TSUJI ELECTRONICS PM16C-16 User manual

16ch STEPPING MOTOR CONTROLLER

PM16C-16

USER’S MANUAL

No. 3288(rev.2)

APPLICATION OF ELECTRONIC DEVICES

TSUJI ELECTRONIC CO. Ltd.

3739 Kandatsu-machi Tsuchiura-city

Ibaraki-Pre 300-0013 JAPAN

PHONE.+81-(0)29-832-3031 FAX. +81-(0)29-832-2662

URL http://www.tsujicon.jp/

E-mail info2@tsuji-denshi.co.jp

CONTENTS

1

CONTENTS

CONTENTS ............................................................................................................ 1

1 Abstract................................................................................................................ 4

1-1 Introduction.................................................................................................... 4

1-2 Architecture ................................................................................................... 5

1-3 Connection Diagram...................................................................................... 5

2 Parts names and function..................................................................................... 6

2-1 Front Panel.................................................................................................... 6

MOTOR STATUS LED................................................................................... 7

2-2 Rear Panel .................................................................................................... 8

Pulse out Dub connector (PULSE) Pin assignment....................................... 8

Limit switch input Dsub connector(LS IN) Pin assignment............................ 9

RS-232C connector....................................................................................... 9

3 Preparation of a communication line.................................................................. 10

3-1 The outline of communication control.......................................................... 10

The display method of a SETUP screen...................................................... 10

3-2 Configuration of LAN communication.......................................................... 10

3-3 Configuration of RS-232C and GP-IB communication................................. 10

3-4 About delimiter character............................................................................. 10

4 The outline of motor control.................................................................................11

4-1 Remote mode and Local mode ....................................................................11

4-2 Drive mode...................................................................................................11

4-3 Drive speed setting.......................................................................................11

Constant drive (Const)................................................................................. 12

Trapezoidal form acceleration drive (Trape)................................................ 12

S shaped form acceleration drive (Schar) ................................................... 12

4-4 Control screen............................................................................................. 13

Initial screen................................................................................................ 13

Motor drive screen....................................................................................... 13

Mode setup screen...................................................................................... 14

4-5 Home Position Set and Search drive........................................................... 15

At the beginning .......................................................................................... 15

Selection of detecting ways......................................................................... 15

4-6 Hand box (Optional) .................................................................................... 17

04TYPE Hand box controller (PM16-HDX 4 axis control) ........................... 18

02TYPE Hand box controller (PM16-HDX 2 axis simultaneous control) ..... 18

16TYPE Hand box controller(PM16-HDX16 16 axis selected control)....... 19

5 SETUP MODE.................................................................................................... 20

5-1 Page1 Motor activation, limit switch setting................................................. 20

5-2 Page2 Digital limit switch setting ................................................................. 21

For digital limit switch .................................................................................. 21

5-3 Page3 Speed setting................................................................................... 22

5-4 Page4 Acceleration and deceleration setting............................................... 22

5-5 Page5 REL/ABS/SCAN PRESET data setting ............................................ 23

5-6 Page6 Home position setting....................................................................... 24

5-7 Page7 TIMING OUT setting......................................................................... 25

5-8 Page8 TIMING OUT channel setting........................................................... 26

5-9 Page9 Parameters of remote mode setting................................................. 26

CONTENTS

2

5-10 Page10 LAN setting...................................................................................27

5-11 Page11: Program version change, return time from mode set screen, and

LCD brightness adjustment................................................................................27

6 Operation of Motor..............................................................................................28

6-1 Local mode operation ..................................................................................28

6-2 Remote/Local switching command ..............................................................28

6-3 Command to read out of motor status..........................................................29

Limit switch(LS) status read command........................................................30

Commands for current positon read or set ..................................................31

6-4 Motor control command...............................................................................32

JOG step drive command............................................................................32

Speed select command...............................................................................32

Continuous move commands ......................................................................33

Absolute drive command(ABS)....................................................................34

Relative drive command (REL)....................................................................34

Home position return commands.................................................................36

6-5 STOP commands.........................................................................................36

6-6 Speed change command while driving ........................................................36

6-7 Command for Synchronous start for action pending....................................37

