Truper MAX-20SC User manual

Manual

Cordless

Circular Saw

MAX-20SC

ModelCode

MAX-20SC

Applies for:

102480

Disc

6-1/2”

CAUTION Read this manual thoroughly

before using the tool.

ENGLISH

ESPAÑOL

2

Technical Data

Power requirements

General power tools safety warnings

Safety rules for the use of circular saws

Parts

Preparation

Start up

Maintenance

Notes

Authorized Service Centers

Warranty Policy

3

3

4

5

7

8

9

11

12

13

14

MAX-20SC

CAUTION

Contents

Keep this manual for future references.

The illustrations in this manual are for reference

only. They might be different from the real tool.

To gain the best performance of

the tool, prolong the duty life,

make the Warranty valid if

necessary, and to avoid hazards

of fatal injuries please read and

understand this Manual before

using the tool.

3

MAX-20SC

102480

6-1/2”

Cordless circular saw

Code

Description

Disc

Voltage

4 200 RPM

Speed

IP20

IP Grade

The power cable has cable clamps type: Y

The construction class of the tool is: Class III

Construction class of the charger is: Reinforced insulation

Battery

Input: Voltage: 127 V

Frequency: 60 Hz

Current: 1.1 A

Output: 21.5 V 3.5 A

Charger

Ion-lithium 20 V 4 Ah | Charging time: 80 min approximately

20 V

Maximum

cutting depth a 90º: 2 1/8” | a 45º: 1 1/2”

ENGLISH

Technical Data

Power Requirements

Tools with double insulation are equipped with a polarized plug

(one prong is wider than the other). This plug will only fit in the right way into a

polarized outlet. If the plug cannot be introduced into the outlet, reverse the plug. If

it still doesn’t fit, call a qualified electrician to install for you a polarized outlet. Do

not alter the plug in any way. Double insulation eliminates the need of both a

grounded third power cord with three prongs or a grounded power connection.

When using an extension cable, verify the gauge is enough for

the power that your product needs. A lower gauge cable will cause voltage drop in the line, resulting in power loss and

overheating. The following table shows the right size to use depending on cable’s length and the ampere capability shown in

the tool’s nameplate. When in doubt use the next higher gauge.

WARNING

WARNING

WARNING

from 0 A and up to 10 A

from 10 A and up to 13 A

from 13 A and up to 15 A

from 15 A and up to 20 A

18 AWG(*)

16 AWG

14 AWG

8 AWG

16 AWG

14 AWG

12 AWG

6 AWG

3 (one grounded)

from 6 ft to 49 ft | higher than 49 ft

Ampere

Capacity Number of

Conductors Extension gauge

*It is safe to use only if the extensions have a built-in artifact for over current protection.

AWG = American Wire Gauge. Reference: NMX-J-195-ANCE

When operating power tools outdoors, use a grounded

extension cable labeled “For Outdoors Use”. These extensions are especially designed

for operating outdoors and reduce the risk of electric shock.

WARNING

WARNING Avoid the risk of electric shock or severe injury. When the power cable gets damaged

it should only be replaced by the manufacturer or at a Authorized Service Center.

The build quality of the electric insulation is altered if spills or liquid gets into the tool while in use.

Do not expose to rain, liquids and/or dampness.

Before gaining access to the terminals all power sources should be disconnected.

4

General power tools

safety warnings

ENGLISH This tool is in compliance with the Official Mexican Standard (NOM - Norma Oficial Mexicana).

Work area

Keep your work area clean, and well lit.

Cluttered and dark areas may cause accidents.

Never use the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Sparks generated by power tools may ignite the flammable material.

Keep children and bystanders at a safe distance while operating

the tool.

Distractions may cause loosing control.

Electrical Safety

The tool plug must match the power outlet. Never modify

the plug in any way. Do not use any adapter plugs with

grounded power tools.

Modified plugs and different power outlets increase the risk of electric shock.

Avoid body contact with grounded surfaces, such as pipes,

radiators, electric ranges and refrigerators.

The risk of electric shock increases if your body is grounded.

Do not expose the tool to rain or wet conditions.

Water entering into the tool increases the risk of electric shock.

Do not force the cord. Never use the cord to carry, lift or unplug

the tool. Keep the cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a tool outdoors, use an extension cord suitable

for outdoor use.

Using an adequate outdoor extension cord reduces the risk of electric shock.

If operating the tool in a damp location cannot be avoided, use

a ground fault circuit interrupter (GFCI) protected supply.

Using a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense

when operating a tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication.

A moment of distraction while operating the tool may result in personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as safety glasses, anti-dust mask, non-skid shoes,

hard hats and hearing protection used in the right conditions significantly

reduce personal injury.

Prevent unintentional starting up. Ensure the switch is in the

“OFF” position before connecting into the power source and /

or battery as well as when carrying the tool.

Transporting power tools with the finger on the switch or connecting power

tools with the switch in the “ON” position may cause accidents.

Remove any wrench or vice before turning the power tool on.

Wrenches or vices left attached to rotating parts of the tool may result in

personal injury.

Do not overreach. Keep proper footing and balance at all times.

This enables a better control on the tool during unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep

hair, clothes and gloves away from the moving parts.

Loose clothes or long hair may get caught in moving parts.

If you have dust extraction and recollection devices connected

onto the tool, inspect their connections and use them correctly.

Using these devices reduce dust-related risks.

Power Tools Use and Care

Do not force the tool. Use the adequate tool for your

application.

The correct tool delivers a better and safer job at the rate for which it was designed.

Do not use the tool if the switch is not working properly.

Any power tool that cannot be turned ON or OFF is dangerous and should be

repaired before operating.

Disconnect the tool from the power source and / or battery

before making any adjustments, changing accessories or

storing.

These measures reduce the risk of accidentally starting the tool.

Store tools out of the reach of children. Do not allow persons

that are not familiar with the tool or its instructions to

operate the tool.

Power tools are dangerous in the hands of untrained users.

Service the tool. Check the mobile parts are not misaligned or

stuck. There should not be broken parts or other conditions that

may affect its operation. Repair any damage before using the

tool.

Most accidents are caused due to poor maintenance to the tools.

Keep the cutting accessories sharp and clean.

Cutting accessories in good working conditions are less likely to bind and are

easier to control.

Use the tool, components and accessories in accordance with

these instructions and the projected way to use it for the type of

tool when in adequate working conditions.

Using the tool for applications different from those it was designed for, could

result in a hazardous situation.

Use and care of the battery-operated tool

Recharge only with the charger specified by .

A charger that is suitable for one type of battery pack may create a risk of fire when

used with another battery pack.

Use power tools only with specifically designated battery packs.

Use of any other battery packs may create a risk of injury and fire.

When battery pack is not in use, keep it away from other metal

objects, like paper clips, coins, keys, nails, screws, or other

small metal objects, that can make a connection from one

terminal to another.

