Trumbull 367-1414 User manual

Page 1 of 12

A. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

B. Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

C. Literature Sheet, Cast Iron Mud Valves . . . . . . . . . . . . . . . . . . . Page 4

(Catalog Page G-21)

D. Literature Sheet, Cast Stainless Steel Mud Valves . . . . . . . . . . . . Page 5

(Catalog Page G-25)

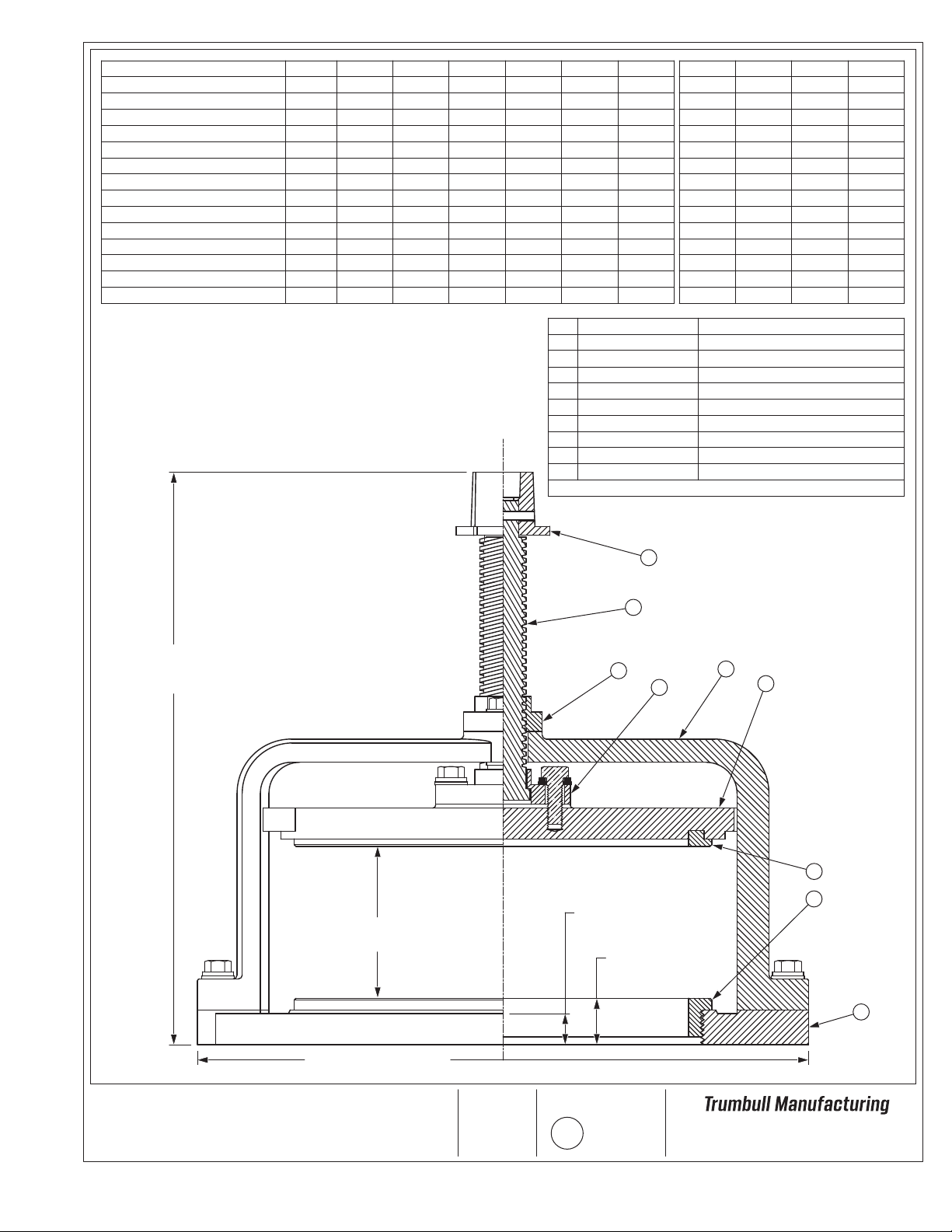

E. Product Drawing, Cast Iron Mud Valves, Non-Rising Stem . . . . . . . . Page 6

(Catalog Page G-22)

