Trolex TX3706 User manual

TX3706-UM-EN-02 3

TX3706 • User Manual

TX3706 • FALCON 25 Series Ex Connectors

Contents

1. Product Overview 4

1.1 Operating Features 4

1.2 Application 5

1.3 Dimensions 5

1.4 Technical Data 6

1.5 Contact Inserts 7

2. Certification & Conformity 8

3. Fitting and Installation 10

3.1 Precautions 10

3.2 Tools and Equipment 11

3.3 Free Plug and Free Receptacle 11

3.3.1 General assembly & definitions 11

3.3.2 Connecting 12

3.3.3 Earth bonding 14

3.3.4 Security coding 14

3.4 Fixed Receptacle 15

3.4.1 General assembly & definitions 15

3.4.2 Bush mounting 16

4. Operation 17

4.1 Engage and separate 17

4.2 Safety precautions 18

4.2.1 Isolate elsewhere 18

4.2.2 Pilot circuit interlocking 19

4.2.3 Live engagement 20

5. Accessories 22

6. Maintenance 23

Disclaimers 23

Trademarks 23

Contact Details 23

www.trolex.com

4 TX3706-UM-EN-02

1. Product Overview

1.1 Operating Features

• Multi-pin connector for use in Group I and Group II hazardous areas

• Precision cast metal Line Plug and Line Receptacle for cable mounting

• Precision cast metal Fixed Receptacle for Ex d or Ex e box mounting

• Standard cable glands are utilised to user preference

• Simple connection - no special tools required

• Double insulated contact cartridge for added safety and ease of connection

• Rapid double bayonet engagement ensures that contacts make or break under Ex d

protection for live disconnection

• Pilot circuit interlocking safety protection can be incorporated

• Security coding options to prevent non-permitted engagement

• Supplied with flexible ingress protection cover caps

• Ex d blanking cover caps may be supplied where specified

• Mounting clamp available for Unistrut bulkhead mounting of Free Connectors

www.trolex.com

TX3706 • User Manual

TX3706-UM-EN-02 5

1.2 Application

• High integrity, multi path, robust, explosion proof connector, designed for extra heavy

duty and critical applications.

• ATEX and IECEx industrial hazardous area applications and underground mines. Suitable

for use in flammable gas and dust atmospheres.

• Rapid and convenient connect/disconnect of control circuits and power circuits for

electrical equipment installation.

• Live disconnect of critical equipment for maintenance and change-out.

• Offshore oil and gas platforms, mining, tunnelling, petrochemical plants, process plants,

storage areas, pump stations, well head control panels, mobile equipment, on shore drill

rigs and top drive control room systems.

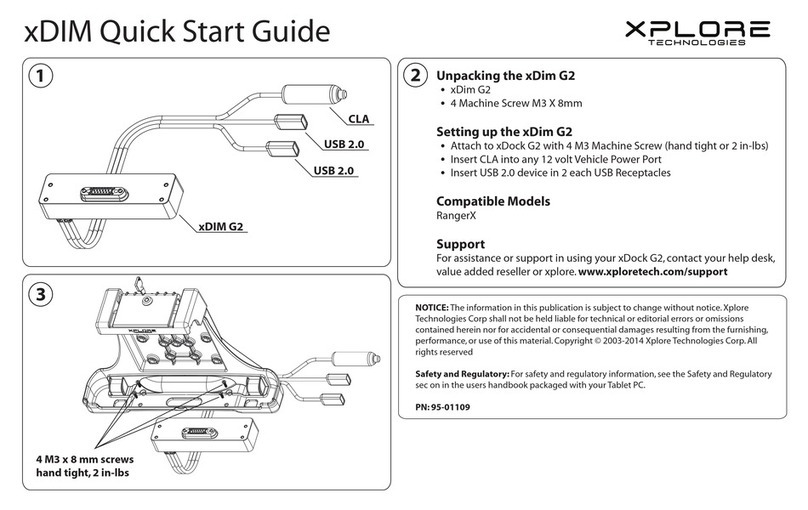

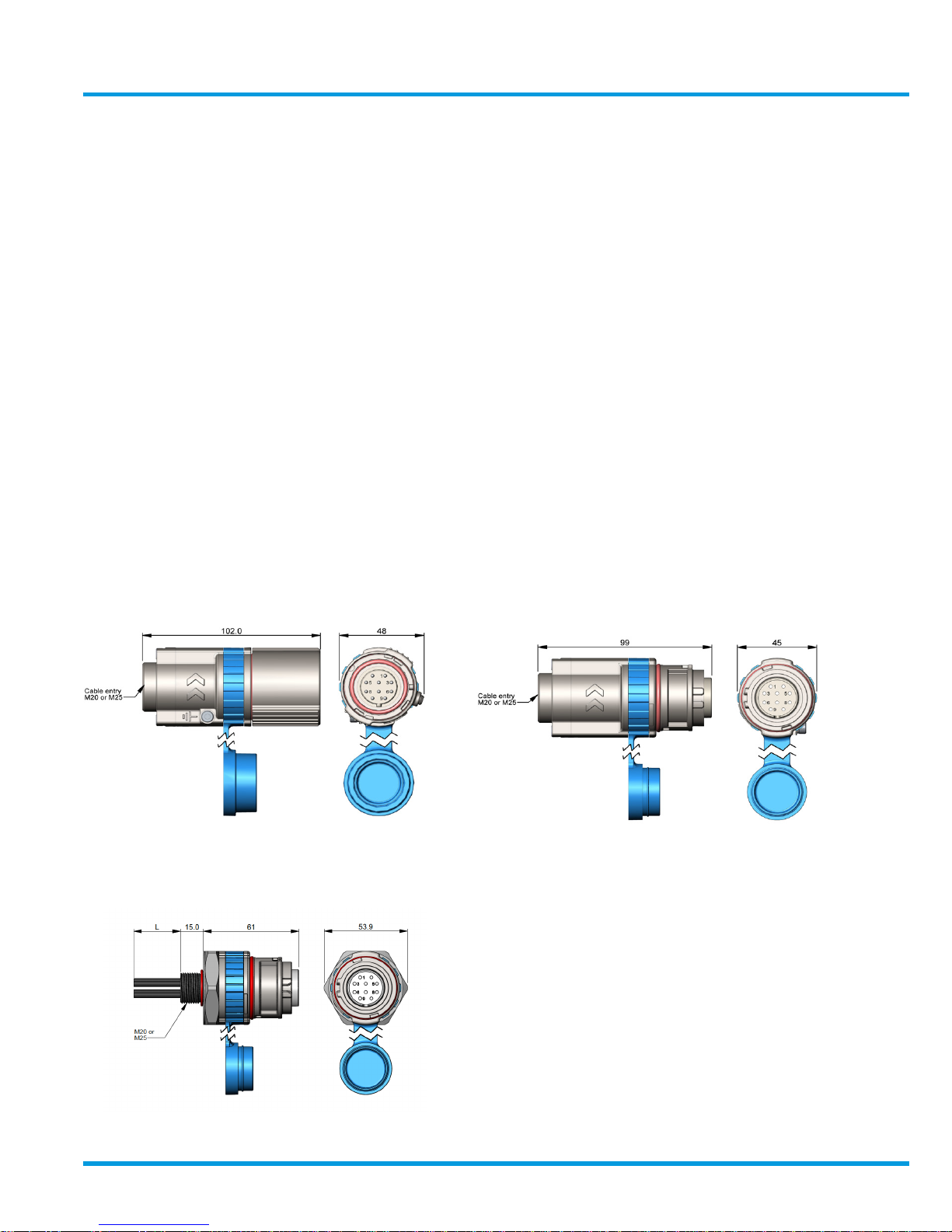

1.3 Dimensions

TX3706.1 Line Plug

TX3706.3 Fixed Receptacle

M20 or M25 bush mounting on

Ex d or Ex e enclosures

TX3706.2 Line Receptacle

www.trolex.com

6 TX3706-UM-EN-02

1.4 Technical Information

Housing material: Stainless Steel : ANC4B

Aluminium Alloy : LM

25

TF with hard anodised protection

Cable entry on free

plug and receptacle:

