CaloSys Modules3

Table of Contents

1. Introduction .....................................................................................................................7

2. Instructions for safe Operation.........................................................................................8

2.1. General Safety Instructions .............................................................................................8

2.1.1. Proper Use......................................................................................................................8

3. Operating Principle..........................................................................................................9

4. PC Requirements............................................................................................................9

5. Installation Drivers, Interface, Software.........................................................................10

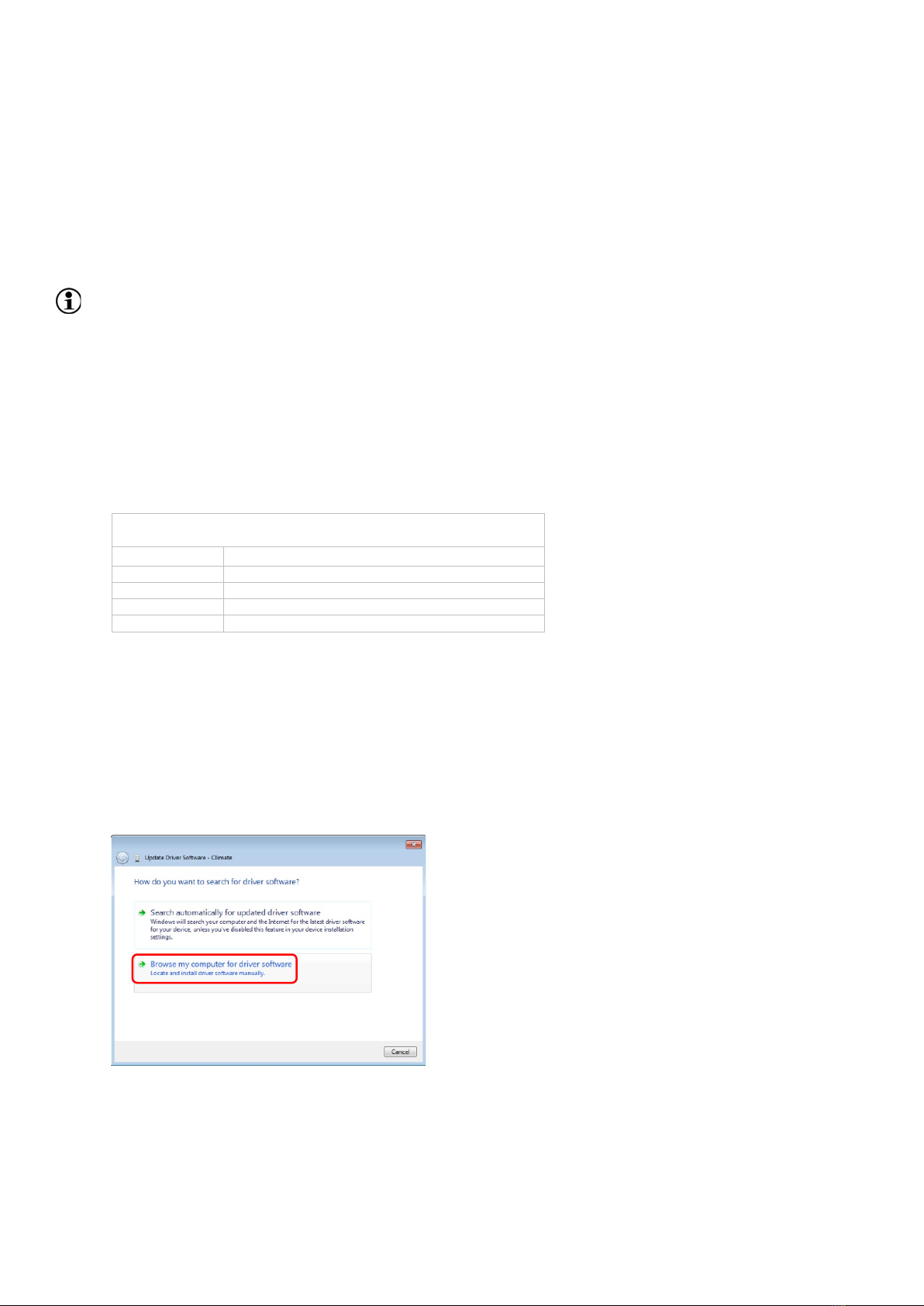

5.1. USB Interface................................................................................................................10

5.1.1. Installing *.inf file (TSE USB Adapter*)..........................................................................10

5.2. WireOne Driver..............................................................................................................12

6. Connecting Devices - General.......................................................................................16

7. Cage Rack ....................................................................................................................16

8. System Software...........................................................................................................16

9. Performing a Measurement...........................................................................................16

10. Maintenance and Cleaning............................................................................................17

10.1. Cage .............................................................................................................................17

10.1.1. Cage Lid........................................................................................................................17

10.1.1.1. Calorimetry Cage Lid.....................................................................................................17

10.2. Air Supply Pump............................................................................................................20

10.2.1. Exchanging Filter...........................................................................................................21

10.2.2. Overpressure Valve.......................................................................................................22

10.2.3. Chamber Block Change ................................................................................................23

10.2.4. Troubleshooting.............................................................................................................24

10.3. Vacuum Pump...............................................................................................................25

10.3.1. Chamber Block Change ................................................................................................25

10.4. Exchanging Protection Air Filter ....................................................................................25

10.5. Exchanging Disk Filter...................................................................................................26

10.6. Air Drying Unit...............................................................................................................27

10.7. Tubing...........................................................................................................................27

10.8. Replacing Flowmeter Battery.........................................................................................28

11. Calorimetry Measurement .............................................................................................29

11.1. Overview Devices and Connections..............................................................................29

11.1.1. Push Principle Respirometry (Overpressure Principle)..................................................30

11.1.1.1. CaloSys Module to be operated with manual Calibration...............................................30

11.1.1.2. CaloSys Module to be operated with automatic or manual Calibration ..........................32

11.1.1.3. CaloSys Module including multiple Calorimetry Control Units........................................33

11.1.2. Pull Principle Respirometry (Underpressure Principle) ..................................................36

11.1.2.1. CaloSys Module to be operated with manual Calibration...............................................36

11.1.2.2. CaloSys Module to be operated with automatic or manual Calibration ..........................38

11.1.2.3. CaloSys Module including multiple High-Speed Sensor Units .......................................40

11.2. Calorimetry Process Control Unit ..................................................................................43

11.2.1. Connections Calorimetry Process Control Unit..............................................................44

11.2.1.1. Connections Calorimetry Master Process Control Unit..................................................45

11.2.1.2. Connections Calorimetry Master Process Control and High-Speed Sensor Unit............46

11.2.1.3. Connections Calorimetry Slave Process Control Unit....................................................47

11.2.2. Mass Flow Controllers in Calorimetry Control Unit.........................................................47

11.2.3. Setting Sample Flow on Calorimetry Master Control Unit..............................................49

11.2.4. Combination Sensor for O2 and CO2 Concentration in Calorimetry Master Control Unit49

11.2.4.1. O2 Sensor - Working Principle ......................................................................................49

11.2.4.2. CO2 Sensor - Working Principle....................................................................................50

11.2.5. Temperature Sensor .....................................................................................................50

11.2.5.1. Analogous Temperature Sensor....................................................................................50

info@TSE-Systems.com www.TSE-Systems.com