Shorting the battery terminals together may cause burns or a fire.

Under abusive conditions, liquid may be ejected from the

battery; avoid contact. If contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

Service

Repair the tool in a Authorized Service Center

using only identical spare parts.

This will ensure that the safety of the power tool is maintained.

WARNING! Read carefully all safety warnings and instruction listed below. Failure to comply with any of

these warnings may result in electric shock, fire and / or severe damage. Save all warnings and instructions for

future references.

5

Kickback refers to the sudden, forceful movement of the

tool away from the workpiece that can cause the operator

to lose control or even cause injury. It is usually caused

when the disc gets stuck in the workpiece or by poor

operation. To avoid this, the following precautions should

be taken:

• Use discs in good condition and make sure they are

properly installed. Poorly installed, damaged, dull or worn

discs tend to jam in the material causing kickback.

• When operating the tool, hold it firmly with one hand

on the handle and the other hand on the auxiliary handle.

Always use both hands. Keep your body well balanced

and in a stable position with both feet on the ground to

resist the force of possible kickback.

• To make a cut, align the disc with the cutting line and

wait for the disc to reach full speed before starting to cut.

Do not start the tool with the cutting teeth resting on the

workpiece, this could cause kickback.

• To restart work within a cut, center the disc in the cut

and check that the teeth are not buried in the material.

• If you notice the disc bending or cutting stops during

tool operation, release the switch and hold the tool inside

the workpiece until the disc comes to a complete stop. Do

not attempt to remove the disc while it is still moving, it

could cause kickback.

Investigate and take corrective action to eliminate the

causes of the disc digging in.

• To minimize the risk of the disc binding and causing

kickback, remove all nails before cutting a piece of wood.

Wet, warped or pressure-treated lumber requires special

Caution during cutting. When cutting large planks, use

supports near both sides of the cutting line to prevent the

weight of the material itself from bending the plank and

closing the cut and trapping the disc. The gum and resin

from the wood that hardens on the cutting discs slows down

the saw. Use gum and resin remover, hot water or kerosene

to remove these buildups. DO NOT use gasoline.

• Be very careful when making a pocket cut in walls or

blind places. The disc may contact hidden objects and

cause kickback.

• While operating the tool, do not place your hand or body

in line with the cutting axis, as the possibility of serious

injury exists if kickback occurs.

• Before starting any cut, the depth of cut and bevel

adjustment knobs must be tightened and secured. If they

move during the cut, they can cause the disc to bend and

kickback may occur. Excessive depth of cut position

increases the load on the unit and the possibility of

bending the disc within the cut.

Safety rules for the use

of circular saws

Kickback

• Use only Truper Max chargers to charge

the tool battery. Using any other charger may result in fire

or risk of injury.

• Use only batteries specifically designed

for the tool. Other batteries may create a risk of injury or

fire.

• Connect the charger to an alternating current (AC) supply

only.

• Do not use the charger outdoors.

• Observe the “+/-” polarity when charging.

• Never recharge a leaking battery.

• Do not use batteries or the charger for purposes other

than those for which they were designed.

• Do not modify the battery or charger contacts.

• Do not expose the battery pack or the tool to fire or

extreme temperatures. Exposure to fire or temperatures

above 130 °C can cause an explosion.

• Never expose batteries to the fire, they

may explode.

• Batteries should be kept away from any

metallic object such as paper clips, coins, keys, nails,

screws or any other object that could cause the terminals

to make contact, and would cause a short circuit that could

cause burns or fires.

• Under extreme conditions, the battery

liquid may leak. If so, avoid any contact. If accidental

contact occurs, wash with abundant water, rinse with

lemon juice and vinegar. If the liquid enters in contact with

the eyes, wash with abundant water during several minutes

and look for medical help immediately. The liquid expelled

from the batteries could cause irradiation or burns.

• To maximize battery life, fully discharge

the battery at least once a month. Do not leave the battery

without recharging for more than three months. Always

charge the battery to its maximum capacity. Before using

the machine for the first time, charge the battery to its

maximum capacity.

• Avoid stopping constantly while cutting to prevent

damage to the battery.

Batteries and charger

ENGLISH

DANGER

DANGER

DANGER

DANGER

CAUTION

CAUTION

CAUTION

6

Retractable guard

General Warnings

• Before each use check the retractable guard and its

spring for proper operation, if the guard does not move

freely or does not close instantly, service it before

operating the tool.

• The retractable guard may operate sluggishly due to

damaged parts, gummy deposits or debris buildup. To

avoid this possibility, regularly clean the inside of both

guards and the disc shaft with kerosene or compressed air.

Before cleaning, switch off the tool and remove the discs.

• The retractable guard can be opened manually, only to

change the blades and to make a cutting or combination

cut. Open the retractable guard with its lever. As soon as

the blade enters the material, the lever must be released.

For all other types of cuts the retractable guard should

operate automatically. Never fix the retractable guard in

the open position.

• The retractable guard can be bent by a blow or fall.

Before operating the tool make sure that it moves freely

at all angles and depths of cut, and that it does not touch

the disc or any other part of the tool.

• Check that the retractable guard

covers the saw blade before placing the saw on a bench

or on the floor. A blade that is spinning by inertia can

cause the saw to move backwards, cutting whatever is in

its path. Verify that the disk stops moving after the tool is

turned off.

• Remember that the guards do not

protect you from the disc moving under the workpiece, so

you should never squat or reach under it while the tool is

running.

Dusts from cutting certain materials contain chemicals

known to cause cancer, birth defects and other

reproductive harm. Some of these chemicals are:

• Lead in lead-based paints.

• Arsenic and chromium in chemically treated wood.

The risk of exposure to these substances varies depending

on how often the work is done. To reduce exposure to

these chemicals, work in well-ventilated areas, and use

appropriate safety equipment, such as dust masks

specifically designed to filter out microscopic particles.

Toxic materials

• Move your hands away from the

cutting area and the cutting disc. When operating the tool

hold it firmly by the handle and auxiliary handle with both

hands to prevent accidental injury and prevent loss of

control.

• Accidental contact with a spinning

cutting disc can result in serious personal injury.

• NEVER hold the piece to be cut with

your hands or on one leg. Hold the workpiece properly to

avoid contact of the body with the cutting disc, prevent

the cutting disc from bending, or lose control of the tool

or workpiece.

• Do not attempt to remove waste

material when the cutting disc is rotating.

• Before each use check that the

retractable guard and its spring work properly, if the guard

does not move freely or does not close instantly correct

this points before operating the tool.

• While moving the tool do not bring

the disc close to your body. In case of accidental start, the

retractable guard can be opened when in contact with

your clothes.

• Operating the tool by holding it by its

insulated parts avoids discharges to the operator in case the

disc makes contact with hidden electrical wiring.

