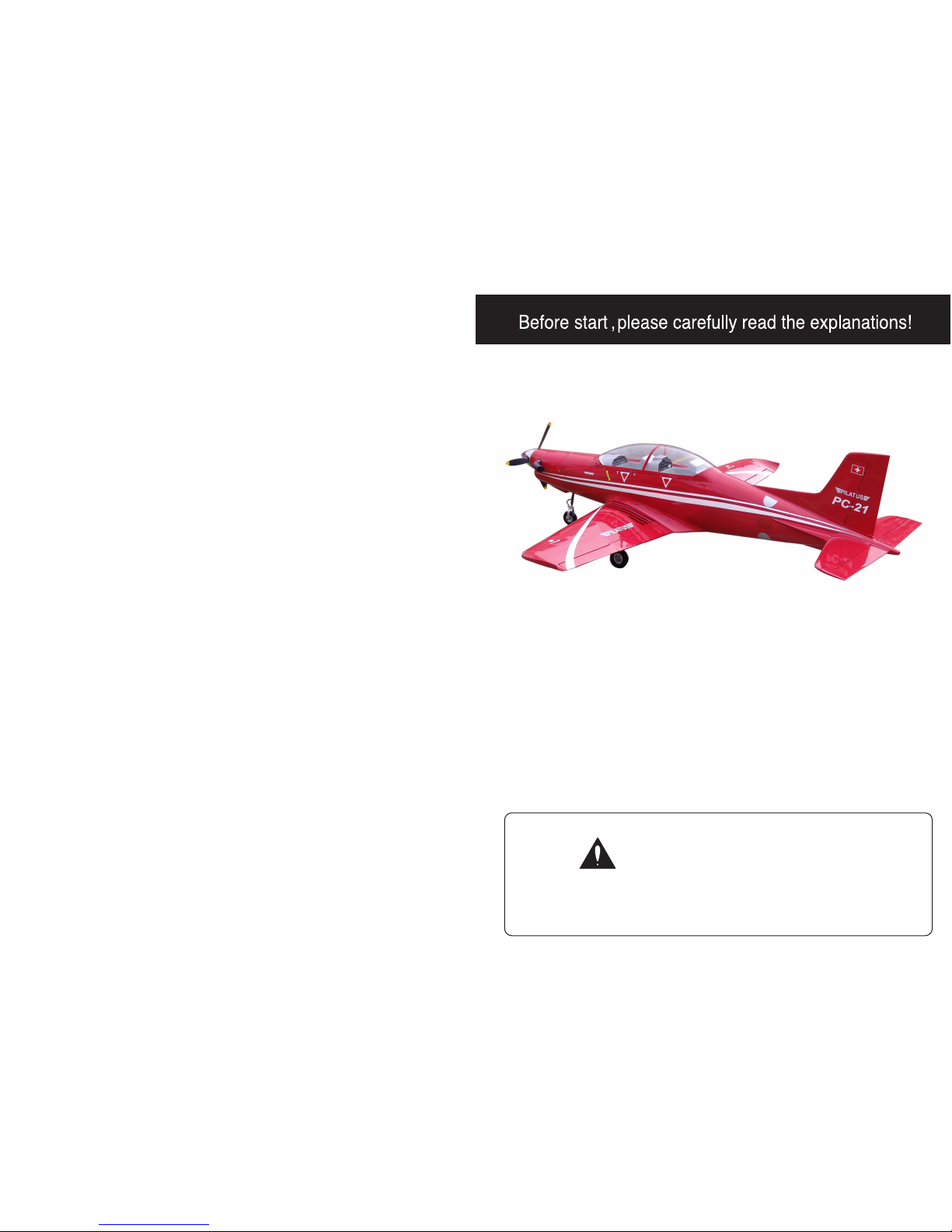

Rod (2x300mm) Ball joint

Retainer

Metal arms

Rod (2x300mm) Ball joint

Retainer

Metal arms

Install the rudder servo.

Install the elevator servo.

Assemble the rudder servo to appropriate position in

the fuselage.

CC’

DD’

Make sure to glue securely.

If not properly glued, a failure in flight may occur.

Temporarily fasten down the main wing and

check its correct position.

Securely glue together.If coming off during flights,

you'll lose control of your airplane which leads

to accidents!

C=C'

D=D'

TP Screw (2.3x12mm)

open a hole on the covering for ensuring assemble and

demount the covering easily.

