Troxler 4140 Instruction Manual

NOTE

Before using the Model 4140 Gyratory Compactor,

carefully read this manual. It is especially important that

the user understand the Safety Warnings on Page 2-2.

Keep this manual in a safe place that is always easily

accessible during the use of the Model 4140.

Manual of Operation and Maintenance

Model 4140

Gyratory Compactor

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Rd. •P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER

Outside the USA: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

ii

Troxler products are protected by U.S. and foreign patents.

Copyright ♥1994 – 2006

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying, recording, or information storage and retrieval

systems, for any purpose without the express written permission of

Troxler Electronic Laboratories, Inc.

GyroPave is a trademark of Troxler Electronic Laboratories, Inc.

IBM is a registered trademark of International Business Machines,

Inc.

Magnalube-G is a registered trademark of Carleton-Stuart

Corporation.

Mobilith is a registered trademark of Carleton-Stuart Corporation.

Slick 50 is a registered trademark and One Lube is a trademark of

Petrolon, Inc.

SUPERPAVE is a trademark of the Strategic Highway Research

Program.

WD-40 is a registered trademark of the WD-40 Company.

Windows, Windows 95, and Windows 98 are registered trademarks

of Microsoft Corporation

PN 106748

November 2006

Edition 6.3

Model 4140

iii

iv

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Technical Support

Phone: 1.877.TROXLER (1.877.876.9537)

E-mail: TroxTechSupport@troxlerlabs.com

Midwestern Branch Office

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Western Regional Branch Office

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Southwestern Branch Office

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Fax: 817.275.8562

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr. Munich,

Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

NOTE

To locate an independent, Troxler-authorized service

center near you, call 1.877.TROXLER (1.877.876.9537).

Model 4140

v

HOW TO USE THIS MANUAL

Congratulations on the purchase of the Model 4140 Gyratory

Compactor.

The Model 4140 Manual of Operation and Maintenance contains

information on safely using this unit. Also included in this manual

are safety warnings, basic parameter setup, system troubleshooting,

and general maintenance.

Do not attempt to operate the Model 4140 before reading this

manual and the safety warnings posted on the unit. Troxler stresses

that the user is solely responsible for ensuring the safe use of the

Model 4140. Neither the manufacturer, its subsidiary,

representatives, or distributors can assume responsibility for any

mishaps, damage, or personal injury that may occur from failure to

observe the safety warnings in this manual and posted on the unit.

vi

WARNING

Indicates conditions or procedures that, if not followed

correctly, may cause personal injury.

CAUTION

Indicates conditions or procedures that, if not followed

correctly, may cause equipment damage.

DISPLAY

-

Typestyle

and shading used to

simulate the 4140

display

CONVENTIONS USED IN THIS MANUAL

Throughout this manual, symbols and special formatting are used to

reveal the purpose of the text as follows:

NOTE

Indicates important information that must be read to

ensure proper operation.

〈KEY〉Angle brackets and a different typestyle indicate a

key or character (number or letter) to press on the

furnace keypad. For example, “Press 〈START〉”

means to press the key labeled START.

DISPLAY A different typestyle is used in text to indicate

information or messages displayed on thefurnace.

♦

Diamonds indicate a list of things needed (suchas

equipment) or things to know.

✓

Check marks indicate the performance of an action.

With lists of check marks, follow the instructions in

the order of the check marks.

►Triangles indicate that more than one option is

available. Carefully select the option that applies.

Model 4140

vii

NOTES

vii

TABLE OF CONTENTS

CHAPTER 1. INTRODUCTION TO THE MODEL 4140

Introduction....................................................................................1-2

Parts and Accessories.....................................................................1-5

Unpacking and Inspection .............................................................1-8

CHAPTER 2. GETTING STARTED AND PRINTING

Safety Warnings.............................................................................2-2

Assembly .......................................................................................2-3

The Keypad....................................................................................2-5

Turning the System On..................................................................2-7

Setup..............................................................................................2-9

Printing ........................................................................................2-18

CHAPTER 3. CALIBRATION AND ADJUSTMENTS

Calibration Schedule......................................................................3-2

Calibrating the Unit .......................................................................3-3

Adjusting the Angle of Gyration..................................................3-16

Converting the Unit for Small Angles.........................................3-18

Changing the Mold Size ..............................................................3-21

CHAPTER 4. MAKING A SPECIMEN

Safety Warnings.............................................................................4-2

Compacting a Specimen ................................................................4-3

Extruding a Specimen....................................................................4-9

APPENDIX A. TROUBLESHOOTING AND SERVICE

Troubleshooting............................................................................A-2

General Maintenance....................................................................A-7

Replacement Parts ......................................................................A-16

Returning Parts for Service.........................................................A-18

