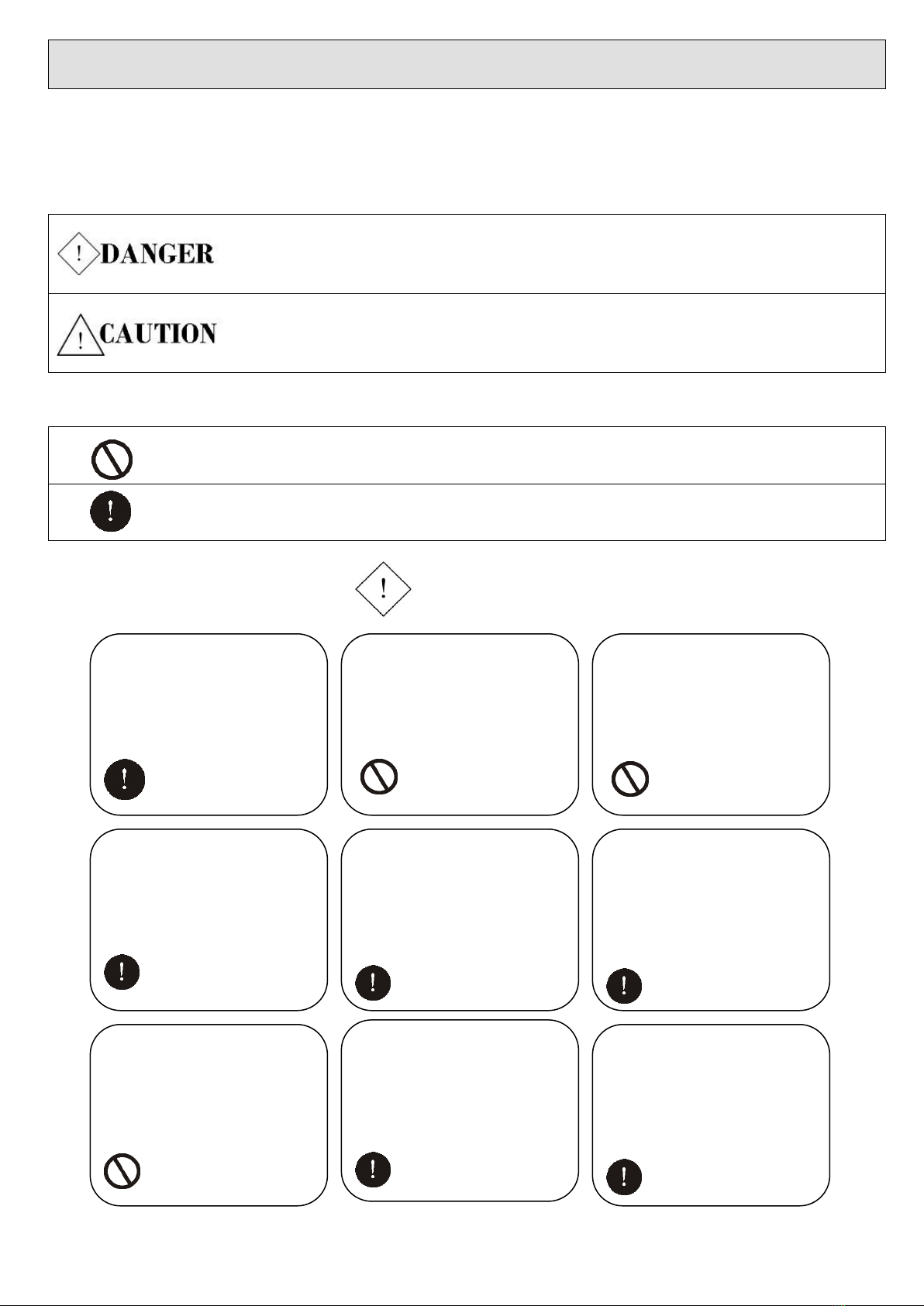

For avoiding of danger of user and others, damage of property, please operate with the

following below.

