type

(48” Height)

Pool

Size

Step Specifications

for Metric Pools

Note: Drawings are for

illustrative purposes and

are not to scale. Attachment

detail will vary for steps from

different manufacturers.

13

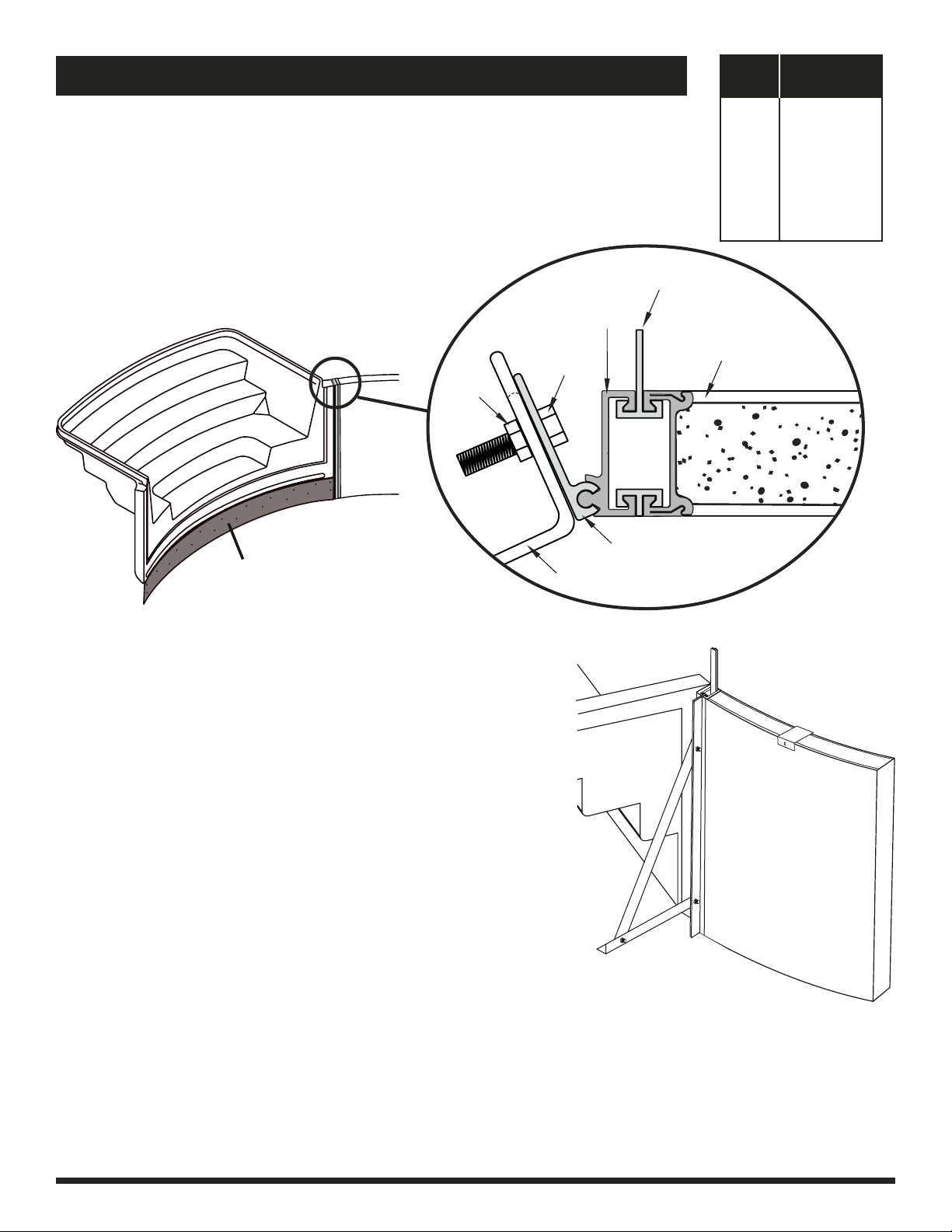

2" Wall Clips

Hex Bolts

Wall Anchor

Pool Interior

Anchor Plates

Wall anchors are located at each compression

seam. With a high speed metal drill bit, drill

two 7/16” holes on each side of the compression

seam in each wall anchor as shown. Insert

a provided nut and bolt through each drilled

hole as illustrated, with the nut on the outside

of the pool (fig.1). Drive rebar through one bottom

hole to secure in proper. Duplicate this

process with the remaining anchor plates.