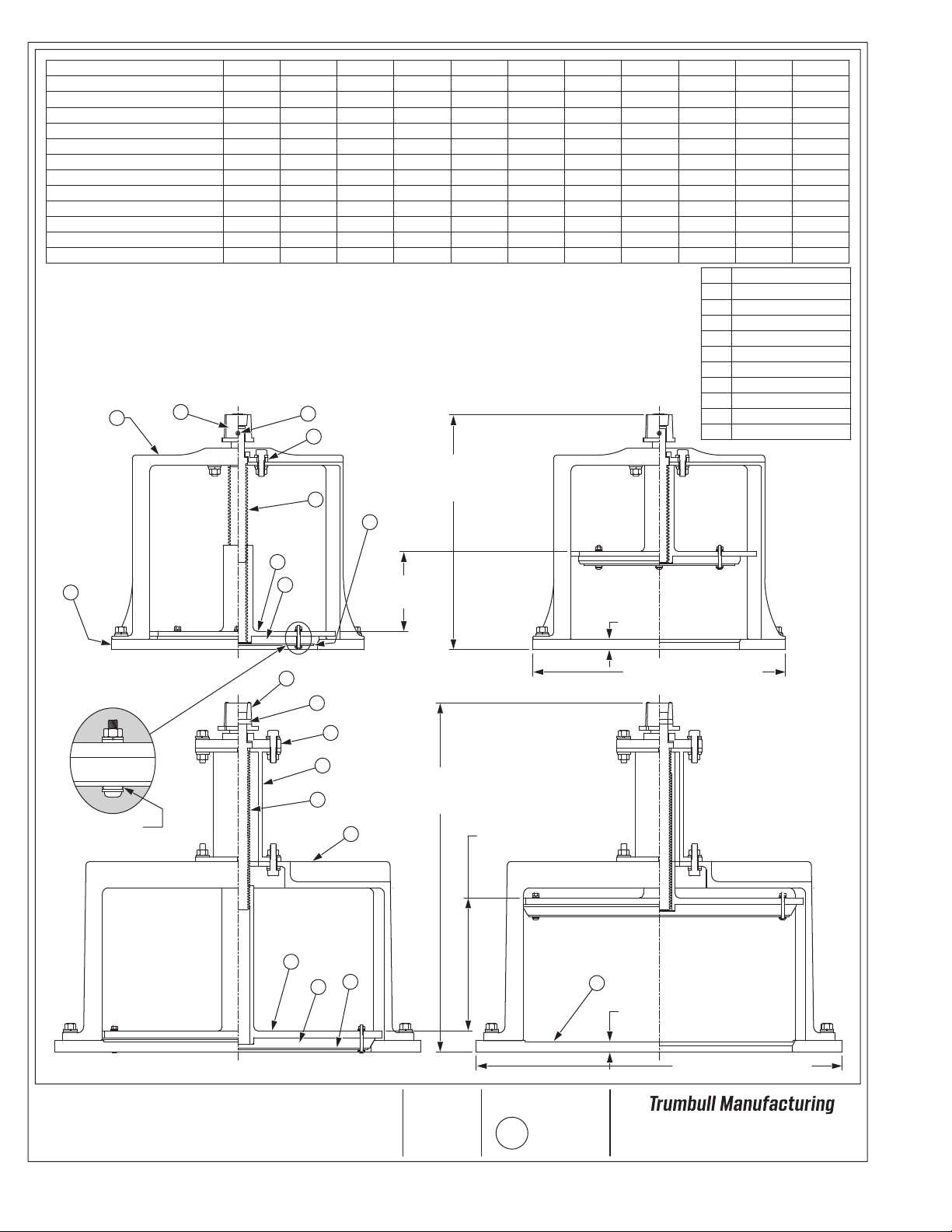

F. Product Drawing, Cast Iron Mud Valves, Rising Stem . . . . . . . . . . Page 7

(Catalog Page G-23)

G. Product Drawing, Cast Stainless Steel Mud Valves, Non-Rising Stem . . Page 8

(Catalog Page G-26)

H. Product Drawing, Cast Stainless Steel Mud Valves, Rising Stem . . . . Page 9

(Catalog Page G-27)

