Troy-Bild TB4BP EC User manual

Operator’s Manual

4-Cycle Backpack Blower

TB4BP EC

769-06928 P02 05/11

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

For assistance regarding the assembly, controls, operation or

maintenance of the unit, please call the Customer Support Department

at 1-800-828-5500 in the United States or 1-800-668-1238 in Canada.

Additional information about the unit can be found on our website at

www.troybilt.com or www.troybilt.ca.

For service, please call the Customer Support Department to obtain a

list of authorized service dealers near you. Service on this unit, both

within and after the warranty period, should only be performed by an

authorized and approved service dealer. When servicing, use only

identical replacement parts.

All information, illustrations, and specifications in this manual are based on

the latest product information available at the time of printing. We reserve

the right to make changes at any time without notice.

Copyright© 2011 MTD SOUTHWEST INC, All Rights Reserved.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Oil and Fuel Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Starting/Stopping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . . . .12

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Optional Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SAVE THESE INSTRUCTIONS

SERVICE INFORMATION

2

SAFETY WARNINGS FOR GAS UNITS

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the fuel

tank. Never remove the fuel tank cap or add fuel when the engine

is hot. Always loosen the fuel tank cap slowly to relieve any

pressure in the tank before fueling. Do not smoke.

• Always add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. Do not smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the engine.

Move the unit at least 30 feet (9.1 m) from the fueling source and

site before starting the engine. Do not smoke.

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Only operate this unit in a well-

ventilated outdoor area.

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

• Read this operating instruction manual carefully. Be thoroughly

familiar with the controls and the proper use of the equipment.

Know how to stop the unit and disengage the controls quickly.

• Do not operate this unit when tired, ill, or under the influence of

alcohol, drugs, or medication.

• Never allow children to operate the equipment. Never allow adults

unfamiliar with the instructions to use the unit. Never allow adults

to operate the equipment without proper instruction.

• All guards and safety attachments must be installed properly

before operating the unit.

• IMPORTANT SAFETY INSTRUCTIONS •

Read the Operator’s Manual and follow all warnings and safety instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

FOR QUESTIONS, CALL 1-800-828-5500 IN U.S. OR 1-800-668-1238 in CANADA

The purpose of safety symbols is to attract your attention to possible

dangers. The safety symbols, and their explanations, deserve your

careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they

give are not substitutes for proper accident prevention measures.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SAFETY ALERT: Indicates danger, warning or

caution. Attention is required in order to avoid serious

personal injury. May be used in conjunction with other

symbols or pictographs.

DANGER: Failure to obey a safety warning will result

in serious injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire, electric

shock and personal injury.

WARNING: Failure to obey a safety warning can

result in injury to yourself and others. Always follow the

safety precautions to reduce the risk of fire, electric

shock and personal injury.

CAUTION: Failure to obey a safety warning may result

in property damage or personal injury to yourself or to

others. Always follow the safety precautions to reduce

the risk of fire, electric shock and personal injury.

RULES FOR SAFE OPERATION

SYMBOL MEANING

WARNING: When using the unit, you must follow the

safety rules. Please read these instructions before operating

the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

WARNING: Gasoline is highly flammable and its

vapors can explode if ignited. Take the following

precautions:

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and 4443),

Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped and maintained

for the prevention of fire. Check with your state or local authorities for

regulations pertaining to these requirements. Failure to follow these

requirements could subject you to liability or a fine. This unit is

factory equipped with a spark arrestor. If it requires replacement,

ask your LOCAL SERVICE DEALER to install the Accessory Part

#753-05669 Muffler Assembly.

CALIFORNIA PROPOSITION 65

WARNING: Engine exhaust, some of its constituents

and certain finished components contain or emit

chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

Wash hands after handling.

3

RULES FOR SAFE OPERATION

WHILE OPERATING

• Wear safety glasses or goggles that are marked as meeting ANSI

Z87.1 standards and are marked as such. Wear ear/hearing

protection when operating this unit.

• Never run the unit without the proper equipment attached.

• To reduce the risk of hearing loss associated with sound level(s),

always wear ear/hearing protection when operating this unit.

• Wear heavy long pants, boots, gloves, and a long sleeve shirt. Do

not wear loose clothing, jewelery, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• To avoid static electricity shock, do not wear rubber gloves or

any other insulated gloves while operating this unit.

• Use the unit only in daylight or good artificial light.

• Keep outside surfaces free from oil and fuel.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Starting/Stopping Instructions.

• Do not set unit on any surface except a clean, hard area while

engine is running. Debris such as gravel, sand, dust, grass, etc.

could be picked up by the air intake and thrown out by the

discharge opening, damaging unit, property, or causing serious

injury to bystanders or operator.

• Use the right tool. Only use this tool for its intended purpose.

• Do not force unit. It will do the job better and with less likelihood

of injury at a rate for which it was designed.

• Do not overreach or use from unstable surfaces such as ladders,

trees, steep slopes, rooftops, etc. Always keep proper footing

and balance.

• Always hold the unit with a firm grip when operating.

• Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop the impeller when it is rotating. Do not

operate without guards in place.

• Do not put any object into openings. Do not use with any

opening blocked; keep free of dirt, debris, and anything that may

reduce the air flow.

• Do not touch the engine or muffler. These parts get extremely hot

from operation, even after the unit is turned off.

• Do not operate the engine faster than the speed needed to do

the job. Do not run the engine at high speed when not in use.

• Always stop the engine when operation is delayed or when

walking from one location to another.

• Stop the engine for maintenance, repair, to install or remove the

blower tubes. The unit must be stopped and the impeller no

longer turning to avoid contact with the rotating blades.

• If you strike or come into contact with a foreign object, stop the

engine immediately and check for damage. Do not operate

before repairing damage. Do not operate the unit with loose or

damaged parts.

• Use only replacement parts recommended for this tool that are

sold by a Troy-Bilt outlet. Use of any replacement parts purchased

elsewhere may be hazardous, and will also void your warranty.

• Never use this unit for spreading chemicals, fertilizers or other

substances which may contain toxic materials.

• To reduce fire hazard, replace faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

• Turn the engine off and disconnect the spark plug for

maintenance or repair.

• Never point the blower or blowing debris in the direction of

people, animals, or in the direction of windows. Always direct the

blowing debris away from people, animals, and windows. Use

extra caution when blowing debris near solid objects such as

trees, automobiles, walls, etc.

OTHER SAFETY WARNINGS

• Always disconnect the spark plug before performing

maintenance or accessing movable parts. See Replacing the

Spark Plug.

• Never store the unit, with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

• Allow the engine to cool before storing or transporting. Be sure to

secure the unit while transporting.

• Store the unit in a dry place, secured, or at a height to prevent

unauthorized use or damage. Keep out of the reach of children.

• Never douse or squirt the unit with water or any other liquid.

Keep handles dry, clean, and free from debris. Clean after each

use, see Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan these

instructions to them.

SPECIAL NOTE: Exposure to vibrations through prolonged use of

gasoline powered hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of people prone to

circulation disorders or abnormal swelling. Prolonged use in cold

weather has been linked to blood vessel damage in otherwise

healthy people. If symptoms occur such as numbness, pain, loss of

strength, change in skin color or texture, or loss of feeling in the

fingers, hands or joints, discontinue use of this tool and seek

medical attention. A reduced vibration system does not guarantee

avoidance of these problems. Users who operate power tools on a

regular basis must closely monitor their physical condition and the

condition of this tool.

SAVE THESE INSTRUCTIONS

4

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating, maintenance,` and repair information.

RULES FOR SAFE OPERATION

• WARNING: READ OPERATOR'S MANUAL

Read the operator’s manual(s) and follow all warnings

and safety instructions. Failure to do so can result in

serious injury to the operator and/or bystanders. • KEEP BYSTANDERS AWAY

WARNING: Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear eye

protection meeting ANSI Z87.1 standards and ear

protection when operating this unit. Use a full face

shield when needed.

SYMBOL MEANING

• THROWN OBJECTS CAN CAUSE SEVERE

INJURY

WARNING: Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear eye

protection meeting ANSI Z87.1 standards and ear

protection when operating this unit. Use a full face

shield when needed.

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

SYMBOL MEANING

• WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear eye

protection meeting ANSI Z87.1 standards and ear

protection when operating this unit. Use a full face

shield when needed.