Troxler Service Centers..............................................................A-19

APPENDIX B. SPECIFICATIONS

Electrical Specifications ...............................................................B-2

Mechanical Specifications............................................................B-4

INDEX

WARRANTY

viii

LIST OF FIGURES

Figure Title Page

1-1

Model 4140 Gyratory Compactor.............................. 1-3

1-2

Model 4140 Parts and Accessories............................ 1-5

2-1

Sample Calc %Gmm Table...................................... 2-23

2-2

Sample Calc %Gmm Graph..................................... 2-24

3-1

Load Cell and PIM-3 Connections ............................ 3-4

3-2

Angle Excursion Indicator......................................... 3-8

3-3

View from Front Access Panel................................ 3-10

3-4

Setting the Adjustable Angle Stop........................... 3-17

3-5

Converting the Unit for Small Angles..................... 3-18

3-6

Changing the Mold Size .......................................... 3-21

4-1

Loading the Mold....................................................... 4-5

4-2

Mold in the Extruder................................................ 4-10

A-1

Cleaning and Greasing the Bearing and

Related Parts ............................................................A-12

Model 4140

ix

ATTENTION COMPACTOR OWNER

This unit contains functions that require an ACCESS CODE.

This code must be entered before using these functions.

The ACCESS CODE for this unit is:

5388

This page should be removed if the access code is not to be

distributed to other parties or users of this unit.

x

NOTES

Model 4140

1-1

CHAPTER 1

INTRODUCTION TO THE MODEL 4140

This chapter provides an introduction to the Model 4140 Gyratory

Compactor. Also included are a list of parts and accessories, and

instructions for unpacking and inspecting the system.

CONTENTS

Introduction....................................................................................1-2

Parts and Accessories.....................................................................1-5

Unpacking and Inspection .............................................................1-8

1. INTRODUCTION

1-2

INTRODUCTION

The engineering properties of an asphalt mix relate directly to the

compaction method. Thus, the method of specimen compaction is

crucial to creating asphalt specimens that behave like asphalt used in

construction and in obtaining meaningful test results. Studies show

that gyratory compacted asphalt specimens possess engineering

properties similar to those achieved under actual paving conditions.