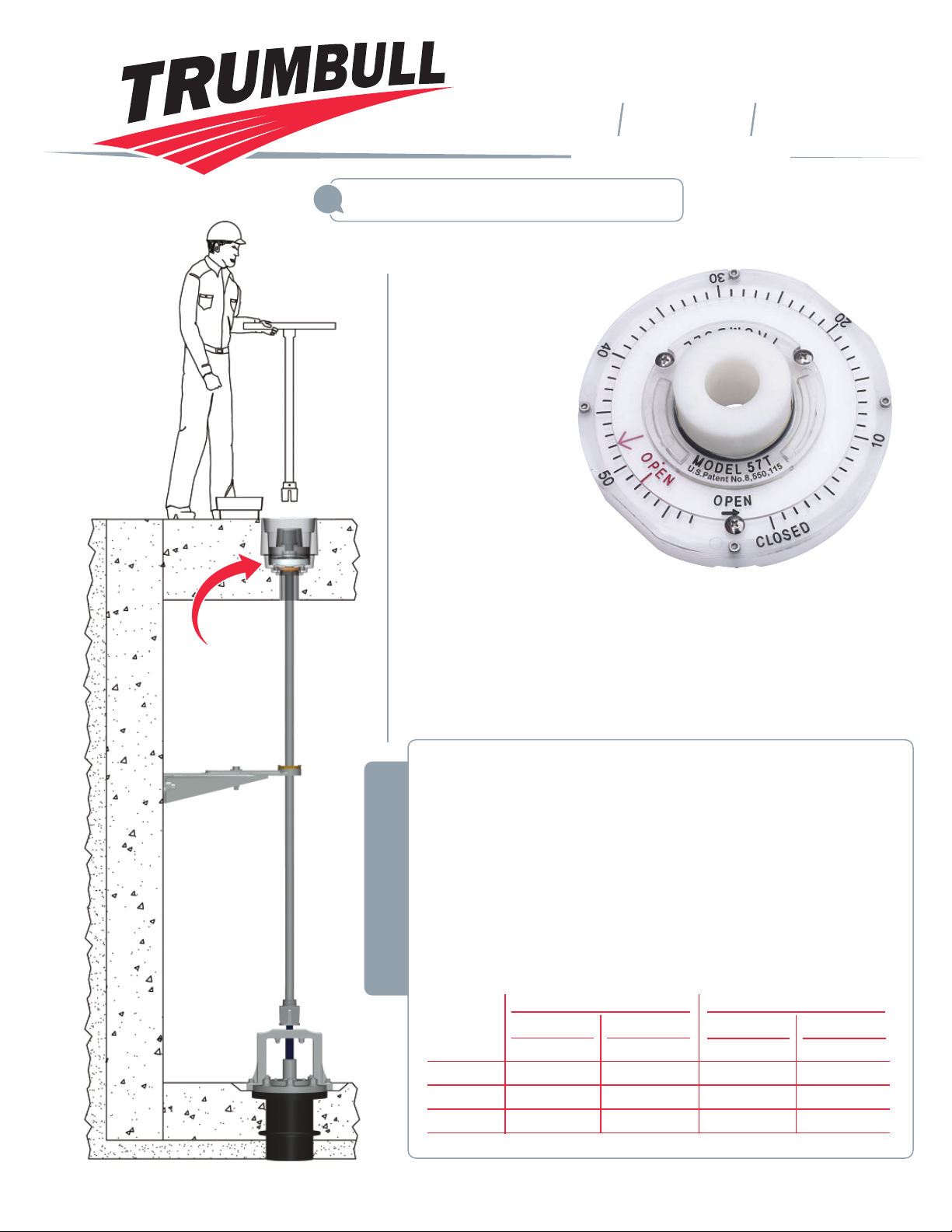

I. Position Indicator Installation in Floor (Optional) . . . . . . . . . . . . . Page 10

J. Position Indicator Installation over open tank (Optional) . . . . . . . . . Page 11

K. Operation of Mud Valves . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

L. Maintenance of Mud Valves . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

M. Storage of Mud Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

N. Trumbull Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

End of Table of Contents

TRUMBULL MUD VALVES

CAST IRON AND STAINLESS STEEL MODELS

RISING STEM AND NON-RISING STEM STYLES

Installation, Operation and Maintenance Manual

Table of Contents

Page 2 of 12

General information:

Trumbull Mud Valves are designed for use in draining large volumes of fluids by means of static head pressure.

They are particularly useful in reservoirs, and in tanks of water and wastewater treatment plants, for normal

operations, and when draining is required for maintenance or cleaning.

These valves are generally intended for low pressure applications; however, please consult Trumbull for special

requirements, such as high head pressure, or back pressure applications.

There are two different Mud Valve models available: Cast Iron, and Cast Stainless Steel. The standard Cast Iron

model uses brass seats in the body and gate; however, resilient seats are also available as an option. The cast

iron assembly features bronze stems and bronze threaded guides for use in submerged installations. The fasten-

ers are stainless steel to prevent corrosion during the life of the valve.

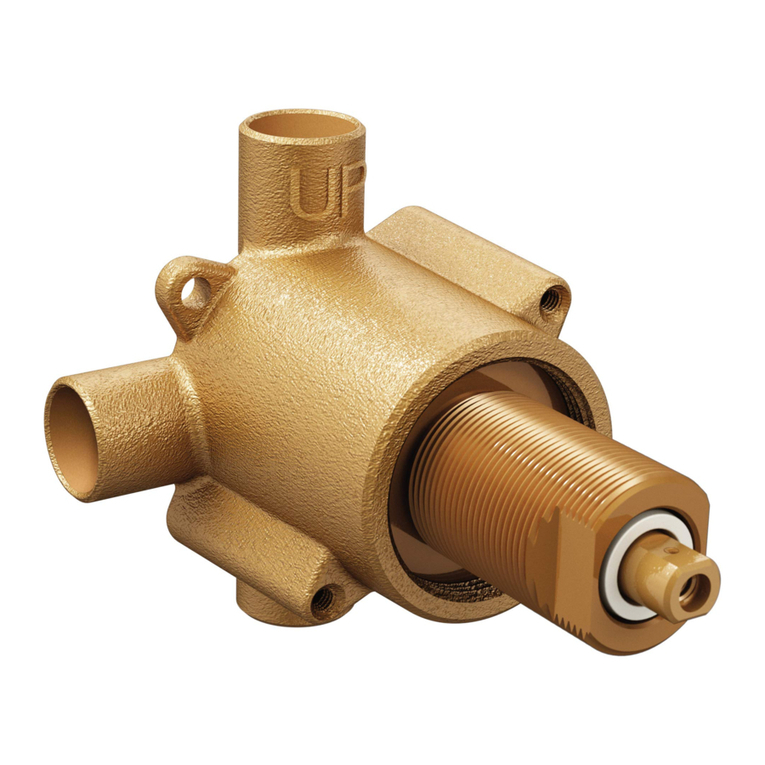

Cast Iron, Non-rising Stem Type Valve

The Cast Stainless Steel model uses SBR seats in the gate (other seat materials are available), and seals against

the stainless steel base flange. All metallic components of the Cast Stainless Steel mud valve are Type 316 stain-

less steel. The stem has a proprietary coating to eliminate galling and provide decades of service life.

Cast Stainless Steel, Non-rising Stem Type Valve

Trumbull mud valves can be furnished with extension stems of carbon or stainless steel. The extension stems can

then be operated thru a 2” operating nut in a floorbox (see illustration on page 4), or with an indicating floorstand.

Position Indicators are also available for installation in the floor (see page 10), or over an open tank (see page

11.)

When ordering extension stems, the material type must be specified along with either the overall length required,

or the distance from the face of the mud valve flange to the top of the handwheel, the 2” nut, or to the base of the

floorstand.

Page 3 of 12

Installation:

To insure proper operation of the Mud Valve, the following instructions must be followed:

1) The Mud Valve must be mounted to a mating floorpipe having a standard 125# flange.

The mounting flange should be recessed below the floor surface; the mud valve base seating surface

should be below the floor surface for complete draining of the fluid.

The flange must be installed level to provide vertical alignment for an extension stem.

Note: The Mud Valve flange is drilled in accordance with the ANSI 125# template on all sizes; however,

one hole under each Yoke leg is not available for fastening to the mating flange.

Fasteners for mounting are not furnished but can be ordered separately.

2) The area surrounding the mounting flange should be clean, and clear of obstructions.

Typical installation is shown on the following pages 4 and 5.

