Simco-Ion 6432e User manual

IONIZATION SOLUTIONS

Point of Use

Ionizing Blower

Model 6432e

User’s Manual

19-6432-M-01 Rev 4

About Simco-Ion

Simco-Ion develops, manufactures, and markets system solutions

to manage electrostatic charge. As the world's largest provider of

electrostatics management products and services, Simco-Ion

improves its customers' business results by providing a total

solution to their electrostatic discharge and electromagnetic

interference challenges. Simco-Ion Technology Group is a division

of Illinois Tool Works (ITW), located in Alameda, California. For

more information about Simco-Ion visit www.simco-ion.com or call

800-367-2452. Simco-Ion is ISO 9001 and ANSI ESD S20.20

certified.

© 2013 Simco-Ion

19-6432-M-01 Rev 4

Contents

1 Description .......................................................................... 1

1.1 Point of Use Ionizing Blower Model 6432e .............................................. 2

1.2 IsoStat® Technology................................................................................ 4

1.3 Performance ............................................................................................ 5

1.4 Power Requirements ............................................................................... 6

2 Set Up & Operation ............................................................. 7

2.1 Box Contents ........................................................................................... 8

2.2 Mounting Stand Installation and Placement........................................... 10

2.3 Mounting Stand Knob Replacement ..................................................... 13

2.4 Blower Placement.................................................................................. 14

2.5 Power Connections............................................................................... 15

2.6 FMS Connection ................................................................................... 18

2.7 Turning on the Blower........................................................................... 19

2.8 Alarms................................................................................................... 20

3 Maintenance ...................................................................... 21

3.1 Maintenance Requirements.................................................................. 22

3.2 Cleaning the Chassis............................................................................ 23

3.3 Cleaning the Emitter Points .................................................................. 24