• ALWAYS keep the power cord away from the cutting

area. The power cord should NEVER hang over the

workpiece when making the cut.

• Always wear safety glasses with side protection. In case

of producing dust also use a dust mask.

It also increases the likelihood that the cut will close and

the available area above the disc will increase.

• When the disc jams or gets caught in the workpiece by

the saw cut, the disc stops and consequently the motor

reaction quickly directs the tool toward the operator.

• If the disc becomes warped or misaligned during the

cut, the cutting-edge teeth on the back of the disc can

become buried in the wood which can cause the disc to

come out of the cut gap and the tool to be directed

toward the operator.

Safety rules for the use

of circular saws

ENGLISH

DANGER

DANGER

DANGER

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

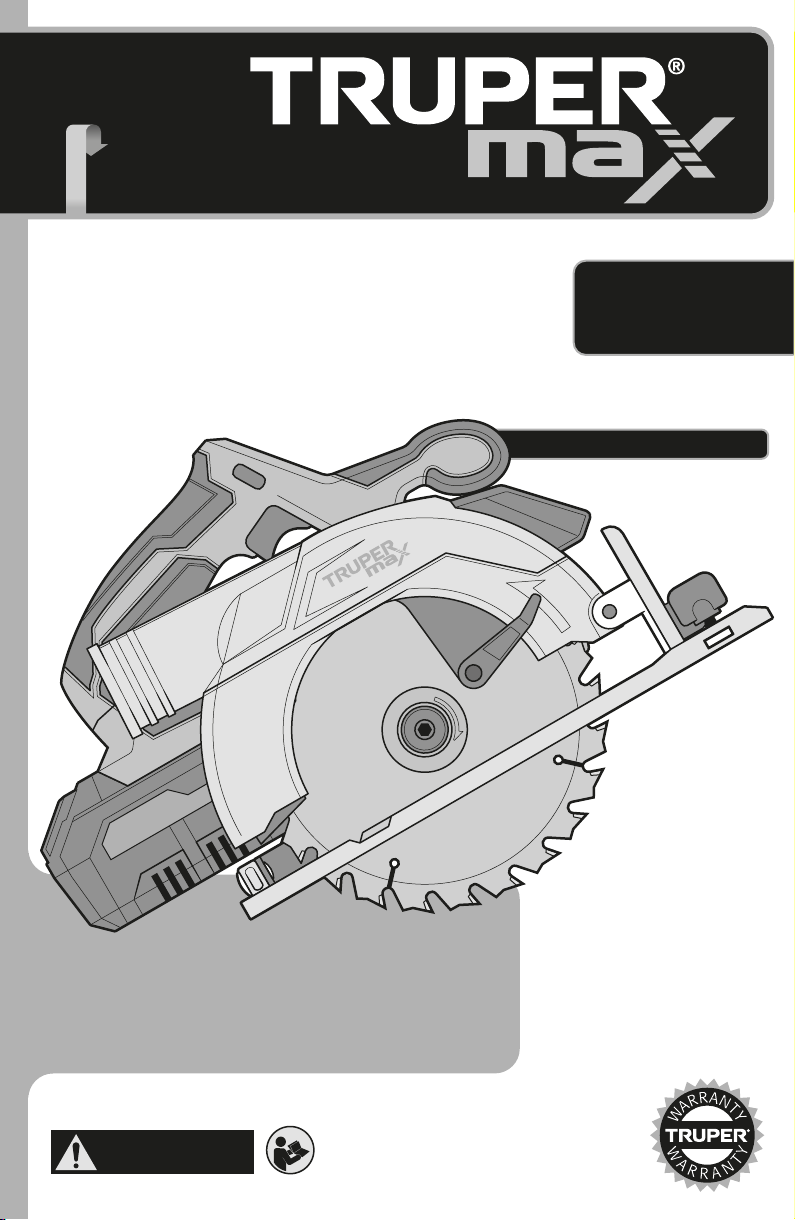

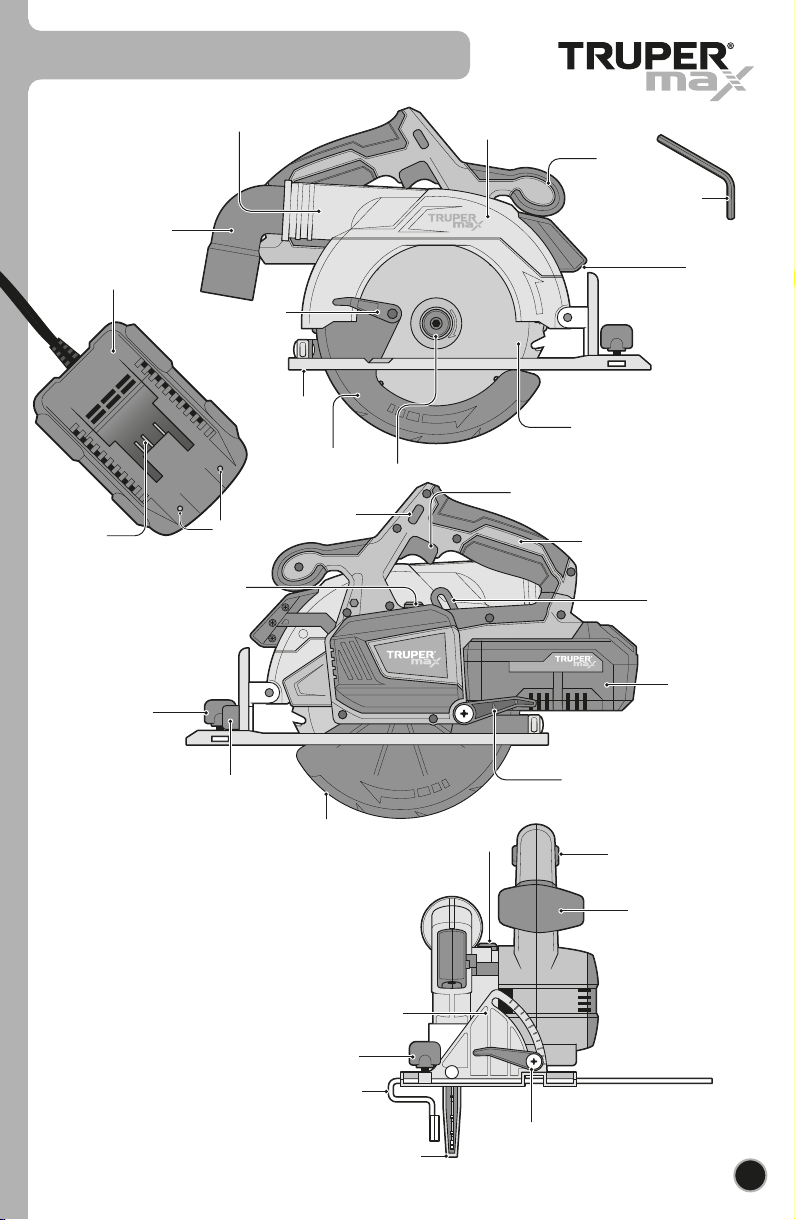

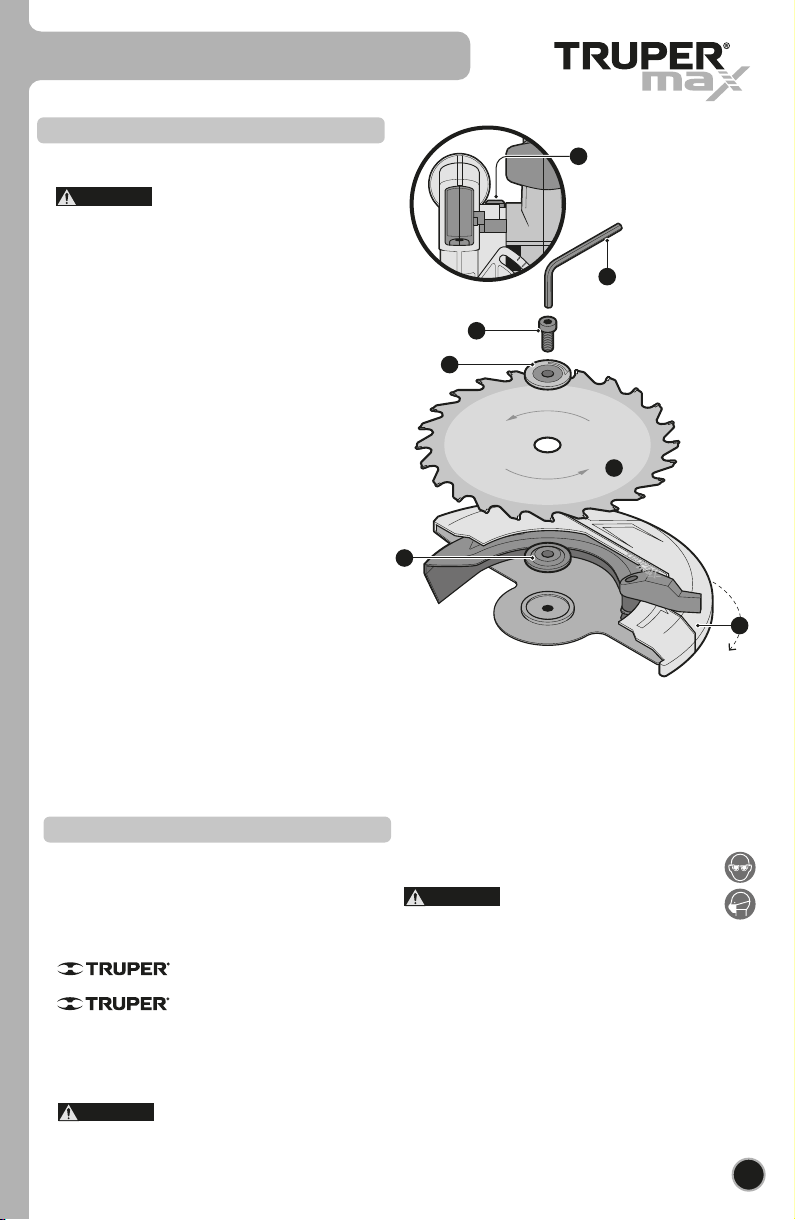

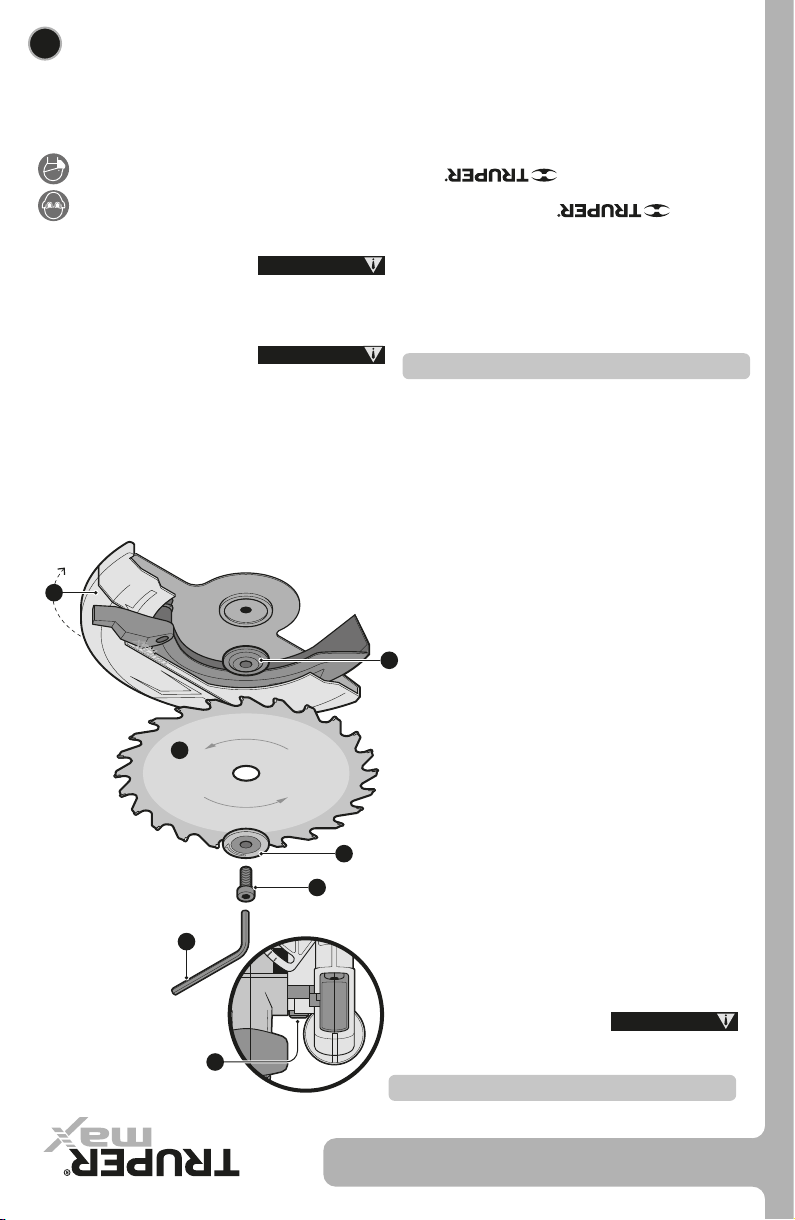

Retractable

guard

control lever

TRUPER ST-624 6-1/2”

tungsten carbide cut-off disc

Base

Shaft lock

button

Auxiliary

handle

Auxiliary

handle

Motor

housing

Fixed

guard

Cutting guide

Retractable

guard

Retractable

guard

Cutting angle

locking lever

Cutting guid

locking knob

Switch lock

button

Cutter guard

lock knob

Retractable

guard

45° lock

Outer flange

Cutting angle

locking lever

Cutting depth

lock lever

Sawdust

ejector

Dust

nozzle

Switch lock

button

Shaft

lock

button

Switch

LED light

Handle

Allen

key

Battery

Charger

Battery

connection

prongs

Charge

indicators

7

Parts

Sawdust ejector.