•OIL

Refer to operator’s manual for the proper type of oil.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• ON/OFF STOP CONTROL

OFF or STOP

• ON/OFF STOP CONTROL

ON / START / RUN

• HOT SURFACE WARNING

Do not touch a hot surface. You may get burned.

These parts get extremely hot from operation. They

remain hot for a short time after the unit is turned off.

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• BLOWERS – ROTATING IMPELLER

BLADES CAN CAUSE SEVERE INJURY

WARNING: Stop the engine and allow the impeller

to stop before opening the vacuum door, installing or

changing tubes or bag, or before cleaning or

performing any maintenance.

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING: It has been proven that fuel containing

greater than 10% ethanol will likely damage this

engine and void the warranty.

5

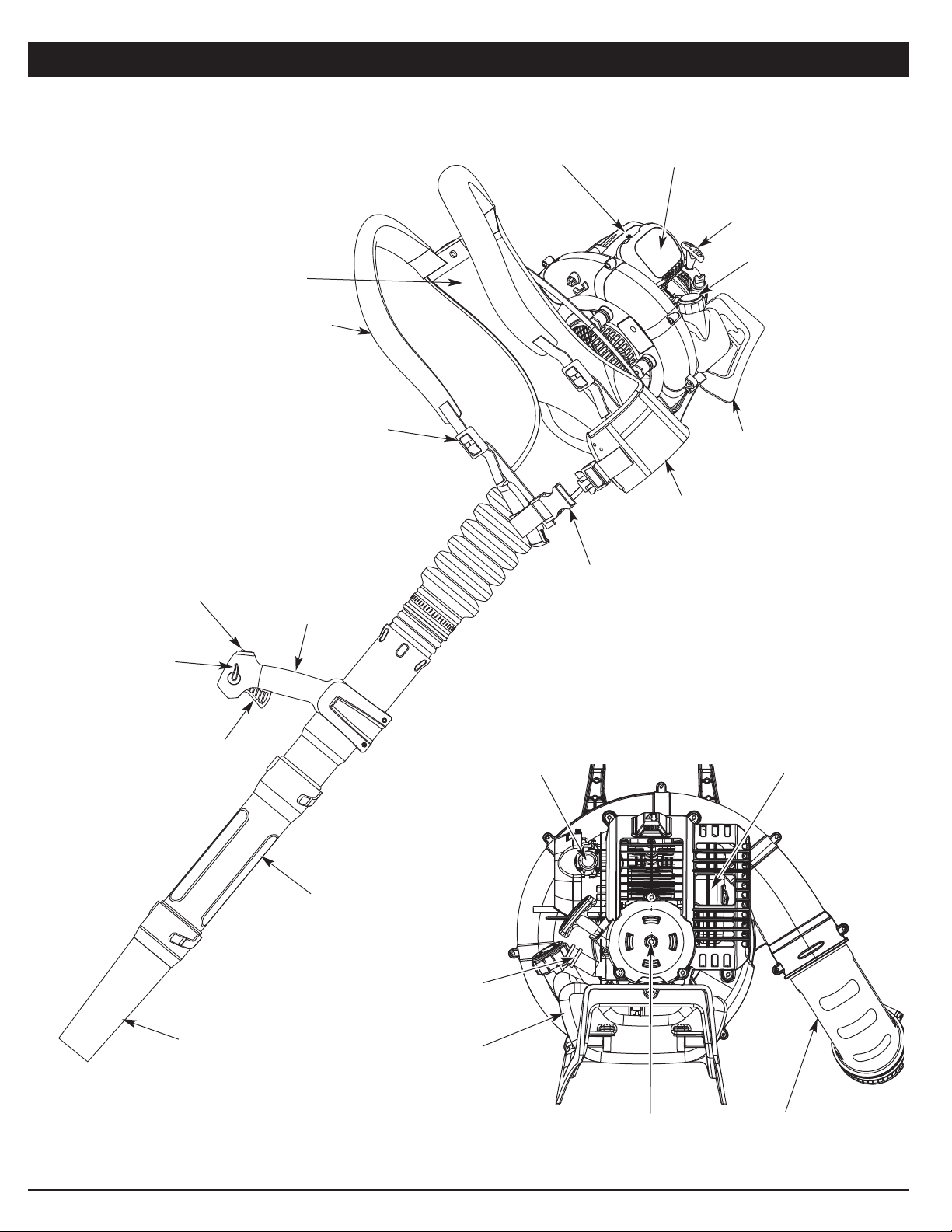

Stand

Throttle Grip

Starter Rope

Handle

Waist

Support

Clip

Muffler

Air Filter Cover

KNOW YOUR UNIT

Primer Bulb

Oil Fill Plug

Suspension System

Gas Tank

Choke Lever

Waist

Support

Gas Cap

Trigger

Blower

Tube

Shoulder

Support Buckle

Cruise Control

Electric Start

Feature

Nozzle

Shoulder Support

On/Off Control

Elbow Tube

TOOLS REQUIRED:

• T-20 Torx® Screwdriver

• Flathead Screwdriver

6

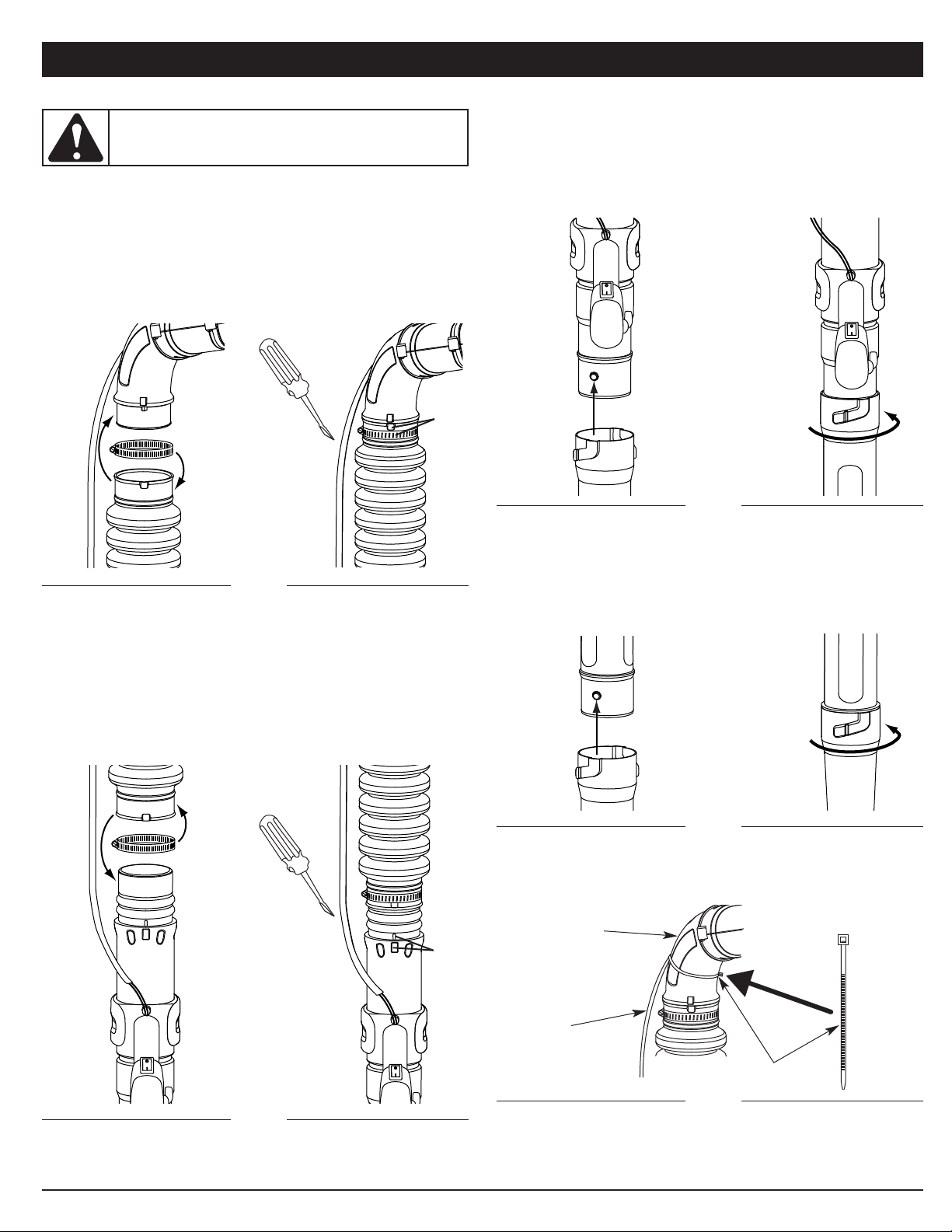

ASSEMBLING THE BLOWER TUBE

Installing the Flex Tube

1. Place a hose clamp over the end of the Flex Tube (Fig. 1A).

2. Slide the end of the Flex Tube with the clamp on it over the

elbow tube (Fig. 1B).

