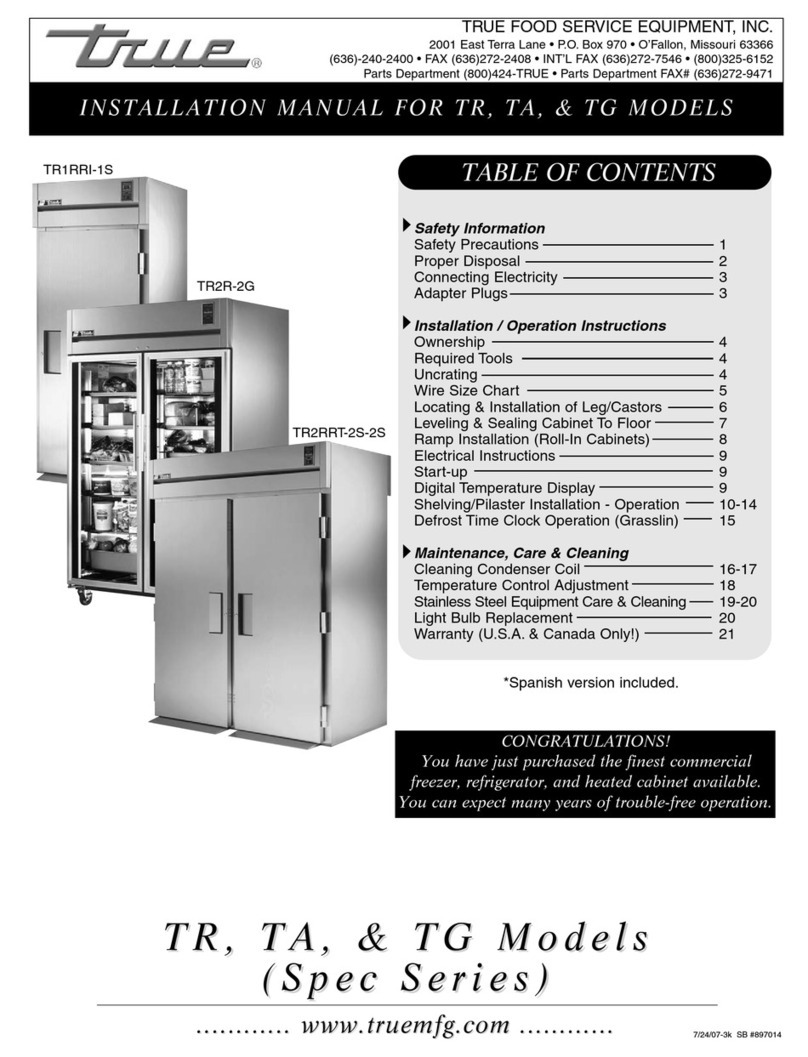

............ www.truemfg.com ............

True Food Service Equipment, Inc.

77

INSTALLATION / OPERATION INSTRUCTIONS

Leg levelers in the bottom of the cabinet

can be backed out for leveling.

Leg Levelers:

Ifthecabinetisnotleveluseanopen-endwrenchandturn

adjustabletipsonlegsuntilcoolerislevel.(Seeimage1).

Castor Installation:(KitContents)

2-Castormountingbracket

2-Castor,2-1/2”diameterwheelwith3/8”-16x1-

1/2”threadedstemwithoutbrake

2-Castor,2-1/2”diameterwheelwith3/8”-16x1-

1/2”threadedstemwithbrake

4-Washer,flat,3/8”I.D.x1”O.D.

4-Washer,splitlock,3/8”I.D.

4-Nut,hex,3/8”-16

(See image 2).

CAUTION

To avoid damage to lower rail assembly, slowly raise unit to

upright position after installing castors.

2

A. Beforeyournewunitisconnectedtoapowersupply,

checktheincomingvoltagewithavoltmeter.If

anythinglessthan100%oftheratedvoltagefor

operationisnoted,correctimmediately.

B. Allunitsareequippedwithaservicecord,andmust

bepoweredatproperoperatingvoltageatalltimes.

Refertocabinetdataplateforthisvoltage.

TRUErequiresthatasolecircuitbededicatedfortheunit.

Failuretodosovoidswarranty.

WARNING

Compressor warranties are void if compressor burns out due

to low voltage.

WARNING

Power supply cord ground should not be removed!

WARNING

Do not use electrical appliances inside the food storage

compartments of the appliances unless they are of the

type recommended by the manufacturer.

NOTE

To reference wiring diagram - Remove lower rear grill. Wiring

diagram is positioned on the inside cabinet wall.