Sawdust is blown to the

rear and to the side, as far

away from the operator as

possible. The cooling air

from the motor is blown

out through the housing

and also assists in the

ejection of the sawdust.

Retractable guard.

The retractable guard

opens automatically when

the blade enters the

workpiece. When the cut is

completed, the retractable

guard is spring-loaded

closed to cover the blade.

Cutting depth

guide

ENGLISH

A

8

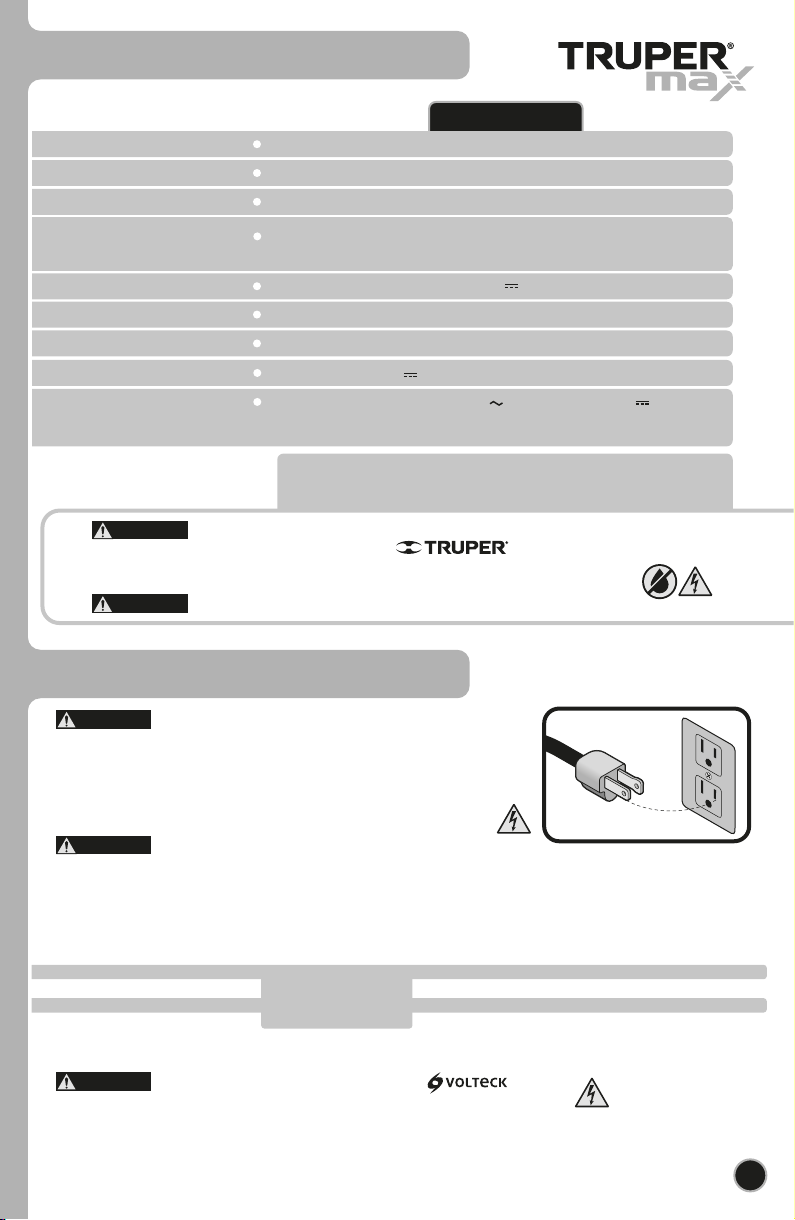

Preparation

Battery charging

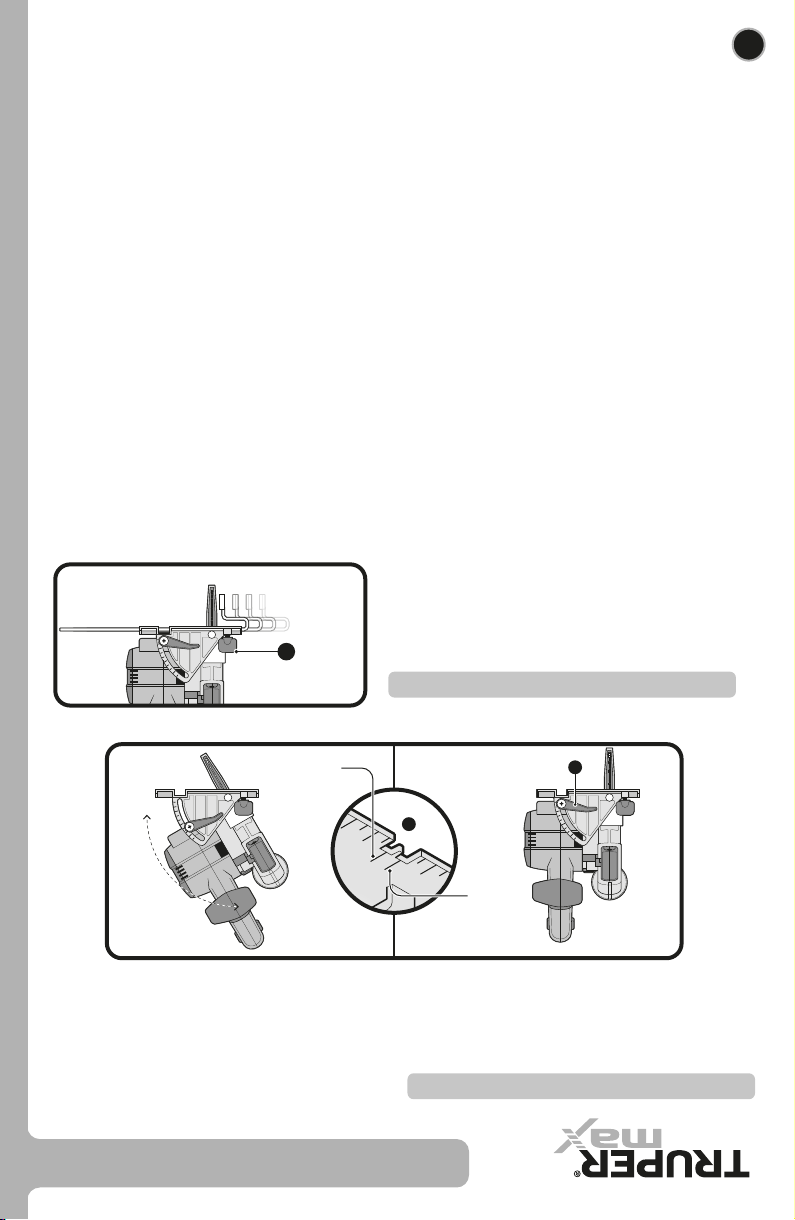

NOTE: Depending on the conditions of use and ambient

temperature, the indication may differ slightly from the

actual capacity.