Choice of threaded cable entry sizes for standard Ex d cable glands

M20 and M25

Mounting of fixed

receptacle:

• M20 onto Ex d or Ex e housing

• M25 onto Ex d or Ex e housing

Connections of fixed

receptacle:

1.5 mm2x 1m / 2m / 3m (L)

2.5 mm2x 1m / 2m / 3m (L)

Mating cycles: 100,000 with no load connected

(Limited to 200 for live disconnect)

Security Coding: 5 selectable coding positions - A, B, C, D, E

Ingress protection: IP66

Temperature limits: -50 °C to +60 °C

Weight:

Free Plug

Free Receptacle

Fixed Receptacle

Stainless Steel Aluminium

0.5kg 0.2kg

0.43kg 0.17kg

0.4kg 0.15kg

Conformity: EN 61984: 2009 - Safety Requirements

EN 60664: 2007 - Insulation Co-ordination

EN60079-0: 2012+A11:2013 - General Requirements

EN60079-1: 2014 - Flame-proof Enclosures

EN60079-7: 2015 -Explosive atmospheres. Equipment protection by

increased safety “e”

EN60079-31: 2014 - Equipment Dust Ignition Protection

by Enclosure “t”

www.trolex.com

TX3706-UM-EN-02 7

TX3706 • User Manual

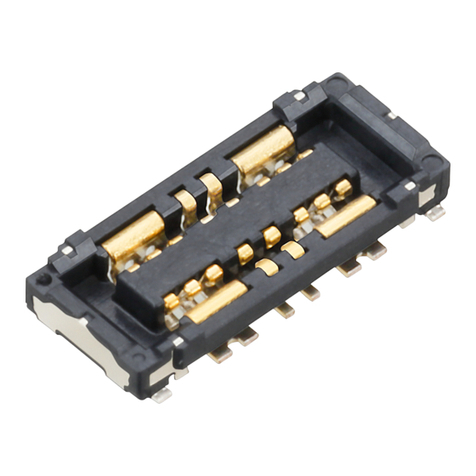

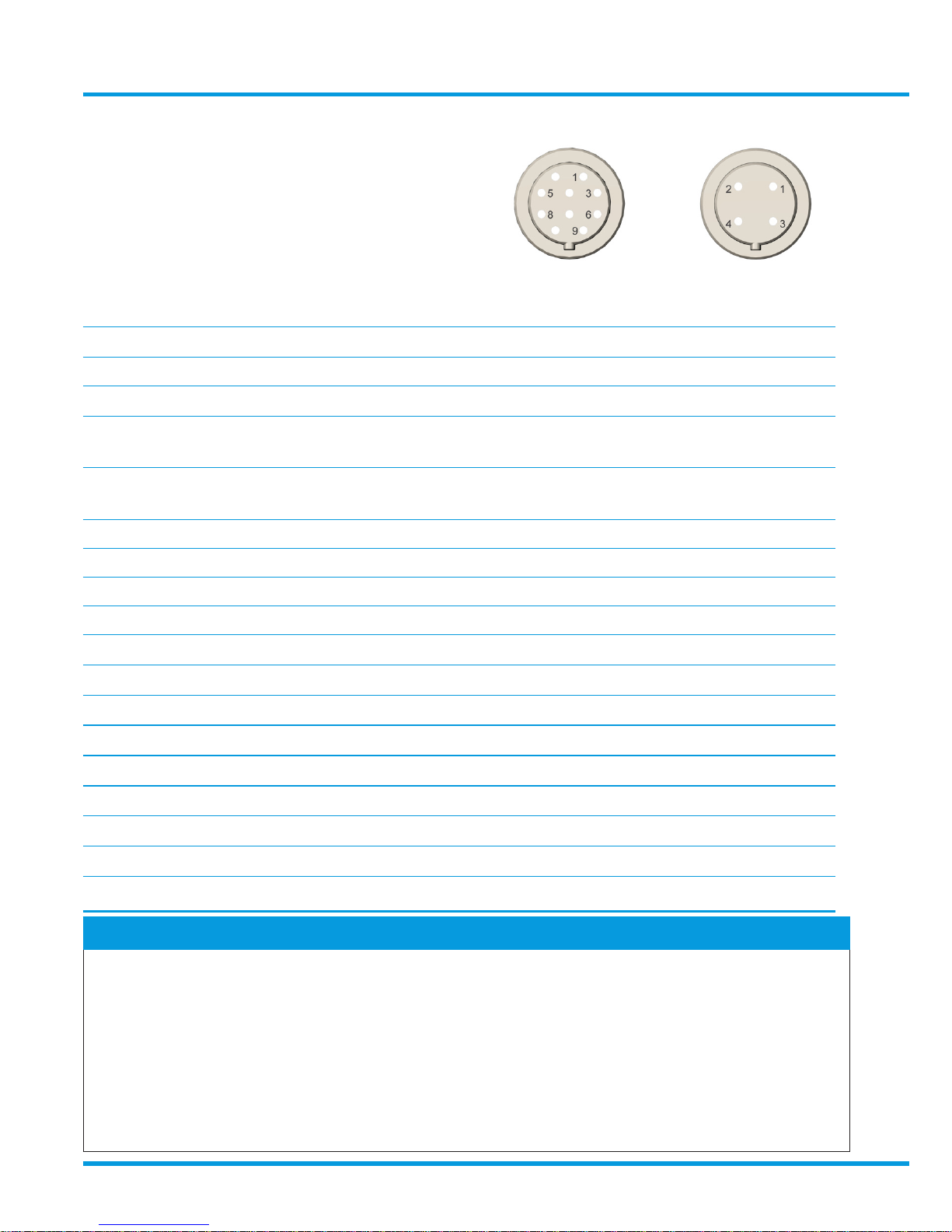

Contact Inserts

Contact ways: 10 4

Maximum rated current per contact: 25 A 25 A

Maximum total current (all contacts): 100 A 100 A

Rated voltage: 250 V ac/ 100 V dc 250 V ac/ 100 V dc

Maximum live disconnect voltage

Power factor 0.4 to 0.5

80 V ac/dc 250 V ac/dc

Load breaking current

(up to 200 mating cycles):

1 A 1 A

Creepage and clearance: (IEC 60664-1) 2 mm 5 mm

Cable terminations: 6 or 8 point crimp or solder - IEC 60352-2

Wire size: 1.5 mm2or 2.5 mm2

Insert material: Glass filled polymer

Fire rating: VL94, V-0

Contacts: Multi-spring wire socket and solid pin

Insertion force: 6 N per contact

Contact protection: Passivated silver plating

Contact resistance: 400 ohm

Test Voltage: 2000 V

Insulation: Class II double insulated BS 61140

Over voltage transients: 3000 V

Protective earth connections Screw clamp terminals for 2.5 mm cables

Checkpoint

Intrinsically safe circuits

The contact inserts are clearance compatible for use with approved intrinsically safe

circuits up to 30 Volts. This feature can be used to maintain flameproof properties where

intrinsically safe circuits are exiting a flameproof enclosure.