3. Align the bump on the Flex Tube with the bump on the elbow

tube (Fig. 1C).

4. Tighten the screw on the hose clamp to secure the Flex Tube

to the elbow tube (Fig. 1D).

Installing the Upper Blower Tube

1. Place a hose clamp over the other end of the Flex Tube (Fig. 2, A).

2. Slide the end of the hose with the clamp on it over the top end

of the upper blower tube (Fig. 2, B).

3. Align the bump on the Flex Tube with the bump on the upper

blower tube (Fig. 2, C).

4. Tighten the screw on the hose clamp to secure the Flex Tube to

the upper blower tube (Fig. 2, D).

Installing the Lower Blower Tube and Nozzle

1. Align the bump slot on the end of the lower blower tube with the

bump on the bottom end of the upper blower tube (Fig. 3, A).

2. Insert the bump on the upper blower tube into the bump slot on

the lower blower tube (Fig. 3, A).

3. Twist the lower blower tube clockwise around the upper blower

tube until the upper blower tube bump locks into place (Fig. 3, B).

4. Align the bump slot on the top end of the nozzle with the bump

on the bottom end of the lower blower tube (Fig. 4, A).

5. Insert the bump on the lower blower tube into the bump slot on

the nozzle (Fig. 4, A).

6. Twist the nozzle clockwise around the lower blower tube until the

nozzle bump locks into place (Fig. 4, B).

Secure the Throttle Cables

Place a zip tie around the elbow tube and the throttle cables, as shown

(Fig. 5). Tighten the zip tie, making sure not to crimp the cables.

ASSEMBLY INSTRUCTIONS

WARNING: To avoid serious personal injury and

damage to the unit, shut the unit off before removing or

installing the blower tube.

Fig. 1

A

BD

Fig. 2

A

B

D

Fig. 3

A

B

C

C

Fig. 4

AB

Fig. 5

Cables

Elbow Tube

Zip Tie

7

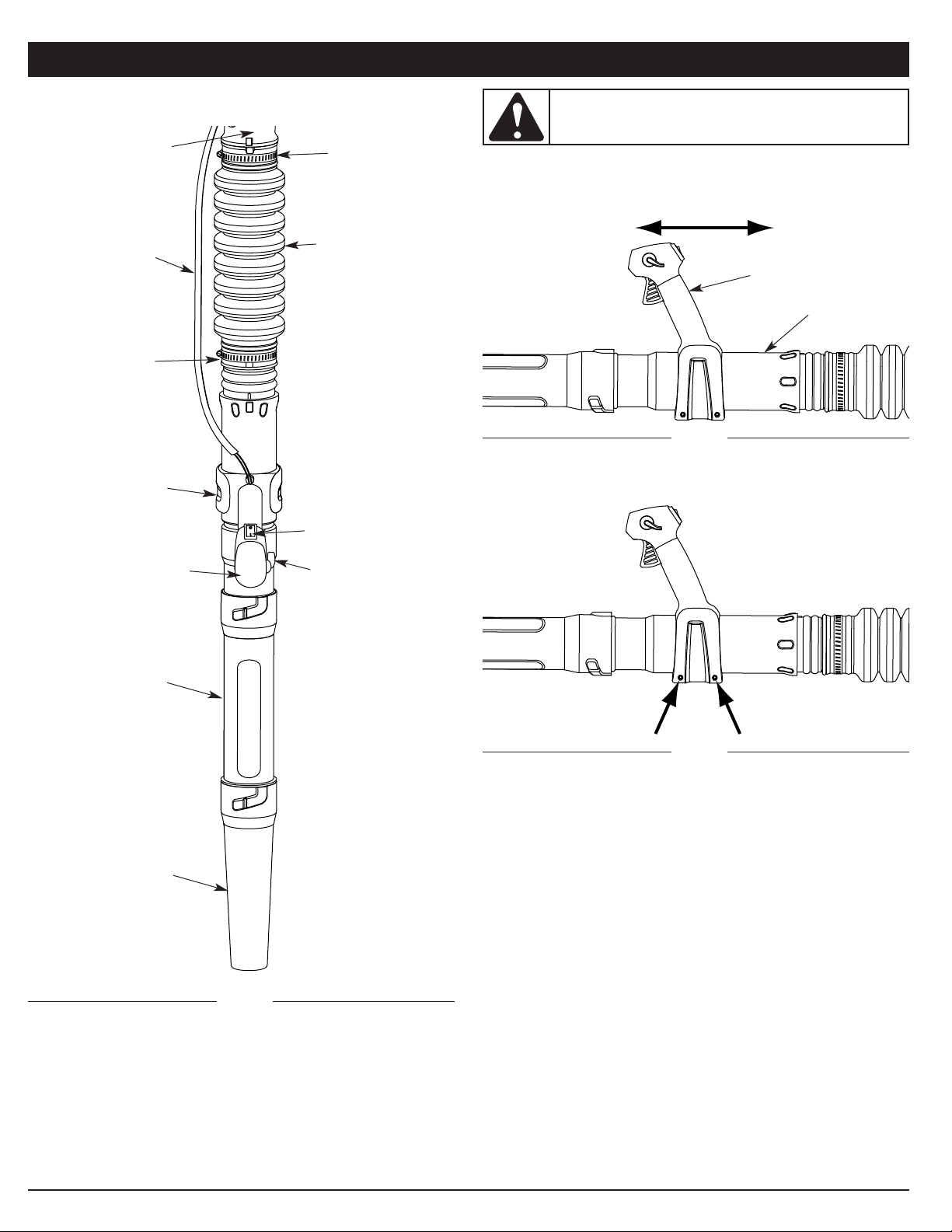

WARNING: To avoid serious personal injury, make

sure that the blower tubes are locked in place or firmly

installed.

ASSEMBLY INSTRUCTIONS

The completed blower tube should look like Figure 6.

Fig. 6

Adjusting the Throttle Grip

1. Move the throttle grip to a location on the upper blower tube

that is comfortable for you (Fig. 7).

2. Using a Torx® screwdriver, tighten the two screws at the

bottom of the throttle grip (Fig. 8).