4 Specifications.................................................................... 25

5 Warranty & Service .......................................................... 31

19-6432-M-01 Rev 4 1

1

Description

1.1 Point of Use Ionizing Blower Model 6432e

1.2 IsoStat® Technology

1.3 Performance

1.4 Power Requirements

19-6432-M-01 Rev 4 2

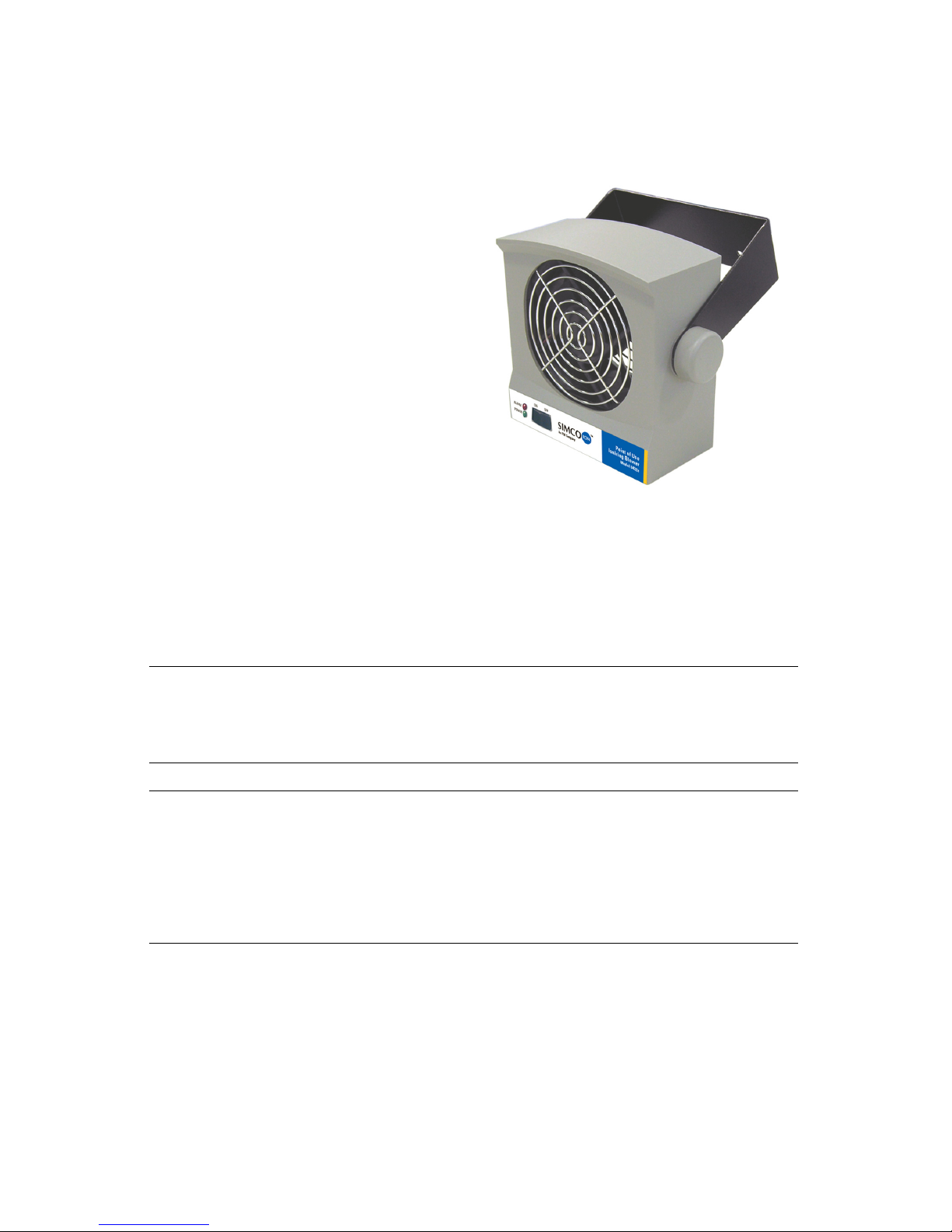

1.1 Point of Use Ionizing Blower Model

6432e

The Point of Use Ionizing Blower Model 6432e controls static

discharge in areas where static build-up can cause contamination,

ESD, material-handling problems, or microprocessor lock-up. The

internal emitter points are electrostatically shielded to eliminate

field-induced charging. Steady-state DC ion emission provides fast

discharge with low airflow.

The Model 6432e features a red alarm indicator LED on the front of

the Blower. See 2.8 Alarms section for a discussion of the alarm

function. The eight-pin terminal strip provides a 4-20 mA current

loop and relay output connection to your facility monitoring system

(FMS) in addition to the 24 VDC input connection.

Figure 1. Front of the Model 6432e Blower

19-6432-M-01 Rev 4 3

Figure 2. Back of Model 6432e Blower

19-6432-M-01 Rev 4 4

1.2 IsoStat®Technology

IsoStat technology makes Simco-Ion ionizing Blowers the most

reliable ionizers available. IsoStat enables them to operate without

grounding wires or cables and still maintain ionizer balance. The

Model 6432e Blower’s internal emitter points are electrostatically

shielded to eliminate field-induced charging. Steady-state DC ion

emission provides fast discharge with low airflow.

Ionizers incorporating IsoStat technology never need calibration

and require very little maintenance. IsoStat is based on a law of

physics, Conservation of Charge, which states that charge cannot

be created or destroyed in an isolated system. By isolating the

ionizer’s emitter points from ground, IsoStat ensures equal numbers

of positive and negative ions.

19-6432-M-01 Rev 4 5

1.3 Performance

The Blower will reduce a static charge of ±1,000V down to ±100V in

approximately 4 seconds at a distance of 1 ft. (30.48 cm) when

powered with 24 VAC. See the table below for typical discharge

times as determined by distance. Distance is measured from the

front center of the Blower. Ionization balance is better than ±20V at

1 ft. (30.48 cm).

Table 1. Distance/Discharge Time when Powered with 24 VAC

Testing was performed with a charged plate monitor in accordance

with ionization standard ANSI/ESD STM3.1-2006 of the ESD

Association.