Caution

Intrinsically safe circuits must not be mixed with non-intrinsically safe circuits on the same

connector.

www.trolex.com

8 TX3706-UM-EN-02

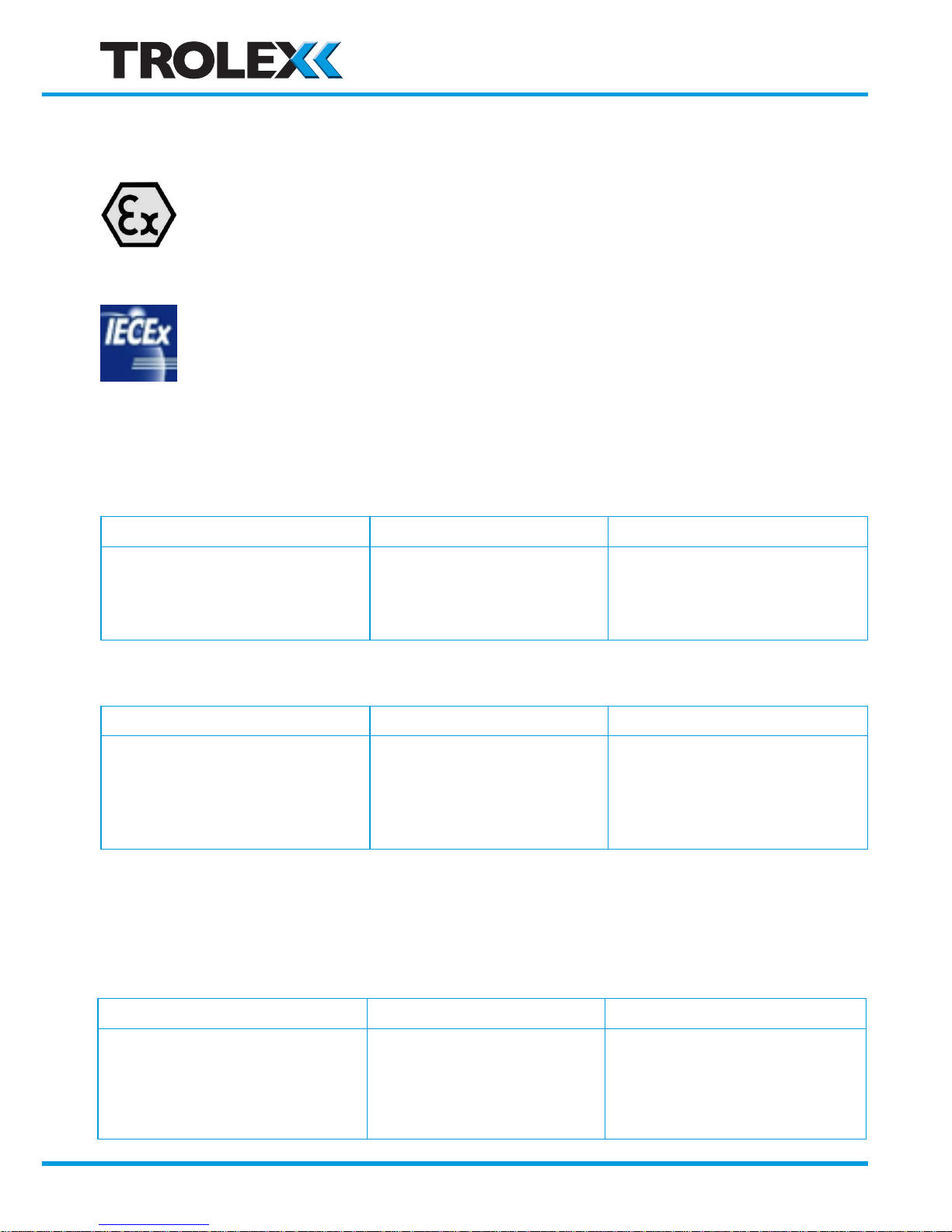

2. Certification and Conformity

ATEX (European Union) certification for use in underground mines and surface

industry with explosive gas and dust atmospheres.

Complies with ATEX Directive 2014/34/EU

IECEx (International) certification for use in underground mines and surface industry

with explosive gas and dust atmospheres.

2.1 Underground mines (stainless steel versions only)

1) Line Plug and Line Receptacle

Product Code: Ex Certificate Number: Ex Certification Code:

TX3706.1.19.01.xx.xx.xx.xx

TX3706.2.19.01.xx.xx.xx.xx

TX3706.4.19.01

CML 15ATEX1143X

IECEx CML 15.0070X

I M2

Ex db I Mb

-50 °C ≤ Ta ≤ +60 °C

2) Fixed Receptacle (low risk of mechanical danger only-refer to conditions of use below)

Product Code: Ex Certificate Number: Ex Certification Code:

TX3706.3.19.01.xx.xx.xx.xx.xx CML 15ATEX1143X

IECEx CML 15.0070X

I M2

Ex db I Mb

Ex db eb I Mb

-50 °C ≤ Ta ≤ +60 °C

2.2 Surface industry with explosive gas and dust atmospheres

(stainless steel and aluminium versions)

1) Line Plug and Line Receptacle

Product Code: Ex Certificate Number: Ex Certification Code:

TX3706.1.20.xx.xx.xx.xx.xx

TX3706.2.20.xx.xx.xx.xx.xx

TX3706.4.20.xx

CML 15ATEX1143X

IECEx CML 15.0070X

II 2GD

Ex db IIC T4 Gb

Ex tb IIIC T135 °C Db

-50 °C ≤ Ta ≤ +60 °C

www.trolex.com

TX3706-UM-EN-02 9

TX3706 • User Manual

2) Fixed Receptacle

Product Code: Ex Certificate Number: Ex Certification Code:

TX3706.3.20.xx.xx.xx.xx.xx.xx CML 15ATEX1143X

IECEx CML 15.0070X

II 2GD

Ex db IIC T4 Gb

Ex db eb IIC T4 Gb

Ex tb IIIC T135 °C Db

-50 °C ≤ Ta ≤ +60 °C

2.3 The following Conditions of Certification and Special

Conditions for Safe Use apply to the above ATEX and IECEx

Certificates:

The following conditions relate to safe installation and/or use of the equipment:

1) When included, the total capacity of all pin options shall not exceed 100 A, with a maximum

rating per pin of 25 A.

2) The cable entries and cable used with the TX3706 Falcon 25 Connectors may reach 60°C

above ambient temperatures, therefore, shall be selected accordingly for these temperatures.

3) The connector arrangement remains flameproof through the first stage of disconnection

which fully disconnects the pins, however, this only applies to circuits with a power factor of

between 0.6 and 1.0. For circuits outside this range, unless for resistive loads only, additional

time delays shall be considered before fully disconnecting the connector even if de-energised.

