TSL MDU12-PMi User manual

MAINS DISTRIBUTION UNIT

MDU12-PMi

Television Systems Limited.

Vanwall Road, Maidenhead, Berkshire, SL6 4UB

Telephone +44 (0)1628 676200, FAX +44 (0)1628 676299

MDU12-PMi Manual 2 Issue 4

This Page is Blank

MDU12-PMi Manual 3 Issue 4

Contents

1.0 Installation.

2.0 Description

3.0 Introduction

4.0 Operation

4.1 The Home Screen

4.2 The Output Screen

4.3 The System Screen

4.4 The SNMP Screen

4.4.1 SNMP Alarms

4.4.2 Email Alerts

5.0 Initial Configuration

6.0 Pin-outs

7.0 Response Times

8.0 Temperature Indications

9.0 Specifications.

Appendix 1

MIB File information

MDU12-PMi Manual 4 Issue 4

This Page is Blank

MDU12-PMi Manual 5 Issue 4

SAFETY

1.0 Installation.

Unless otherwise stated TSL equipment may be installed at any angle or position within an operating

temperature range of 5°~ 30°C .

The RJ45 connector is for use only with an Ethernet 10/100 system.

All TSL equipment conforms to the EC Low Voltage Directive:

EC Low Voltage Directive (73/23/EEC)(OJ L76 26.3.73)(LVD).

Amendment: (93/68/EEC) (OJ L220 30.8.93).

CAUTION:

Always disconnect equipment connected to a powered MDU before performing any maintenance.

Potentially hazardous voltages are present even after the operation or removal of a fuse, unless the front

panel circuit breaker is set to OFF.

Earthing/Grounding

In all cases, the frame of the equipment must be earthed on installation. Connection to an earthed strip

running the length of the frame is ideal.

The earth pin on the mains inlet connector is connected to the metal frame of the equipment, to 0 volts on the

internal DC PSU and to signal ground, unless otherwise stated. All metal panels are bonded together. Rack

mounted equipment must be earthed (grounded).

Mounting

Careful consideration of the equipment location and mounting in racks must be made. In particular,

consideration must be given to the stability of free-standing racks by mounting heavy equipment low in the

rack. The rear of the unit should be supported in the rack.

Power

This equipment is designed for installation in any position in a rack.

Consideration must be given to the supply circuit loading and switch on/fault surges that will affect overcurrent

protection trips and switches etc.

Check that the fuse rating is correct for the local power (mains) supply. Replacement fuses must be of the

same rating and type for continued protection against fire risk.

The equipment rating is shown on the rear panel.

No power supply cord is provided with this equipment but the inlet connector is.

Do not switch on until all connections are made.

Ventilation

Due consideration for cooling requirements must be given when mounting the equipment. The equipment

contains an internal temperature sensor.

General

If equipment is installed in a closed unit, consideration must be given to providing forced air cooling in order

that the maximum recommended temperature is not exceeded.

MDU12-PMi Manual 6 Issue 4

WARRANTY, MAINTENANCE AND REPAIR

All TSL equipment is guaranteed for one year from the date of delivery to the customer’s premises. If the

equipment is to be stored for a significant period, please contact TSL concerning a possible extended

warranty period.

Failure during warranty

If any TSL product should fail or become faulty within the warranty period, first please check the PSU fuses.

All maintenance work must be carried out by trained and competent personnel.

If equipment has to be returned to TSL for repair or re-alignment, please observe the following overleaf:

Technical support information

E-Mail address: support@televisionsystems.ltd.uk

Telephone Support Number for the UK and Europe: +44 (0) 1628 670000

Telephone Support Number for the USA only: 1 877 591 2108

MDU12-PMi Manual 7 Issue 4

TSL Returns Procedure

Please telephone +44 (0)1628 676200 (Fax: +44 (0)1682 676299) and ask for Sales who will provide a

Returns Number. This will enable us to track the unit effectively and will provide some information prior to the

unit arriving.

For each item, this unique Returns Number must be included with the Fault Report sent with the unit.

A contact name and telephone number are also required with the Fault Report sent with the unit.

Fault report details required.

•Company:

•Name:

•Address:

•Contact Name:

•Telephone No:

•Returns Number:

•Symptoms of the fault (to include switch setting positions, input signals etc):

Packing

Please ensure that the unit is well packed as all mechanical damage is chargeable. TSL recommends that

you insure your equipment for transit damage.

The original packaging, when available, should always be used when returning equipment..

If returned equipment is received in a damaged condition, the damage should be reported both to TSL

and the carrier immediately.