9

TP Screw (2.3x6mm)

Ply (15x15x3mm) 9

1.5mm

Assembly of the stabilizer.

Epoxy the plies to appropriate position under the tail landing

gear covering and assemble the tail landing gear covering

to the fuselage as below.

Assemble the elevator servo to appropriate position in

the fuselage.

8

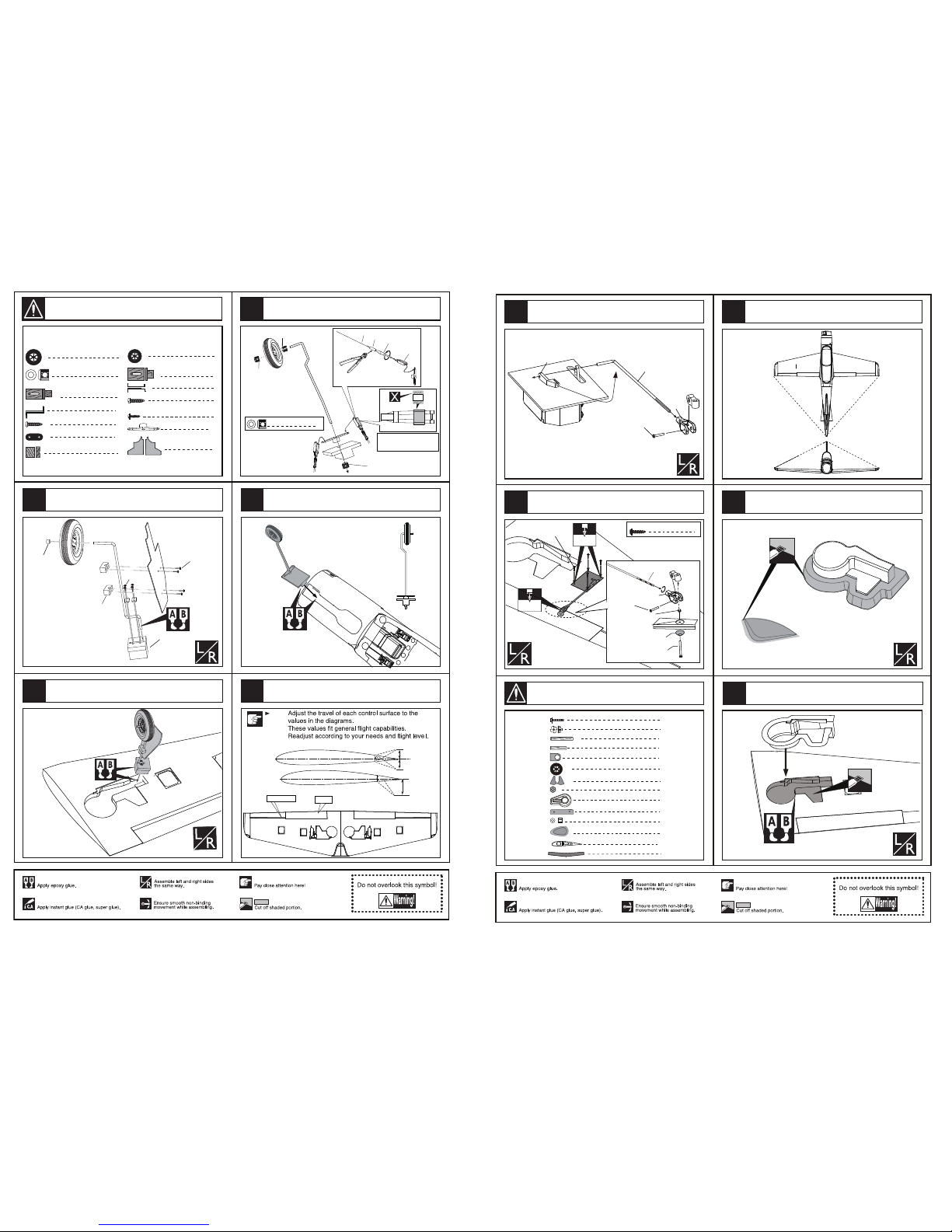

43

42

39

41 44

40

2

Steel wire (0.5x1200mm)

1.5mm

4

TP Screw (3x20mm)

Collar (5mm) 2

1

Wheel (75 mm)

1

TP Screw (3x20mm)

Steering fullarm (60x6mm)

2

Steel wire (0.5x1500mm)

TP Screw (3x20mm) 4

8

TP Screw (2.3x12mm)