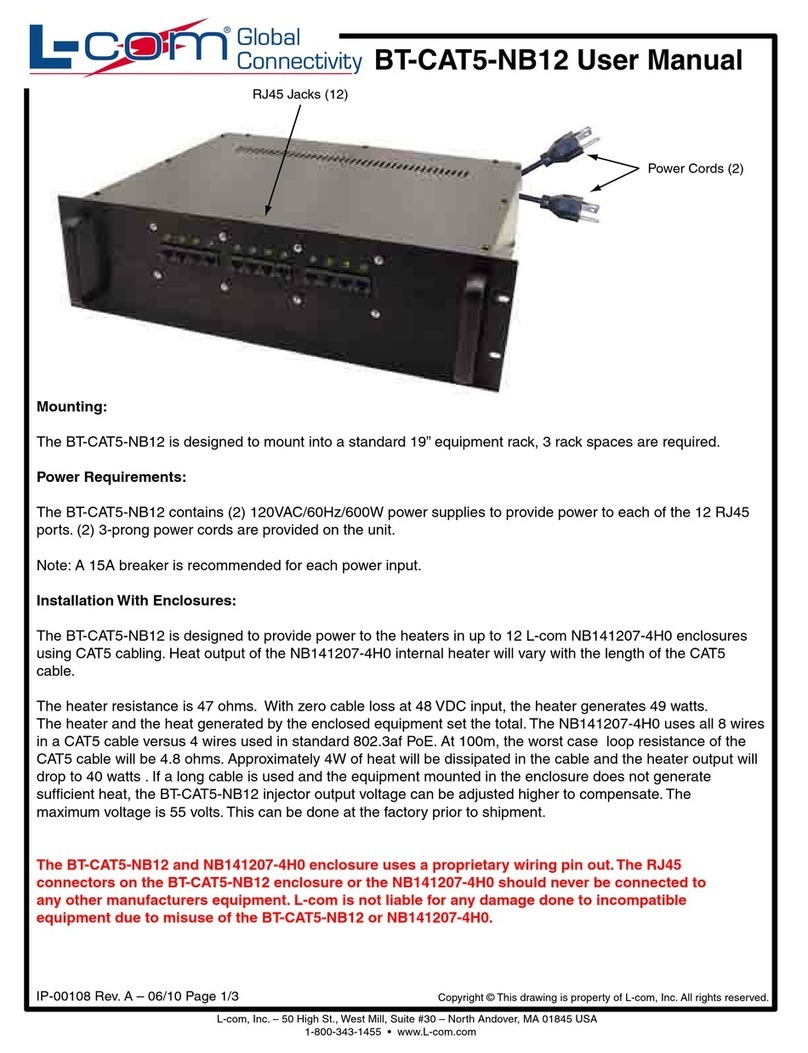

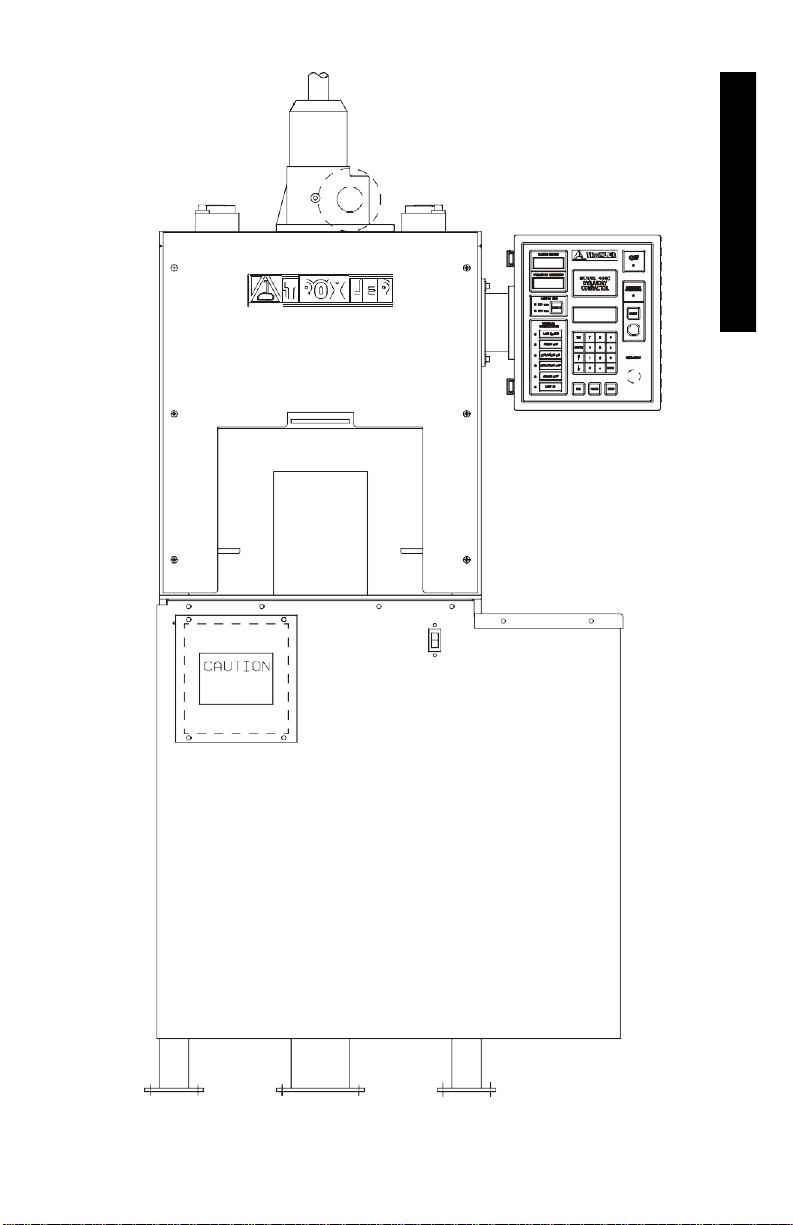

The Model 4140 Gyratory Compactor (Figure 1-1) meets or exceeds

all Federal Highway Administration (FHWA) SUPERPAVE™

specifications. The unit provides safe, reliable gyratory compaction

of asphalt specimens at a given consolidation pressure and angle of

gyration. The Model 4140 provides significant improvements over

other gyratory compactors in user safety, machine durability, noise

levels, heat output, and energy consumption.

For user safety, all rotating parts are covered and cannot be

physically accessed during compaction. The gyratory compactor

will not compact a specimen with either the shrouds improperly

positioned or the specimen chamber door open. The red

〈EMERGENCY〉safety button found in the lower right corner of

the control unit stops all moving parts and releases all forces that

could pose a threat to the user.

Two access doors, one on the front and one on the left side of the

compactor, provide easy access for angle verification and

adjustment. The shrouds allow access to the rotating parts and

machine control electronics for maintenance.

The Model 4140 requires little maintenance. To reduce the effects

of gyration on moving parts, the gyratory compactor requires some

lubrication. If necessary, the user may easily replace the turntable

insert. For a schedule of machine maintenance see page A-8.

To offer more flexible laboratory use, the Model 4140 provides two

compaction modes: automatic and manual. The automatic

compaction mode compacts the asphalt specimen with the touch of

a single key. The manual compaction mode allows the user to

control each phase of specimen compaction.