Fig. 7

Throttle Grip

Fig. 8

Flex Tube

Hose Clamp

Elbow Tube

Upper Blower Tube

Lower Blower

Tube

Nozzle

Throttle Cables

Hose Clamp

Cruise Control

On/Off Switch

Throttle Grip

Upper Blower Tube

8

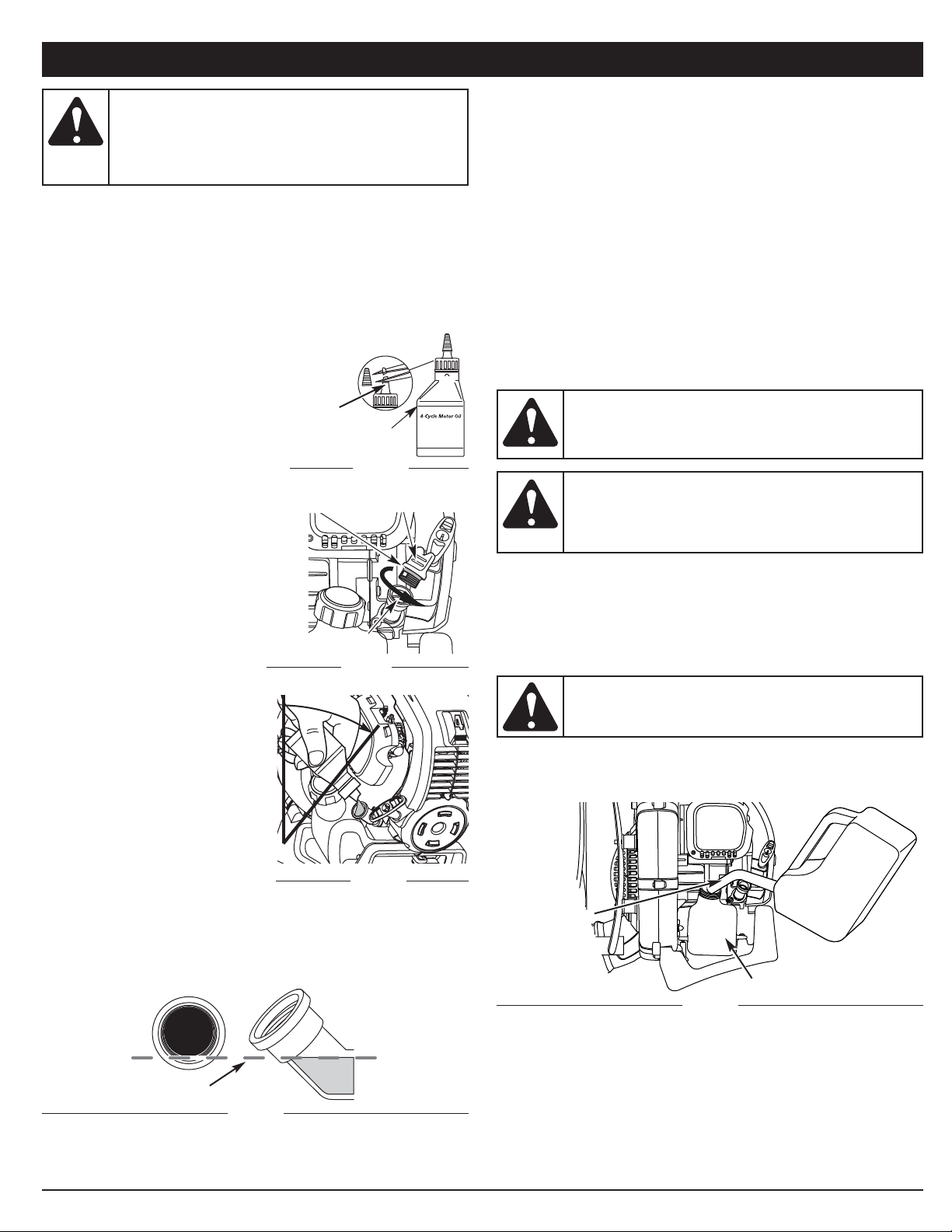

OIL AND FUEL INFORMATION

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase is extremely

important. Check the oil before each use and change the oil regularly.

Failure to use the correct oil, or using dirty oil, can cause premature

engine wear and failure.

Use a high-quality SAE 30 weight oil of API (American Petroleum

Institute) service class SF, SG, SH.

ADDING OIL TO CRANKCASE: INITIAL USE

NOTE: This unit is shipped without

oil. In order to avoid damage to the

unit, put oil in the crankcase before

you attempt to start the unit.

Your unit is supplied with one 3.04

fluid oz. (90 ml) bottle of SAE 30 SF,

SG, SH oil (Fig. 9).

NOTE: Save the bottle of oil. It can be

used to measure the correct

amount during future oil changes

(Fig. 9). See Changing the Oil.

1. Unscrew the top of the bottle

of oil and remove the paper

seal covering the opening.

Replace the top. Next, cut the

tip off the funnel spout (Fig. 9).

2. Remove the oil fill plug from

the crankcase (Fig. 10).

3. Tilt the unit backwards 30°

(Fig. 11).

4. Pour the entire bottle of oil

into the oil fill hole (Fig. 11).

NOTE: Never add oil to the fuel or

fuel tank.

5. Wipe up any oil that may have

spilled and reinstall the oil fill

plug.

Check oil before each use and

change as needed. Refer to

Checking the Oil Level.

CHECKING THE OIL LEVEL

Check the oil only when the engine is

off and cool.

1. Place the unit on its stand on a

level surface.

2. Remove the oil fill plug from the

crankcase (Fig. 10).

3. Look into the oil fill hole (Fig. 10). If the oil level comes up to

the first thread, then the oil is full (Fig. 12). If it does not, fill with

oil until it does.

Fig. 9

Funnel

Spout

RECOMMENDED FUEL TYPE

Old fuel is the primary reason for improper unit performance. Be

sure to use fresh, clean, unleaded gasoline.

NOTE: This is a four cycle engine. In order to avoid damage to the

unit, do not mix oil with gasoline.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs

water. As little as 1% water in the fuel can make fuel and oil

separate or form acids when stored. Use fresh fuel (less than 30

days old), when using alcohol-blended fuel.

Using Blended Fuels

If you choose to use a blended fuel, or its use is unavoidable, follow

recommended precautions:

• Always use fresh unleaded gasoline

• Use the fuel additive STA-BIL® or an equivalent

• Drain tank and run the engine dry before storing unit

Using Fuel Additives

The use of fuel additives, such as STA-BIL® Gas Stabilizer or an

equivalent, will inhibit corrosion and minimize the formation of gum

deposits. Using a fuel additive can keep fuel from forming harmful

deposits in the carburetor for up to six (6) months. Add 0.8 oz. (23 ml)

of fuel additive per gallon of fuel according to the instructions on the

container. NEVER add fuel additives directly to the unit's gas tank.

FUELING THE UNIT

1. Remove the fuel cap.

2. Place the gas container’s spout into the fill hole on the fuel tank

(Fig. 13) and fill the tank.

NOTE: Do not overfill the tank.

3. Wipe up any gasoline that may have spilled.

4. Reinstall the fuel cap.

5. Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine.

NOTE: Dispose of the old gasoline in accordance with federal, state

and local regulations.

Fig. 11

WARNING: Add fuel in a clean, well ventilated

outdoor area. Wipe up any spilled fuel immediately.

Avoid creating a source of ignition for spilt fuel. Do not

start the engine until fuel vapors dissipate.

WARNING: Gasoline is extremely flammable. Ignited

vapors may explode. Always stop the engine and allow

it to cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames at a

distance from the area.

WARNING: Remove fuel cap slowly to avoid injury

from fuel spray. Never operate the unit without the fuel

cap securely in place.

WARNING: OVERFILLING OIL CRANKCASE MAY

CAUSE SERIOUS PERSONAL INJURY. Check and

maintain the proper oil level in the crank case; it is

important and cannot be overemphasized. Check the oil

before each use while the engine is cold and change it

as needed. See Changing the Oil.

Fig. 13

Fuel Tank

Gas Can

Spout

Fig. 12

Oil Full Line

Fill Level

30°

Oil Fill Plug

Oil Fill Hole

O-Ring

Fig. 10

9

STARTING INSTRUCTIONS

1. Check the oil level in the crankcase. Refer to Checking the Oil

Level.

2. Fill the fuel tank with fresh, clean unleaded gasoline. Refer to

Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off Control is in

the ON ( I ) position at all times.

3. Fully press and release the primer bulb 10 times, slowly. Some

amount of fuel should be visible in the primer bulb (Fig. 14). If

fuel cannot be seen in the bulb, press and release the bulb until

fuel is visible.

4. Move the choke lever to Position 1 (Fig. 14).

NOTE: The unit should be started in idle. Do not squeeze the trigger

until step 8 (Fig. 15, A).

5. Do not squeeze the trigger. Crouch in the starting position

(Fig. 16). Pull the starter rope 5times in a controlled motion.

6. Move the choke lever to Position 2 (Fig. 14).

7. Do not squeeze the trigger. Pull the starter rope 3-5 times in a

controlled motion to start the engine.

8. Squeeze and hold the trigger, or press down the cruise control

(Fig. 15, A), and allow the engine to warm up for 30 to 60

seconds.

9. Continue to squeeze the trigger. Move the choke lever to

Position 3 (Fig. 14) and continue warming the engine for an

additional 60 seconds. During this time the unit may be used.

IF... the engine does not start, go back to step 3.

IF... the engine fails to start after a few attempts, move the choke

lever to Position 3 and pull the starter rope 3-8 times in a

controlled motion.

IF WARM... If the engine is already warm, go back to step 6.

STOPPING INSTRUCTIONS

1. Release your hand from the trigger. Allow the engine to cool

down by idling.