1

Steering fullarm (60x6mm)

Collar (5mm) 2

1

Wheel (75 mm)

2

Washer(4x8mm)

2

Screw (4x25mm)

1

Aluminum shaft(5x50mm)

2

Washer(4x8mm) 2

Screw (4x25mm)

1

Aluminum shaft(5x50mm)

Brass collar (5mm)

Brass collar (5mm)

Wheel (75 mm)

Aluminum shaft

Screw (4x25mm)

Screw (4x25mm)

Washer(4x8mm)

Washer(4x8mm)

Steering fullarm (60x6mm) 2

2

2

Clevis

Copper joiner

Aluminum tube(3x6mm)

2

2

Screw (2x10mm)

Nut (2mm )

2

Washer(2x5mm)

Steel wire

Copper joiner

Aluminum tube Lock Nut (2mm )

Screw (2x10mm)

Ball joint

Washer(2x5mm)

2

2

2

Clevis

Copper joiner

Aluminum tube(3x6mm)

2

2

Screw (2x10mm)

Nut (2mm )

2

Washer(2x5mm)

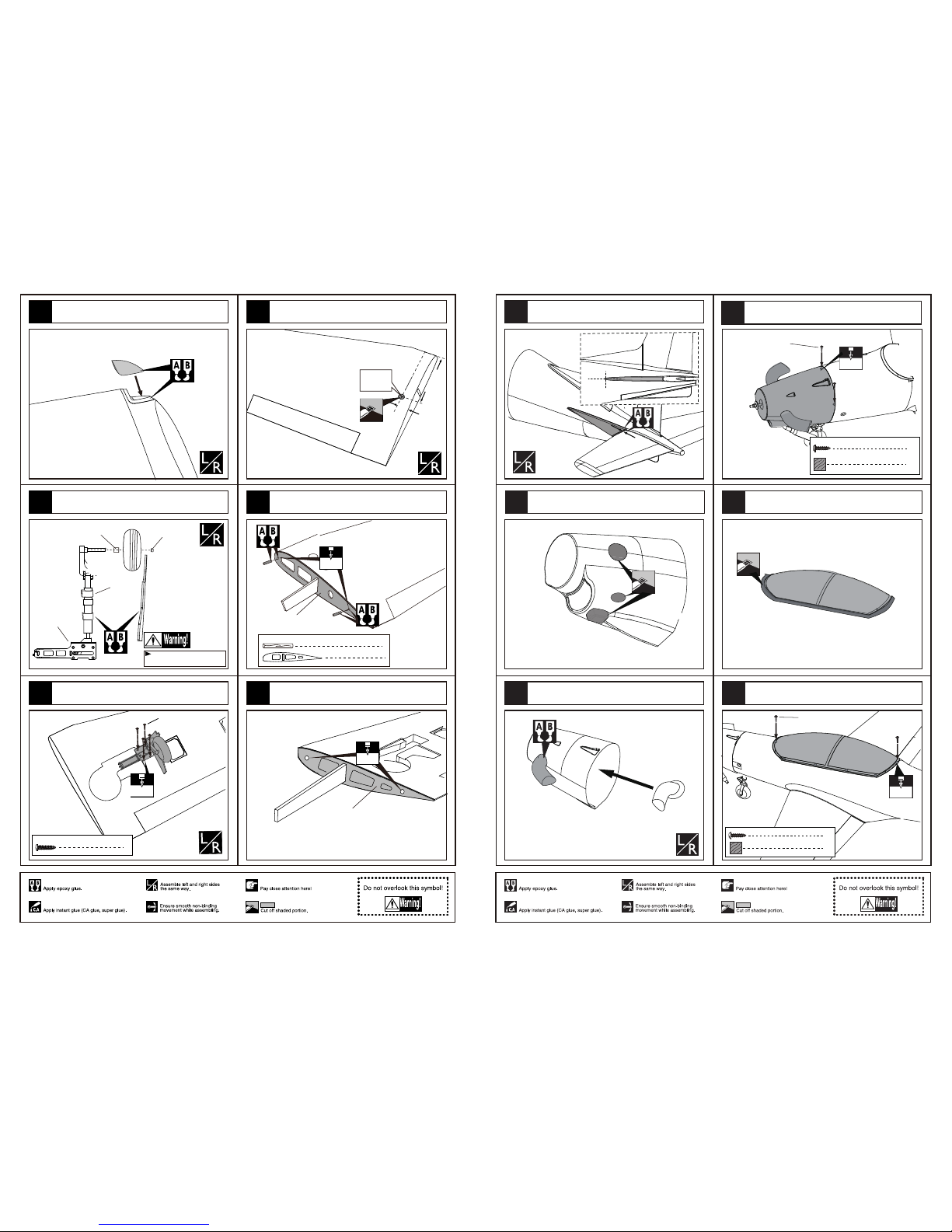

Assemble the servo to the relevant position in the fuselage.