1. Plug the charger plug into a 127 V~ socket.

The green light of the charging indicator will turn on.

2. Insert the battery into the charger by sliding it as shown

in the picture. The green light will turn off and the red

light should turn on, indicating that charging has started.

• When the battery is fully charged, the green light will

turn on and the red light will turn off.

• Disconnect the charger from the power supply when

charging is complete.

• If the red light flashes, it is a sign that the battery has a delay caused by the heat; wait until the battery temperature is in

the proper range to be able to charge.

• The red light remains on exceeding the recommended charging time or if the red and green light flash alternately it is a

sign that the battery is defective; you must replace it or use a Authorized Service Center.

• Once the battery is charged, insert it into the receptacle

on the back of the motor housing.

• Slide the battery into the receptacle until you hear a click

to make sure it is properly seated.

• To remove the battery, press the latch (A) and slide the

battery out.

• To make sure the battery is charged, press the indicator

button (B). The color of the light indicates the charge level.

Batteries

Remaining battery capacity

1

2

Indicator

lamp

Illuminated

OFF

Green

Orange

Red

51% to 100%

Orange

Red

26% to 50%

Red

10% to 25%

Important load considerations

• Longer life and better performance can be obtained if the

battery unit is charged in room temperature between 5ºC

and 45ºC. Allow a hot battery pack to cool before charging.

• The charger and battery unit may heat up slightly during

the charging process. This is normal and does not represent

any problem. To make it easier to cool the battery unit after

use, avoid placing the charger or battery unit in a warm

place, such as a metal shed or trailer without thermal

insulation.

• The battery unit should be recharged when it is not able to

produce enough power for jobs that were easily performed

before. DO NOT CONTINUE to use it under these

circumstances. Follow the charging procedure.

• The best storage place is one that is cool and dry, away

from direct sunlight and excess heat or cold.

• For optimal results during extended storage times, it is

recommended to store the fully charged battery unit in a

cool, dry place outside the charger.

• The tool is equipped with a system that

automatically stops the tool to prolong both its useful life and

that of the batteries, this happens in the following cases:

Overload. When the tool is forced, the battery consumes

abnormally high current levels. Suspend overexertion work

and turn the tool back on.

Overheating. Let the tool and battery cool before turning it

back on.

Over-discharge. The battery level is low. In this case,

remove the battery from the tool and charge it.

Tool/battery protection system

B

ENGLISH

CAUTION

Battery failures

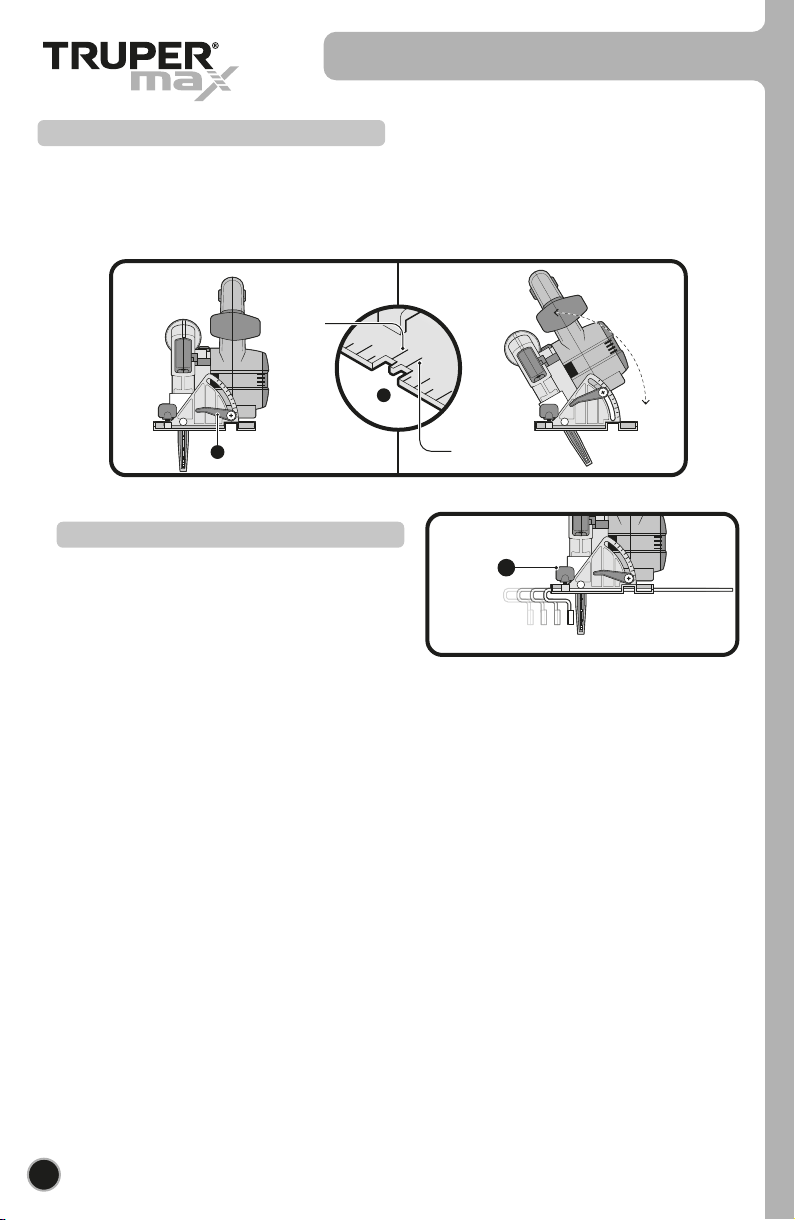

Cutting depth adjustment

1. Loosen the depth of cut lock lever (C).

2. With the base stationary, raise the housing until the blade protrudes from the base to the desired depth. Use the depth

guide (D) as a reference.

3. Tighten the depth of cut lock lever to prevent the housing from moving during cutting.

4. The depth of cut can be up to 2”.

• The cutting depth must be equal to the thickness of the workpiece or protrude from the workpiece by a

maximum of one tooth of the blade to avoid accidents.

Base

• Press the safety catch (A) to release the trigger switch.

• Press the switch (B) to start the disc spinning, the disc will

reach its maximum speed.

• To stop the disc, release the switch.