2. Press and hold the On/Off switch in the OFF (O) position until

the unit comes to a complete stop (Fig. 15, A). Starter Rope

STARTING/STOPPING INSTRUCTIONS

Fig. 16

Fig. 14

Primer

Bulb

Choke Lever

WARNING: Operate this unit only in a well- ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING: Avoid accidental starting. Make sure you

are in the starting position when pulling the starter rope

(Fig. 16). To avoid serious injury, the operator and unit

must be in a stable position while starting.

To avoid serious personal injury, make sure that the

blower tube is locked in place or firmly installed.

Using the Cruise Control

1. Once the engine has started and warmed up, squeeze the

trigger to accelerate the unit as needed (Fig. 15, A).

2. For longer periods of operation and to eliminate possible finger

fatigue, move the cruise control toward the FAST position to

incrementally increase or maintain the unit’s engine speed (Fig.

15, B). When the cruise control is pressed, the trigger will

recede into the handle.

3. To decrease engine speed, move the cruise control to the SLOW

position and the trigger will return to idle position (Fig. 15, B).

Trigger

Fig. 15

On/Off Switch

Cruise

Control

FAST

SLOW

AB

10

STOPPING INSTRUCTIONS

1. Release your hand from the trigger. Allow the engine to cool

down by idling.

2. Press and hold the On/Off switch in the OFF (O) position until

the unit comes to a complete stop (Fig. 15, A).

STARTING/STOPPING INSTRUCTIONS

WARNING: Operate this unit only in a well- ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING: Avoid accidental starting. Make sure you

are in the starting position when pulling the starter rope

(Fig. 16). To avoid serious injury, the operator and unit

must be in a stable position while starting.

To avoid serious personal injury, make sure that the

blower tube is locked in place or firmly installed.

Using the Cruise Control

1. Once the engine has started and warmed up, squeeze the

trigger to accelerate the unit as needed (Fig. 15, A).

2. For longer periods of operation and to eliminate possible finger

fatigue, move the cruise control toward the FAST position to

incrementally increase or maintain the unit’s engine speed (Fig.

15, B). When the cruise control is pressed, the trigger will

recede into the handle.

3. To decrease engine speed, move the cruise control to the SLOW

position and the trigger will return to idle position (Fig. 15, B).

IF USING THE OPTIONAL ELECTRIC STARTER OR POWER START BIT™ ACCESSORY

NOTE- This Unit Can Use an Electric Start or Power Start Bit™

Optional Accessory!

Please refer to the Electric Starter or Power Start BitTM operator’s

manual for proper use of this feature. (Items Sold Separately!

Please refer to page 15 of this manual about purchasing these

accessories.)

STARTING INSTRUCTIONS

1. Check the oil level in the crankcase. Refer to Checking the Oil

Level.

2. Fill the fuel tank with fresh, clean unleaded gasoline. Refer to

Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off Control is in

the ON ( I ) position at all times.

3. Fully press and release the primer bulb 10 times, slowly. Some

amount of fuel should be visible in the primer bulb (Fig. 14). If

fuel cannot be seen in the bulb, press and release the bulb until

fuel is visible.

4. Move the choke lever to Position 1 (Fig. 14).

NOTE: The unit should be started in idle. Do not squeeze the

trigger until step 10 (Fig. 15, A).

5. Crouch in the starting position (Fig. 16). Insert the electric

starter or Power Start Bit™ into the back of the unit (Fig. 32).

Refer to the Operation section of the Electric Starter or Power

Start BitTM operator’s manual.

6. Do not squeeze the trigger. Press and hold the electric starter

or drill’s ON (I) button for 2 seconds.

7. Move the choke lever to Position 2 (Fig. 14).

8. Do not squeeze the trigger. Press and hold the electric starter

or drill’s ON (I) button for 2-second intervals until the unit starts.

9. Remove the electric starter or drill from the unit.

10. Squeeze and hold the trigger, or press down the cruise control

(Fig. 15, A), and allow the engine to warm up for 30 to 60

seconds.

11. Continue to squeeze the trigger. Move the choke lever to

Position 3 (Fig. 14) and continue warming the engine for an

additional 60 seconds. During this time the unit may be used.

IF... the engine does not start, go back to step 3.

IF... the engine fails to start after a few attempts, place the choke

lever in Position 3 and squeeze the throttle control. Press and

hold the electric starter or drill ON (I) button for 2-second

intervals until the unit starts.

IF WARM... If the engine is already warm, go back to step 7.

11

OPERATING INSTRUCTIONS

ADJUSTING THE SUSPENSION SYSTEM

1. Place the unit’s shoulder supports over the shoulders while the

unit is behind you.

2. Close the suspension system’s waist support by sliding the

waist support clips together (Fig. 17, A).

NOTE: Make sure the weight of the unit is supported on the hips by

the waist support (Fig. 18, A).

3. If weight is not on hips, loosen the shoulder supports (Fig. 19,

A) and pull the waist support handle (Fig. 18, B) to tighten.

Adjust until the unit’s weight rests on the hips.

4. Pull the shoulder support handles to tighten the shoulder

supports (Fig. 17, B).

Releasing the Suspension System

1. To release the shoulder supports, pull up on bottom tab of the

shoulder support buckles (Fig. 19, A).

2. Squeeze the top and bottom of the waist support clips to

release the waist support (Fig. 19, B).

HOLDING THE BLOWER

Before operating the unit, stand in the operating position (Fig. 20).

Check for the following:

• Operator is wearing proper clothing, such as boots, safety

glasses or goggles, ear/hearing protection, gloves, long pants

and long sleeve shirt.

Fig. 20

WARNING: To avoid serious personal injury, wear

goggles or safety glasses at all times when operating this

unit. Wear a face mask or dust mask in dusty locations.

• If the conditions are dusty, the operator is wearing a dust mask or

face mask.

• The unit is in good working condition.

• The tubes are in place and secure.

OPERATING TIPS

• Assure the unit is not directed at anybody or any loose debris

before starting the unit.

• Verify that the unit is in good working condition. Make sure the

tubes are in place and secure.

• Always hold the unit securely when operating.

• To reduce the risk of hearing loss associated with sound level(s),

hearing protection is required.

• Operate power equipment only at reasonable hours— not early in the

morning or late at night when people might be disturbed. Comply with

times listed in local ordinances. Usual recommendations are 9:00 am

to 5:00 pm, Monday through Saturday.

• To reduce noise levels, limit the number of pieces of equipment

used at any one time.

• To reduce noise levels, operate power blowers at the lowest

possible speed to do the job.

• Check your equipment before operation, especially the muffler,

air intakes and air filters.

• Use rakes and brooms to loosen debris before blowing.

• In dusty conditions, slightly dampen surfaces or use a mister

attachment when water is available.

• Conserve water by using power blowers instead of hoses for

many lawn and garden applications, including areas such as

screens, patios, grills, porches, and gardens.

• Watch out for children, pets, open windows or freshly washed

cars, and blow debris safely away.

• Use the full blower nozzle extension so the air stream can work

close to the ground.

• Clean up after using blowers and other equipment. Dispose of

debris appropriately.

• Use the cruise control (Fig. 15) to keep the trigger depressed

while operating to make continuous operation easier.

APPLICATIONS

1 Use the blower for trees, shrubs, flower beds and hard-to-

clean areas.

2. Use the unit around buildings and for other normal cleaning

procedures.

3. Use the blower around walls, overhangs, fences and screens.

Fig. 17

A

B

B

WARNING: To prevent serious personal injury or

damage to the unit, make sure blower tubes are in place

before you operate the unit.

Fig. 19

BA

A

Fig. 18

B

A

A

12

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Failure to maintain your air filter properly can result in poor performance or

can cause permanent damage to your engine.

1. Open the air filter cover. Push the locking tab on the under side of

the cover inward. Then pull the air filter cover out and up. (Fig. 23).

2. Remove the air filter (Fig. 24).

3. Wash the filter in detergent and water. Rinse the filter

thoroughly and allow it to dry.

4. Apply enough clean SAE 30 motor oil to lightly coat the filter.

5. Squeeze the filter to spread and remove excess oil.

6. Replace the filter (Fig. 24).

NOTE: If the unit is operated without the air filter, you will VOID the

warranty.

7. Reinstall the air filter cover. Position the slots on the top of the air

filter cover onto the tabs at the top of the back plate (Figs. 23 & 24).

8. Swing the cover down until the tab on the air filter backplate

snaps into place in the slot on the air filter cover (Fig. 25).

