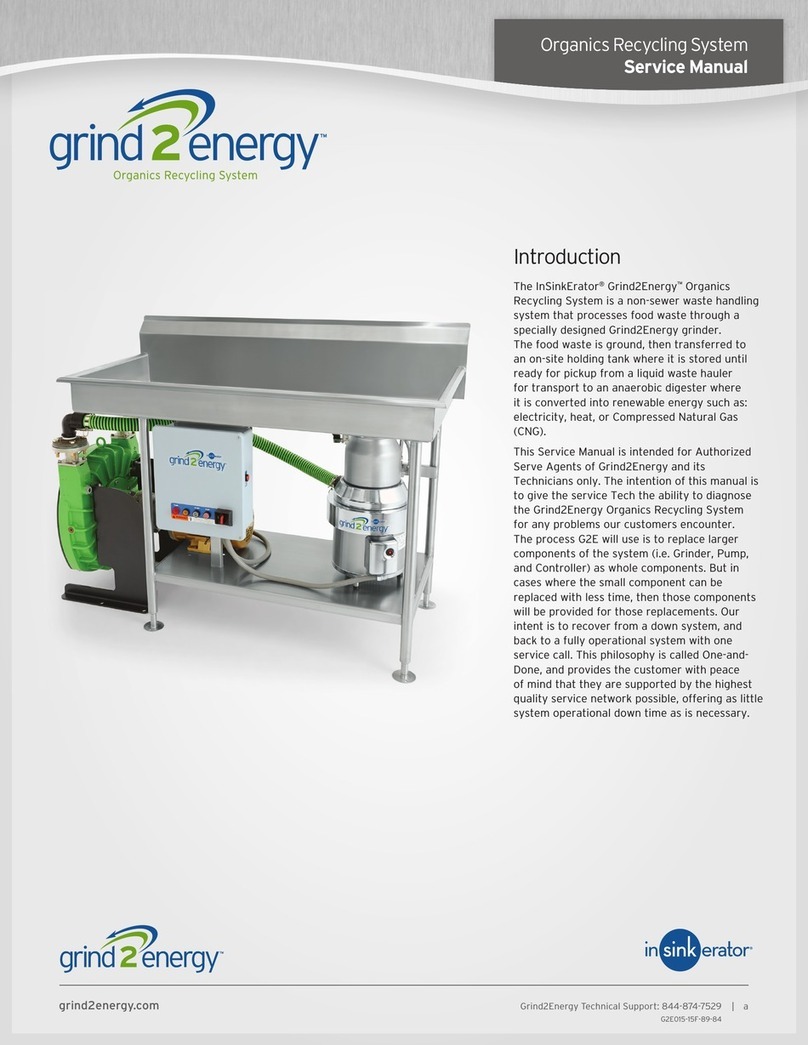

GENERAL NOTES

• When positioning disposer, ensure that the overload reset button is

accessible by end user.

• Connect cold water to either the sink bowl or end of trough.

• For proper removal of discharge chute, ease of cleaning, and general

maintenance: Position the dewatering unit with the front surface of

the discharge chute recessed 3" (76.2 mm) (see Figure 1) from the

front edge of the table and with a minimum clearance of 1" (25.4 mm)

between the underside of the table and top of the discharge chute

(see Figure 2).

• Position the dewatering unit within 10' (3.1 m) of the disposer outlet

flange (see Figure 2).

• When positioning control panel, ensure it is within sight of the

disposer and dewatering unit.

• For ease of installation and serviceability: Position the control panel

with the front surface recessed 1-1/2" (38.1 mm) from the front edge

of the table and with a minimum clearance of 2" (50.8 mm) between

the underside of the table and the top of the control panel.

• Maintenance: Disassemble and clean the dewatering unit a minimum

of once daily. Interior of cabinet and discharge chute can be cleaned

with hot soapy water. Auger, screen, and bearing bracket can be

cleaned either manually with hot soapy water or in a dishwasher.

PLUMBING NOTES

• 2" NPT – used between disposer, dewatering unit, and drain.

• When connecting the drain line from the disposer to the dewatering unit,

use a maximum of (4) 90° bends (45° bends are recommended) with a

minimum 1/4" (6.4 mm) drop per foot of run or as local codes apply.

• Trough applications in excess of 10' (3.1 m) and/or systems plumbed

with a cold water supply greater than 7 GPM (26.5 LPM) must

incorporate the second drain outlet from the pulper and be drained

independently to the floor sink or drain.

• 1/2" NPT – used on syphon breaker, solenoid, and flow control valve.

• 1/2" NOM compression – used on sink bowl nozzles.

• 1/2" Ridged Copper (compression) – used on hot water connection

to dewatering unit.

•

If water pressure exceeds the allowable pressure of 80 psi (551.6

kPa), pressure regulators should be used.

• It is recommended that all fresh water and waste line plumbing

connections be terminated with unions for ease of serviceability.

• Note: Some applications can benefit from installing a ball type

shutoff valves in the cold and hot water lines. Contact your

InSinkErator Representative or the factory for more information.

TROUGH APPLICATIONS – CONTACT FACTORY

• The recommended maximum trough length is 10' (3.1 m).

• A silver saver should be fabricated prior to end of trough to catch

utensils and dishes.

• For trough lengths of 10' (3.1 m) or less place water nozzle at end of

trough.

• For trough lengths greater than 10' (3.1 m), place one water nozzle at

end of trough and one mid stream.

• Trough magnets should be placed within 12" (304.8 mm) of end of

trough or trough intersection with sink bowl (see Figure 4).

• Trough magnets can be mounted to trough either by tack welding or

using weld studs (see Figure 5 for weld stud pattern).

• Additional trough magnets can be used as necessary.

TYPICAL INSTALLATION

SYSTEM COMPONENTS

WasteXpress

Disposer

WasteXpress

Control Panel

WasteXpress

Dewatering Unit

SYSTEM INCLUDES:

• WasteXpress Disposer (WX500)

• WasteXpress Control Panel (WX101A)

• WasteXpress Dewatering Unit (WX)

• Mounting –

Collar with Removable or

Permanent

Splash Baffle OR Bowl with

Removable Splash Baffle and Sink Cover

• Syphon Breaker

• Flow Control Valve*

• 10 gallon (37.9 liter) Waste Bin

• (2) 24V Water Solenoids

• Magnetic Silver Saver (trough only)

ITEMS SUPPLIED BY OTHERS:

Plumbing from cold water supply to

bowl or trough

Plumbing from hot water supply to

dewatering unit

Plumbing from disposer to dewatering

unit or dewatering unit to floor sink or

floor drain

Shut-off valves

Electrical connections

NOTE:

Install all components per the

Instruction, Care and Use manual and in

accordance to local, state, and/or national

plumbing and electrical codes.

Typical installation shown. Dish table, plumbing,

and electrical connections not included.

*Size varies by application: 2 GPM (7.6 LPM) for LEED, 3 GPM (11.4 LPM) for Bowl, 5 GPM (18.9 LPM) for Trough