6-8 Command of SRQ output function...............................................................37

SRQ for GPIB communication.....................................................................37

SRQ for LAN/RS-232C communication.......................................................38

7 Commands for parameter set up........................................................................39

7-1 Basic configuration of motor ........................................................................39

7-2 Moving speed setting...................................................................................40

7-3 Acceleration and deceleration Rate Setting.................................................41

7-4 Setting of the limit switch-related .................................................................42

7-5 Setting of the home position related ............................................................43

7-6 Setting of the local mode data .....................................................................44

7-7 Display setting .............................................................................................45

8 Timing out signal output......................................................................................47

GATE signal.................................................................................................47

Pulse signal .................................................................................................47

Output method.............................................................................................48

Timing output channel fixed mode (from V1.01) ..........................................50

9 Auto-change drive function.................................................................................52

1. Data input ................................................................................................52

2. Confirm data............................................................................................53

3. Scan preparation .....................................................................................54

4. Scan execution........................................................................................54

10 Other Operation................................................................................................55

10-1 Channel comment setting..........................................................................55

How to set the channel comments (local mode)..........................................56

How to set the channel comments (remote mode) ......................................57

10-2 All reply mode ............................................................................................58

10-3 Maintenance command..............................................................................59

11 Firmware version up .........................................................................................62

12 Appendix...........................................................................................................64

12-1 Acceleration and Deceleration Rate...........................................................64

CONTENTS

3

12-2 Command List ........................................................................................... 65

13 Revision History ............................................................................................... 67

14 Performance and Specifications....................................................................... 68

1 Abstract

4

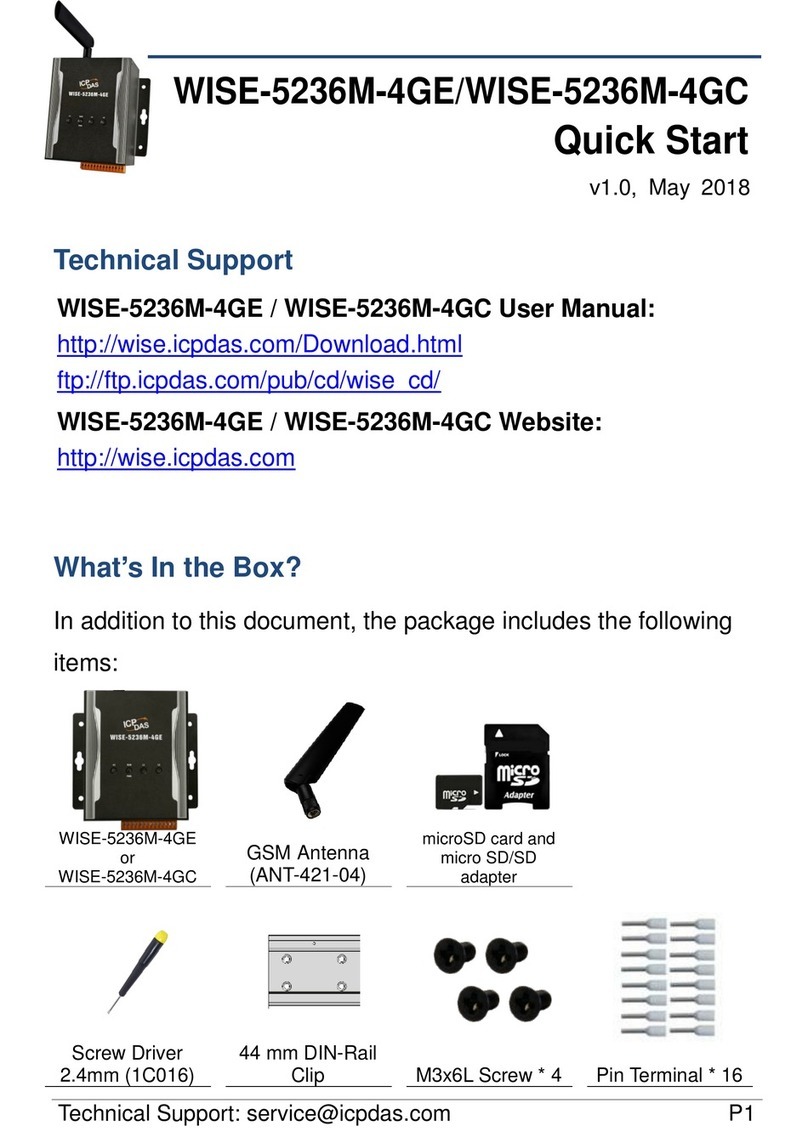

1 Abstract

1-1 Introduction

PM16C-16 made based on PM16C-04XDL is pulse motor controller unit which controls

16 motors at the same time by remote operation. An operation system is almost the same as