MAINTENANCE AND REPAIR INSTRUCTIONS

CHANGING THE OIL

Change the oil while the engine is still warm. The oil will flow freely and

carry away more impurities.

1. Remove the oil fill plug.

2. Pour the oil out of the oil fill

hole and into a container by

tipping the unit to the side

(Fig. 21). Allow ample time

for complete drainage.

3. Wipe up any oil residue on the

unit and clean up any oil that

may have spilled. Dispose of

the oil according to federal,

state and local regulations.

4. Tilt the unit backwards 30°

(Fig. 22).

5. Refill the crankcase with

3.04 fluid ounce (90 ml) of

SAE 30 SF, SG, SH oil.

b Use the bottle and spout

saved from initial use to measure the correct amount of oil. The

top of the label on the bottle measures approximately 3.04

ounces (90 ml) (Fig. 22). Check the level, See Checking the Oil

Level. If the level is low, add a small amount of oil and recheck.

Do not overfill (Fig. 22).

6. Replace the oil fill plug.

Fig. 21

Fig. 23

Fig. 24

WARNING: Wear gloves to prevent injury when

handling unit.

WARNING: To avoid serious personal injury, always

turn the unit off and allow it to cool before you clean or

service it.

Locking Tab

Tabs

Back Plate

Air Filter

Locking

Tab

Air Filter Cover

WARNING: To prevent serious injury, never perform

maintenance or repairs with unit running. Always service and

repair a cool unit. Disconnect the spark plug wire to ensure

that the unit cannot start. See Replacing the Spark Plug.

FREQUENCY MAINTENANCE REQUIRED SEE

Every 10 hours Clean and oil air filter p 12

After 1st 10

hours

Change oil

Check rocker arm to valve clearance

and adjust

p 12

p 13

Every 40 hours

Change oil

Check rocker arm to valve clearance

and adjust

Check spark plug condition and gap

p 12

p 13

p 14

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures, take your unit to

a Troy-Bilt or other qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission control

devices and system may be performed by a Troy-Bilt or other

qualified service dealer.

NOTE: Please read the California/EPA statement that came with the

unit for a complete listing of terms and coverage for the

emissions control devices, such as the spark arrestor, muffler,

carburetor, etc.

Fill Level

Fig. 22

30°

13

2. Disconnect the spark plug wire.

3. Clean dirt from around the spark

plug. Remove the spark plug from

the cylinder head by turning a 5/8 in.

socket counterclockwise.

4. Remove the engine cover (Fig. 27).

5. Clean dirt from around the rocker

arm cover. Remove the screw

holding the rocker arm cover with a

large flat blade screwdriver or Torx®

T-25 bit (Fig. 28). Remove the rocker

arm cover and gasket.

6. Pull the starter rope slowly to bring

the piston to the top of its travel,

(known as top dead center). Check

that:

• The piston is at the top of its travel while looking in the spark

plug hole (Fig. 29).

• Both rocker arms move freely, and both valves are closed.

If these statements are not true, repeat this step.

7. Slide the feeler gauge between the rocker arm and the valve return

spring. Measure the clearance between the valve stem and rocker

arm (Fig. 29). Measure both the intake and exhaust valves.

The recommended clearance for both intake and exhaust is .003 –

.006 in. (.076 – 0.152 mm). Use a standard automotive .005 in.

(0.127 mm) feeler gauge. The feeler gauge should slide between the

rocker arm and valve stem with a slight amount of resistance,

without binding. See Figures 29 and 30.

IDLE SPEED ADJUSTMENT

The idle speed of the engine is

adjustable. An idle adjustment screw

is between the air filter cover and the

engine starter housing (Fig. 26).

NOTE: Careless adjustments can

seriously damage your unit. An

authorized service dealer should

make carburetor adjustments.

If, after checking the fuel and

cleaning the air filter, the engine still

will not idle, adjust the idle speed

screw as follows:

1. Start the engine and let it run at

a high idle for a minute to warm up. Refer to Starting/Stopping

Instructions.

2. Release the throttle trigger and let the engine idle. If the engine

stops, insert a small Phillips screwdriver in between the air filter

cover and the engine cover (Fig. 26). Turn the idle speed screw

in, clockwise, 1/8 of a turn at a time (as needed) until the

engine idles smoothly.

Checking the fuel, cleaning the air filter, and adjusting the idle

speed should solve most engine problems. If not and all of the

following are true:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

Have the carburetor adjusted by an authorized service dealer.

ROCKER ARM CLEARANCE

This requires disassembly of the engine. If you feel unsure or unqualified

to perform this, take the unit to an authorized service center.

• The engine must be cold when checking or adjusting the valve

clearance.

• This task should be performed inside, in a clean, dust free area.

1. Remove the seven (7) screws on the back of the engine cover

with a Flat-head or T-25 Torx® screwdriver (Fig. 27).

MAINTENANCE AND REPAIR INSTRUCTIONS

Rocker

Arm

Cover

Fig. 28

Spark

Plug

Hole

Air Filter Cover

Air Filter

Back Plate

Tab

Fig. 25

Adjusting Nuts

Feeler Gauge

Rocker Arms

Fig. 29

INTAKE

EXHAUST

Spark Plug Hole

Idle

Adjustment

Screw

Fig. 26

Remove

Screws

Fig. 27

Remove

Screws Fig. 30

Feeler Gauge

Adjusting Nut

Rocker Arm

.003–.006 in.

(.076–.152 mm)

Valve Stem

Intake Valve

Stem

14

MAINTENANCE AND REPAIR INSTRUCTIONS

8. If the clearance is not within specification:

a. Turn the adjusting nut (Fig. 30) using a 5/16 inch (8 mm) wrench

or nut driver.

• To increase clearance, turn the adjusting nut counterclockwise.

• To decrease clearance, turn the adjusting nut clockwise.

b. Recheck both clearances, and adjust as necessary.

9. Reinstall the rocker arm cover using a new gasket. Torque the

screw to 20–30 in•lb (2.2–3.4 N•m).

10. Check the spark plug and reinstall. See Replacing the Spark Plug.

11. Replace the spark plug wire.

12. Reinstall the engine cover. Check alignment of the cover before

tightening the screws. Tighten screws.

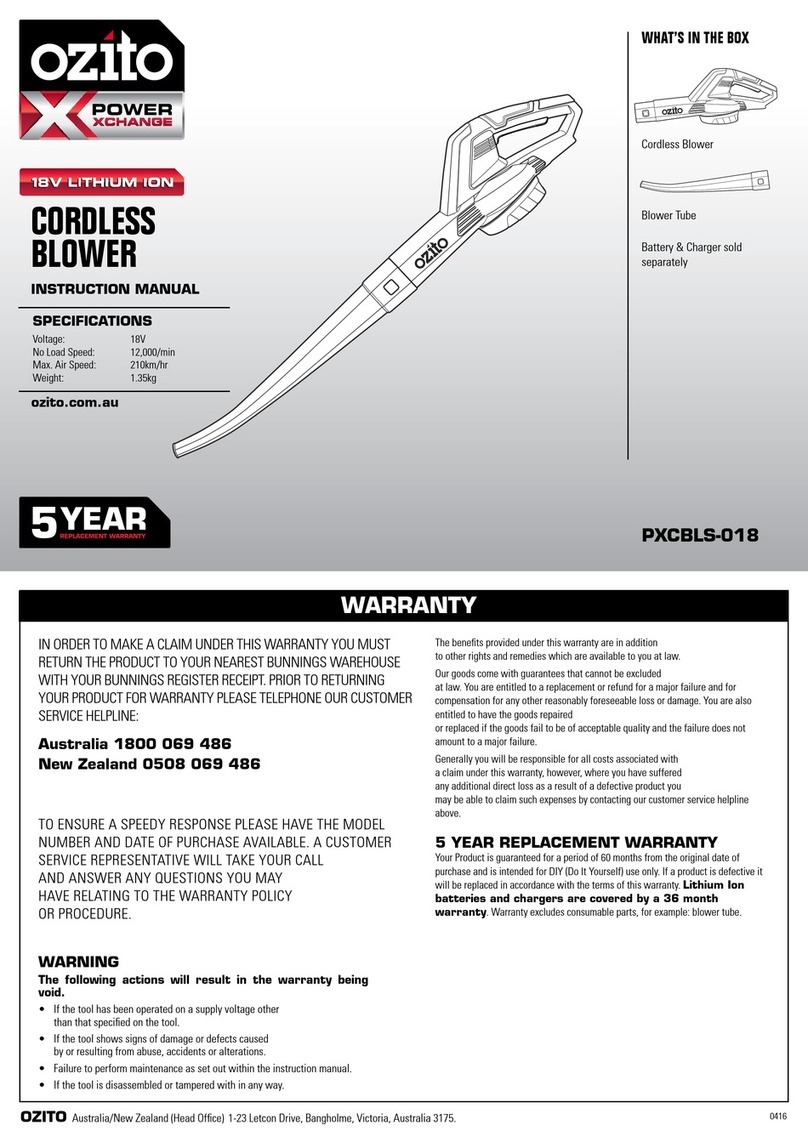

REPLACING THE SPARK PLUG

Use a replacement part number 753-05784 or Champion® RDZ4H

spark plug. The correct air gap is 0.025 in. (0.635 mm).