Distance Discharge Time

1 foot (30.48 cm) 4 seconds

2 feet (61 cm) 7 seconds

3 feet (91.44 cm) 11 seconds

4 feet (122 cm) 17 seconds

Note: The performance of the Model 6432 will be reduced slightly

when the unit is powered with 24 VDC.

19-6432-M-01 Rev 4 6

1.4 Power Requirements

The Model 6432e Blower can receive power from four different

sources. Three different power supplies are available as options for

the Blower, providing 24 VDC or 24 VAC. The fourth power source

for the Blower is 24 VDC from your process equipment using the

terminal block and eight pin connector on the rear of the Blower.

The maximum power requirement for the Blower is 6W.

Simco-Ion offers three power supplies for use with this product:

• Transformer (part number 14-1320-01) for use with 120 VAC/60

Hz systems.

• Transformer (part number 14-1330) for use with 230 VAC/50 Hz

systems.

Both 14-1320-01 and 14-1330 provide the Blower with appropriate

24 VAC power.

• Universal power supply (part number 14-1322) for use with

100-240 VAC systems provides 24 VDC output.

Caution:

The use of improper input voltage may result in poor

performance or damage to the unit. The transformer should

not be operated beyond the specified electrical limit as

described in the Specifications section of this manual.

Damage caused to the transformer from operation in an

environment that exceeds the specified limits will void the

warranty.

Achtung:

Unzulässige Eingangsspannung kann zu schlechter Leistung

und Beschädigung des Gerätes führen. Der Transformator

sollte nicht außerhalb der spezifizierten Grenzen, wie in

diesem Handbuch angegeben, betrieben werden. Schäden

am Transformator, verursacht durch Betrieb außerhalb der

festgelegten Grenzwerte, fallen nicht unter die

Garantiebestimmungen.