3) Prior to the installation of the mud valve, check the bottom of the valve flange for any adhering materials,

such as wood or packing debris, and for any visible damage.

4) Open the valve and clean the seating surfaces.

5) Operate the valve before installation to make sure it operates properly and was not damaged during ship-

ment or handling.

6) Do not use chains or other lifting devices on the stem or the bronze seats as this could deform the

threads, bend the stem, or damage the sealing surfaces.

7) For proper lifting, use a nylon strap of sufficient lifting capacity, and lift from under the yoke, as shown in

the figures below.

Proper lifting of mud valves, using a sling

Cast Iron Cast Stainless Steel

Non-rising Stem Type Non-rising Stem Type

8) Install the valve to the mounting flange using a full face, 1/8”, rubber flange gasket with the proper sized

bolts, or studs and nuts, for this size valve.

9) Tighten fasteners using a star tightening pattern. Uneven or over tightening could cause excessive leak-

age.

Note: Mud valves are not designed to be bubble-tight, and are not covered by an AWWA standard. Some

leakage may occur.

10) Check for obstacles between the gate and the yoke, then cycle the valve fully open and fully closed, to

make sure it opens and seals properly.

11) Complete the installation of related accessories such as extension stem, stem guides, floorstand or floor

box, as specified by the design engineer.

www.trumbull-mfg.com

Trumbull Manufacturing

3850 Hendricks Road, Youngstown, Ohio 44515

Phone:

330.270.7888

Toll Free:

877.504.1507

Fax:

330.392.0756

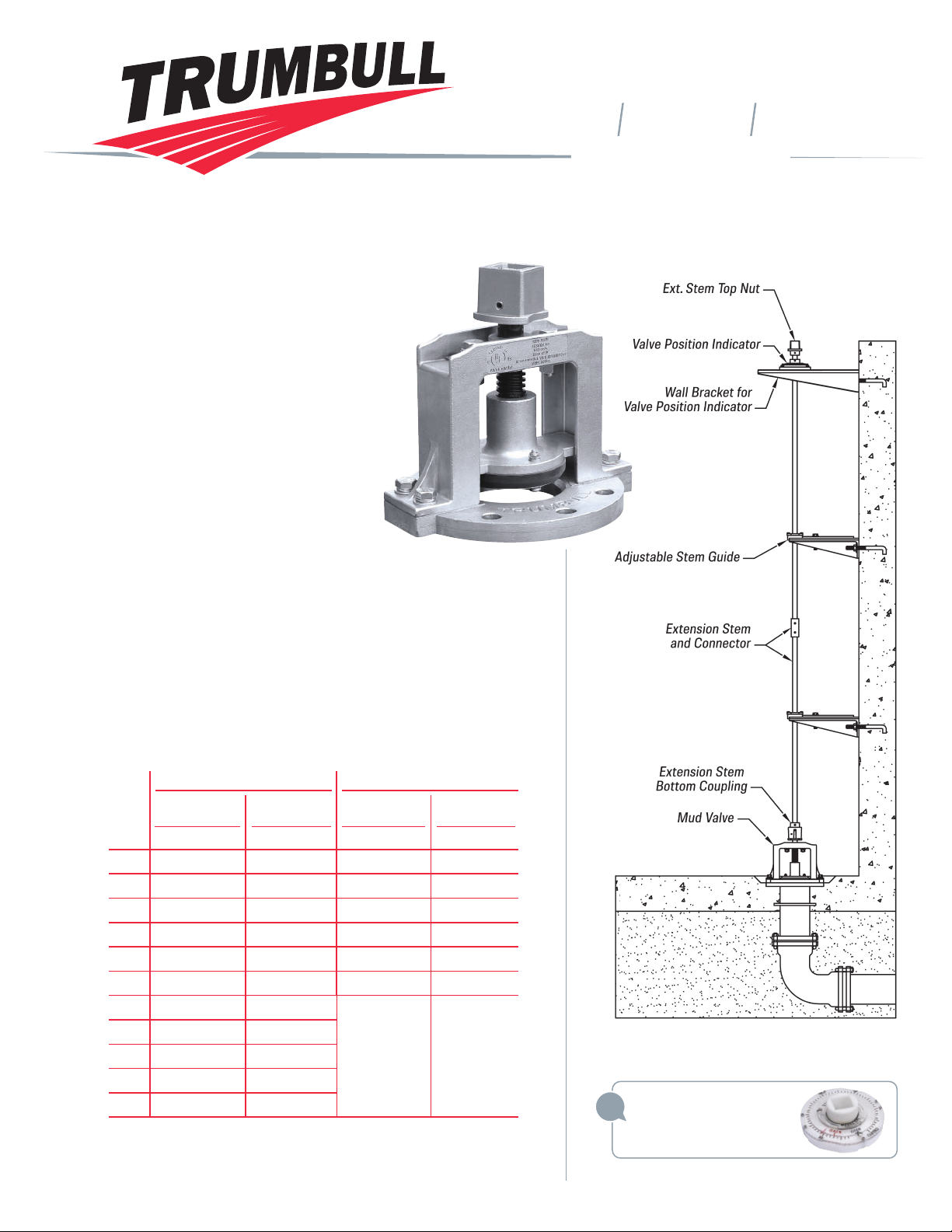

i

Trumbull Mud Valves are designed primarily for use in

settling tanks of water and wastewater treatment plants.

Their intended use is to drain tanks for maintenance or

cleaning. They are for low pressure applications only;

consult Trumbull for special requirements.

Mud Valves are furnished with a 2”square operating

nut; however, they can be supplied with optional

extension stem or handwheel (see page G-5).