YEAR 2000 CONFORMITY REQUIREMENTS

This product conforms to the following rules:

Rule 1 No value for the current date will cause any interruption in operation.

Rule 2 Date based functionality will behave consistently for dates prior to, during and after the Year

2000.

Rule 3 In all interfaces and data storage, the century in any date is specified either explicitly or by

unambiguous algorithms or by inferencing rules.

Rule 4 The Year 2000 is recognised as a leap year.

MDU12-PMi Manual 8 Issue 4

EC DECLARATION OF CONFORMITY

Application of Council Directives Nos:

EC Low Voltage Directive (73/23/EEC)(OJ L76 26.3.73)(LVD).

Amendment: (93/68/EEC) (OJ L220 30.8.93).

Conformity Standards Declared:

EN 60950

EMC Directive: 89/336/EEC, Amended 92/31/EEC.

Conformity Standards Declared:

EN 50081-1, EN 50082-1

Manufacturer’s Name: Television Systems Ltd

Manufacturer’s Address: Vanwall Road

Maidenhead SL6 4UB

England

United Kingdom

Type of Equipment: Mains Distribution Unit

Model No: MDU12-PMi

Part Number: TSLP- MDU12-PMi

Date CE Mark Affixed: 04

I, the undersigned, declare that the equipment specified above conforms to the quoted Directives and

Standards.

Place: Maidenhead, England Signature:

Date: TBA Print: A J Mackinder

Position: PRODUCT MANAGER

MDU12-PMi Manual 9 Issue 4

Power Manager Mains Distribution Unit MDU12-PMi

0

I

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

2.0 Description

Features:

•19" 1RU.

•16 Amp Double Pole Breaker / Switch.

•12 Fused IEC outlets.

•LED Indication

oPower - Blue - Power applied to the unit.

oLAN - Flashing Amber LAN connected & active

oOutput LEDs 1-12

oGreen - Circuit on and fuse OK

oAmber – Circuit off and fuse OK.

oRed – Circuit off and fuse failed.

oOff – Circuit on but fuse has failed

•Serial D9 & RJ11 set up ports.

•Cable tie bar.

•Ethernet SNMP status reporting and Email alerts for:

oEach mains circuit.

o16 Opto-isolated GPI inputs via D37 connector.

oInput mains failure.

oAccess to unit configuration and SNMP data via secure web browser interface.

•Relay controlled outputs with delayed power up.

•Latching relays are fitted to reduce internal heat dissipation as they draw no current once set.

•Outputs can be controlled via SNMP, or the secure web browser interface (which also provides

SNMP control lockout per output if required).

•Start up can be immediate, sequential, or individual delay.

This 1RU unit is designed to fit into a rack in any position. The inlet is via a Neutrik Powercon NAC3FCA

connector. A free cable mounted connector is supplied with each unit.

A 16 A TCB (Thermal Over current Circuit Breaker) is fitted to the input and the rear 12 IEC outlets are via

10A fuses located on the front panel.

The MDU12-PM can accept up to 16 opto isolated GPI alarms on a D37F connector.

There is a rear D9F and front RJ11 port for TCP/IP programming requirements and a standard CAT5 RJ45

Ethernet socket for network connection.

MDU12-PMi Manual 10 Issue 4

3.0 Introduction

The unit presents three control interfaces; web interface (http), SNMP interface, and the serial port on the rear

of the unit.

The default IP address from the factory is 192.168.100.235, with a subnet mask of 255.255.255.0. The serial

port interface can be used to set a new IP configuration and also to set a user name and password (needed to

access the web pages). The power must be cycled after this operation for changes to take effect.

Refer to section 5 p15 for initial configuration settings.

4.0 Operation

Upon connecting the unit to power it will go through a quick boot up procedure with normally the LEDs going

from Red to Amber to Green.

The following login screen will be seen. The unit is now on-line.

The default IP address is 192.168.100.235

The Username is <<root>>

The Password is <<telsys>>

MDU12-PMi Manual 11 Issue 4

Home Screen

This shows the total power consumed by the MDU in Watts, VA, and current in amps with the power factor.

To navigate back to this page from any other, click on the TSL Logo at the top LHS of screen.

MDU12-PMi Manual 12 Issue 4

4.1 The Input Screen

This page allows the user to configure all the GPI alarms for the MDU.

All items in the boxes may be changed for this screen.

The Input names may be changed from the default. Highlight the text & type new text as in any Windows style

application.

The input circuit polarity may be set at either Normally Open, or Normally Closed as indicated.

Press << Update >> when done.

NB Allow the page to refresh before cycling the power to check the settings.