4) The stainless steel fixed receptacle, when used in Group I areas, shall only be used in areas

considered to be low risk of mechanical danger or shall be additionally protected from heavy

mechanical impact by installation.

Under certain extreme circumstances, the non-metallic parts of the clamp may store

electrostatic charge and therefore the user/installer shall implement precautions to prevent

the build-up of electrostatic charge, e.g. locate the clamps where a charge-generating

mechanism (such as wind- blown dust) is unlikely to be present. In addition, the clamp shall

only be cleaned with a damp cloth.

www.trolex.com

10 TX3706-UM-EN-02

3. Fitting and Installation

3.1 Precautions

•Special conditions of use relating to the Ex

certification may apply to particular applications.

• The cable gland used with Free Plugs and Free

Receptacles must be an approved Ex d type

which is suitably certified for the equipment and

the type of cable to be used.

• Gland entries must be fitted with suitable ingress

seals to maintain the overall ingress protection of

the connector.

• Ensure that the current and voltage parameters

of the electrical circuits are within the limits

specified.

• The sealing faces and flame paths will have

been treated with a protective film of grease

during manufacture. Renew if necessary before

assembly or engagement, in accordance with the

relevant installation standards and procedures.

• Ensure that the end cap screws are in place and

are fully tightened before engagement.

• Always fit either a rubber ingress protection cap

or an Ex protection cap to disengaged connectors

to protect flame paths and to exclude debris and

moisture.

• Do not disengage the connector by pulling on the

cable as this may damage the fitting of the cable

into the cable gland.

• A connector with a damaged flame path is an

explosion risk and should be removed from

service.

www.trolex.com

TX3706-UM-EN -02 11

TX3706 • User Manual

3.2 Tools and Equipment

• 2.5mm & 3mm Allen key

• Wire cutters

Product Options

1. Body (Plug or receptacle) Group I Stainless Steel

1. Body (Plug or receptacle) Group II Stainless Steel/Aluminium

2. End cap

3. End cap screws

4. Contact insert 10 way/4 way

5. Backing ring

6. Contacts 1.5 mm2Pins/Sockets

2.5 mm2Pins/Sockets

7. Retainer

8. Sleeve (Upper and lower pair)

9. Ingress protection cap

10. Earth bonding terminal

11. Flame path

12. Cable entry for standard Ex cable glands M20/M25

• Wire strippers

• 6 or 8 point crimping tool

(or soldering iron for soldered connections)