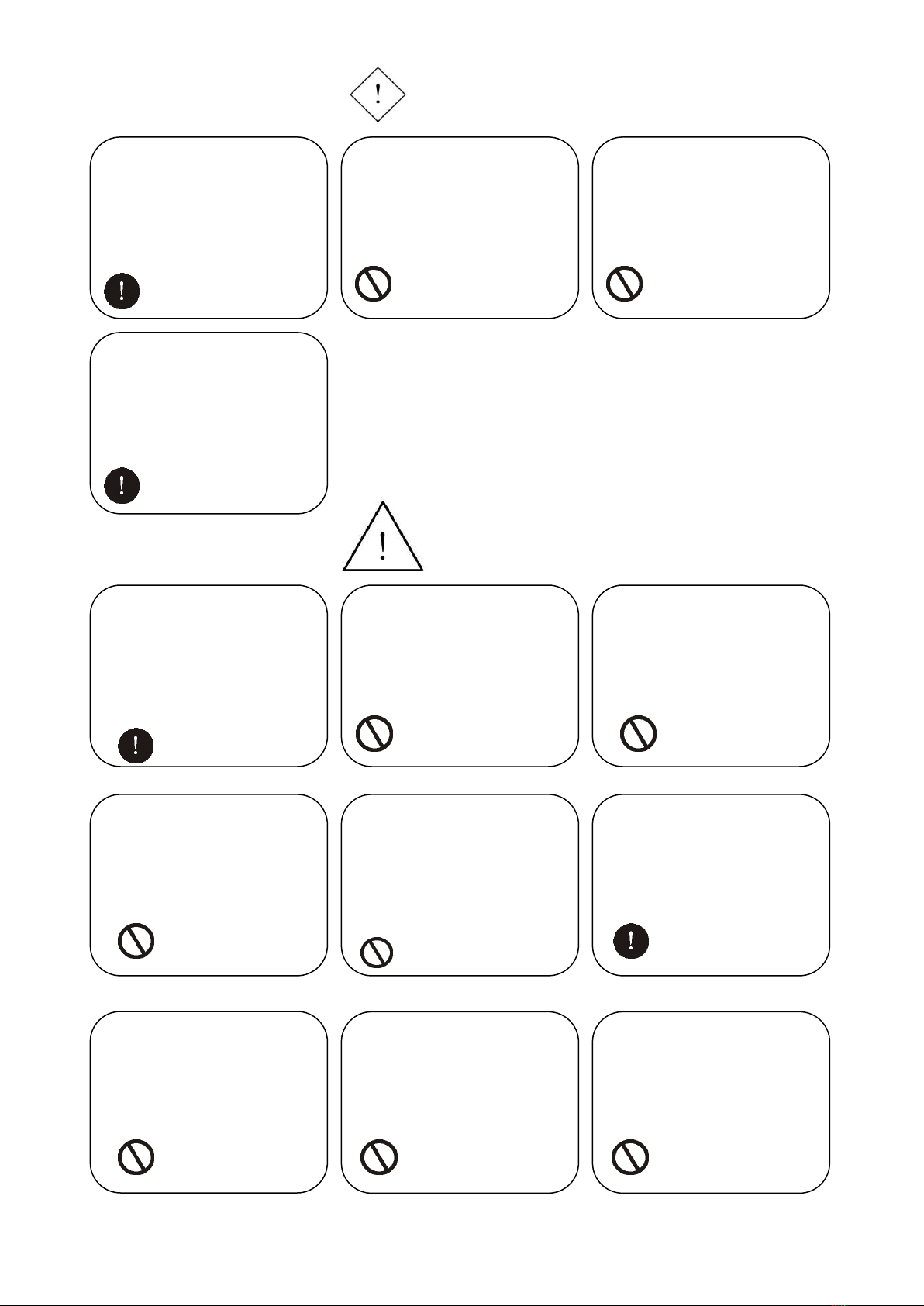

(1)Safety ranks of the cautions as ignoring the following points

Improper operation or use is most likely to result in serious injury or

death.

Improper operation or use is most likely to result in average or minor

injury, or in property damage

(2)Following ranks are provided

Take protective device of

overcurrent, instant stop,

over temperature, ground

fault interrupter.

Do not use product near

explosive, water, corrosive

gas or combustible

material.

temperature protective,

ground fault interrupter.

Do not forcibly put

stress, or lead a heavy

article on or stuff foreign

matter into it.

Avoid damage caused by

earthquake, fire, artificial

accident, please confirm

setting and fix it.

Install an external

emergency stop circuit to

turn the power off in the

instant halt of operation.

injury,trouble,damage,fire

Connect the Driver and

Stepping Motor to ground.

Neither reach nor touch

the Driver terminals while

electric power is on.

Execute safety

examination after

earthquake.

Have a professional expert

the wiring operation

accurately.

injury,trouble,damage,fire