ELECTRICAL INSTRUCTIONS

LEVELING

Securing Castors

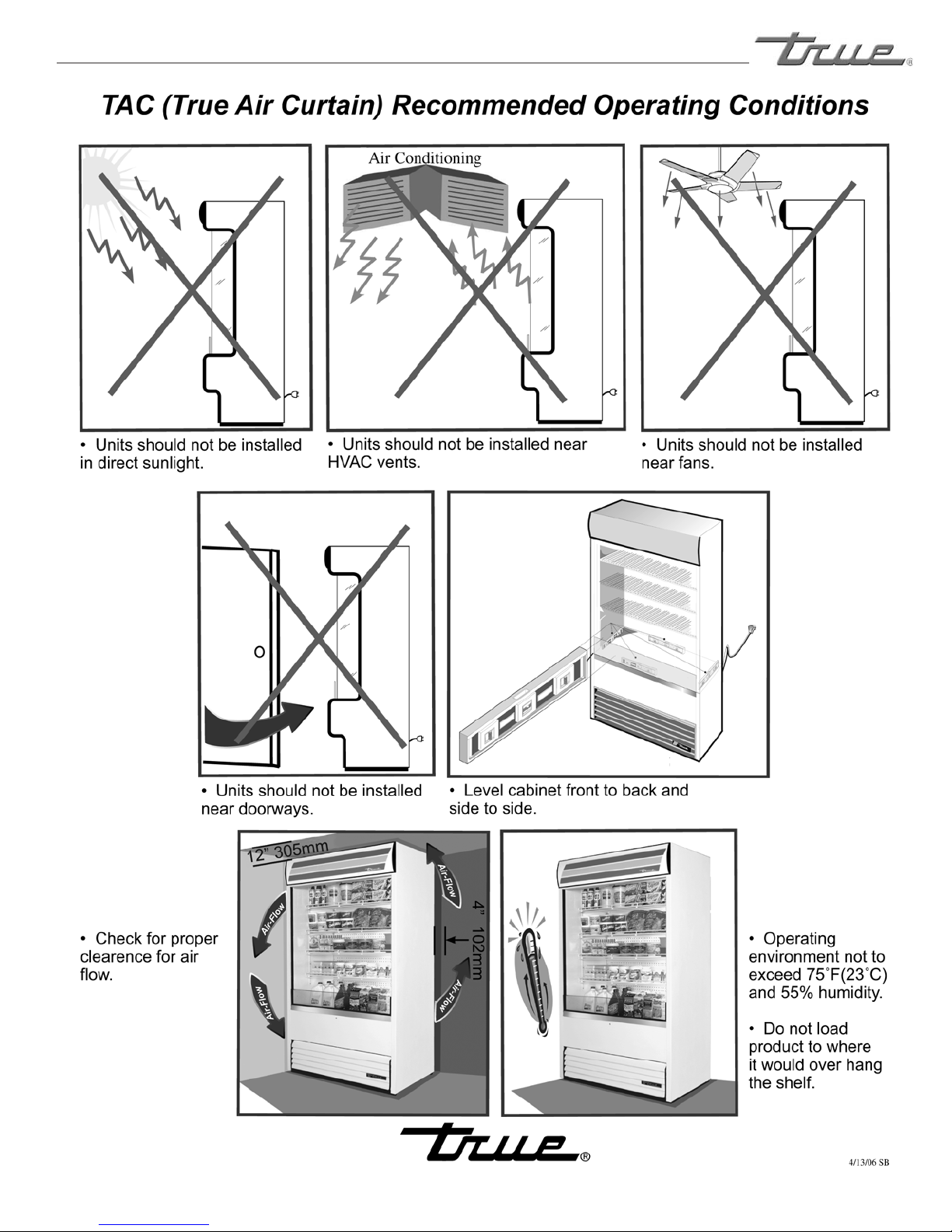

A. Setunitinitsfinallocation.Besurethereisadequate

ventilationinyourroom.Underextremeheat

conditions,youmaywanttoinstallanexhaustfan.

WARNING

Warranty is void if ventilation is insufficient.

B. ProperlevelingofyourTRUEcooleriscriticalto

operatingsuccess(fornon-mobilemodels).Effective

condensateremovalanddooroperationwillbe

effectedbyleveling.

C. Thecoolershouldbeleveledinsidethecabinetfront

tobackandsidetosidewithalevel.

D. Ensurethatthedrainhoseorhosesarepositionedin

thepan.

E. Freeplugandcordfrominsidethelowerrear

ofthecooler(donotplugin).

F. Theunitshouldbeplacedcloseenoughtothe

electricalsupplysothatextensioncordsarenever

used.

WARNING

Cabinet warranties are void if OEM power cord is tampered

with. TRUE will not warranty any units that are connected to an

extension cord.

INSTALLATION OF LEGS AND CASTORS

1