4

TRUE

glass door merchandisers www.truemfg.com

WIRE GAUGE CHART WIRING INSTRUCTION ADVISEMENT

(115V Application Only)

NOTE: It is the customer’s responsibility to make sure receptacle

wiring meets all local electrical codes. TRUE recommends hiring a

licensed qualified electrician to make this change.

WIRING CONVERSION

At Receptacle Box:

1. Turn breaker off

2. Disconnect all wires from receptacle

3. Insulate red wire (tape or wire nut)

4. Connect black, white, and green

wires to 3 prong plug NEMA 5-20R per

instructions on receptacle.

At Breaker Panel:

1. With breaker turned off, remove wires

2. Remove double pole breaker

3. Install single pole breaker

4. Connect black wire to breaker

5. Insulate red wire

6. Turn breaker back on

1

2

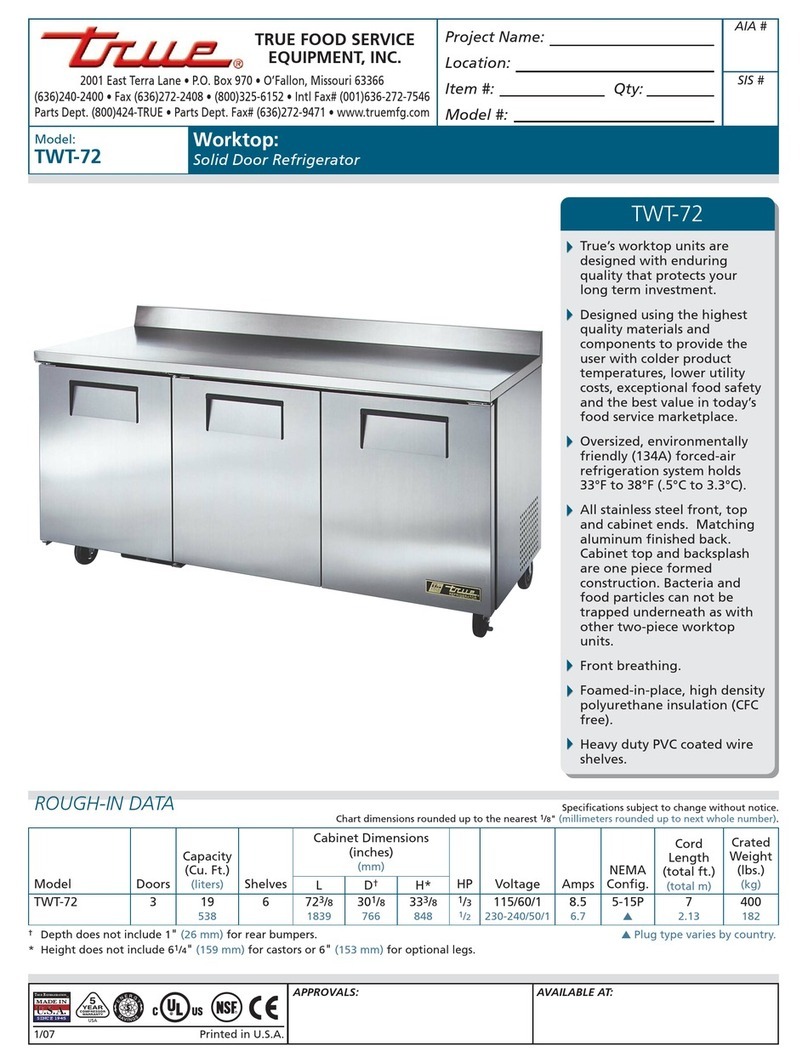

230 Volts Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

5 14 14 14 14 14 14 14 14 14 14 14 14

6 14 14 14 14 14 14 14 14 14 14 14 12

7 14 14 14 14 14 14 14 14 14 14 12 12

8 14 14 14 14 14 14 14 14 14 12 12 12

9 14 14 14 14 14 14 14 14 12 12 12 10

10 14 14 14 14 14 14 14 12 12 12 10 10

12 14 14 14 14 14 14 12 12 12 10 10 10

14 14 14 14 14 14 12 12 12 10 10 10 8

16 14 14 14 14 12 12 12 10 10 10 8 8

18 14 14 14 12 12 12 10 10 10 8 8 8

20 14 14 14 12 10 10 10 10 10 8 8 8

25 14 14 12 12 10 10 10 10 8 8 6 6

30 14 12 12 10 10 10 8 8 8 6 6 6

35 14 12 10 10 10 8 8 8 8 6 6 5

40 14 12 10 10 8 8 8 6 6 6 5 5

50 12 10 10 8 6 6 6 6 6 5 4 4

60 12 10 8 6 6 6 6 6 5 4 4 3

70 10 10 8 6 6 6 5 5 4 4 2 2

80 10 8 8 6 6 5 5 4 4 3 2 2

90 10 8 6 6 5 5 4 4 3 3 1 1

100 10 8 6 6 5 4 4 3 3 2 1 1

115 Volts Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

2 14 14 14 14 14 14 14 14 14 14 14 14

3 14 14 14 14 14 14 14 14 14 14 14 12

4 14 14 14 14 14 14 14 14 14 12 12 12

5 14 14 14 14 14 14 14 12 12 12 10 10

6 14 14 14 14 14 14 12 12 12 10 10 10

7 14 14 14 14 14 12 12 12 10 10 10 8

8 14 14 14 14 12 12 12 10 10 10 8 8

9 14 14 14 12 12 12 10 10 10 8 8 8

10 14 14 14 12 12 10 10 10 10 8 8 8

12 14 14 12 12 10 10 10 8 8 8 8 6

14 14 14 12 10 10 10 8 8 8 6 6 6

16 14 12 12 10 10 8 8 8 8 6 6 6

18 14 12 10 10 8 8 8 8 8 8 8 5

20 14 12 10 10 8 8 8 6 6 6 5 5

25 12 10 10 8 8 6 6 6 6 5 4 4

30 12 10 8 8 6 6 6 6 5 4 4 3

35 10 10 8 6 6 6 5 5 4 4 3 2

40 10 8 8 6 6 5 5 4 4 3 2 2

45 10 8 6 6 6 5 4 4 3 3 2 1

50 10 8 6 6 5 4 4 3 3 2 1 1

Reason for the instructions:

To advise that the electrical requirements have changed for some

current models.

The previous design for some models include a 4 prong NEMA

14-20R. This configuration required a 4-wire circuit. (see image 1.)

The current design for the same model may now include a 3 prong

NEMA 5-20R. This configuration requires a 3-wire circuit. (see image

2).

If your new TRUE model is replacing the same existing TRUE model

and the main power cord has changed from previous 4 prong to the

current 3 prong configuration, please follow the below instructions.