4 EN

digital soldering station PSIS 10-230V

General Power Tool Safety Warnings– Power tool

use and care

•Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was designed.

•Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

•Disconnect the plug from the power source and/or

remove the battery pack, if detachable, from the power

tool before making any adjustments, changing

accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

•Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

•Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the

power tool's operation. If damaged, have the power

tool repaired before use. Many accidents are caused by

poorly maintained power tools.

•Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to

bind and are easier to control.

•Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

•Keep handles and grasping surfaces dry, clean and

free from oil and grease. Slippery handles and grasping

surfaces do not allow for safe handling and control of the

tool in unexpected situations.

General Power Tool Safety Warnings– Service

•Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

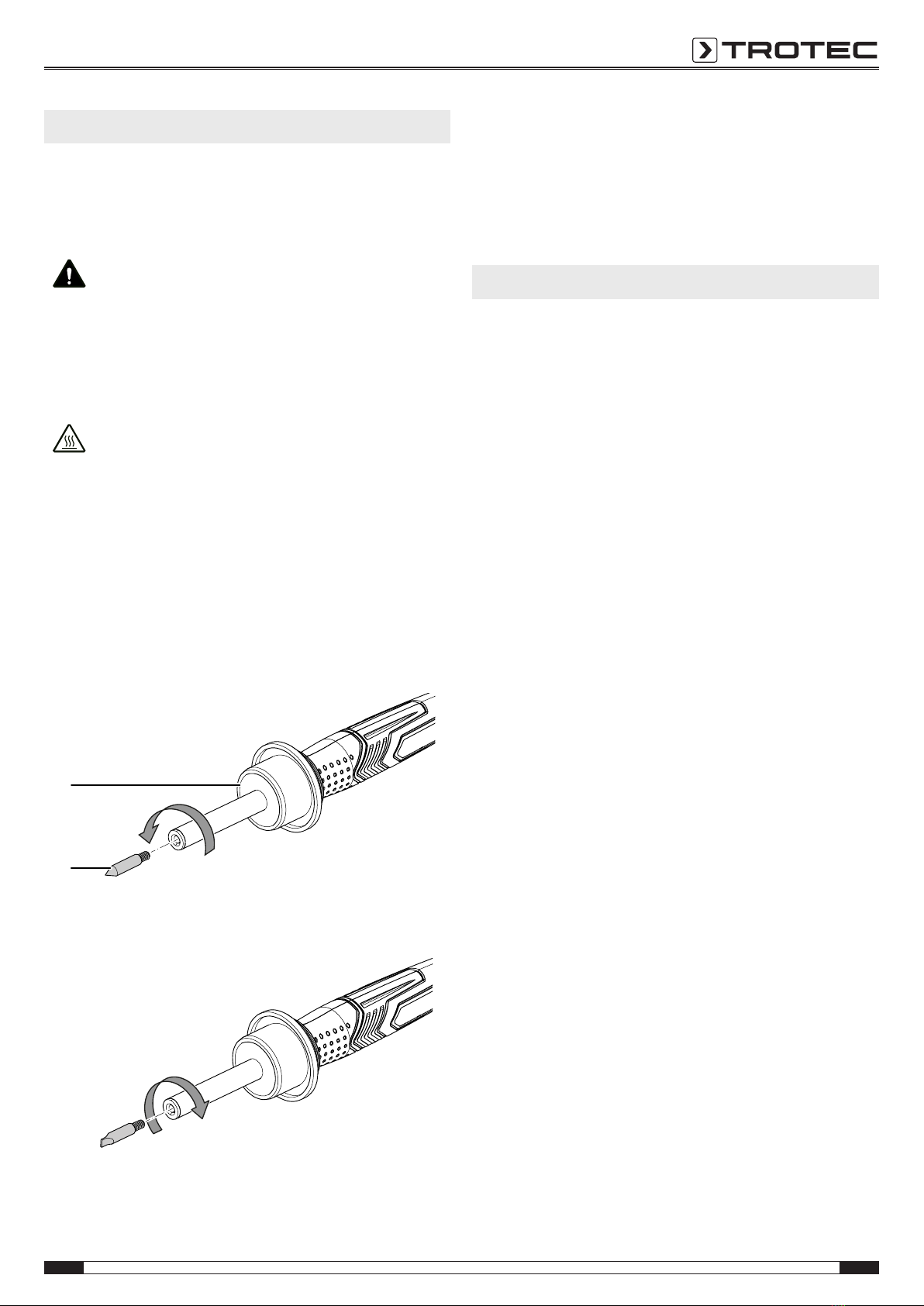

Device-specific safety warnings for soldering

stations

•Never touch the heated soldering tip or the molten

solder. Risk of burns.

•Do not under any circumstances use water to cool

down the soldering iron. Only allow the soldering iron to

cool down in the air after use.

•Use the holder if you interrupt your work for breaks or

for setting the soldering iron down. The high

temperature of the soldering iron can set inappropriate

mats on fire.

•Keep the device at a distance of combustible

materials.

•Do not inhale vapours. If you perform longer works

during which vapours hazardous to health may occur,

always provide sufficient ventilation of the workplace.

•Avoid touching the hot soldering tip with the plastic

parts of the holder. Otherwise the device may be

damaged.

•Avoid eating, drinking and smoking in rooms where

soldering work is carried out. Otherwise, traces of lead

remaining on your hands may enter the human organism

via food or cigarettes.

•Always wash your hands thoroughly after soldering

work.

•Do not dispose of solder waste in the domestic waste.

Solder waste must be disposed of in the hazardous waste.

•If you are carrying out soldering works on electrical

components, first disconnect the power supply before

starting soldering. There is a risk of an electric shock and

damages on the electrical components due to a short

circuit.

Intended use

The device PSIS 10-230V is intended for soldering electronical

parts in leisure and DIY sectors. It can be used for soldering

works, glue welding plastics or for applying embellishments.

We recommend using the power tool with original Trotec

accessories.