19-6432-M-01 Rev 4 7

2

Setup & Operation

2.1 Box Contents

2.2 Mounting Stand Installation and Placement

2.3 Mounting Stand Knob Replacement

2.4 Blower Placement

2.5 Power Connections

2.6 FMS Connection

2.7 Turning on the Blower

2.8 Alarms

19-6432-M-01 Rev 4 8

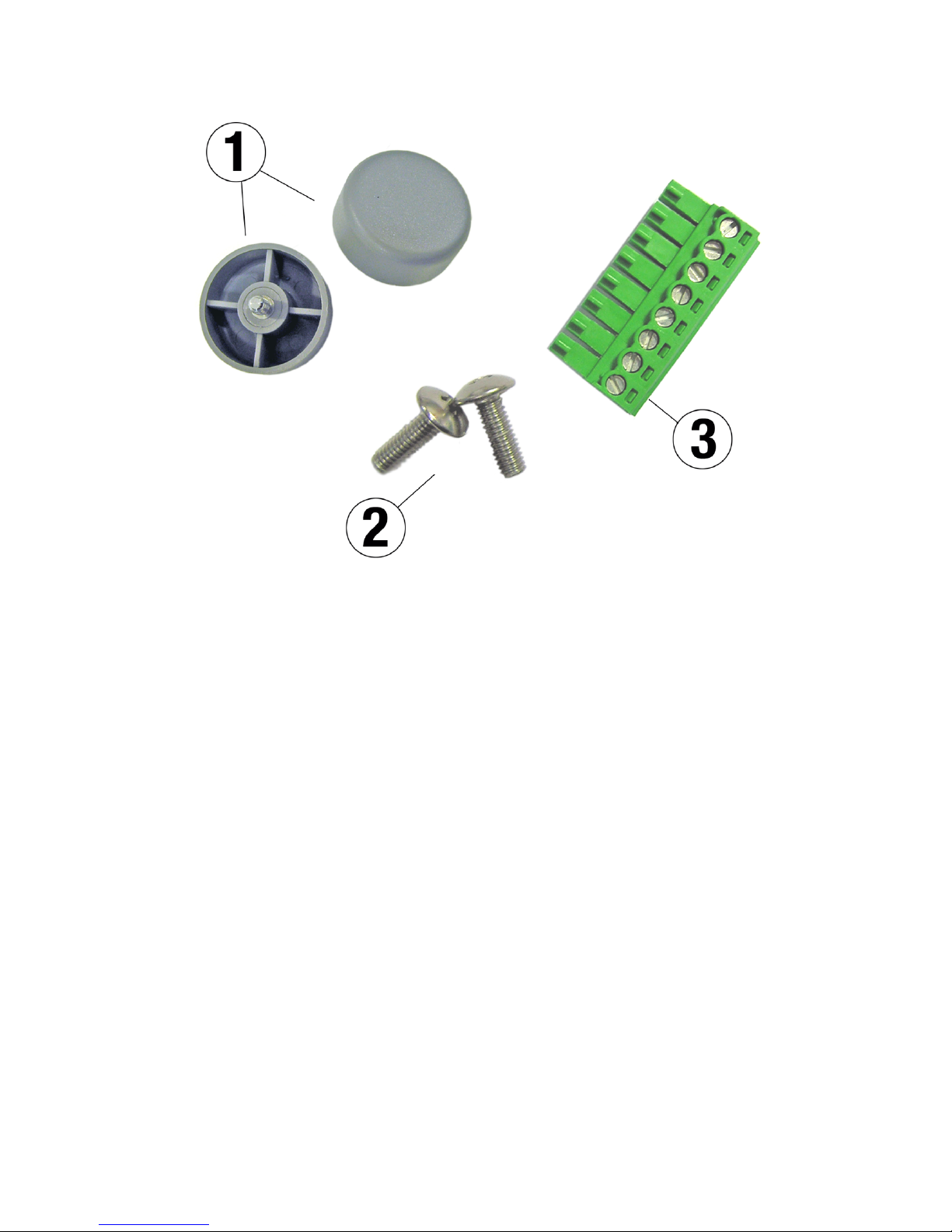

2.1 Box Contents

The Blower is supplied with:

• Two round mounting stand knobs.

• Two truss-head screws for securing the bracket (p/n 28-3328).

• One 8-pin terminal block plug for connecting to tool power

(p/n 18-2308).

• Certificate of Compliance.

In addition, the following options may be included if they have been

ordered:

• A benchtop or in-tool mounting stand.

• One of the following three power supplies:

- 120 VAC transformer (#14-1320-01)

- 230 VAC transformer (#14-1330)

- AC/DC universal power supply (#14-1322).

If you ordered an AC/DC universal power supply (#14-1322), you

will have one of the following plug adapters:

• US wall outlet adapter (p/n 18-0285)

• UK wall outlet adapter (p/n 18-0286)

• Europe wall outlet adapter (p/n 18-0287)

• Australia/China wall outlet adapter (p/n 18-0288).

19-6432-M-01 Rev 4 9

Figure 3. Mounting Stand Knobs, Screws, and 8-pin Terminal Block

19-6432-M-01 Rev 4 10

2.2 Mounting Stand Installation and

Placement

Two mounting stands are available with the Blower.

• Benchtop

• In-tool

Benchtop Stand

Figure 4. Benchtop Stand

1. Fasten the Blower to the mounting stand using the molded

knobs supplied with the chassis.

2. To adjust the stand, loosen the side knobs on the Blower and

adjust the Blower to the appropriate angle.

3. Re-tighten the knobs to secure the Blower in place.

4. Aim the Blower so that its airflow travels directly to your target.

19-6432-M-01 Rev 4 11

In-tool Stand

In-tool stand placement: Use the included truss-head screws (see

Figure 3) to secure the bracket to a surface.

1. Fasten the Blower to the

mounting stand using the

molded knobs supplied with

the chassis.

2. To adjust the benchtop

stand, loosen the side knobs

on the Blower and adjust the

Blower to the appropriate

angle.

