DE Originalbetriebsanleitung

GB Translationof the original

instructions

ES Traduccióndel manual original

FR traductionde la notic e originale

IT Traduzionedelle istruzioni originali

PT traduçãodo manual ori ginal

NL vertalingvan de oorspronkelijke

gebruiksaanwijzing

SV Översättning av bruksanvisning

ioriginal

DK oversættelse af den originale

brugsanvisning

FI alkuperäistenohjeiden

käännös

GR Μετάφραση του πρωτοτύπου

των οδηγιών χρήσης

TR Orijinal işletme talimatı ç evirisi

CZ překlad původního návodu

k používání

PL Tłumaczeniem instrukcji oryginalnej

HU Eredeti használati utasítás fordítása

SK preklad pôvodného návodu

na použitie

SL prevodizvirnih navodil

EE algupärasekasutusjuhendi tõ lge

LV Instrukcijutulkojumam no

oriģinālvalodas

LT Originaliosinstr ukcijos vertimas

BG превод на оригиналната

инструкция

RO traducere a instrucțiunilor

originale

HR Prijevodoriginalnih uputa

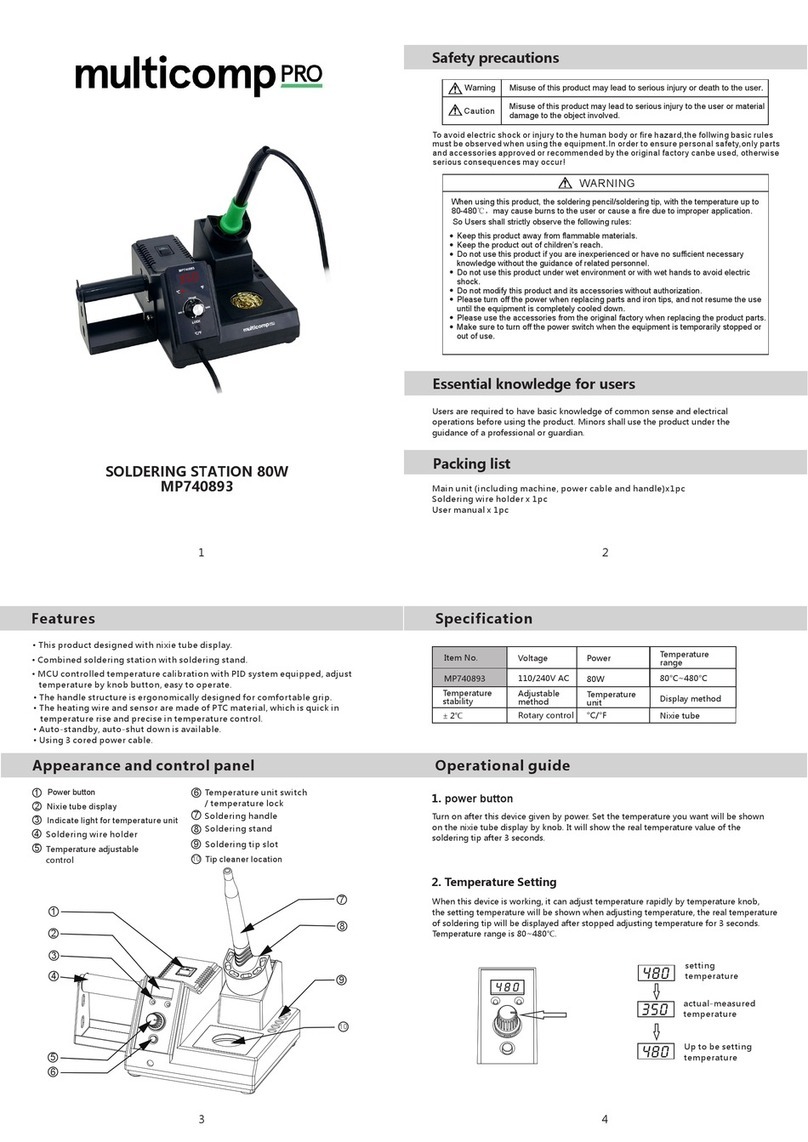

LASERLINE 150 MG140

DE Originalbetriebsanleitung

GB Translationof the original instructions

ES Traduccióndel manual original

FR Traductionde la notice originale

IT Traduzionedelle istruzioni originali

PT Traduçãodo manual original

NL Vertalingvan de oorspronkelijke gebruiksaanwijzing

SV Översättningav bruksanvisning i original

DK Oversættelseaf den originale brugsanvisning

FI Alkuperäistenohjeiden käännös

GRΜετάφρασητουπρωτοτύπουτωνοδηγιώνχρήσης

TROrijinalişletmetalimatıçevirisi

CZPřekladpůvodníhonávodukpoužívání

PLT łumaczenieminstrukcjioryginalnej

HUEredetihasználatiutasításfordítása

SK Prekladpôvodnéhonávodunapoužitie

SL Prevodizvirni h navodil

EE Algupärasekasutusjuhendi tõlge

LV Instrukcijutulkojumamnooriģinālvalodas

LT Originaliosinstrukcijos vertimas

BGпреводнаоригиналнатаинструкция

RO Traducerea instructiunilor originale

HR Prijevodoriginalnih uputa

RUОригинальноеруководствопоэксплуатации

WT 1

WT 1H