This valve series uses bronze seats in the body and

gate (also available with resilient seat). The cast iron

body assembly features manganese bronze stems

and guides for use in submerged installations.

The fasteners are furnished in stainless steel to

prevent corrosion from years of submerged service.

Nuts, bolts and gaskets for mounting to floor pipe are

NOT furnished but can be ordered separately. Ductile

iron components are coated with Tnemec N140-1211

epoxy, per NSF 61.

See pages G-28 and G-29 for drawings.

Typical Mud Valve Installation

See page G-34 for installation options.

RISING

STEM

STYLE

NON-RISING

STEM STYLE

VALVE POSITION

INDICATORS

are recommended

on all Mud Valves

(see page F-7)

Size Item №Weight Item №Weight

3”367-1414 26.00 lbs. 367-1421 25.00 lbs.

4”367-1415 31.00 lbs. 367-1420 30.00 lbs.

6”367-1416 47.00 lbs. 367-1423 46.00 lbs.

8”367-1418 76.00 lbs. 367-1425 73.00 lbs.

10”367-1428 95.00 lbs. 367-1494 90.00 lbs.

12”367-1430 130.00 lbs. 367-1495 130.00 lbs.

14”367-1431 142.00 lbs.

Consult Trumbull

for availability.

16”367-1432 169.00 lbs.

18”367-1433 256.00 lbs.

20”367-1434 281.00 lbs.

24”367-1435 450.00 lbs.

Non-Rising Stem Rising Stem

The flange drilling is according to ANSI 125#STD.

on all sizes; however, one hole under each leg of the

yoke is not available for fastening to the mating flange.

Cast Iron Mud Valves

Certified to NSF-61 and NSF-372 in USA and Canada

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page G-27

Page 4of 12

www.trumbull-mfg.com

Trumbull Manufacturing

3850 Hendricks Road, Youngstown, Ohio 44515

Phone:

330.270.7888

Toll Free:

877.504.1507

Fax:

330.392.0756

i

Typical Mud Valve Installation

See page G-34 for installation options.

Valve Position Indicators

recommended on all Mud

Valves (see page F-9).

Size Item №Item №Item №Item №

3”1367-1349 367-1453 1367-1369

*367-1469

4”1367-1350 367-1454 1367-1370

*367-1470

6”1367-1351 367-1455 1367-1371

*367-1472

8”1367-1352 367-1456 1367-1372

*367-1474

10”1367-1353 367-1457 1367-1373

*367-1480

12”1367-1354 367-1458 1367-1374

*367-1481

14”1367-1355

*367-1459

**

16”1367-1356

*367-1460

18”1367-1357

*367-1461

20”1367-1358

*367-1462

24”1367-1359

*367-1463

Non-Rising Stem** Rising Stem**

Trumbull Mud Valves are designed primarily

for use in settling tanks of water and wastewater

treatment plants. Their intended use is to

drain tanks for maintenance or cleaning.

They are for low pressure applications only;

consult Trumbull for special requirements.

For applications requiring more corrosion

protection than cast iron, the yoke,

flange, guides and gate of these

Mud Valves are cast from Type 316

stainless steel. The one-piece, Type

316 stem has a permanently bonded

coating to protect against galling for

a lifetime of maintenance-free operation.

Cast components eliminate corrosion problems frequently

caused when stainless steel is welded. Castings are

passivated after machining, per ASTM A-967. Heavy-duty

design incorporates generous wall thicknesses and stem

diameters for maximum strength and corrosion protection.

Seat is SBR rubber for positive shutoff. Mechanically retained

seat is field-replaceable. Fasteners are Type 316 stainless.

See pages G-32 and G-33 for drawings.

Nuts, bolts and gaskets for mounting to floor pipe are

NOT furnished but can be ordered separately.

Cast 316 Stainless Steel Mud Valves

Heavy-Duty Design – Certified to NSF-61 and NSF-372 in USA and Canada

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page G-31

Domestic

Non-

Domestic Domestic

Non-

Domestic

* Consult Trumbull for availability.

** For product weights, see drawings on Pages G-32 & G-33.

Page 5of 12

Materials

19-3/4

17

12-3/8 14-1/2

B - Width at Yoke

Turns to Open

E - Flange Thickness

Bolt Dia.

Bolts in full Pattern*

Bolt Circle

Bolt Hole Dia.

C - Valve opening

1

17.0

1

7/8

12*

25-1/22017

7/81

3/4

8*

7/8

9.5

3/4

8*

11.75

7/8

3-1/2 4

21

7/8

7/8

4-1/16

1

14.25

12*

5

A - Overall height 13

Valve Size (Bore Dia.)

11-3/411-1/4

68

12-13/16

10 12

All Fasteners are Stainless Steel

Yoke

Gate

Seat, Gate

Base Flange (Body)

Guide, unthreaded

Guide, threaded

Operating Nut, 2" sq.

Stem

Seat, Base Flange

Part

7

5

3

4

1

8

9

2

Item

10-1/2

5/8

4

3/4

6.0

3/4

2-1/4

9-7/8

10

3

3728-1/2

24-5/8 30-5/8

1-7/8

29.5

1-3/8

1-1/4

20*

63

49

40

1-9/161-1/4

1

16*

1-1/8

21.25

1-1/8

20*

25.0

1-1/4

7-3/4 9-3/4

43

1-3/8

1-1/8

8-1/2

1-1/4

22.75

16*

12-1/4

23-1/219-3/416-3/4

16 20

18-3/4

18 24

6

Flange mounting gasket and fasteners are not included,

finished with NSF61 (TNEMEC 140-1211) coating.

*Two of the bolts in the bolt pattern are under the yoke feet

Standard 125 pound drilling template.

and must be ordered separately.