Model 4140

1-3

Figure 1-1. Model 4140 Gyratory Compactor

1. INTRODUCTION

1-4

The Model 4140 allows the user to produce either 150-mm diameter

or 100-mm diameter asphalt specimens. The user specifies the

number of gyrations (or end specimen height) and consolidation

pressure. The user can adjust the angle of gyration from 0.5 to 2.0°;

the default angle is 1.25°. When using the automatic compaction

option, the user may also choose to automatically send the gyration

versus height and/or pressure versus height data to a computer or a

printer. The unit also allows manual printing of the last six

compacted specimens. All output is in SI units as described in

ASTM E380-90A Standard for Metric Practice.

Before compaction the user heats both the loose asphalt and the

mold/puck assembly. The user then loads the mold with a

predetermined amount of hot mix asphalt (HMA) and places it on

the turntable. The initial angle is 0°. The specimen is now ready for

gyratory compaction.

After compacting the asphalt, the user removes the asphalt specimen

from the mold using the extruder furnished. Once removed from the

mold, the specimen is ready for testing.

NOTE

Do not attempt to operate the Model 4140 before

reading this manual and the safety warnings posted on

the unit. Troxler stresses that the user is solely

responsible for ensuring the safe use of the Model 4140.

Neither the manufacturer, its subsidiary,

representatives, or distributors can assume

responsibility for any mishaps, damage, or personal

injury which may occur from failure to observe the

safety warnings in this manual and posted on the unit.

Model 4140

1-5

PARTS AND ACCESSORIES

RAM COVER

CONTROL UNIT

ON/OFF

SWITCH

FRONT

ACCESS

DOOR

DOT MATRIX PRINTER

PUCK

MOLD EXTRUDER

Figure 1-2. Model 4140 Parts and Accessories

1. INTRODUCTION

1-6

The Model 4140 Gyratory Compactor includes the electrical and

mechanical parts necessary to continuously compact hot mix

asphalt. Use Figure 1-2 to locate and identify the following parts:

1.

The power switch is located under the worktable.

2.

The control unit, located on the right side of the compactor,

contains the control electronics for the gyratory compactor. It

provides the user interface with the Model 4140 and the

interface for optional equipment.

3.

The mold, with a puck inserted, receives the asphalt for making

specimens. The molds are manufactured from hardened steel to

resist wear and pitting, while limiting weight. Sizes: 150 mm

and 100 mm.

4.

The puck inserts in the mold. The puck is also made of

hardened steel to resist wear and pitting. Sizes: 150 mm and

100 mm.

5.

The extruder removes the compacted asphalt specimen from

the mold.

6.

The dot matrix printer allows the user to print data.

7.

The parallel printer cable (not shown) connects the control

unit to the dot matrix printer.

8.

The serial cable (not shown) connects the control unit to a

serial device, like a computer.

9.

The height calibration standard (not shown), used in

conjunction with a puck, aids in calibrating the specimen height

after setting the target pressure.

10.

The Model 4140 Manual of Operation and Maintenance (not

shown) provides the operating instructions for the compactor.

11.

The specimen papers (not shown) prevent the asphaltspecimen

from sticking to either the puck or the loading head. Sizes:

150 mm or 100 mm.

Model 4140

1-7

12.

The optional Performance Verification Kit (not shown) allows

the user to verify the pressure and angle calibrations. The

pressure and angle are initially calibrated at the factory.

13.

The optional temperature probe (not shown) allows the user to

test the initial temperature of a HMA specimen.

14.

The optional mold lifter (not shown) enables any user to easily

lift the mold in or out of the specimen chamber.

1. INTRODUCTION

1-8

UNPACKING AND INSPECTION

Upon receipt of the Model 4140 Gyratory Compactor from the

factory, a complete inspection and inventory should be performed.

If any parts or accessories appear damaged, notify the carrier and

your Troxler Representative immediately.

Check to see that the following are included:

♦

Model 4140 Gyratory Compactor

♦

Extruder

♦

Printer

♦

Parallel printer cable

♦

Serial cable

♦

Height calibration spacer

♦

Specimen papers (500 per package)

♦

Manual of Operation and Maintenance

Inspect each part for damage.

See page 2-3 for a guide to assembly.

Table of contents

Other Troxler Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

MYERSON

MYERSON HotShotElite instruction manual

Scion Instruments

Scion Instruments 436-GC Service manual

Metrohm

Metrohm 940 Professional IC Vario TWO manual

TSE

TSE Calorimetry PhenoMaster Hardware operating instructions

Chopin

Chopin Mixolab 2 Quick installation and first test

Thermo Scientific

Thermo Scientific Orbitrap Fusion Lumos Getting started guide