15

GAUI TAI SHIH HOBBY CORPORATION

GAUI TAI SHIH HOBBY CORPORATION

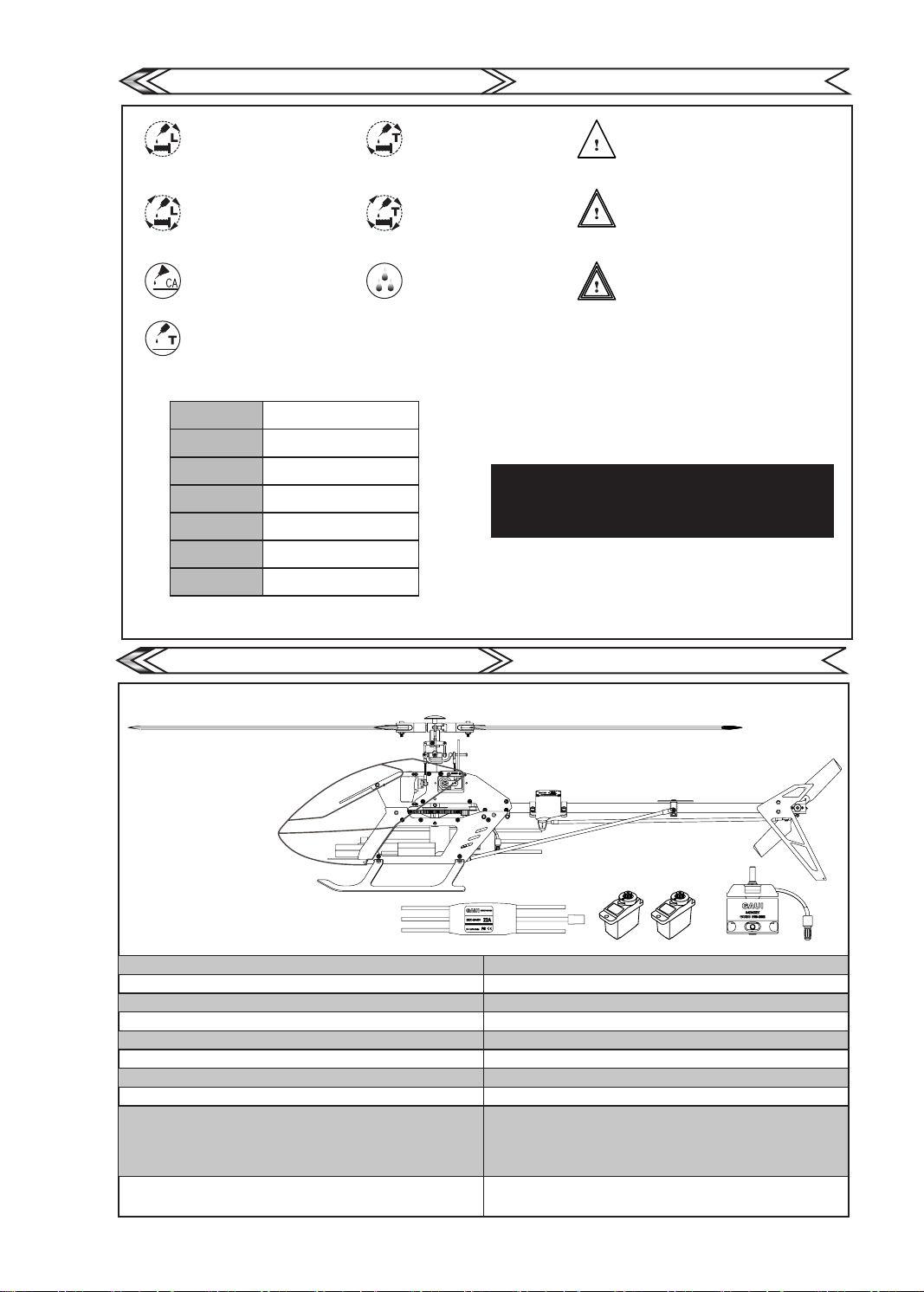

1.油門搖桿上推,確認連接3顆伺服機的十字盤是否同時向上移動,若無同時向上移動,請至搖控器選單設定【伺服機正反向設定】選項更改動作相反的

伺服機使十字盤同時向上移動。

2.向右撥動副翼搖桿,確認十字盤是否向右傾斜,若無向右傾斜,請至遙控器選單中SWASIA選項內的AIL(副翼)的%數更改為負值。

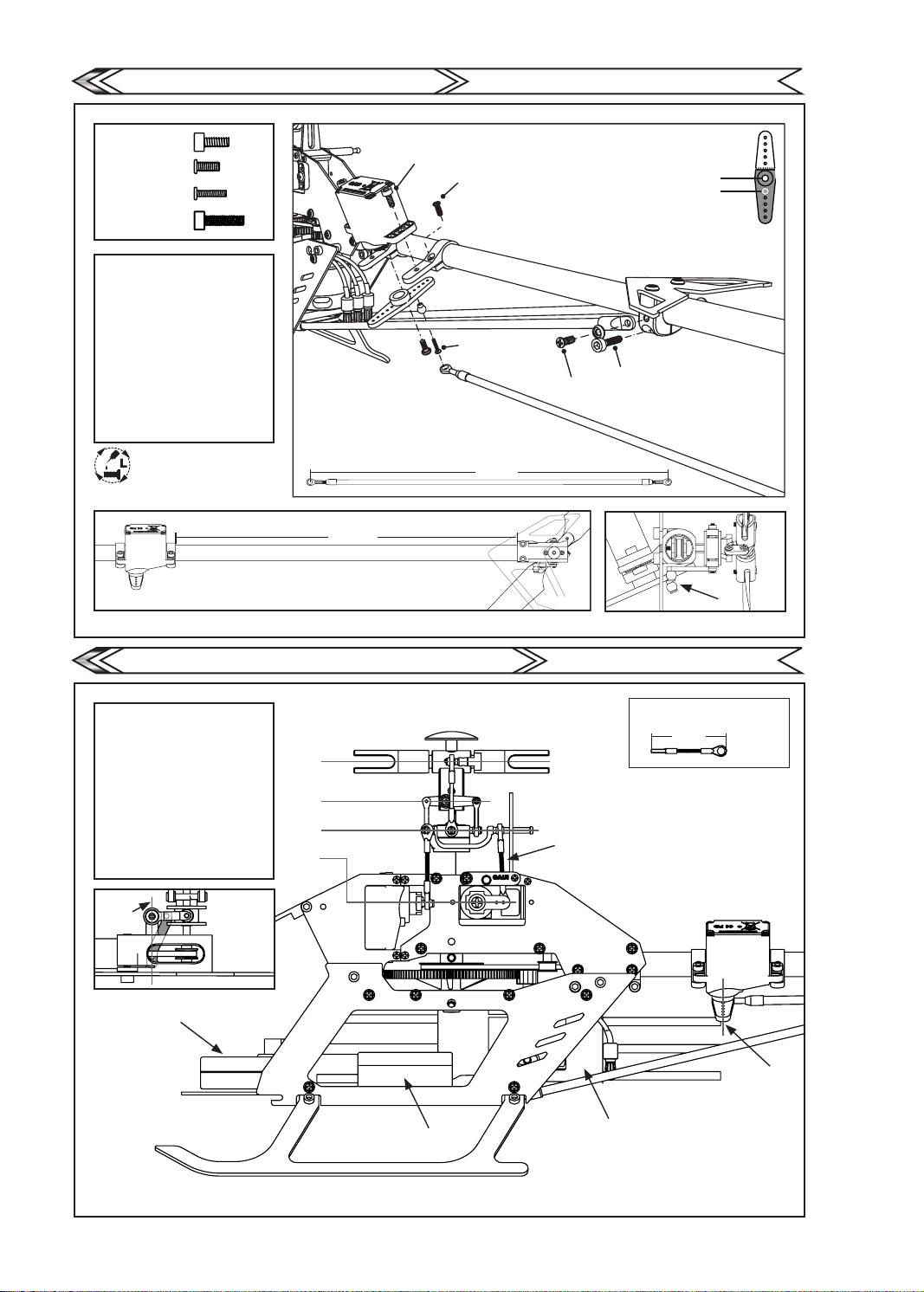

◎適當的增減數值可調整AILE動作量大小。

3.向前撥動升降搖桿,確認十字盤是否向前傾斜,若無向前傾斜,請至遙控器選單中SWASH選項內的【ELEV】升降的%數更改為負值。

◎適當的增減數值可調整ELEV動作量大小。

4.至遙控器選單中的【伺服機微調選項的 ”Subtrim ”功能】將十字盤3顆伺服機擺臂微調至垂直90度。

5.請將油門搖桿撥至中立,以螺距尺測量主旋翼的度數是否為0度。 若不是0度,請調整連桿長度使2支主旋翼均為0度。

6.調整3顆伺服機連桿長度至十字盤、相位器、皆水平。

7.請將油門搖桿向上撥至最高,測量主旋翼最大【正】螺距度數,應為+11至+13度。若不是,請調整遙控器選單中【SWASH】內的【PIT】數值。

請將油門搖桿向下撥至最低,測量主旋翼最大【負】螺距度數,應為-11至-13度。【正】【負】螺距度數需一樣若不是,請調整遙控器選單中的

【伺服機大小行程量】數值,三顆伺服機需同時增加或減少至測量結果與正螺距度數相同。

◎請、上、下、左、右、前、後撥動搖桿,查看十字盤行程動作是否有干涉。若有干涉請至SWASH減少AIL、ELE數值。