3. Re-tighten the knobs to

secure the Blower in place.

4. Aim the Blower so that its

airflow travels directly to your

target. Figure 5. In-tool Stand

Caution:

To ensure proper Blower stability, the “in-tool” stand should

always be fastened to an underlying support structure and not

used as an unsecured, free-standing unit.

Achtung:

Um eine ausreichende Stabilität des Blowers zu

gewährleisten, sollte der "In-Tool"-Stand immer auf einer

darunter liegenden Tragkonstruktion befestigt werden und

nicht als ungesicherte, freistehende Einheit verwendet

werden.

19-6432-M-01 Rev 4 12

Figure 6. In-tool Bracket--Mounting Hole Locations on Underside of Bracket

19-6432-M-01 Rev 4 13

2.3 Mounting Stand Knob Replacement

The standard knobs on the mounting stand may be replaced with

the truss head screws that are packaged with the Blower if desired.

The screws allow for an improved grip on the mounting stand as

they can be tightened down using a standard Phillips screwdriver.

To install the screws:

1. One side at a time, unscrew and remove the knobs from the

sides of the Blower.

2. Thread the machine screws through the mounting stand and

into the chassis. Use a Phillips screwdriver to tighten the

screws.

Figure 7. Machine Screw Installed in a Benchtop Mounting Stand

19-6432-M-01 Rev 4 14

2.4 Blower Placement

Place the Model 6432e Blower in the desired in-tool or benchtop

location. (See Table 1 on page 5 for discharge time distance

recommendations.)

Caution:

Do not use this Blower in an explosive environment. Poorly

maintained ionizers could produce minuscule electric arcs at

the emitter points. This may cause detonation in an explosive

environment.

Achtung:

Verwenden Sie dieses Gebläse nicht in

explosionsgefährdeten Bereichen. Schlecht gewartete

Ionisatoren können an den Emitter-Punkten Lichtbögen

erzeugen und in explosiver Umgebung eine Explosion

auslösen.

19-6432-M-01 Rev 4 15

2.5 Power Connections

The Blower may be powered by an optional 24 VAC 120 or 220 volt

transformer or a 24 VDC universal AC adapter, sold separately by

Simco-Ion. Plug the transformer or universal AC adapter into a

properly grounded VAC receptacle with the correct voltage for your

power supply.

Power Supply Connection

Insert the power cable from the transformer or AC adapter into the

Power In receptacle on the back of the Blower. See the

Performance and Power Requirements sections for additional

information.

AC Adapter Connection

The AC adapter (Simco-Ion p/n 14-1322) output is 24 VDC at 400

mA, maximum.

The AC adapter is shipped with its plug adapter uninstalled. To

install the plug adapter, slide it into the bay on the AC adapter. Push

it in until it clicks into place, see figure below.