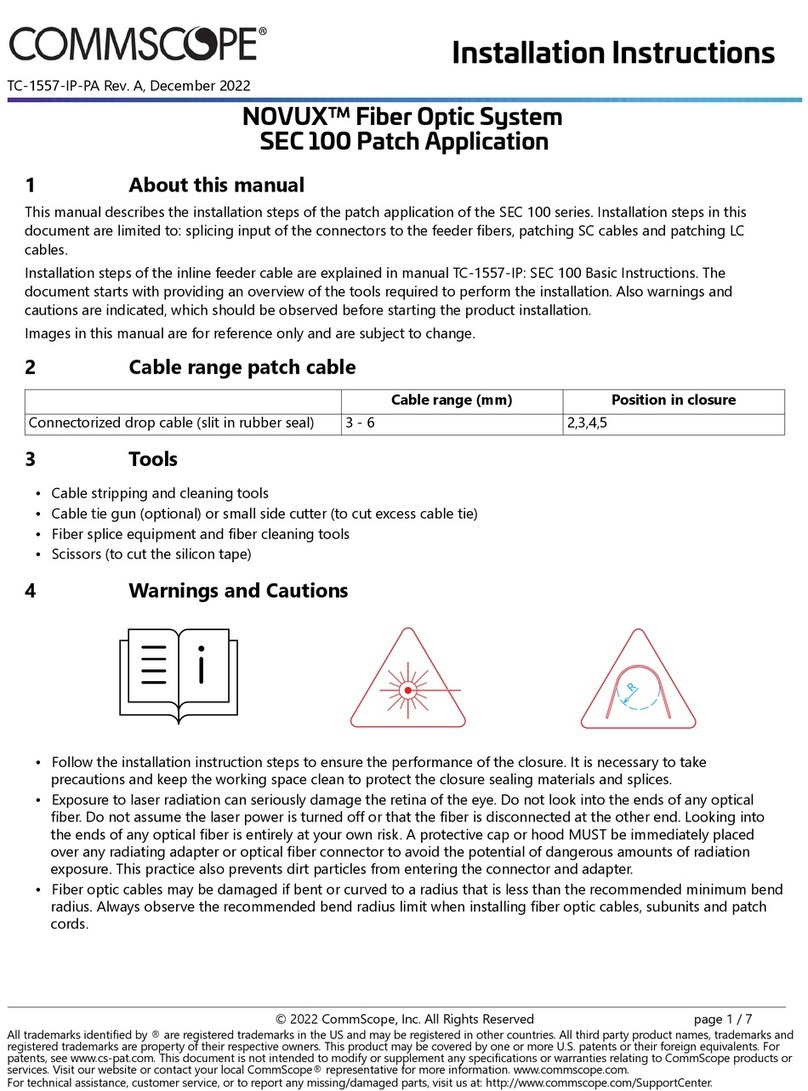

3.3 Free plug and free receptacle

3.3.1 General assembly and definitions

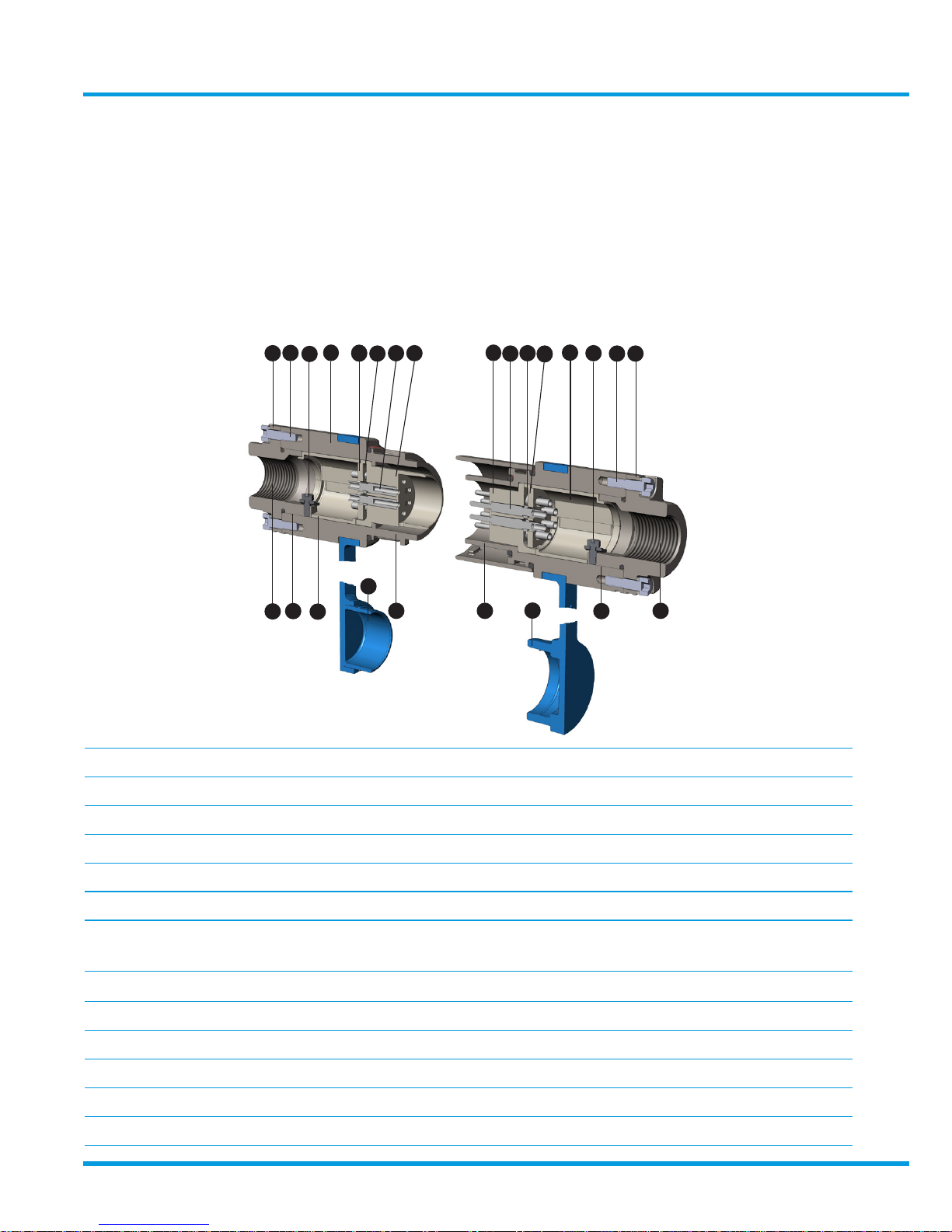

1

2 3 5 7 6 4 4 6 7 5 8

10 3 2

12

11

9

11

11

9

11

12

10

8

www.trolex.com

12 TX3706-UM-EN-02

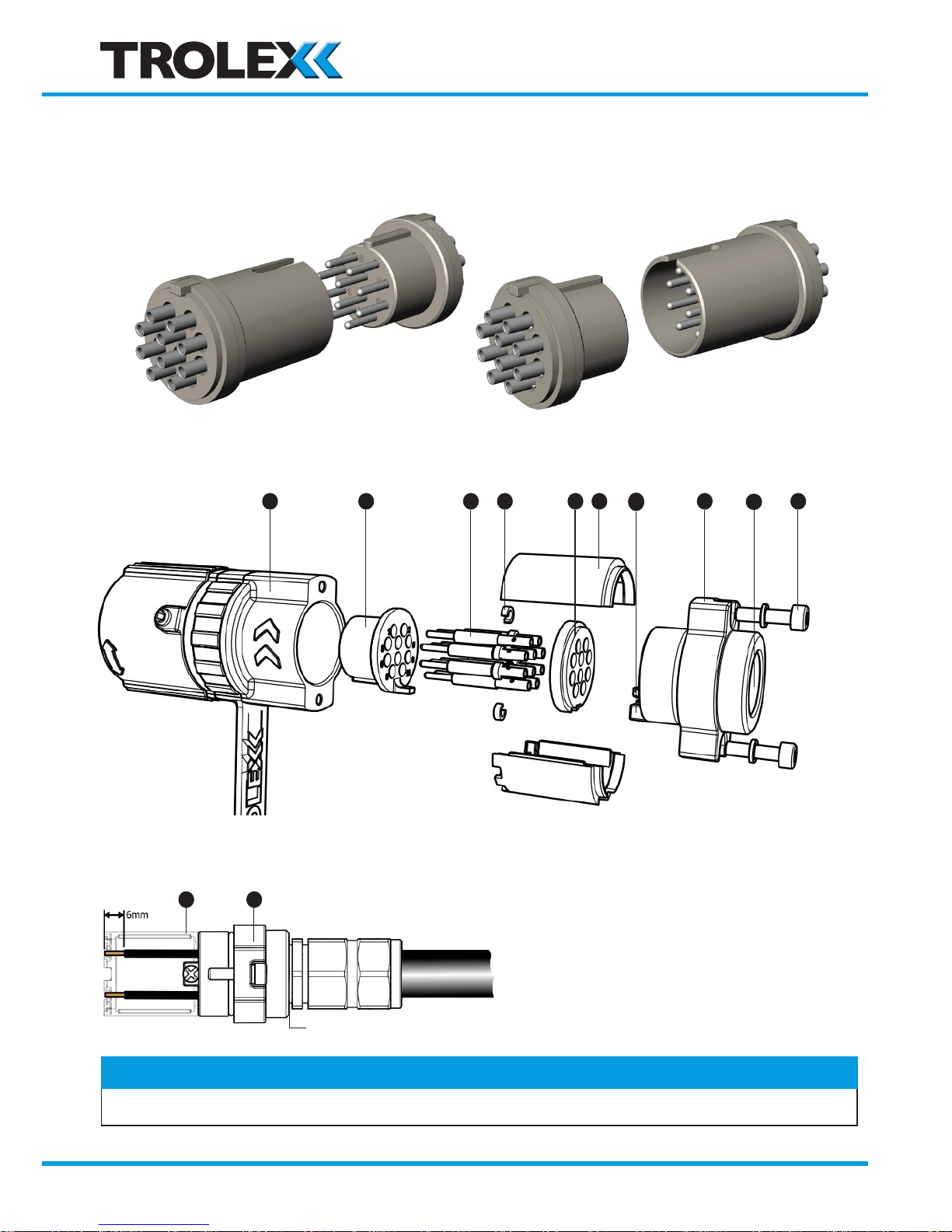

3.3.2 Connecting

• Prepare cable

• PINS or SOCKETS can be fitted into MALE or FEMALE contact inserts

• MALE or FEMALE contact inserts can be fitted into PLUGS or RECEPTACLES

Checkpoint

Use sleeve 8 as a temporary wire length cutting gauge.

1 4 6 7 5 8

10 2

12 3

8 2

Standard Ex cable gland and approved cable (Not supplied)

Ingress protection seal (Not supplied)