The circular saw is a multi-purpose tool for cutting soft or hard wood, chipboard, plywood, resopal-coated materials, etc.

This tool is not designed for cutting metal, masonry, concrete or brick materials. Use extreme caution

when cutting wet, pressure treated or knotty wood. Maintain a smooth, flat tool feed without reducing blade speed to

avoid overheating the blade tips.

C

D

A

B

Start up

9

Preparation

Start up

• Take the dust nozzle (A)and place it on the inside of the

sawdust ejector (B).

• Rotate the nozzle to the preferred direction to dislodge

the sawdust.

Dust nozzle assembly

A

B

ENGLISH

CAUTION

CAUTION

• Loosen the cutting angle adjustment knobs (D).

• With the base stationary, rotate the housing until the blade is at the desired angle.

• Tighten the cutting angle adjustment knobs to prevent the housing from moving during cutting.

• The tool can make cuts from 0° to 45°.

• The cutting line marked on the graduated scale on the base (E) changes depending on the angle set.

D

E

• To keep the width of the workpiece fixed when making cuts,

use the cutting guide.

• To adjust the width, loosen the knob (E) and move the

cutting guide to the desired position.

• This action improves the quality of the cut and reduces the

possibility of deformation of the cut-off disc.

E

10

Start up

Cutting angle adjustment

Cutting line adjustment

Cutting

line at 0°

Cutting

line at 45°

ENGLISH

They contain chemicals that can damage or destroy the

plastic.

• When using pressurized air to clean

particles ALWAYS wear safety glasses with side shields or

face shield, in case of high dust ejection, also wear a dust

mask.

It is not recommended to use this tool for extensive work

on fiberglass, plasterboard, drywall or plaster materials,

since its particles are highly abrasive to the components

of any power tool. In case of using the tool in any of these

materials it is very important that it is frequently cleaned

with pressurized air to increase the useful life of the tool.

11

•Cleaning, maintenance; method to keep tools sharp and

regular lubrication.

• Remember to remove the batteries from the tool before

cleaning or servicing.

• All tool components are an important part of the

insulation system and should only be serviced by a

Authorized Service Center.

• When servicing the tool, ALWAYS ask for

original spare parts.

• When cleaning plastic parts, avoid using solvents. Most

plastic materials are susceptible to damage from various

types of commercial solvents.

• To clean dirt, carbon or dust use a clean cloth or

pressurized air.

NEVER bring the tool into contact with

brake oil, petroleum-based products, penetrating oils, etc.

Once the cut-off disc wears out, they should be replaced

immediately.

The cut-off disc specified for this tool

are 6-1/2”. Do not use any other size. Failure to do so

may result in an accident or damage to the tool and void

your warranty.

• Do not use damaged or oversized washers and bolts.

The included bolts and washers are specially designed to

ensure proper operation and safety when using the tool.

• Use cut-off discs with holes of the correct size and shape

for the shaft. Otherwise, they may rotate in an eccentric

motion causing loss of control.

1. Remove the battery from the tool and set the cutting

depth to minimum, do not use abrasive discs (see page

10).

2. Fully open the retractable guard (F) and hold it in that

position.

3. Place the wrench (G) on the hex bolt (H) and press

and hold the spindle lock knob ( I). Turn the bolt

counterclockwise. The cutting disc will rotate at the same

time as the bolt, until the shaft is fully locked when the

locking knob is fully engaged.

4. Loosen and remove the bolt, remove the outer washer

(J), disc and inner washer (JI). Release the shaft locking

knob.

5. Place the inner washer (JI) and the new cut-off disc

(K). Make sure that the direction of the arrow printed on

the disc matches that of the arrow engraved on the tool

guard.

6. Place the washer (J) on the disc and insert the

hexagonal screw (H).

7. Press the shaft lock button again. Tighten the hex bolt

with the wrench (G) clockwise. Once the disc is secured,

release the spindle lock button.

Only clean, sharp and properly installed discs

can guarantee a good cut. Keep extra cutting

discs on hand so that sharp discs are always

available.

K

J

JI

H

I

G

F

Maintenance

Change of the cut-off disc

General maintenance

ENGLISH

WARNING

WARNING

WARNING

Notes

12 ENGLISH

13

ENGLISH

Authorized Service Centers

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

MEXICO

CITY

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

In the event of any problem contacting a Authorized Service Center, please see our

webpage www.truper.com to get an updated list, or call our toll-free numbers 800 690-6990 or 800 018-7873

to get information about the nearest Service Center.

14 www.truper.com

08-2022

102480 MAX-20SC

ENGLISH

Warranty

policy

3

YEARS

Code Model Brand

Stamp of the business. Delivery date:

Warranty. Duration: 3 years. Coverage: parts, components and workmanship against manufacturing or

operating defects, except if used under conditions other than normal; when it was not operated in

accordance with the instructive; was altered or repaired by personnel not authorized by .

To make the warranty valid, present the product, stamped policy or invoice or receipt or voucher, in the

establishment where you bought it or in Corregidora 22, Centro, Cuauhtémoc, CDMX, 06060, where you

can also purchase parts, components, consumables and accessories. It includes the costs of transportation of

the product that derive from its fulfillment of its service network. Phone number 800-018-7873.

Made in China. Imported by Truper, S.A. de C.V. Parque Industrial 1, Parque Industrial Jilotepec, Jilotepec,

Edo. de Méx. C.P. 54257, Phone number 761 782 9100.

14 ESPAÑOL www.truper.com

08-2022

102480 MAX-20SC

Póliza de

Garantía

Código Modelo Marca

3

AÑOS

Sello del establecimiento comercial. Fecha de entrega:

Garantía. Duración: 3 años. Cobertura: piezas, componentes y mano de obra contra defectos de fabricación

o funcionamiento, excepto si se usó en condiciones distintas a las normales; cuando no fue operado

conforme instructivo; fue alterado o reparado por personal no autorizado por Truper®. Para hacer efectiva la

garantía presente el producto, póliza sellada o factura o recibo o comprobante, en el establecimiento donde

lo compró o en Corregidora 22, Centro, Cuauhtémoc, CDMX, 06060, donde también podrá adquirir partes,

componentes, consumibles y accesorios. Incluye los gastos de transportación del producto que deriven de su

cumplimiento de su red de servicio. Tel. 800-018-7873. Made in/Hecho en China. Importador Truper, S.A. de

C.V. Parque Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx. C.P. 54257, Tel. 761 782 9100.

Centros de Servicio Autorizados

13

ESPAÑOL

En caso de tener algún problema para contactar un Centro de Servicio Autorizado

consulte nuestra página www.truper.com donde obtendrá un listado actualizado, o llame al:

800 690-6990 ó800 018-7873 donde le informarán cuál es el Centro de Servicio más cercano.

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

CIUDAD DE

MÉXICO

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

Notas

12 ESPAÑOL

11

ESPAÑOL

• Limpieza, mantenimiento; método para mantener las

herramientas afiladas y lubricación regulares.