Assemble the nose wheel.

Install the nose landing gear to appropriate

position in the fuselage.

Assemble the steeling fullarm around the landing gear.

Install the servo.

9

49

48

47

45

46

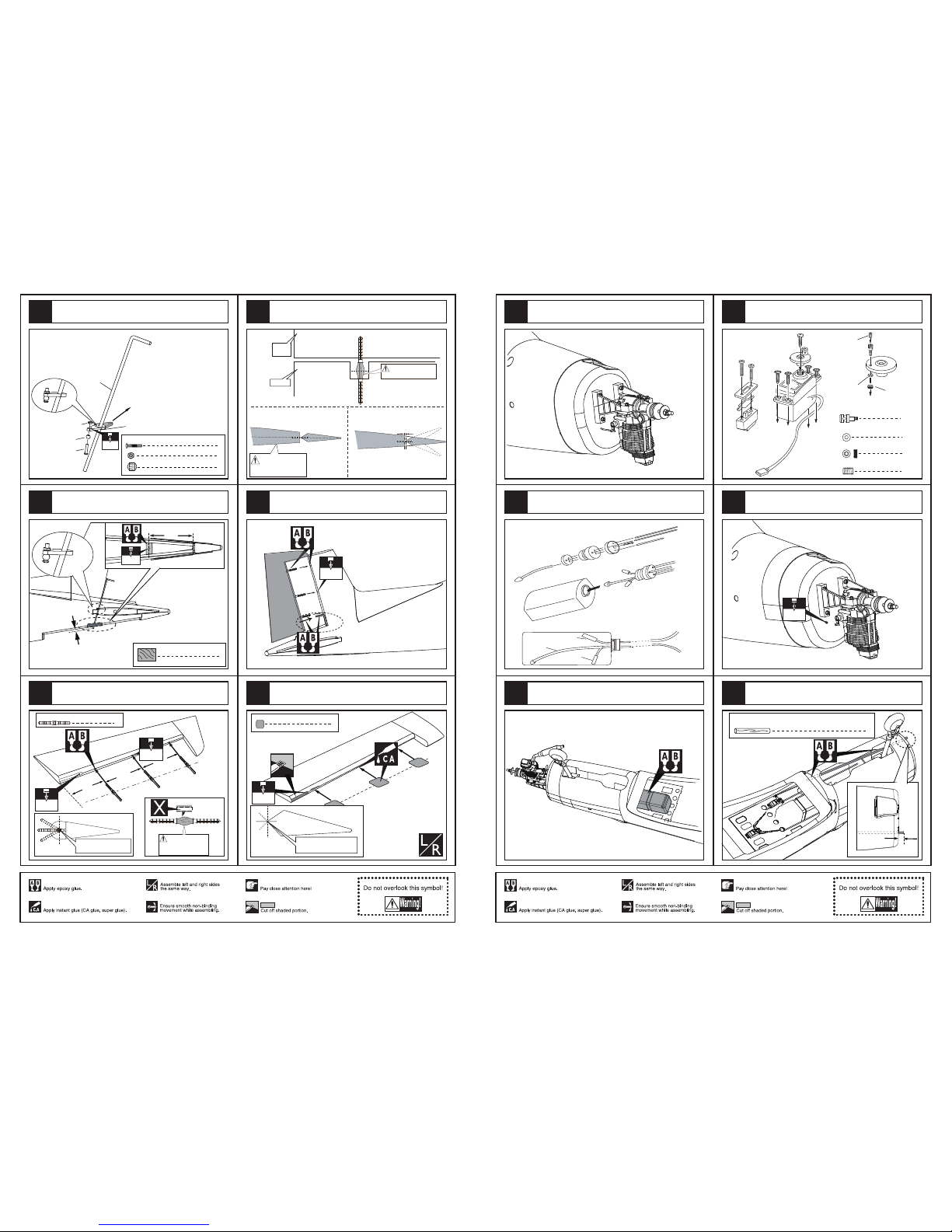

Accessory list for the coming installation steps.