roundhouse HBK18 Katie R/C Fittings Only Kit User manual

Other roundhouse Toy manuals

roundhouse

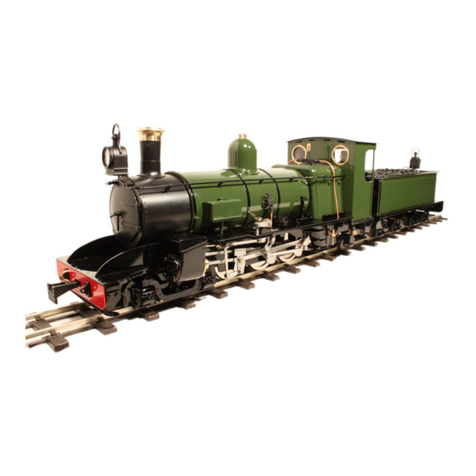

roundhouse Darjeeling C Class User guide

roundhouse

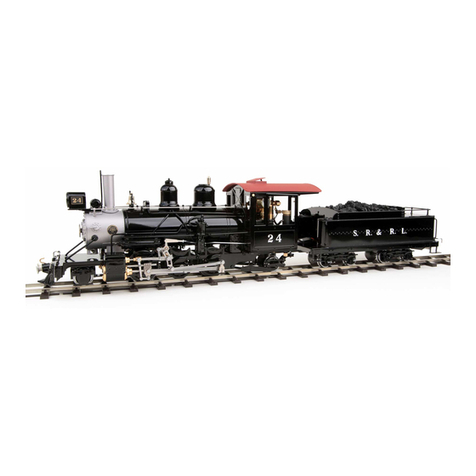

roundhouse SR&RL 24 User guide

roundhouse

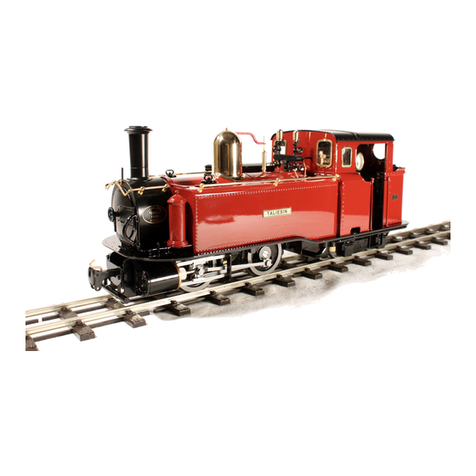

roundhouse TALIESIN User guide

roundhouse

roundhouse Linda User guide

roundhouse

roundhouse ATLANTIC User guide

roundhouse

roundhouse MILLIE User guide

roundhouse

roundhouse Little John User guide

roundhouse

roundhouse HBK8 User manual

roundhouse

roundhouse Vale of Rheidol 2-6-2 User guide

roundhouse

roundhouse FOWLER User guide

roundhouse

roundhouse TOM ROLT User guide

roundhouse

roundhouse SAMMIE & BERTIE User guide

roundhouse

roundhouse WILLIAM User guide

roundhouse

roundhouse Beddgelert 0-6-4 User guide

roundhouse

roundhouse LEEK & MANIFOLD User guide

roundhouse

roundhouse Katie User guide

roundhouse

roundhouse Carrie User guide

roundhouse

roundhouse RUSSELL User guide

roundhouse

roundhouse Mildred User guide

roundhouse

roundhouse Criccieth Castle User guide