PM16C-04XDL.

The difference with PM16C-04XDL is described below.

1. PM16C-16 controls 16 motors at the same time by LAN, RS-232C, and GP-IB

communication.

2. The command which reads the state of all channel was added.

3. “Answer all mode”which adds an answer to all the commands was added.

4. Two axis interpolation commands which starts with “C0” or “C1” and Oscillation drive

command which starts with “Y” are not mounted now

Take over the following functions of PM16C-04XDL.

1. Count pulse step bit is 32bits. Numerical range is -2,147,483,647 to +2,147,483,647.

2. Each characteristics (HSPD, MSPD, LSPD, RATE, LMSW, DGLS)is available for

each channel.

3. Absolute position drive, relative position drive, continuous drive, and find home position

drive is available. These drive have 3 acceleration and deceleration mode, constant,

trapezoid, and “S” shaped.

4. The output of trigger pulse or gate signal (TTL) is available at the arbitrary sections and

intervals.

5. There are five kinds of the way of stopping motor.

by the limit switch signal

by the home position limit switch signal

by the digital limit switch signal

when the “STOP” button is pushed

when the stop command is published

6. Firmware ROM update via communication line is available.

1 Abstract

5

1-2Architecture

1-3 Connection Diagram

Front panel

LCD display

Control switch

Limit switch input

connector × 16ch

FLSH ROM

for firmware

version up × 2

Data Memory

Communication Line

LAN

RS-232C

GP-IB

main

CPU

Pulse controller

2ch × 8

Pulse output

connector × 16ch

LS Cable (Dsub 9pin)

Pulse Cable

(Dsub 9pin)

LAN Cable

RS-232C Cable

GP-IB Cable

Up to 16 set connectable.