www.trolex.com

TX3706 • User Manual

TX3706-UM-EN-02 13

• Crimp or solder connectors

• Fit backing ring 5

• Clip a retaining clip 7 to each contact

• Load contacts into the contact insert 4

• Slide the backing ring 5 up to the contact insert 4

• Clip the sleeves 8 in place

• Load into connector body 1

• Fit end cap screws and washers

54 8 2

8

Align markers

6 2

7 5 2

1 4 5 8 2 3

www.trolex.com

Code C

14 TX3706-UM-EN-02

3.3.3 Earth Bonding

• External Earth bonding

• Internal Earth Continuity bonding

3.3.4 Security Coding

Female Male

< 2.5mm2

1

10 2

Leading Earth Pin

TX 3706.031. 15

TX 3706.031. 25

6 4 5 8 2

E

D

C

B

A

8 8

E

D

C

B

A

Code B

E

D

C

B

A

→

→

Pull

Push

Pull

Push

Contact insert Contact insert

www.trolex.com

TX3706-UM-EN-02 15

TX3706 • User Manual

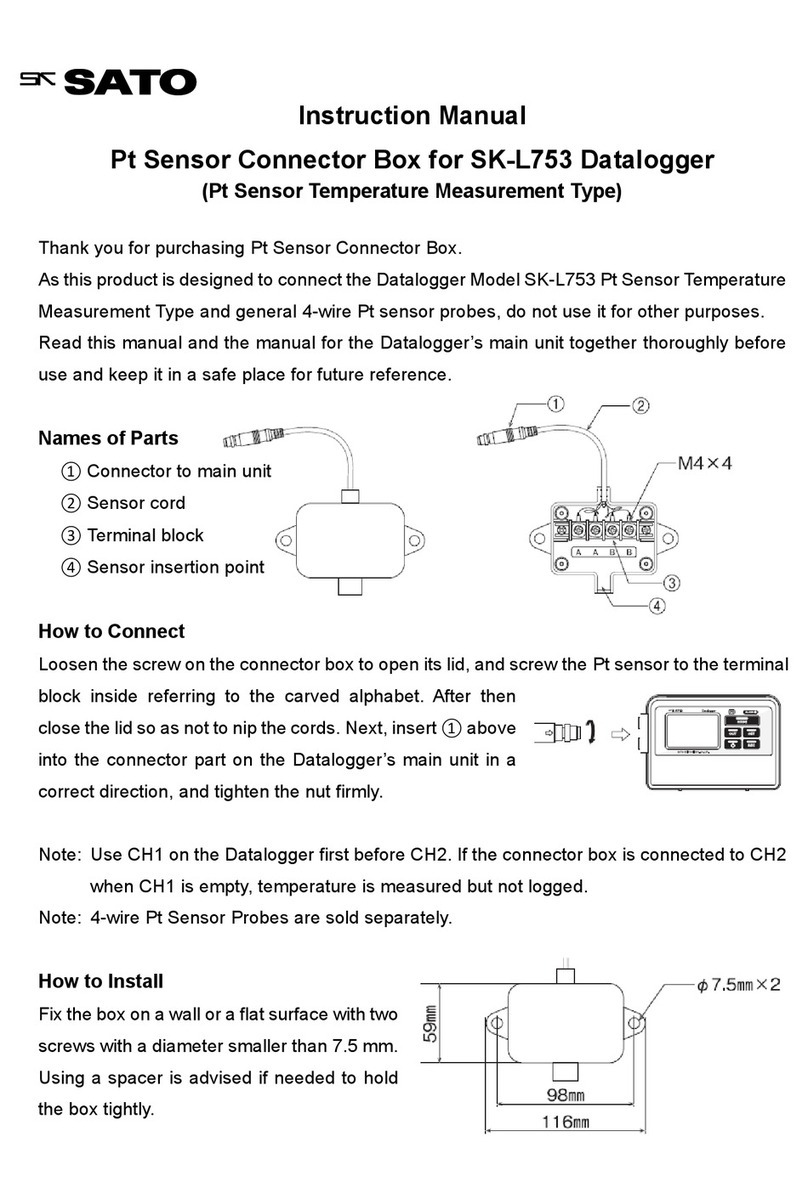

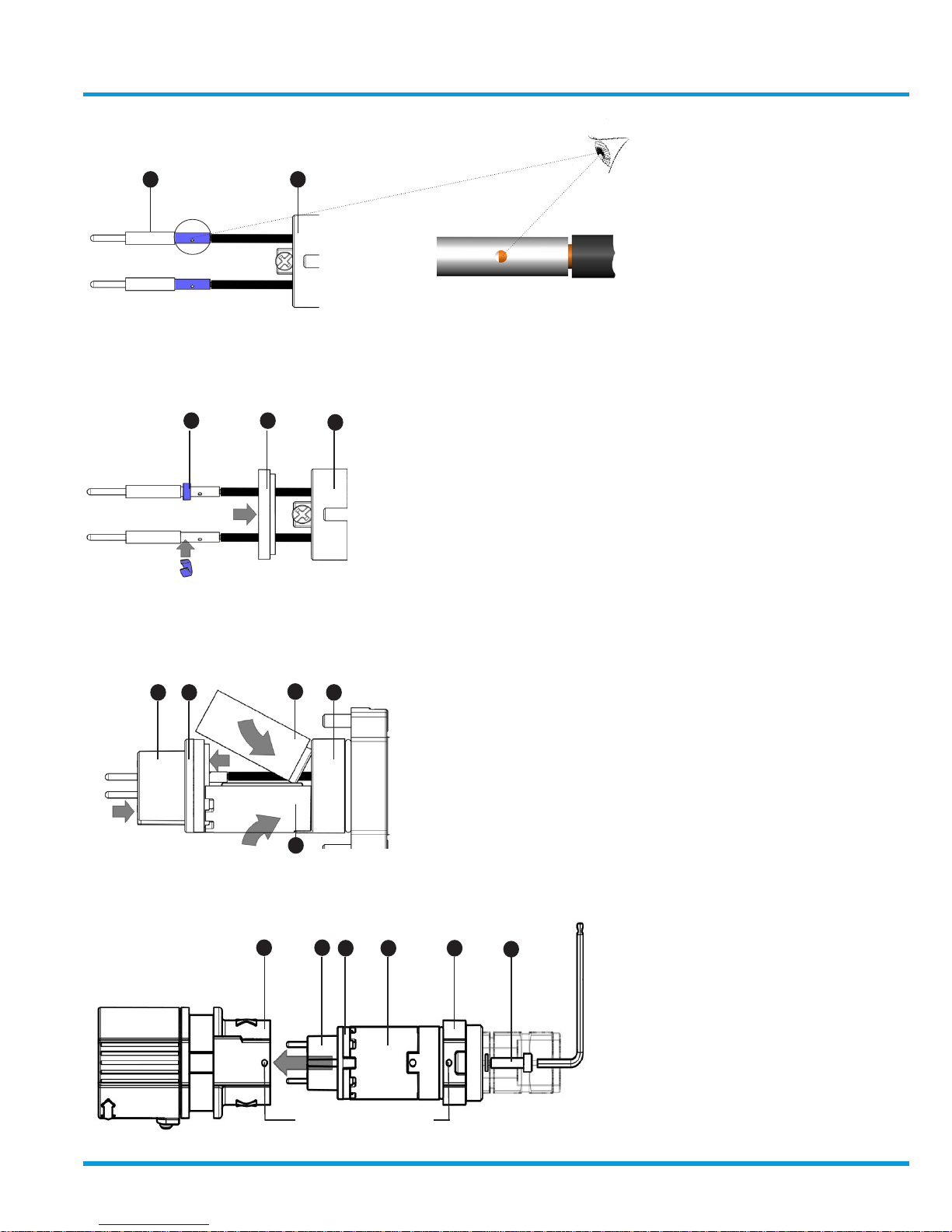

3.4 Fixed Receptacle

3.4.1 General assembly and definitions

Product options

1. Body (Plug or receptacle) Group I Stainless Steel

1. Body (Plug or receptacle) Group II Stainless Steel/Aluminium

2.Threaded entry mounting bush M20/M25

3. Locking ring with ingress seals

4. Ingress seal for surface mounting

5. Ingress protection cap

6. Pre-wired encapsulated connections 1.5 mm2 X 1M / 2M / 3M (L)

2.5 mm2 X1M / 2M / 3M (L)