1. Stop the engine and allow it to cool. Remove the seven (7)

screws on the back of the engine cover with a Flat-head or T-

25 Torx® screwdriver (Fig. 27).

2. Grasp the plug wire firmly and pull the cap from the spark plug.

3. Clean dirt from around the spark plug. Remove the spark plug

from the cylinder head by turning a 5/8 in. socket

counterclockwise.

4. Replace cracked, fouled or dirty spark plug. Set the air gap at

0.025 in. (0.635 mm) using a feeler gauge (Fig. 31).

5. Install a correctly-gapped spark plug in the cylinder head. Turn

the 5/8 in. socket clockwise until snug.

If using a torque wrench torque to:

110-120 in.•lb. (12.3-13.5 N•m)

Do not over tighten.

0.025 in.

(0.635 mm)

Fig. 31

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as pine

and lemon, and solvents such as kerosene, can damage plastic

housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes may reach

an open flame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

Long Term Storage

1. Drain all gasoline from the gas tank into a container. Do not use gas

that has been stored for more than 30 days. Dispose of the old

gasoline in accordance with federal, state and local regulations.

2. Start the engine and allow it to run until it stalls. This ensures

that all gasoline has been drained from the carburetor.

3. Allow the engine to cool. Remove the seven (7) screws on the

back of the engine cover with a Flat-head or T-25 Torx®

screwdriver. Remove the spark plug and put 5 drops of high

quality motor oil into the cylinder. Pull the starter rope slowly to

distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the

cylinder before attempting to start the unit after storage.

4. Change the oil, referring to Changing the Oil. Dispose of the

old oil in accordance with federal, state and local regulations.

5. Thoroughly clean the unit and inspect for any loose or

damaged parts. Repair or replace damaged parts and tighten

loose screws, nuts or bolts. The unit is ready for storage.

CAUTION: Do not sand blast, scrape or clean

electrodes. Grit in the engine could damage the cylinder.

WARNING: To avoid serious personal injury, always

turn your unit off and allow it to cool before you clean or

service it.

CLEANING AND STORAGE

15

OPTIONAL ACCESSORY

ELECTRIC STARTER AND POWER START BIT™ FEATURES

This unit is designed to be started with an optional electric starter or

Power Start Bit™ that are sold separately. If choosing to start the

unit using one of these features or have questions, please contact

your local retailer or call 1-800-828-5500 in the U.S (1-800-668-1238

in Canada) for more information and purchasing. You may also go to

www.troybilt.com or www.troybilt.ca.

Electric Start Feature

Fig. 32

CAUSE ACTION

16

TROUBLESHOOTING

If further assistance is required, contact your authorized service dealer.

Air filter is plugged Replace or clean the air filter

Old fuel (over 30 days) Drain fuel tank and add fresh fuel

Improper idle speed Adjust according to the Idle Speed Adjustment section

Empty fuel tank Fill fuel tank with fuel

Primer bulb wasn't pressed enough Press primer bulb fully and slowly 10 times

Old fuel (over 30 days) Drain fuel tank and add fresh fuel

Fouled spark plug Replace or clean the spark plug

Old fuel (over 30 days) Drain fuel tank and add fresh fuel

Fouled spark plug Replace or clean the spark plug

Old fuel (over 30 days) Drain fuel tank and add fresh fuel

Dirty air filter Clean or replace the air filter

ENGINE WILL NOT START

ENGINE WILL NOT IDLE

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STALLS

17

SPECIFICATIONS*

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 4-Cycle

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.95 in.3(32 cc)

Operating RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6,500–7,500 rpm

Idle Speed RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,800–4,400 rpm

Blower Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 150 mph (240 kmh)

Blower Air Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 500 cfm (14.2 cmm)

Valve clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.003–0.006 in. (0.076–0.152 mm)

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 inch (0.635 mm)

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SAE 30 Oil

Crankcase Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.04 oz (90 ml)

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unleaded

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 oz (768 ml)

MANUFACTURERʼS LIMITED WARRANTY FOR:

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose, applies after the

applicable period of express written warranty above as to the parts

as identified. No other express warranty or guaranty, whether

written or oral, except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any product shall

bind Troy-Bilt During the period of the Warranty, the exclusive

remedy is repair or replacement of the product as set forth above.

(Some states do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the sole and

exclusive remedy arising from the sales. Troy-Bilt shall not be liable

for incidental or consequential loss or damages including, without

limitation, expenses incurred for substitute or replacement lawn

care services, for transportation or for related expenses, or for

rental expenses to temporarily replace a warranted product. (Some

states do not allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the amount of the

purchase price of the product sold. Alteration of the safety features of

the product shall void this Warranty. You assume the risk and liability for

loss, damage, or injury to you and your property and/or to others and

their property arising out of the use or misuse or inability to use the

product.

This limited warranty shall not extend to anyone other than the original

purchaser, original lessee or the person for whom it was purchased as

a gift.

How State Law Relates to this Warranty: This warranty gives you

specific legal rights, and you may also have other rights which vary from

state to state.

To locate your nearest service dealer, dial 1-800-828-5500 in the United

States or 1-800-668-1238 in Canada.

Troy-Bilt LLC

P.O. Box 361131

Cleveland, OH 44136-0019

The limited warranty set forth below is given by Troy-Bilt LLC (Troy-Bilt)

with respect to new merchandise purchased and used in the United

States, its possessions and territories.

Troy-Bilt warrants this product against defects in material and

workmanship for a period of two (2) years commencing on the date of

original purchase and will, at its option, repair or replace, free of charge,

any part found to be defective in material or workmanship. This limited

warranty shall only apply if this product has been operated and

maintained in accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse, commercial use,

neglect, accident, improper maintenance, alteration, vandalism, theft,

fire, water or damage because of other peril or natural disaster. Damage

resulting from the installation or use of any accessory or attachment not

approved by Troy-Bilt for use with the product(s) covered by this manual

will void your warranty as to any resulting damage. This warranty is

limited to ninety (90) days from the date of original retail purchase for any

Troy-Bilt product that is used for rental or commercial purposes, or any

other income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE THROUGH YOUR LOCAL AUTHORIZED

SERVICE DEALER. To locate the dealer in your area, visit our website at

www.troybilt.com or www.troybilt.ca, check for a listing in the Yellow

Pages, call 1-800-828-5500 or 1-800-668-1238 in Canada, or write to

P.O. Box 361131, Cleveland, OH 44136-0019. No product returned

directly to the factory will be accepted unless prior written permission

has been extended by the Customer Service Department of Troy-Bilt.

This limited warranty does not provide coverage in the following

cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting Line, Inner

Reels, Starter Pulley, Starter Ropes, Drive Belts, Saw Chains,

Guide Bars, Cultivator Tines.

C. Troy-Bilt does not extend any warranty for products sold or

exported outside of the United States of America, its possessions

and territories, except those sold through Troy-Bilt’s authorized

channels of export distribution.

Troy-Bilt reserves the right to change or improve the design of any

Troy-Bilt Product without assuming any obligation to modify any

product previously manufactured.

Manuel de L'utilisateur

Souffleur à dos à 4-temps

TB4BP EC

769-06928 P02 05/11

Toutes les informations, illustrations et spécifications contenues dans

ce manuel tiennent compte des dernières informations techniques

disponibles au moment de mettre sous presse. Nous nous réservons

le droit d'y apporter des modifications à tout moment, sans préavis.