MDU12-PMi Manual 13 Issue 4

4.2 The Output Screen

All items in the boxes may be changed for this screen.

This is showing the individual status. The output names may be changed.

Individual circuits may be remotely switched on or off.

The Delay column figures are enabled by selecting Delay in the Mode check box on the System page.

This ranges from 0-256 seconds.

NB These delays are only effective on initial powering of the unit.

The SNMP Lock box if checked disables remote control access for that channel via SNMP protocol.

Press << Update >> when done.

NB Allow the page to refresh before cycling the power to check the settings.

Front Panel LED Indications:

•LED Indication

oPower - Blue - Power applied to the unit.

oLAN - Flashing Amber LAN connected & active

oOutput LEDs 1-12

oGreen - Circuit on and fuse OK

oAmber – Circuit off and fuse OK.

oRed – Circuit off and fuse failed.

oOff – Circuit on but fuse has failed

MDU12-PMi Manual 14 Issue 4

4.3 The System Screen

All items in the boxes may be changed for this screen.

Mode:

Immediate will switch on all circuits immediately.

Selecting Delay will enable the Delay set in the Outputs screen

Sequential will allow circuit by circuit delay as set in the box.

Lower and upper voltage alarm thresholds can be set from this page. If the input voltage breaks either

threshold then an SNMP alarm, and email alert is generated.

Press <<Update>> when done.

NB Allow the page to refresh before cycling the power to check the settings.

MDU12-PMi Manual 15 Issue 4

4.3 The Status Screen

This page shows the overall alarm status for the unit and refreshes every 10 seconds.

MDU12-PMi Manual 16 Issue 4

4.4 The SNMP Screen

4.4.1 SNMP Alarms

The unit generates SNMP Trap Alarms to the IP address(es) configured in the SNMP setup page when the

following events occur:

1) A GPI input changes state.

2) A fuse fails or is replaced with a good fuse.

3) The internal unit temperature exceeds/drops below the threshold set in the SNMP web page.

4) An output goes Over Current or Under Current as set from the Output page.

5) The input voltage breaks the upper or lower threshold values as set on the system page.

For details of these and other SNMP features, see the supplied SNMP MIB file.

Press << Update >> when done.

NB Allow the page to refresh before cycling the power to check the settings.

4.4.2 Email Alerts

For each of the alarms as detailed above, the unit can send an email alert as well.

Check the box “Enable Email alerts on alarm event:”

Then put in the IP address of the email server, and the email address to where the alert should

be sent.

Your IT manager will be able to help in setting this up.

Press << Update >> when done.

NB Allow the page to refresh before cycling the power to check the settings.

MDU12-PMi Manual 17 Issue 4

5.0 Initial Configuration

Consult your System Administrator for appropriate IP and subnet mask settings.

•Connect a terminal running at 9600, N, 8, 1, Flow control-None; to the serial port.

(HyperTerminal for example).

•Power the unit.

The following ident string will display:

MDU12-PM FVX.XX

After a short delay the unit will then report:-

Ready

To program the parameters:

•Press <<Escape>> and wait for the prompt:

IPAddr?

•Enter the desired IP address, e.g. 192.168.0.1

•Then wait for the next prompt:

Subnet?

•Enter the appropriate mask e.g. 255.255.255.0

•Then wait for the next prompt:

User?

•Enter a username (max 12 characters). Factory default is <<root>>

•Then wait for the next prompt:

Pass?

•Enter a password (max 12 characters). Factory default is <<telsys>>

When these settings have been saved, the prompt <<Updated>> will appear.

•For the new IP settings to take effect, cycle the power on the unit.

Checking units for IP address via serial port.

If you need to check an MDU’s address then once the ready prompt has appeared type “?” and the current

settings for IP Address; Subnet Mask; Gateway; & Mac Address will be shown on the screen.

Web interface (http)

Using any browser (e.g. Microsoft Internet Explorer) you can browse to the IP address previously set. Use

the username and password you have previously set to access the configuration pages.

MDU12-PMi Manual 18 Issue 4

6.0 Pin-outs

Input

Neutrik Powercon connector – L – Brown (Phase), N – Blue (Neutral), E – Green/Yellow (Earth or Ground).