INGROUND: ANCHORS PLATES AND WALL CLIPS

Wall Clips for Installation of CP2 or

Extrusion Coping

Slide clips, evenly spaced, over radius wall

panels to attach concrete receptor coping.

Clips are to be secured in place with tek

screws, through exterior pool wall.

Wall Clip Detail

Pool Exterior

Tek Screw

2" Wall Clip

Pool Exterior

14

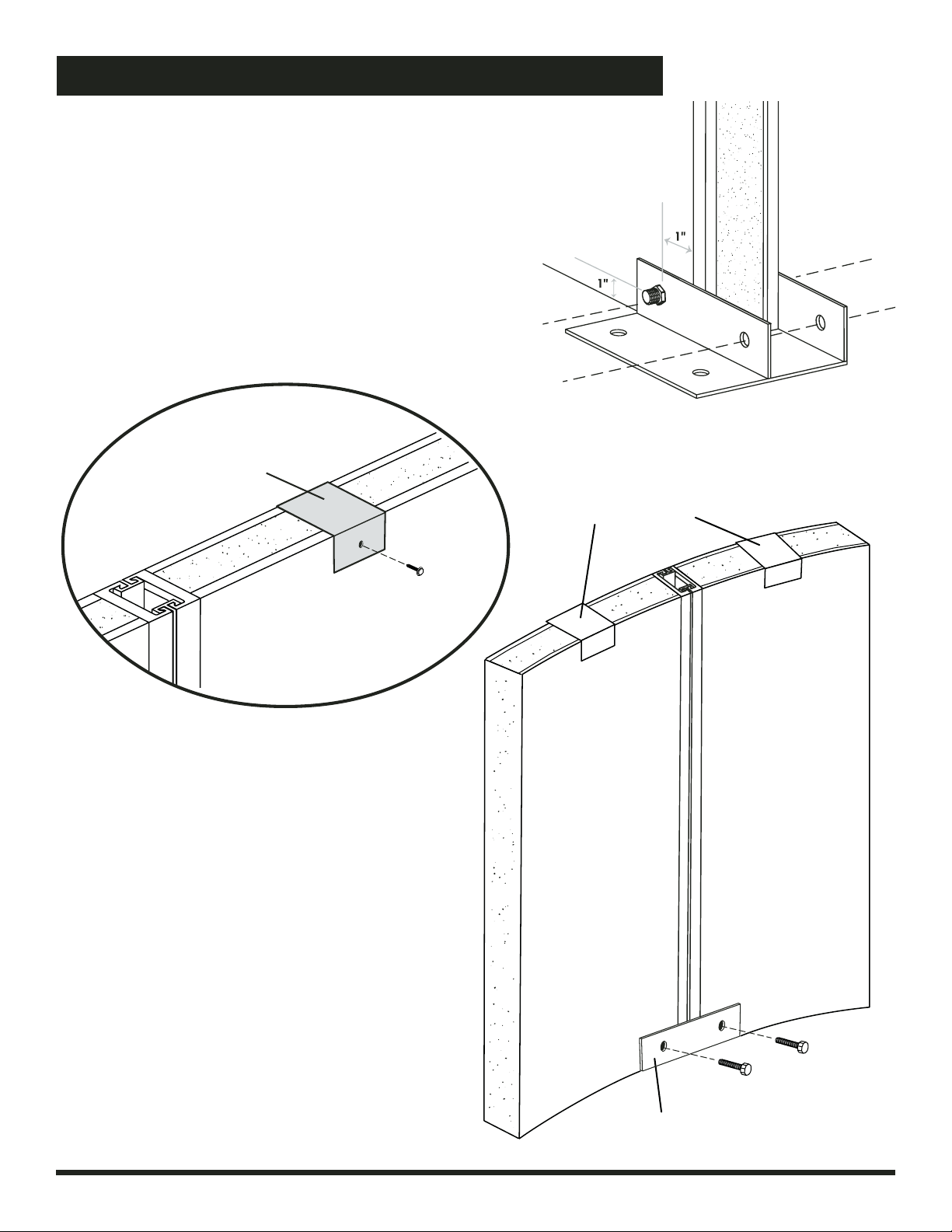

INGROUND: SKIMMER ASSEMBLY

Countersunk Bolts (4)

Nuts (4)

Skimmer Mounting

Brackets (2)

Skimmer

2" Male Adapter

Skimmer

Support

Plastic Skimmer

Mounting Plate (1)

with gasket (1)

Install rubber gasket on the

mounting plate,

making sure the gasket straddles

both sides of the mounting plate.