8.請將油門搖桿撥至最低點,測量主旋翼【負】螺距度數約在-2至-3度,並請進入遙控器選單中【PITCH曲線設定】選項,至【NORM模式】中增加數值最低

的數值,使主旋翼【負】螺距度數約在-2至-3度。【設定完的數值大約在40%至45%之間】至曲線設定中間的數值,增加數值至55至60%

請至遙控器設定選單中【陀螺儀感度GYRO】至鎖定狀態,向右撥動尾舵搖桿,尾軸滑套須向尾齒箱移動,若不是請調整遙控器選單中

【伺服機正反向設定】選項中【RUDD】的正反向。

設定尾舵左右最大行程量,左右最大行程量保持與尾齒箱及尾旋翼頭 0.5mm 距離不干涉為主。

(各廠牌陀螺儀行程量設定方法不同請參照陀螺儀說明書作設定)。

1.Move the throttle stick upward, check and make sure 3 linkages of swashplate all moved upward, if any one of the CCPM servos does not push up the

swash plate. Go to the transmitter setting to set Norm/Reverse to set the correct movement.

2.Move the AIL stick rightward, check and make sure the swashplate tilt to right side, if it tilt to the opposite side, set the “AIL %” in transmitter function “

Swash Mix ” to Negative value to make the swashplate move as your control. ( Ex. Set the “AIL +50%” to “AIL -50%” )

* Increase or decrease the “AIL %” to get the proper response of the AIL control.

3.Move the ELE stick forward, check and make sure the swashplate tilt forward, if it tilt to the opposite side, set the “ELE %” in transmitter function “

Swash Mix ” to Negative value to make the swashplate move as your control. ( Ex. Set the “ELE +50%” to “ELE -50%” )

* Increase or decrease the “ELE %” to get the proper response of the ELE control.

4.Set the transmitter function “ Subtrim ” to adjust the neutral position of CCPM servos, the servos at neutral should have the servo arms at level position,

and each arm should be perpendicular to the control linkage.

5.Move the throttle stick to the neutral (middle at 50% value), use a pitch gauge to check the pitch of both blades, adjust the linkages to make sure they

are all in 0 degrees of both blades.