Figure 8. Push the Adapter into the Power Supply

19-6432-M-01 Rev 4 16

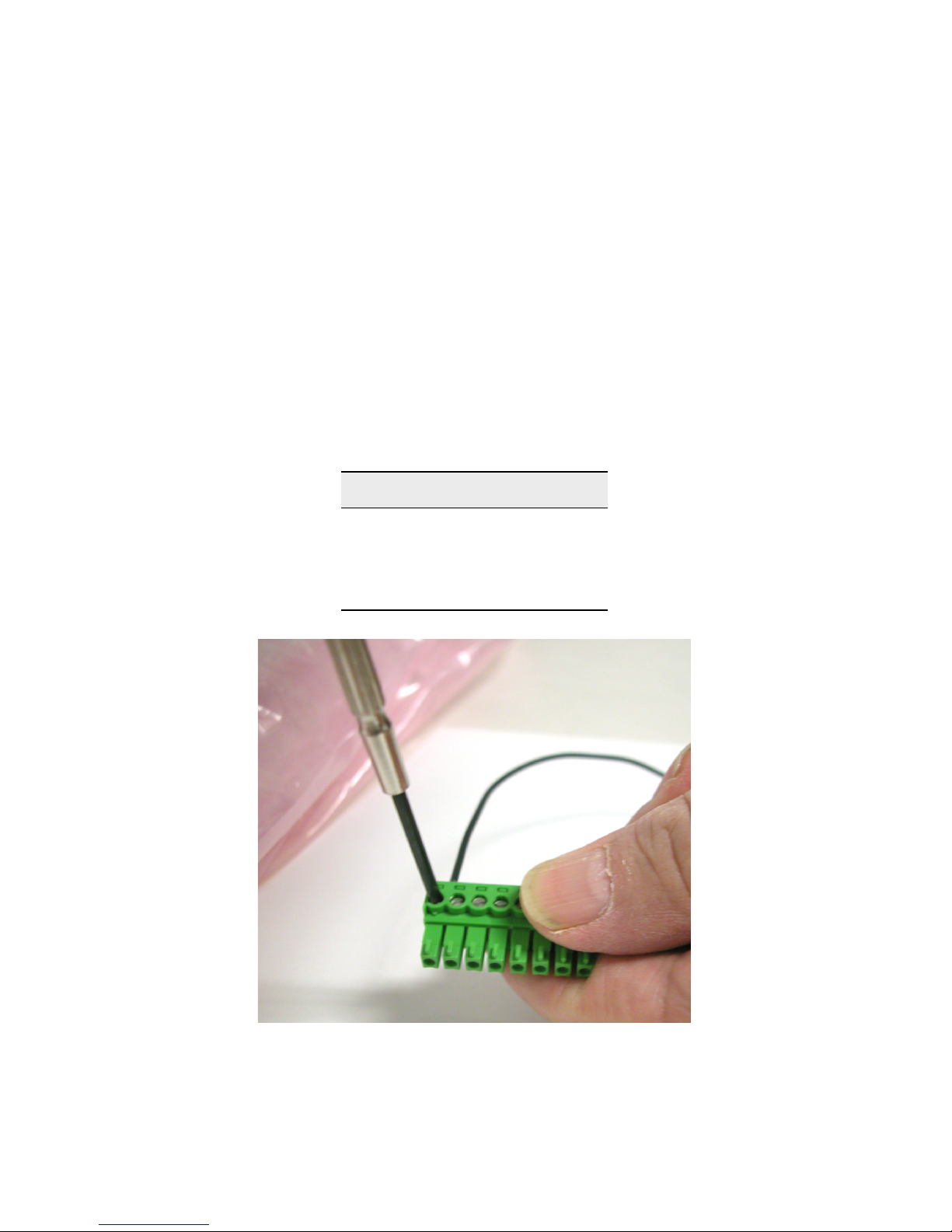

Process Equipment Power Connection

Two pins on the eight-pin terminal strip on the rear of the Blower can

receive 24 VDC power from your process equipment. An included

terminal block (Simco-Ion p/n 18-2308) is used to connect 24 VDC

power to the Blower from your process equipment. The terminals

are designed to accept wiring between 22 AWG and 16 AWG.

When wiring the Blower directly to a 24 VDC source, observe the

maximum voltage and power requirements for the unit [24 VDC

(±10%), 400 mA DC maximum].

Use a small flatblade screwdriver to secure cables into the terminal

block. See figure below.

Figure 9. Use a Small Flatblade Screwdriver to Secure Connecting Cables

Pins State

8 24 VDC return

7+24V

6-1 Not used

19-6432-M-01 Rev 4 17

Figure 10. Connected Terminal Block

Caution:

Damage to the product as a result of improper wiring

connections or failure to heed maximum voltage limits will not

be covered by the warranty.

Achtung:

Schäden am Produkt infolge unsachgemäßer Verdrahtung

oder wegen unterlassener Beachtung von maximal

zulässigen Spannungen werden nicht durch die Garantie

abgedeckt.

Table of contents

Other Simco-Ion Blower manuals