(fig.H)

Slide skimmer face through

pre-cut skimmer opening,

keeping skimmer body on

outside of pool wall. Fasten

assembly by inserting 2”

countersunk bolts through

corner holes in mounting plate,

through pre-cut holes in pool

wall and through skimmer

mounting brackets, securing

with hex nuts. Tighten nuts to

a snug fit.

Do not over tighten as this will

damage the mounting plate.

Install skimmer support.

It is recommended that

2” PVC pipe be cut to size,

depending on installation. Utilizing

a 2” male adapter, attach support

to bottom of skimmer as shown.

Extension Collars (fig.I) are used

to raise the top of the skimmer to

the height of decking. The number

of extension collars needed is

determined by the variable decking height.

The skimmer faceplate is attached after the liner is installed.

Mounting Plate Gasket

Tek screw

2" Wall Clip

Tek screw

Pool Interior

I.

H.

INGROUND: CP2 COPING INSTALL

Place pre-bent coping length on top of the pool wall. Se-

cure it with Tek screws at the previously installed 2” wall

clips. The next length is placed adjacent to the end of the

first length, continuing around the pool. It is not necessary

to leave spacing as with the standard white coping. If you

are installing a walk-in step, start at the step and continue

around the pool, cutting the last length to fit. Install coping

clips to cover the ends of the lengths.

15

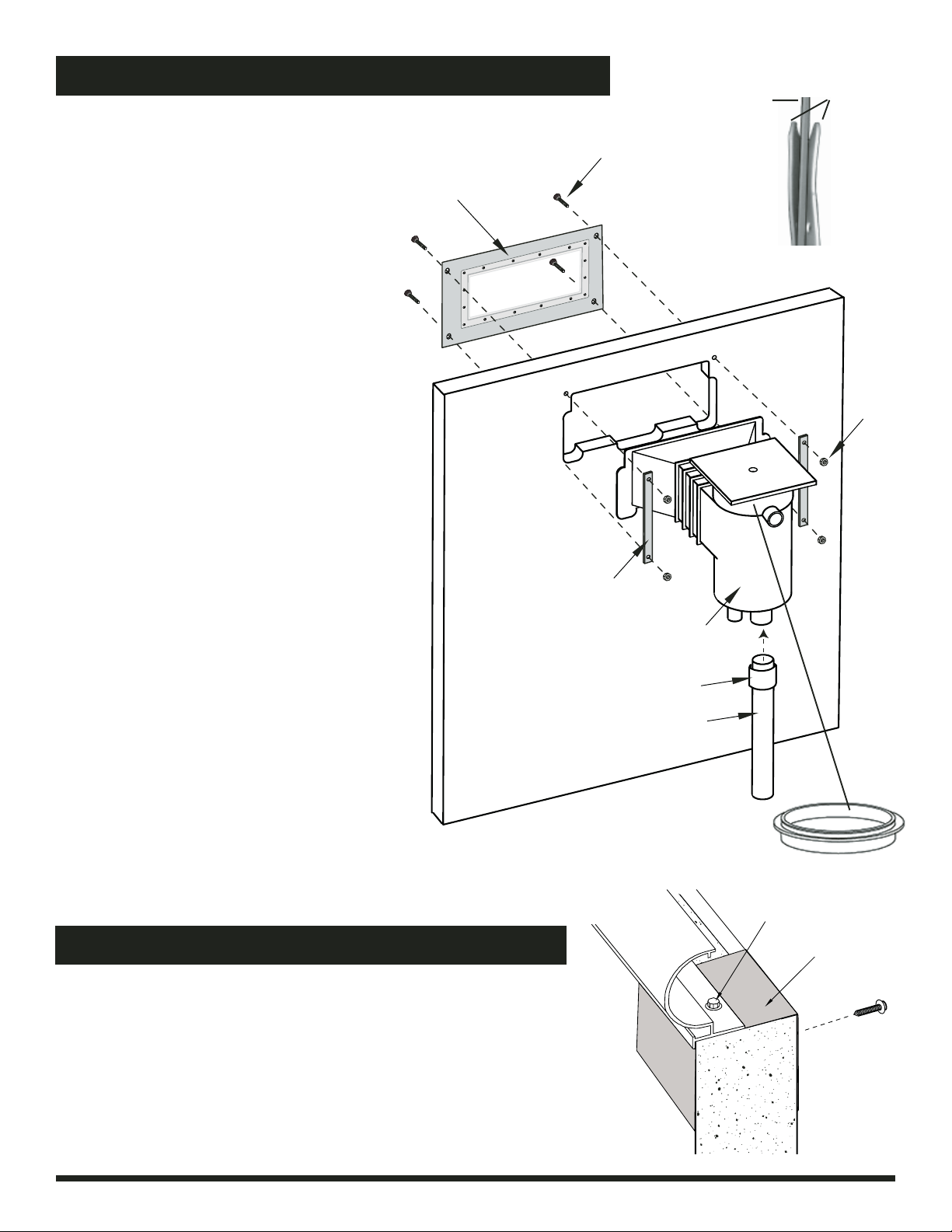

CONCRETE COLLAR GUIDE

16

2'