7. Female contact insert 10 way/4 way

(Security code to be specified)

8. Contacts Pins/Sockets

(Leading earth pin when specified)

(Lagging pilot pin when specified)

TX3706. 03

Fixed Receptacle

Bush mounting onto Ex e or Ex d housing (Section 3.4.2)

6 2 3 1 8 7

5

www.trolex.com

16 TX3706-UM-EN-02

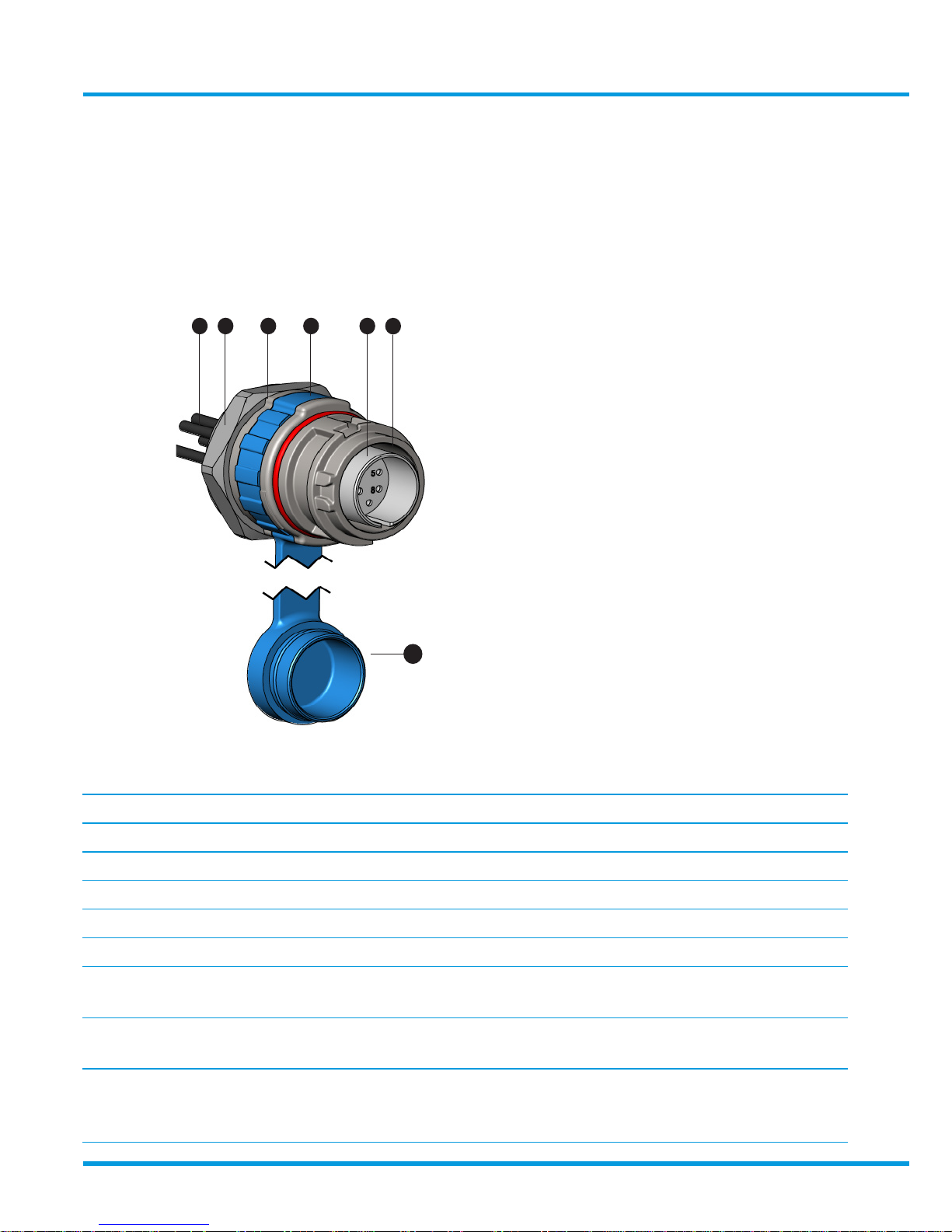

3.4.2 Ex d bush mounting

TX 3706.3...20

TX 3706.3...25

Ex e

Ex d

1. Screw the locking ring all the way home.

2. Screw the Receptacle all the way into the mounting bush on the enclosure. This must be

a minimum of five threads engaged on an Ex d enclosure.

3. Use a half-spanner to apply counter-clockwise locking force to the locking ring.

A locking ring enables the Receptacle to be radially positioned to suit user preference and

incorporates ingress seals to IP66 standards.

• Position the Receptacle to concur with any radial position of the corresponding free plug.

• Align Receptacles for best visual appearance

• Locks against the effect of rotational forces which may occur from the connecting cable.