Serial Connector RS232

SERIAL RS 232 CONNECTOR

D9 SOCKET

1 SCL-X 6 SDA-X

2 TX 7 -

3 RX 8 -

4 DTR 9 -

5 0v

MDU12-PMi MDU12-PMi COMPUTER COMMS PORT

Serial Port Serial Port AT XT or PC

D 9 socket RJ11 Front Panel D 9 socket D 25 socket

3 5

←3 2

2 2

→2 3

5 4 GND 5 7

GPI Connector – D37 F

GPI INPUT CONNECTOR

D37 SOCKET

1 Input 1 20 Input 1

2 Input 2 21 Input 2

3 Input 3 22 Input 3

4 Input 4 23 Input 4

5 Input 5 24 Input 5

6 Input 6 25 Input 6

7 Input 7 26 Input 7

8 Input 8 27 Input 8

9 Input 9 28 Input 9

10 Input 10 29 Input 10

11 Input 11 30 Input 11

12 Input 12 31 Input 12

13 Input 13 32 Input 13

14 Input 14 33 Input 14

15 Input 15 34 Input 15

16 Input 16 35 Input 16

17 +5V 36 +5V

18 0V 37 0V

19 0V

MDU12-PMi Manual 19 Issue 4

Typical external wiring for Circuit 1.

This shows the +5V supply as switched.

The circuit is not polarity conscious. The maximum input voltage without additional current limiting resistors is

+12V The internal resistors are 4K7 per circuit. Either the 0v or the +5V may be switched.

The Ethernet connector

A 1:1 cable should be used to connect to a hub as is normal practise.

7.0 Response Times

Remote Monitoring

The full unit status of the unit is sampled every 200mS. Any further delay is due to the SNMP agent compiling

the trap and then sending it on the network interface.

Typically, agents give priority to analysing network traffic and then look at the trap queue when idle.

Start up delays

Maximum delay is 256 seconds between each relay in Sequential Start mode and up to 50 seconds delay per

output in Delay Start mode.

8.0 Temperature Indications

The temperature reading is designed to assist in knowing the overall temperature in the rack, as the MDU is

at the top of it.

The maximum recommended figure is 65° C.

Going over or under the preset threshold generates an SNMP trap alarm, as detailed in the MIB.

9.0 Specifications

Input 110-240V AC 50/60Hz Max load 16A

Power consumption 8W No load.

Connector Powercon

Power Consumption 8W

Output 110-240V AC Max load 10A per outlet, fused on front panel.

Connectors 12 x IEC 3 pin

Pin 17 +5V

Pin 1

Pin 20

Pin 37 0v

Ext Circuit

Wired in Connector

MDU12-PMi Manual 20 Issue 4

Ethernet

Standard: IEEE 802.3

Physical layer 10/100 Base-T

Data Rate: 10/100 Mbps (auto-sensing)

Mode Full or half duplex (auto-sensing)