8"

Undistrubed Earth

Drift Pin Drift Pin

Undistrubed Earth

8"

12"

Drift Pin

Concrete Collar

at Step and

A-Frame

Location

Concrete Collar

fig.1

fig.2

Estimating Concrete Requirements:

These are minimum estimating figures. It is recommended that estimates be on the high end

as the excess can be poured around A-Frame and step. Combine both figures below for

total yards of concrete required.

Collar: Pool Perimeter (ft.) x .02 = Yards required.

Pool

Interior

Pool

Interior

Check with local building codes before installing your Radiant Metric pool inground. If the pool

is to be installed in geographic areas with winter ground freezing, Radiant Pools recommends

a 6” to 8” concrete collar around the entire pool (fig.1).

If you are installing a walk-in step, Radiant Pools REQUIRES that a concrete collar be poured

around the entire pool (fig.2). Add 2.5 yards of concrete to the ‘estimating concrete requirements’

for the concrete around the step and A-frames.

Step

Concrete

A-Frame

Trojan Leisure Products, LLC. 440 North Pearl Street, Albany, NY 12207

518-434-4161 fax 518-432-6554

ANY IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTIBILITY AND FITNESS FOR A PARTICULAR PURPOSE,

ARE HEREBY LIMITED TO THE DURATION AND SCOPE OF THIS WRITTEN WARRANTY. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. UNDER NO CIRCUMSTANCES SHALL TROJAN LEISURE PRODUCTS, LLC BE LIABLE FOR

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, ANY DAMAGES FOR LOSS OF USE OF POOL, INJURY TO, OR DEATH OF,

ANY PERSON, OR DAMAGE TO PROPERTY, AND ANY CLAIMS THEREFORE ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED. SOME STATES DO NOT ALLOW

THE EXCLUSION OF SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. THEREFORE, THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

✁

Owner Name ____________________________ Serial No. ________________________________________

Address ____________________________ City, State, Zip ________________________________________

Pool Size _________________________ Purchased From ________________________________________

Installed By: Dealer Private Installer Owner Date of Installation ____________________________

IMPORTANT: PLEASE READ AND SIGN: I have received and reviewed the Pool Owner’s Operating and Safety Information

package which includes: Safety

Guide, Consumer Care Manual, Liner Warranty, “No Diving” stickers/instructions, “No Diving Sign, Pool Owner

Warning.

________________________________________________________________________________________

Owner’s Signature Date

RADIANT POOLS METRIC SERIES RESIDENTIAL SWIMMING POOL

NON-PRORATED LIFETIME LIMITED WARRANTY

There are no warranties that extend beyond the description on the face hereof. This Warranty, offered by Trojan

Leisure Products LLC, dba Radiant Pools, of Albany, NY, herein called the “Manufacturer”, is effective upon completion of

payment by purchaser. Manufacturer warrants its manufactured swimming pool components against manufacturing defects.

These components include wall panels, panel connectors, top and bottom channels, all aluminum bracing components,

splines and aluminum nuts and bolts only. This Warranty does not extend to equipment and other accessories not

manufactured by Trojan Leisure Products, LLC. Manufacturer’s Warranty performance is subject to the following terms

and conditions:

Transportation: Purchaser is responsible for all

transportation charges incurred for any item returned for

repair or replacement.

Costs: Purchaser is responsible for the cost of installation

or reinstallation of any item repaired or replaced under this

Warranty.

Notification and Delivery: Purchaser must notify

Manufacturer of any defect, and the defective item must

be delivered to Manufacturer, transportation costs prepaid

to: 440 North Pearl Street, Albany, NY 12207. Manufacturer

will effect repair or replacement within thirty (30) days of

receipt, unless purchaser is otherwise notified.

Warning: For maximum use and enjoyment, your Radiant

Pool must be kept filled with water at all times.