All cast iron surfaces, except machined surfaces, to be

22-3/4

1-1/8

18.75

1-1/8

1

12*

34

6-3/4

15

14

7

5

3

4

8

9

6

B - Overall Width at Yoke

C

Valve Opens

D - Basin depth in floor, min. 1-5/8 1-5/8 1-5/8 1-3/41-3/8 1-7/8 2-1/42-1/8 2-5/81-3/4

D

Base to Seat surface

E

Flange Thickness

Flange O.D.

Stem Diameter 1-1/21-1/8

11 13-1/2

1-1/4 1-3/8

16 197-1/2

1 1-3/41-1/2

23-1/2 27-1/2

1-3/41-3/4

25 32

1-1/2

21

and not used (except for 3").

Ductile Iron, ASTM A536 (65-45-12)

Gray Iron, ASTM A126 (B)

Gray Iron, ASTM A126 (B)

Bronze, ASTM B62; B584

Bronze, ASTM B62; B584

Bronze, ASTM B584

Bronze, ASTM B584

2

1

Weight, pounds 1307347 11026.3 453

280

167 243139

A

Overall Height

(Open and Closed)

Also available in Cast T316 Stainless Steel.

11

5/8

8*

13/16

7.5

3/4

2

9-1/2

10

4

1-3/8

9

1

27

(except 3")

Ductile Iron, ASTM A536 (65-45-12)

Ductile Iron, ASTM A536 (65-45-12)

Drawn to Scale

CAST IRON MUD VALVES

NON-RISING STEM TYPE 10/16/17

FCN

Drawn: Revision:

02/13/20

FCN

BYoungstown, Ohio

www.trumbull-mfg.com

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page G-28

Page 6of 12

19-3/4

17

12-3/8 14-1/2

B - Width at Yoke

Turns to Open

E - Flange Thickness

Bolt Dia.

Bolts in full Pattern*

Bolt Circle

Bolt Hole Dia.

C - Valve opening

1

17.0

1

7/8

12*

2520-1/217

7/81

3/4

8*

7/8

9.5

3/4

8*

11.75

7/8

3-3/8 4

20

7/8

7/8

4

1

14.25

12*

5

A - Overall height, closed 13

Valve Size (Bore Dia.)

11-3/411

68

12-3/4

10 12

11

5/8

8*

13/16

7.5

3/4

2-1/8

9-3/4

10

4

3728-1/2

24-5/8 30-5/8

1-7/8

29.5

1-3/8

1-1/4

20*

60

50

40

1-9/161-1/4

1

16*

1-1/8

21.25

1-1/8

20*

25.0

1-1/4

810

45

1-3/8

1-1/8

9

1-1/4

22.75

16*

12

23-1/219-3/416-3/4

16** 20**

18-3/4

18** 24**

A - Overall height, open 18

15/3/414-3/8 16-3/4

11-7/8 35-1/2

29-3/4

24-3/4 27-3/4

22-3/4

1-1/8

18.75

1-1/8

1

12*

35

7

14-1/2

14

21-1/2

D - Basin depth in floor, min. 1-5/8 1-5/8 1-5/8 1-3/41-3/8 1-7/8 2-1/42-1/8 2-5/81-3/4

Flange O.D.

Stem Diameter 1-1/21-1/8

11 13-1/2

1-1/4 1-3/8

16 199

1 1-3/41-1/2

23-1/2 27-1/2

1-3/41-3/4

25 32

1-1/2

21

Flange mounting gasket and fasteners are not included,

finished with NSF61 (TNEMEC 140-1211) coating.

*Two of the bolts in the bolt pattern are under the yoke feet

Standard 125 pound drilling template.

and must be ordered separately.

All cast iron surfaces, except machined surfaces, to be

5

4

1

8

9

6

B - Overall Width at Yoke

C

Valve Opens D

Base to Seat surface

E

Flange Thickness

and not used.

3

2

7

Weight, pounds 1307346 11030 140 165 240 280 450

A

Overall Height

Open

in the Rising Stem configuration.

** Consult Trumbull on the availability of 16" and larger sizes

Also available in Cast T316 Stainless Steel.

10-1/2

5/8

4

3/4

6.0

3/4

2-1/4

9-3/4

10

3

12

1-3/8

7-1/2

1

26.3

(except 3")

Materials

All Fasteners are Stainless Steel

Yoke

Gate

Seat, Gate

Base Flange (Body)

Guide, unthreaded

Guide, threaded

Operating Nut, 2" sq.

Stem

Seat, Base Flange

Part

7

5

3

4

1

8

9

2

Item

6Ductile Iron, ASTM A536 (65-45-12)

Gray Iron, ASTM A126 (B)

Gray Iron, ASTM A126 (B)

Bronze, ASTM B62; B584

Bronze, ASTM B62; B584

Bronze, ASTM B584

Bronze, ASTM B584

Ductile Iron, ASTM A536 (65-45-12)

Ductile Iron, ASTM A536 (65-45-12)

Drawn to Scale

CAST IRON MUD VALVES

RISING STEM TYPE 10/16/17

FCN

Drawn: Revision:

02/13/20

FCN

BYoungstown, Ohio

www.trumbull-mfg.com

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page G-29

Page 7of 12

All items, except for the Seal and the sealing washers are Type 316 Stainless Steel.

Seal and sealing washers are SBR.

All Fasteners are Stainless Steel, Type 316, ASTM A193, Grade B

Flange mounting gasket and fasteners are not included, and must be ordered separately.

* Standard 125 pound drilling template, with two holes covered by the Yoke (except for 3").

Stem is coated and greased to prevent galling.