Connector RJ45

Table of contents

Popular Power Distribution Unit manuals by other brands

Lucent Technologies

Lucent Technologies H569-445 product manual

Middle Atlantic Products

Middle Atlantic Products Protection Series instruction sheet

Eaton

Eaton Powerware Series user guide

ADC

ADC PowerWorx Select Series user manual

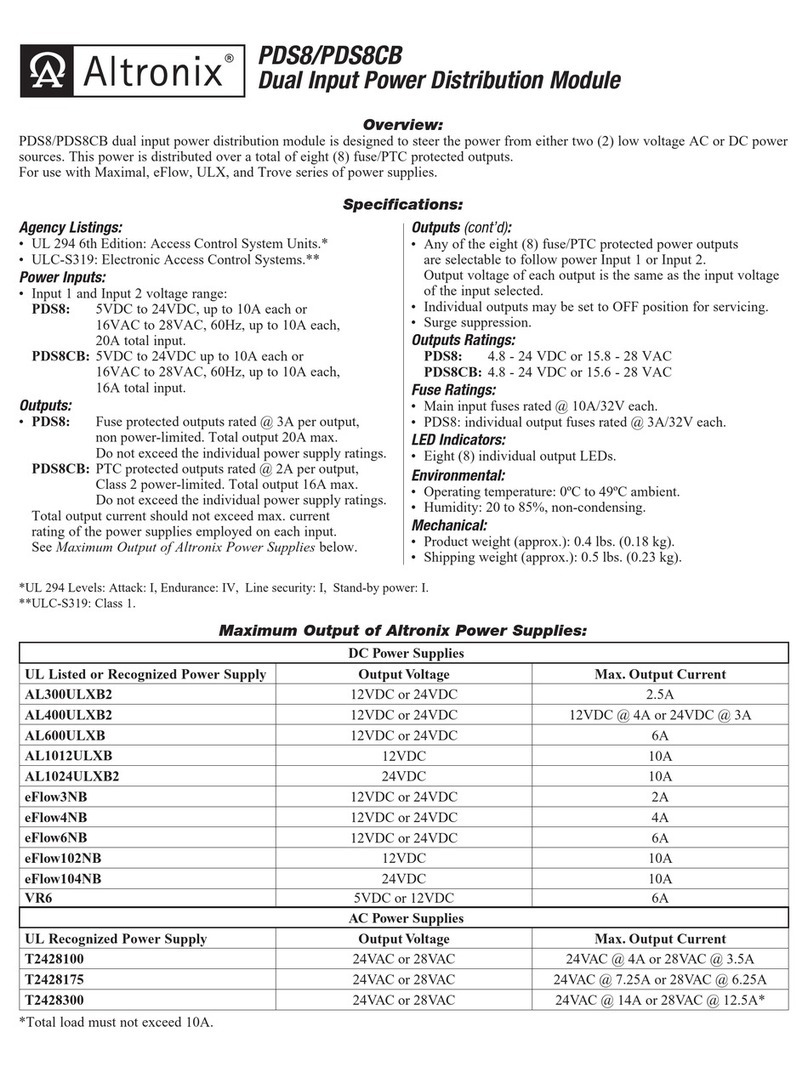

Altronix

Altronix PDS8CB user manual

ABB

ABB Relion 670 series Applications manual

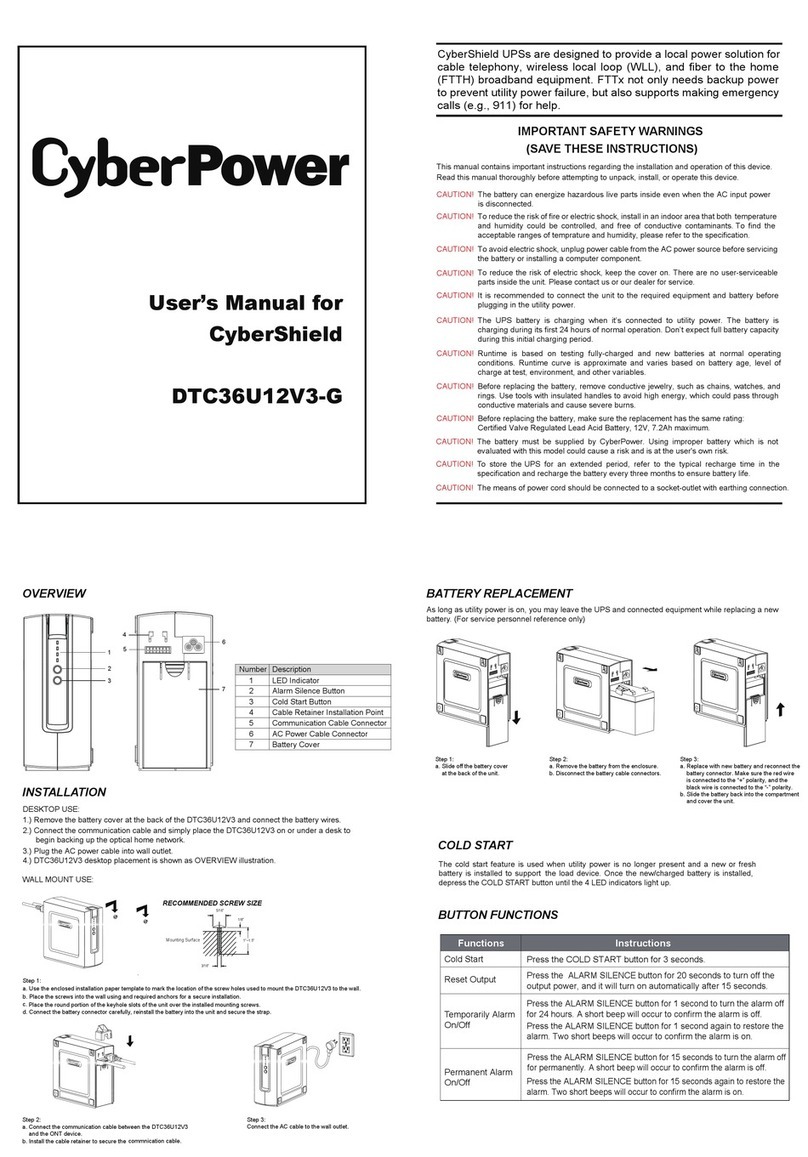

CyberPower

CyberPower CyberShield DTC36U12V3-G user manual

Digitus

Digitus DN-95620 manual

brennenstuhl

brennenstuhl Professional BSV 5 5/4 N5160 AT operating instructions

Micos

Micos ORM 96 Series Instructions for installation

ArcTiv Technologies

ArcTiv Technologies iPDU user manual

Minuteman

Minuteman RPM 1609 user manual