10 ENGLISH

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool.Failuretofollowallinstructions

listedbelowmayresultinelectricshock,reand/or

seriousinjury.

Save all warnings and instruc-

tions for future reference.

Theterm“powertool”inthewarningsreferstoyour

mains-operated(corded)powertoolorbattery-operated

(cordless)powertool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

darkareasinviteaccidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust.Powertoolscreatesparks

whichmayignitethedustorfumes.

3. Keep children and bystanders away while

operating a power tool.Distractionscancause

youtolosecontrol.

Electrical safety

1. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodiedplugsandmatchingoutletswill

reduceriskofelectricshock.

2. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.Thereisanincreasedriskofelec-

tricshockifyourbodyisearthedorgrounded.

3. Do not expose power tools to rain or wet con-

ditions.Waterenteringapowertoolwillincrease

theriskofelectricshock.

4. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts.Damagedorentangledcords

increasetheriskofelectricshock.

5. When operating a power tool outdoors, use an

extension cord suitable for outdoor use.Useof

acordsuitableforoutdoorusereducestheriskof

electricshock.

6. If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.UseofanRCDreduces

theriskofelectricshock.

7. Power tools can produce electromagnetic

elds (EMF) that are not harmful to the user.

However,usersofpacemakersandothersimilar

medicaldevicesshouldcontactthemakeroftheir

deviceand/ordoctorforadvicebeforeoperating

this power tool.

Personal safety

1. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or med-

ication.Amomentofinattentionwhileoperating

powertoolsmayresultinseriouspersonalinjury.

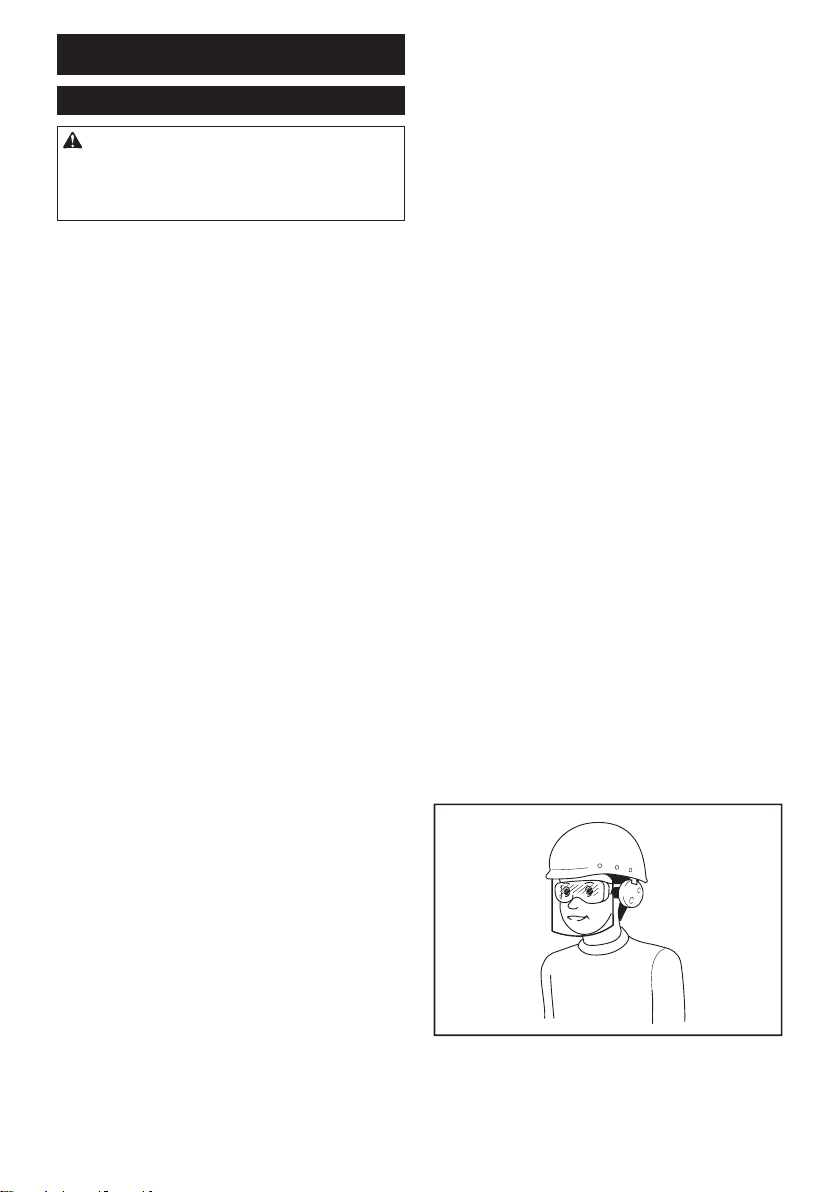

2. Use personal protective equipment. Always

wear eye protection.Protectiveequipmentsuch

asadustmask,non-skidsafetyshoes,hardhator

hearingprotectionusedforappropriateconditions

willreducepersonalinjuries.

3. Prevent unintentional starting. Ensure the

switch is in the o-position before connecting

to power source and/or battery pack, picking

up or carrying the tool.Carryingpowertoolswith

yourngerontheswitchorenergisingpowertools

thathavetheswitchoninvitesaccidents.

4. Remove any adjusting key or wrench before

turning the power tool on.Awrenchorakeyleft

attachedtoarotatingpartofthepowertoolmay

resultinpersonalinjury.

5. Do not overreach. Keep proper footing and

balance at all times.Thisenablesbettercontrol

ofthepowertoolinunexpectedsituations.

6. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away

from moving parts.Looseclothes,jewelleryor

longhaircanbecaughtinmovingparts.

7. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.Useof

dustcollectioncanreducedust-relatedhazards.

8. Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles.Acarelessaction

cancausesevereinjurywithinafractionofa

second.

9. Always wear protective goggles to protect

your eyes from injury when using power tools.

The goggles must comply with ANSI Z87.1 in

the USA, EN 166 in Europe, or AS/NZS 1336

in Australia/New Zealand. In Australia/New

Zealand, it is legally required to wear a face

shield to protect your face, too.

It is an employer's responsibility to enforce

the use of appropriate safety protective equip-

ments by the tool operators and by other per-

sons in the immediate working area.