www.trolex.com

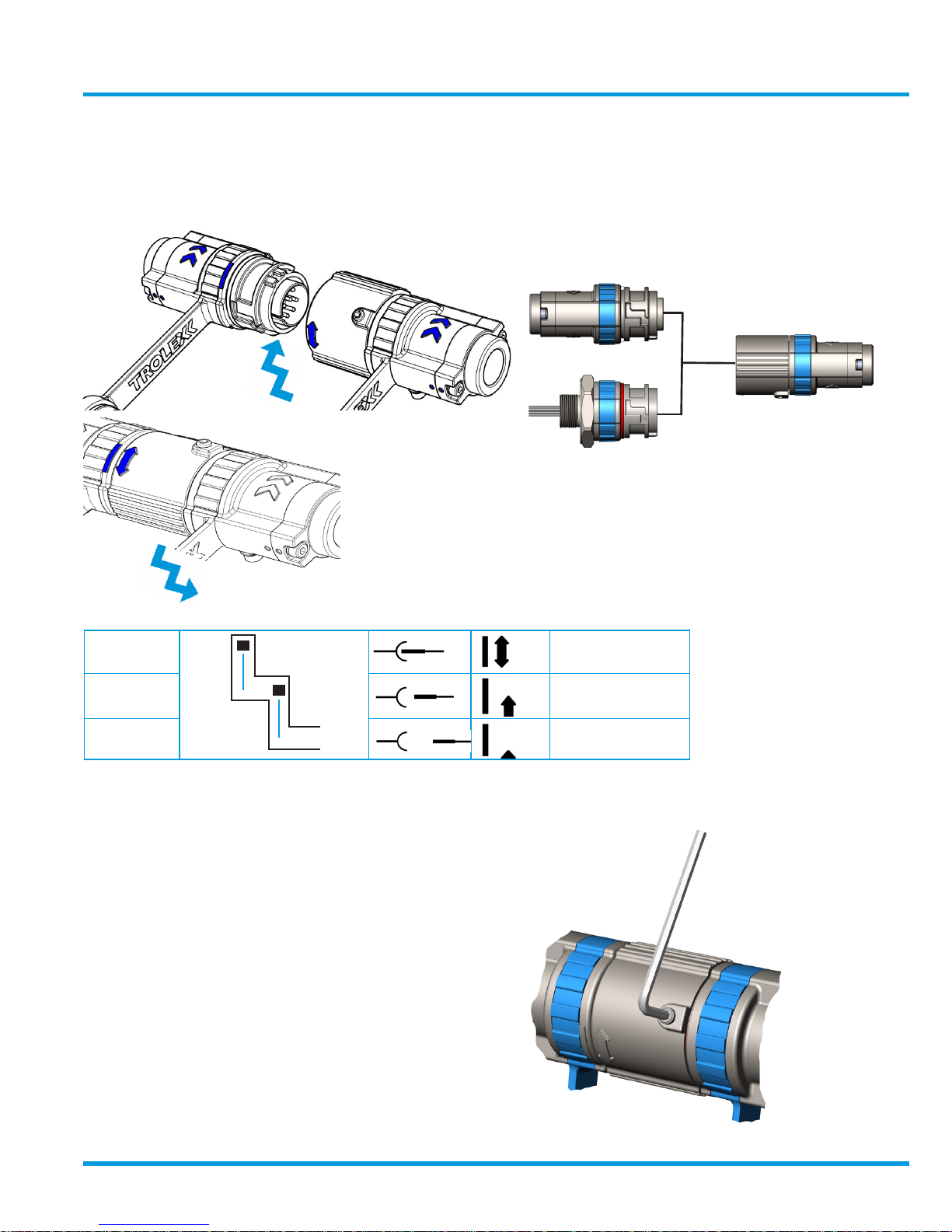

Engage Ex d Protection

Break Ex d Protection

Separate IP30 on Socket

TX3706-UM-EN-02 17

TX3706 • User Manual

4. Operation

4.1 Engage and separate

Locking Screw

→

→

Line Receptacle

TX3706.2

Fixed Receptacle

TX3706.3

Line Plug

TX3706.1

The locking screw must be tightened to complete the

connection process giving full Ex d protection.

www.trolex.com

18 TX3706-UM-EN-02

4.2 Safety Precautions

There are three methods of safety protection depending upon the application and local safety

regulations.

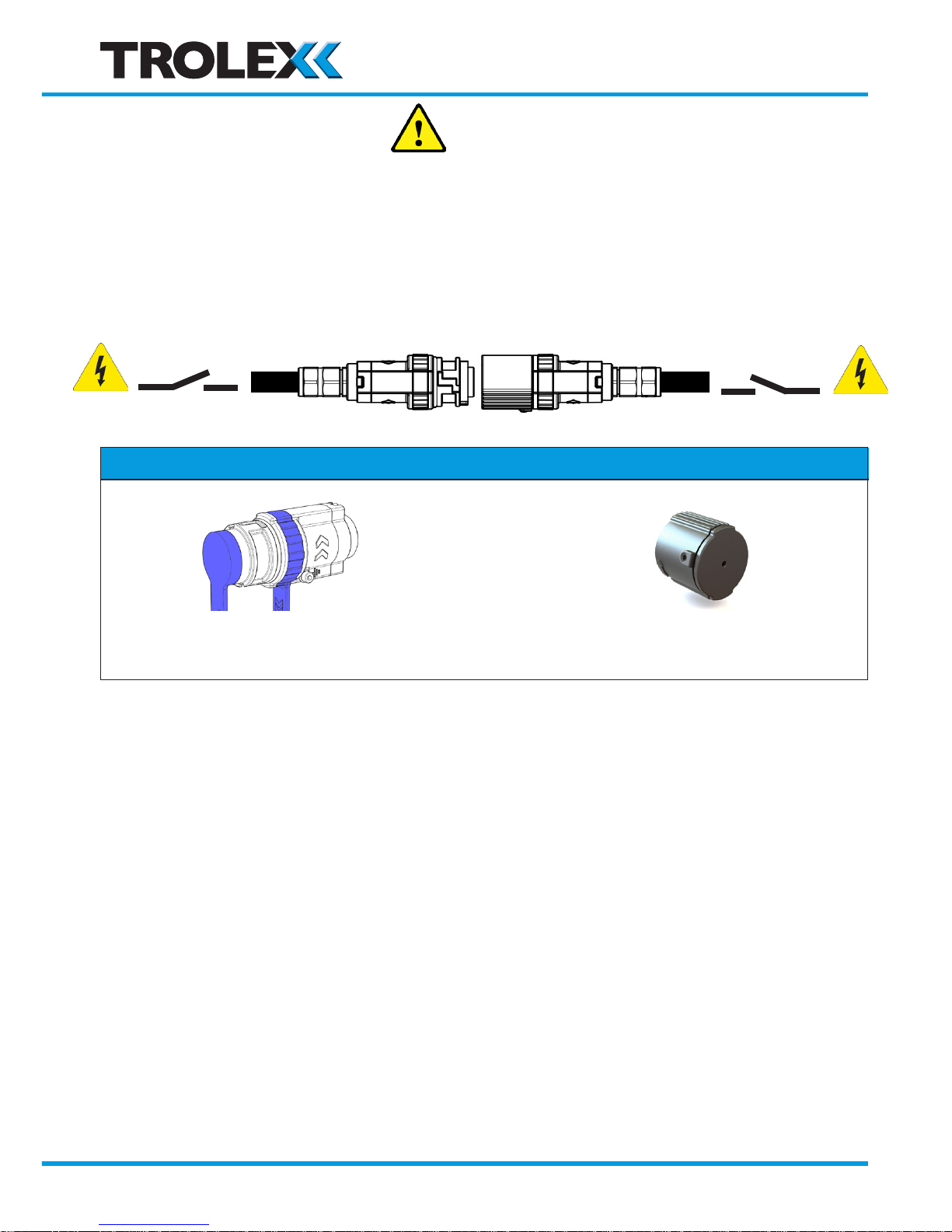

4.2.1 Isolate elsewhere

Isolate all electrical power at source BEFORE separation

Checkpoint

IP65 Ex d + IP66

Fit the rubber ingress protection cap when

separated.

Fit an Ex protection cap if the system

power is to be reinstated.

www.trolex.com

TX3706-UM-EN-02 19

TX3706 • User Manual

4.2.2 Pilot circuit interlocking

Automatic isolation of the power source during separation using one of the connector

contacts for interlocking a pilot switching circuit.

• Fit a lagging pilot pin TX 3700.032.15 or TX 3700.032.25

Engage Ex d Protection

Break Ex d Protection

Separate - - -

IP65 Ex d + IP66

Fit the rubber ingress protection cap when

separated.

Fit an Ex protection cap if the system

power is to be reinstated.

Checkpoint

• The pilot relay will isolate the power source slightly in advance of the main contacts

during separation

• Breaking of the pilot contract will take place under Ex d protection

• The pilot circuit must be de-energised along with the power source.

→

→

www.trolex.com

20 TX3706-UM-EN-02

4.2.3 Live engagement

ENGAGE or SEPARATE the connector with live power in the hazardous area, is permitted for

short periods to allow maintenance or change-out of apparatus.

Power must originate from the SOCKET ONLY.

Engage Ex d Protection

Break Ex d Protection

Separate IP30 on Socket

Checkpoint

Maximum Voltage . 4 way 250 V ac/dc

Maximum Voltage .10 way 80 V ac

Maximum breaking current (per contact) 1 A

Power factor Between 0.6 and 1.0

IP65 Only Ex d + IP66

Fit the rubber ingress protection cap

during temporary separation to exclude

dust and moisture.

Fit an Ex protection cap if the connection

is to remain separated after the permitted

maintenance period.

→

→

www.trolex.com

Table of contents