Copyright© 2011 MTD SOUTHWEST INC., Tous droits réservés.

NE RAMENEZ PAS CET APPAREIL CHEZ LE DÉTAILLANT. UNE

PREUVE D’ACHAT SERA EXIGÉE POUR TOUTE PRISE EN

CHARGE DANS LE CADRE DE LA GARANTIE.

Si vous éprouvez des difficultés à assembler ce produit ou si vous avez

des questions sur les commandes, l'utilisation ou l'entretien de cet

appareil, veuillez contacter le service à la clientèle à 1-800-828-5500 aux

États-Unis ou le 1-800-668-1238 au Canada. Des informations

supplémentaires sont disponibles sur notre site web à www.troybilt.com

ou www.troybilt.ca.

Pour un entretien ou une réparation, veuillez appeler le service à la

clientèle pour obtenir une liste complète des concessionnaires agrées

près de chez vous. L’entretien de cet appareil doit être confié

exclusivement à un concessionnaire agrée pendant et après la période

de garantie. Lors de l’entretien, utilisez uniquement des pièces de

rechange identiques.

CONSERVER CES INSTRUCTIONS

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Familiarisez-vous avec votre appareil . . . . . . . . . . . . . . . . . . . . .23

Instructions de montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Informations sur l’huile et le carburant . . . . . . . . . . . . . . . . . . . . .26

Instructions de démarrage et arrêt . . . . . . . . . . . . . . . . . . . . . . . .27

Mode d’emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Entretien et réparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Nottoyage et entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Accessoire en option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Tableau de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SERVICE TECHNIQUE

20

• IMPORTANTES CONSIGNES DE SÉCURITÉ •

AVERTISSEMENTS DE SÉCURITÉ SPÉCIAUX POUR TÊTES

D’ENTRAÎNEMENT À ESSENCE

• Stockez uniquement le carburant dans des conteneurs prévus

spécifiquement à cet effet et approuvés pour le stockage de

telles substances.

• Coupez toujours le moteur et laissez-le refroidir avant de remplir

le réservoir d’essence. Ne retirez jamais le bouchon du réservoir

d’essence et ne remplissez jamais ce dernier lorsque le moteur

est chaud. Dévissez lentement le bouchon du réservoir

d’essence afin de réduire la pression avant de le remplir. Ne

fumez pas.

• Ajoutez le carburant dans un endroit bien aéré et propre, en plein

air, à l’abri des sources d’étincelles ou flammes vives.

• Ne démarrez jamais l’appareil sans avoir bien revissé le bouchon

du réservoir d’essence.

• Évitez tout ce qui pourrait enflammer le carburant renversé.

L’essence s’étant échappée de l’appareil doit être essuyée

immédiatement avant de démarrer l'appareil. Éloignez l’appareil

d’au moins 9,1 m (30 pieds) du site et de la source du carburant

avant de démarrer le moteur. Ne fumez pas.

• L'appareil ne doit pas être démarré ou utilisé à l'intérieur d'un

espace ou d’un bâtiment clos. Inhaler les fumées du pot

d’échappement peut provoquer la mort. Cet appareil doit

fonctionner uniquement en extérieur, dans une zone bien aérée.

LISEZ TOUTES LES INSTRUCTIONS AVANT L'UTILISATION

• Veuillez lire les instructions avec soin. Familiarisez-vous avec les

commandes et l'utilisation correcte de cet appareil.

• Veuillez lire le manuel de l'utilisateur attentivement. Familiarisez-vous avec

les commandes et l'utilisation correcte de l’appareil. Sachez comment

arrêter l’appareil et désactiver les commandes rapidement.

• N'utilisez pas l'appareil si vous êtes fatigué, malade ou sous

l'effet de l'alcool, de drogues ou de médicaments.

• Ne laissez pas les enfants faire fonctionner l’appareil. Ne laissez jamais

des adultes qui ne se sont pas familiarisés avec les instructions utiliser

l’appareil. Ne laissez jamais des adultes n'ayant jamais reçu les

instructions nécessaires faire fonctionner l’appareil.

• Tous les accessoires de sécurité et protections doivent être

correctement installés avant d'utiliser cet appareil.

Lisez le(s) manuel(s) de l'utilisateur et suivez tous les avertissements et consignes de sécurité. Vous pourriez à défaut entraîner des

blessures graves pour vous ou d'autres personnes.

SI VOUS AVEZ DES QUESTIONS, APPELEZ LE

1-800-828-5500

AUX ÉTATS-UNIS, OU LE 1-800-668-1238 AU CANADA

Les symboles de sécurité attirent votre attention sur des dangers

potentiels. Ces symboles et leurs détails explicatifs méritent que

vous les lisiez et compreniez bien. Les avertissements de

sécurité ne peuvent éviter les dangers de par eux-mêmes. Les

consignes ou mises en garde qu'ils donnent ne remplacent pas

des mesures préventives appropriées contre les accidents.

REMARQUE : donne des informations ou des instructions vitales

pour le fonctionnement ou l'entretien de l'équipement.

ALERTE DE SÉCURITÉ : Indique un danger, un

avertissement ou une mise en garde. Soyez vigilant afin

d'éviter toute blessure grave. Ce symbole peut être

combiné à d'autres symboles ou pictogrammes.

DANGER : le non-respect d’un avertissement peut

causer dommages matériels ou blessures graves pour

tous. Respectez les consignes de sécurité afin de réduire

les risques d'incendie, d'électrocution et de blessures.

AVERTISSEMENT : le non-respect d’un avertissement

peut causer dommages matériels ou blessures graves pour

tous. Respectez les consignes de sécurité afin de réduire les

risques d'incendie, d'électrocution et de blessures.

MISE EN GARDE : le non-respect d’un

avertissement peut causer dommages matériels ou

blessures graves pour tous. Respectez toujours les

consignes de sécurité afin de réduire les risques

d'incendie, d'électrocution et de blessures.

CONSIGNES DE SÉCURITÉ

SYMBOLE SIGNIFICATION

AVERTISSEMENT : suivez soig-neusement les

consignes de sécurité lorsque vous utilisez cet appareil.

Dans l'intérêt de votre sécurité et de celle des personnes

à proximité, prenez soin de lire ces instructions avant de

faire fonctionner la machine. Veuillez garder les

instructions en lieu sûr pour usage ultérieur.

AVERTISSEMENT : L'essence est extrêmement

inflammable et ses vapeurs peuvent exploser si on y

met le feu. Veuillez prendre les précautions suivantes.

PARE-ÉTINCELLES

REMARQUE : à l'intention des utilisateurs opérant dans les terres

forestières des États-Unis et dans les états de Californie, du

Maine, de l'Orégon et de Washington. Toutes les terres forestières

des États-Unis et de l'état de Californie (Codes sur les ressources

publiques 4442 et 4443), de l'Orégon et de Washington exigent de par

la loi que certains moteurs à combustion interne utilisés dans des

zones couvertes de taillis ou d'herbe soient équipés d'un pare-

étincelles en parfait état de fonctionnement, ou qu'ils soient conçus,

équipés et entretenus pour la prévention des incendies. Renseignez-

vous auprès des autorités de votre province ou de votre municipalité

concernant la réglementation en vigueur. Vous pourriez être passible

d'une amende ou être tenu responsable si vous ne respectez pas

cette réglementation. Cet appareil est équipé d'un pare-étincelles en

usine. Si le bloc du pot d’échappement, réf. 753-05669, doit être

remplacé, communiquez avec le service technique.

PROPOSITION DE LOI 65 DE CALIFORNIE

AVERTISSEMENT : La fumée d’échappement du

moteur, certains constituants et composants finis

contiennent ou émettent des produits chimiques connus

de l’État de Californie comme étant à l’origine de

cancers, de malformations congénitales ou autres

anomalies de la reproduction. Lavez-vous les mains

après manipulation.

Table of contents

Languages:

Popular Blower manuals by other brands

Weed Eater

Weed Eater SB180BV Operator's manual

Craftsman

Craftsman INCREDI-PULL 316.791650 Operator's manual

Genius

Genius 1300 DP Use and maintenance handbook

Ozito

Ozito PXCBLS-018 instruction manual

Scheppach

Scheppach SC2200PE Translation of original instruction manual

Echo

Echo PB-9010 H Operator's manual