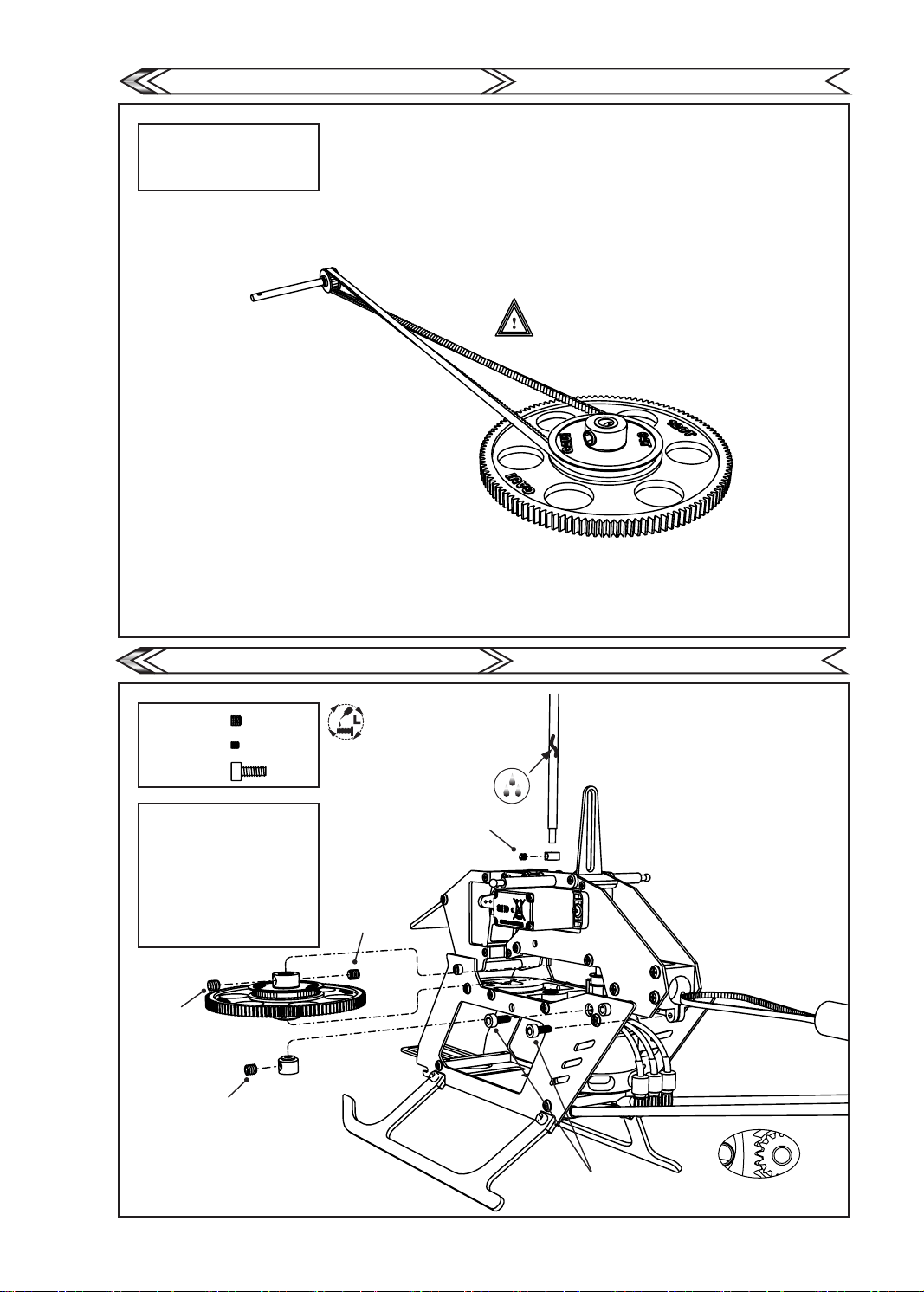

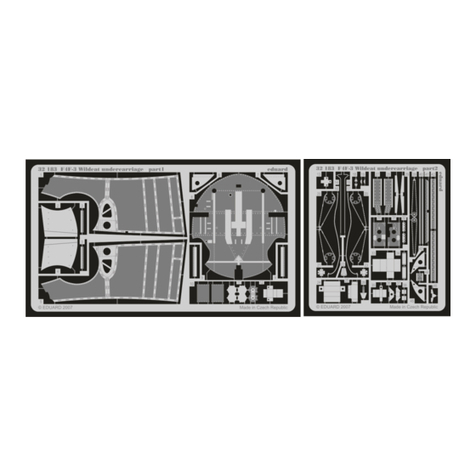

6.The Servo Horns / Swash Plate / Washout Arms / should be set to be horizontally leveled as shown in gure.

7.Move the throttle stick to the top position, the maximum positive pitch should be around +11 to +13 degrees, If is is not the case, set the proper "Pitch%"

in the transmitter function "Swash Mix". Move the throttle stick down to the bottom position, the maximum negative pitch should be around -11 to -13

degrees, set the transmitter function “ Travel Volume / End Point “ properly to adjust to recommended negative pitch. IMPORTANT :

The increase/decrease value of the transmitter function “ Travel Volume / End Point “ of each CCPM servo should be the same in this step.

* Before starting step 8, make sure to move the control sticks to check the movement of the swashplate and set the proper “AIL % and ELE %”

in transmitter function “ Swash Mix ” to make sure each mechanism does not interfered with each other.

8.Move the throttle stick to the lowest position, set the proper “ Pitch Curve % ” in transmitter function “ Normal Mode ” to make the

negative collective pitcht to be -2 or -3 degrees at the lowest throttle stick position( it is about 40% to 45% at the 1st pitch curve point at normal mode).

The value of the middle point of pitch curve in normal mode is about 55% to 60%.

1.Set the gyro to heading-hold mode, move the rudder stick rightward and make sure the tail pitch slider move toward the tail gear case, if it does not,

switch the transmitter function “ Servo Reverse ” of “ Rudder” to the opposite position.

2.Set the “ Limit ” on your gyro properly to have the maximum travel of tail pitch control, make sure the tail pitch slider at its maximum travel to left and

right should not touch the Tail Gear Case and Tail Hub, there should be a distance for 0.5mm( or less ) at each side.

Please follow your own gyro's instruction manual for adjustments.

機構檢查-2

機構檢查-3

Check - 2

Check - 3