Manufacturer shall not be responsible for any irregularities

or imperfections that may result when water is removed

from your Radiant Pools vinyl liner swimming pool.

Winter Damage Provision for Metric Series Pools Only:

The Manufacturer will replace or repair any of its

manufactured swimming pool components, as set forth

above, damaged due to the ill effects of ice or snow directly

on pool only. Any damage resulting from impact of any

objects such as tree limbs or vehicles are excluded.

Purchaser must notify Manufacturer of any winter damage

to receive a winter damage claim form. Manufacturer will

effect repair or replacement within thirty (30) days of receipt

and final processing of winter damage claim form, unless

purchaser is otherwise notified.

Registration of Warranty: After reading your Warranty,

please complete and return the enclosed registration card

within sixty (60) days after delivery of your Radiant Pool,

or within thirty (30) days after installation of your Radiant

Pool if installation is completed within a period less than

sixty (60) days after delivery. UNLESS OUR

REGISTRATION CARD IS RETURNED AS DIRECTED,

THIS WARRANTY IS NULL AND VOID.

Transfer of Warranty: The provisions of this Warranty

are personal to the original purchaser of the Radiant Pool.

This Warranty is 100% transferable from the original

purchaser. The new owner must obtain a warranty transfer

card from the original purchaser to be submitted to

Manufacturer within sixty (60) days of purchase to maintain

warranty.

440 North Pearl Street

Albany, NY 12207

div. Trojan Leisure Products, LLC

PLACE

POSTAGE

HERE

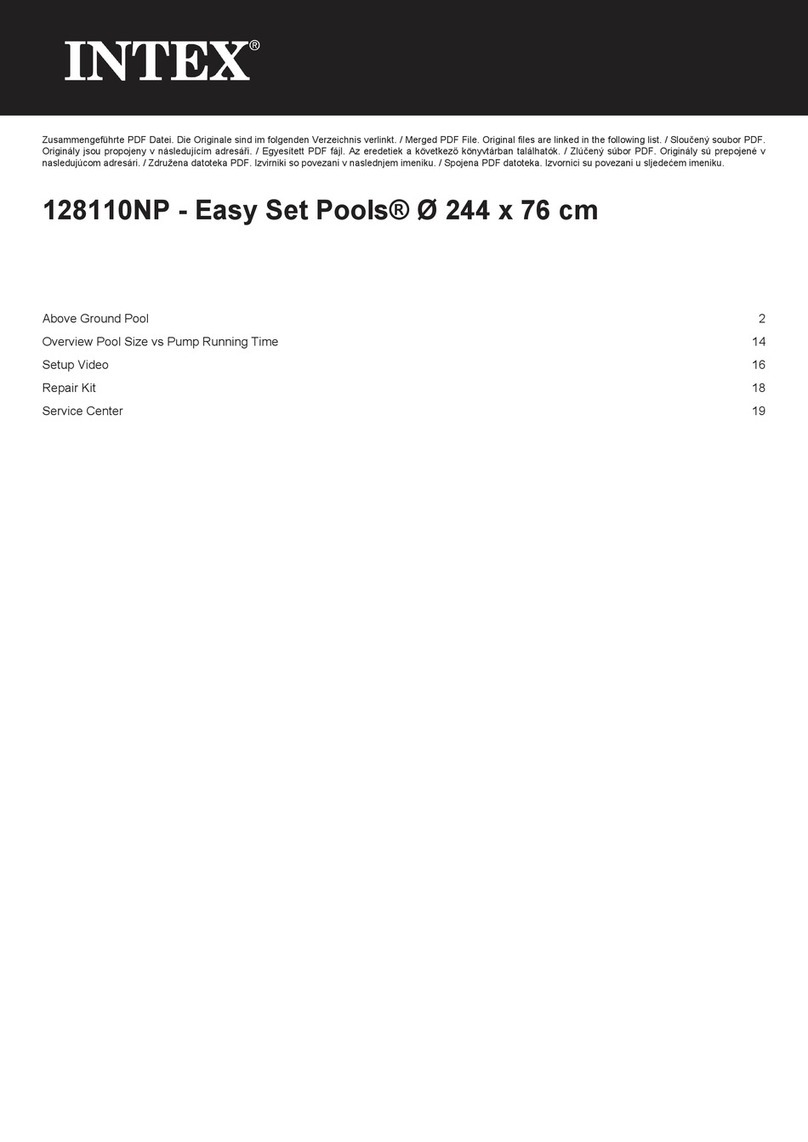

Table of contents