Sizes 3" thru 16"

Sizes 18" thru 24"

Part Description

1

2

3

4

5

6

7

8

9

10 2" Square Nut

Yoke Cylinder (18"+)

Base Flange (Body)

Yoke

Gate

Seat

Seat Retainer

Stem

Guide, Plain

Spring Pin

4

Valve Size (Bore Dia.) 6 8 10 12

1-1/4

Stem Diameter 1-1/4

Bolt / Stud Size

C - Valve opening

Flange O.D.

Bolt Hole Dia.

Bolt Circle Diameter

1-3/4

5/8 3/4

7.50

3/4

9

9.50

7/8

2-3/4

11

A - Overall height

B - Width at Yoke 10-1/4 12-5/8

1-1/21-1/2 1-1/2

3/4 7/8

11.75

7/8

13-1/2

3-1/2

14.25

1

16

4-3/4

7/8

17.00

1

6

19

15-1/8 17-3/8 19

Weight, pounds 24-1/2 33-1/2 48 65 88

810-1/2 12-1/2 14-1/2 17

16 18 20

1-3/41-1/2 1-3/4

11-1/8

21.25

1-1/8

23-1/2

7-1/2

22.75

1-1/4

25

8-1/4

1-1/8

25.00

1-1/4

9-1/4

27-1/2

25-3/4 27-3/4 27-1/2

142 186 206

21-1/4 23 25-3/4

Bolts in full Pattern* 8881212 161620

Basin depth in floor for complete draining, 1" minimum.

D - Flange thickness 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4

1

3

45

6

7

8

9

10

1

3

4

2

6

9

7

10

Turns to Open 9 15-1/2 20 26 30 20-1/2 23 48-1/2

24

1-3/4

1-1/4

29.5

1-3/8

12

32

32

230

34-5/8

20

3/4

60

2

5

3

1-1/4

1-1/2

5/8

6.00

3/4

7-1/2

8

19-1/2

9

4

3/4

7

14

1-1/2

1

18.75

1-1/8

7-3/8

21.0

25-3/4

125

23

12

3/4

37

A

Overall Height

(Open and Closed)

A

Overall Height

(Open and Closed)

C

Valve Opens

C - Valve Opens

D

Flange Thickness

D

Flange Thickness

B - Overall Width at Yoke

B - Overall Width at Yoke

Sealing washer

shown enlarged

Seat retainer fasteners

typical, all valves

Drawn to Scale 07/24/07

FCN

Drawn: Revision:

02/07/20

FCN

FYoungstown, Ohio

www.trumbull-mfg.com

CAST T316 SS MUD VALVES

NON-RISING STEM TYPE

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page G-32

Page 8of 12

All items, except for the Seal and the sealing washers are Type 316 Stainless Steel.

Seal and sealing washers are SBR.

All Fasteners are Stainless Steel, Type 316, ASTM A193, Grade B

Flange mounting gasket and fasteners are not included, and must be ordered separately.

Standard 125 pound drilling template, with two holes covered by the Yoke.

Stem is coated and greased to prevent galling.

9

Basin depth in floor for complete draining, 1" minimum.

1

2

3

4

5

6

8

7

10

Consult Trumbull on the availability of 16" and larger sizes

in the Rising Stem configuration.

shown enlarged

Seat retainer fasteners

Sealing washer

typical, all valves

11-1/2 16 19-1/4 22-3/4 28-1/2

2-1/4 5 7 8-1/4 11-1/2

25 34 48 59 78

8-3/4 10-1/2 12-1/2 14 17

27 28

910

142

23 18 18

13-1/2 26-1/2 30-1/2 36-1/2 50-1/2 45 50

10-1/2

1-1/2

19-1/2

9

7

4

Valve Size (Bore Dia.) 6 8 10 12

1-1/4Stem Diameter 1-1/4

Bolt / Stud Size

C - Valve opening

Flange O.D.

Bolt Hole Dia.

Bolt Circle Diameter

5/8 3/4

7.50

3/4

9

9.50

7/8

11

B - Width at Yoke 10-1/4 12-5/8

1-1/21-1/2 1-1/2

3/4 7/8

11.75

7/8

13-1/2

14.25

1

16

7/8

17.00

1

19

15-1/8 17-3/8 19

Weight, pounds

16 18 20

1-3/41-1/2 1-3/4

11-1/8

21.25

1-1/8

23-1/2

22.75

1-1/4

25

1-1/8

25.00

1-1/4

27-1/2

25-3/4 27-3/4 27-1/2

Bolts in full Pattern* 8881212 161620

D - Flange thickness 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4

Turns to Open

24

1-3/4

1-1/4

29.5

1-3/8

32

32

20

3/4

3

1-1/4

5/8

6.00

3/4

7-1/2

8

4

3/4

14

1-1/2

1

18.75

1-1/8

21.0

25-3/4

12

3/4

A - Overall height, closed

A - Overall height, open

23

3939

1616

8080

142 155 164 218

60

12

35

23

B - Overall Width at Yoke

D - Flange Thickness

C

Valve

Opens

A

Overall Height

Closed

Drawn to Scale

CAST T316SS MUD VALVES

RISING STEM TYPE 10/16/17

FCN

Drawn: Revision:

03/19/20

NJC

CYoungstown, Ohio

www.trumbull-mfg.com

Part Description

1

2

3

4

5

6

7

Base Flange (Body)

Yoke

Gate

Seat

Seat Retainer

Stem

8

9

10

2" Square Nut

Guide, Threaded

Guide, Unthreaded

Coil Type Spring Pin

OPEN CLOSED

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page G-33

Page 9of 12

www.trumbull-mfg.com

Trumbull Manufacturing

3850 Hendricks Road, Youngstown, Ohio 44515

Phone:

330.270.7888

Toll Free:

877.504.1507

Fax:

330.392.0756

Ordering Instructions

1. Specify direction of open (open left or open right)

2. Model required (available in 57, 275 or 870 turns, shown below)

3. Extension Stem required

a. Length required

b. Round (maximum OD of 1.75”), 1-1/4”square, or

round x square stem (see reverse for details)

c. Carbon steel or stainless steel

4. Housing Adapter - Floor Box style

a. Cast iron housing (unsealed), see page F-11

b. Carbon steel or stainless steel (sealed), see page G-13

Model

Number Item №Item №Item №Item №

57T 367-9394 367-9393 367-9404 367-9403

275T 367-9396 367-9395 367-9406 367-9405

870T 367-9400 367-9399 367-9410 367-9409

Open Left Open Right Open Left Open Right

Square Ext. Stem Round Ext. Stem

POSITION

INDICATOR

•Eliminates broken

valve stems caused

by over-opening

or over-closing

•Field-adjustable

for any number

of turns within

the range of

each model

•Constructed

of heavy-duty,

non-corrosive

DuPont™ Delrin®polymer,

providing high-impact

resistance even in cold climates

•Double O-ring seals keep out water and dirt

•Third-party tested to over 1 million revolutions

•Provided with stainless steel hardware

•Also available w/Wall Bracket for mounting to tank walls (pages F-9

to F-10), and in Valve Boxes for buried service (pages F-1 to F-6)

Valve Position Indicators

Installation in Floor

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page F-7

US Patent No.'s 8,550,115 / 9,347,583 / 10,066,760

i

Page 10of 12

www.trumbull-mfg.com

Trumbull Manufacturing

3850 Hendricks Road, Youngstown, Ohio 44515

Phone:

330.270.7888

Toll Free:

877.504.1507

Fax:

330.392.0756

Ordering Instructions

WALL BRACKET

DUCTILE IRON

Item No. 367-2450

CAST 316 STAINLESS

Item No. 367-2460

•Eliminates

broken valve

stems caused

by over-opening

or over-closing

•Field-adjustable for

any number of turns

within the range of each model

•Constructed of heavy-duty, non-corrosive DuPont™ Delrin®

polymer, providing high-impact resistance even in cold climates

•Double O-ring seals keep out water and dirt

•Third-party tested to over 1 million revolutions

•Provided with stainless steel hardware

•Also available for use in the floor (pages F-7 to F-8),

and in Valve Boxes for buried service (pages F-1 to F-6)

1. Specify direction of open (open left or open right)

2. Model required (available in 57, 275 or 870 turns)

3. Extension Stem required

a. Length required

b. Round (maximum OD of 1.75”) see next

page for details

c. Carbon steel or stainless steel

Model

Number

Number

of Turns Item №Item №

57T 0 - 57 367-9404 367-9403

275T 0 - 275 367-9406 367-9405

870T 0 - 870 367-9410 367-9409

Open Left Open Right

Valve Position Indicators

Installation with Wall Bracket

© 2023 Trumbull Manufacturing

09/01/20 Page Revision Page F-9

US Patent No.'s 8,550,115 / 9,347,583 / 10,066,760

i

Page 11of 12

Page 12 of 12

Storage before installation:

There are no special requirements for storage of these mud valves; their intended use can be more severe than

environmental conditions.

However, the valves should be handled with proper care and attention during shipment, handling, and storage to

prevent physical damage, especially from contact with material handling equipment.

Operation and Maintenance Precautions during freezing weather:

Although it is unlikely a tank would be drained during freezing conditions, proper precautions must be observed

during these operations, as water can be retained in the stem protector cavity of the Gate when the valve is

opened after being submerged.

By closing the valve after the tank is drained, air is drawn into the stem protector and forms a cushion. This air

cushion prevents freezing damage to the stem protector.

Always close the valve after the tank has been emptied, if the valve will be subjected to freezing temperatures,

either during operation, or for maintenance.

Operation:

Trumbull mud valves are designed to open left, by turning the stem counterclockwise; they will seat by rotating the

stem in a clockwise rotation.

The mud valve is manufactured to seal with minimum torque.

If the valve does not seal with 35 foot pounds of torque, inspect for obstructions on the seating surfaces.

Using excess closing torque with an obstruction or debris on the seats will not seal the valve; instead it may cause

damage to the seating surfaces. Position Indicators are recommended on the mud valves to avoid over-torquing

(from opening or closing while the gate is obstructed), causing damage to the seats or stems.

Maintenance:

Trumbull mud valves are designed to require very little maintenance.

When the mud valve is available for servicing, the following measures will help to assure trouble-free perfor-

mance.

Clean the valve by pressure washing it to remove any debris.

Wipe the seating surfaces with a clean rag, and allow the valve to dry, by natural or forced

warm air.

Remove all the debris from the area around the valve.

Once the valve is dry inspect the seating surfaces for condition and damage.

Inspect all the fasteners to insure they are tight; retighten if necessary.

Lubricate the stem (a food grade lubricant may be required by the application.)

Loctite 82328 SuperLube is used on all of our stainless steel mud valves.

Document the service. Include a description of inspection observations, all work that was performed,

and recommended follow-up actions.

No spare parts are required for maintenance; replacement parts are available for damaged valves.

Trumbull Manufacturing Resources:

For any questions, comments, or concerns, please contact our people at the following numbers:

Sales and Manufacturing Scott Greaver 330-393-1291

Quality Assurance Dwayne Hill 330-392-1353

Engineering Craig Newmeyer 330-799-3333

revised: Feb. 1, 2013

This manual suits for next models

50

Table of contents