• Recuerde retirar las baterías de la herramienta antes de

limpiarla o darle mantenimiento.

• Todos los componentes de la herramienta son parte

importante del sistema de aislamiento y solamente se les

debe dar mantenimiento en un Centro de Servicio

Autorizado .

• Cuando mande la herramienta a mantenimiento, pida

SIEMPRE refacciones originales .

• Cuando limpie las partes de plástico, evite usar

solventes. La mayoría de los materiales plásticos son

susceptibles a dañarse con varios tipos de solventes

comerciales.

• Para limpiar suciedad, carbón o polvo use un trapo

limpio o aire a presión.

ADVERTENCIA

ADVERTENCIA

Una vez que los discos de corte se desgasten deben

reemplazarse de inmediato.

Los discos de corte especificados

para esta herramienta son de 165 mm (6-1/2”). No use

otra medida. De lo contrario se expone a accidentes o

daños a la herramienta invalidando su garantía.

• No utilice arandelas y pernos dañados o de otra

medida. Los pernos y arandelas incluidos están diseñados

especialmente para asegurar un buen funcionamiento y

brindar seguridad al usar la herramienta.

• Utilice discos de corte con orificios de la medida y forma

correcta para el eje. De lo contrario pueden girar con un

movimiento excéntrico provocando pérdida de control.

1. Retire la batería de la herramienta y ajuste la

profundidad de corte al mínimo, no utilizar discos

abrasivos. (consulte la página 10).

2. Abra por completo la guarda retráctil (F) y manténgala

en esa posición.

3. Coloque la llave (G) en el perno hexagonal (H) y

mantenga presionado el botón de bloqueo del eje ( I).

Gire el perno en sentido contrario a las manecillas del

reloj. El disco de corte girará al mismo tiempo que el

perno, hasta que el eje sea totalmente bloqueado cuando

el botón de bloqueo calce por completo.

4. Afloje y retire el perno, retire la arandela externa (J), el

disco y la arandela interna (JI). Suelte el botón de

bloqueo del eje.

5. Coloque la arandela interna (JI) y el disco de corte

nuevo (K). Asegúrese que la dirección de la flecha

impresa en el disco coincida con la de la flecha grabada

en la guarda de la herramienta.

6. Coloque la arandela (J) en el disco e inserte el tornillo

hexagonal (H).

7. Presione de nuevo el botón de bloqueo del eje. Apriete

el perno hexagonal con la llave (G) en el sentido de las

manecillas del reloj: Una vez que el disco esté asegurado,

suelte el botón de bloqueo del eje.

Sólo discos limpios, afilados y bien instalados

pueden garantizar un buen corte. Tenga a la

mano discos de corte extra para tener discos

afilados siempre disponibles.

K

J

JI

H

I

G

F

ADVERTENCIA

Mantenimiento

Cambio del disco de corte

Mantenimiento general NUNCA se debe poner la

herramienta en contacto con aceite para frenos,

productos con base de petróleo, aceites penetrantes, etc.

Contienen substancias químicas que pueden dañar o

destruir el plástico.

Cuando use aire a presión para

limpiar partículas use SIEMPRE lentes de seguridad con

protectores laterales o careta, en caso de expulsar mucho

polvo, use también una mascarilla contra polvo.

No es recomendable que esta herramienta se use para

trabajos extensos en materiales de fibra de vidrio, cartón

de yeso, emplastecidos o yeso, ya que sus partículas son

altamente abrasivas para los componentes de cualquier

herramienta eléctrica. En caso de usar la herramienta en

alguno de esos materiales es muy importante que se

limpie frecuentemente con aire a presión para aumentar

la vida útil de la herramienta.

• Afloje las perillas de ajuste del ángulo de corte (D).

• Con la base fija, gire la carcasa hasta que el disco tenga el ángulo deseado.

• Apriete las perillas de ajuste del ángulo de corte para evitar que la carcasa se mueva durante el corte.

• La herramienta puede hacer cortes de 0° hasta 45°.

• La línea de corte marcada en la escala graduada de la base (E) cambia dependiendo del ángulo configurado.

D

E

• Para mantener fijo el ancho de la pieza de trabajo al realizar

los cortes utilice la guía de corte.

• Para ajustar el ancho afloje la perilla (E) y recorra la guía de

corte a la posición deseada.

• Realizar esta acción mejora la calidad del corte y reduce la

posibilidad de la deformación del disco de corte.

E

10

Puesta en marcha

ESPAÑOL

Ajuste del ángulo de corte

Ajuste de la guía de corte

Línea de

corte a 0°

Línea de

corte a 45°

Ajuste de la profundidad de corte

1. Afloje la palanca de bloqueo de profundidad de corte (C).

2. Con la base fija, levante la carcasa hasta que el disco sobresalga de la base a la profundidad deseada. Utilice la guía de

profundidad (D) como referencia.

3. Apriete la palanca de bloqueo de profundidad de corte para evitar que la carcasa se mueva durante el corte.

4. La profundidad de corte puede ser de hasta 55 mm

• La profundidad de corte debe ser igual al grosor de la pieza de trabajo o sobresalir de esta la medida

de un diente del disco como máximo para evitar accidentes.

Base

• Presione el seguro (A) para liberar el gatillo interruptor.

• Presione el interruptor (B) para que el disco comience a girar,

el disco alcanzará su máxima velocidad.

• Para detener el disco suelte el interruptor.

La sierra circular es una herramienta multiuso para cortar madera suave o dura, aglomerado, contrachapado, materiales

con cubierta de resopal, etc.

Esta herramienta no está diseñada para cortar metal, ni materiales de mampostería, cemento o ladrillo.

Proceda con extrema precaución al cortar madera húmeda, tratada a presión o con nudos. Mantenga un avance plano y

suave de la herramienta sin reducir la velocidad del disco para evitar el sobrecalentamiento de las puntas del mismo.

C

D

A

B

Encendido

ATENCIÓN

ATENCIÓN

9

Preparación

Puesta en marcha

ESPAÑOL

• Tome la boquilla para polvo (A)y coloquela por el

interior del expulsor de aserrín (B).

• Gire la boquilla a la dirección que prefiera para desalojar

el aserrín.

Ensamble de boquilla para polvo

A

B

This manual suits for next models

1

Table of contents

Other Truper Cordless Saw manuals

Popular Cordless Saw manuals by other brands

Ryobi

Ryobi RWSL1801 Original instructions

HIKOKI

HIKOKI C 3605DA Handling instructions

Hitachi

Hitachi C 18DBAL Safety instructions and instruction manual

MOKENEYE

MOKENEYE RS01Z owner's manual

Parkside Performance

Parkside Performance PHKSAP 20-Li A1 Operation and safety notes

Makita

Makita JR180DWA instruction manual