PM16C-16

PC

Driver

Pulse

Motor

Sensor

Driver

Pulse

Motor

Sensor

2 Parts names and function

6

2 Parts names and function

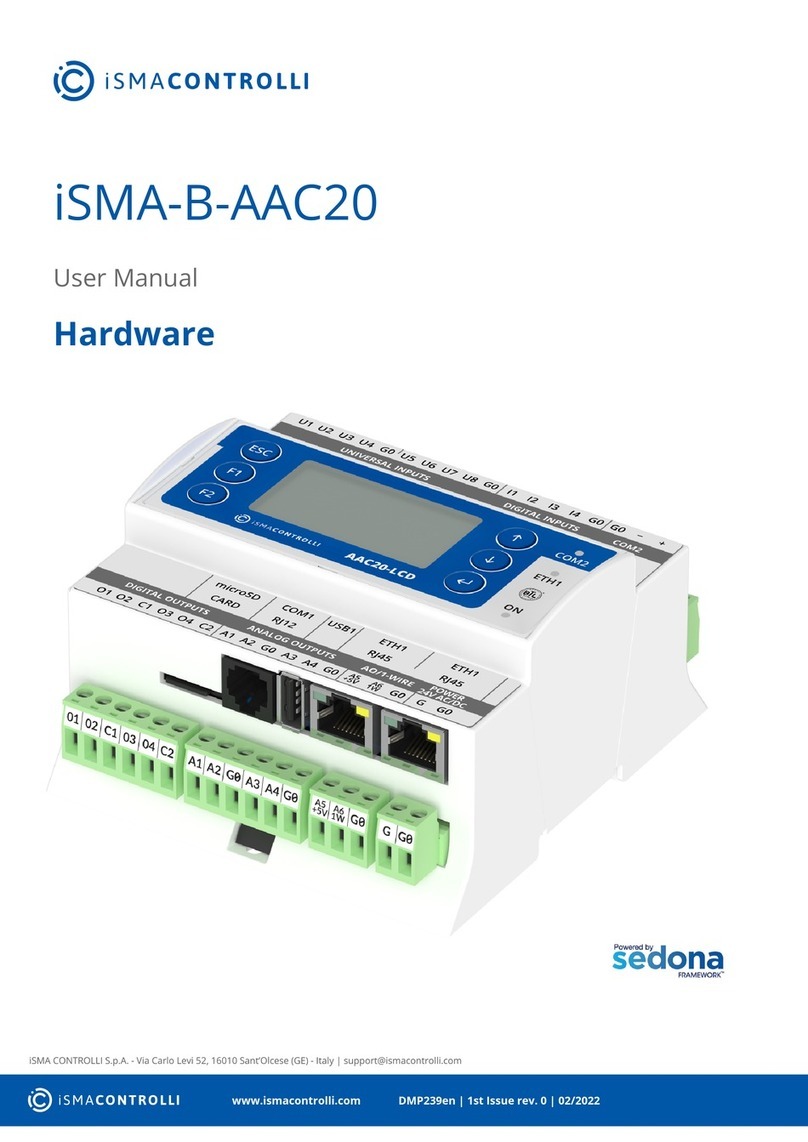

2-1 Front Panel

No.

Name

Function

1

POWER switch

This is the power switch of PM16C-16.

2

Hand Box connector

Connect the Hand Box here (option).

See 17 page.

3

LCD display

20 character and 4 line LCD.

Motor drive status and each channel data are

displayed here.

4

CH select switch

Any 16 motor channel is allocated toA, B, C, D

position. Select the motors to control with this switch.

In SETUP mode, setup channel No. is changeable

with A pos. ch select switch.

5

LCD contrast volume

Adjusts LCD contrast with + screw driver.

6

Motor active button

Set motor drive active or non-active for each position.

Bright position shows active state.

In local mode, motor drives active position only.

7

Motor status LED

These LED shows the motor status.

Details are shown at 7 Page.

8

PRESET button

When motor drive mode is scan, current pulse position

is set to preset value.

9

START button

All activated motor start driving according to the

motor drive mode.

10

STOP button

All activated driving motor stop at local mode.All

driving motor stop at remote mode.

11

REM/LOC button

Exchanges local mode and remote. If you push this

button when turning on the power, various types of

parameter except the current pulse value are

initialized.

12

SETUP button

Goes to motor initial data setting mode (SETUP)

when all motors are stop and local mode. If push it

again, exits SETUP mode.

HP REL ABS SCAN

TP0

TI MI NG OUT(TTL)

START STOP

PRES E T

REM

SETUP

L OC

CHG

4

7

1

5

8

2

6

9

3

+

0

CLR

MODE

-

FAX:029-832-2662TEL: 029-832-3031

URL htt p:// www. tsujicon.jp

CURSOR

BOX

HAND

CH SEL

DEC INC

PM16C-16

16CH STEPPING

MOTOR CONTROLLER

TP1 TP2 TP3

CHG

DSP

POWER

ON

OFF

A pos.

CH

SPD POSITION

MOTOR CONTROLLER

B po s.

C pos.

D pos.

INFO

INC

DEC

INC

DEC

INCDEC

CW

CW LS

CW P

CCW P

CCW L S

0 1 2 3 4 5 6 7 8 9 A

B C D

E F

CCW

JOG

MF

HP

CONT RAST

LCD

DC

B

A

1

2

3

4

5

6

11

12

13

14

18

7

8

9

10

15

16

17

2 Parts names and function

7

MOTOR STATUS LED

0 1

・・・ E F The channel is shown.

CW LS ●●

・・・

●●LED lights when CW direction limit switch is activated.

CW P ●●

・・・

●●LED lights when CW direction pulse is output.

MF ●●

・・・

●●LED lights when motor hold off signal is output.

HP ●●

・・・

●●LED lights when Home Position limit switch is activated.

CCW P ●●

・・・

●●LED lights when CCW direction pulse is output.

CCW LS

●●

・・・

●●LED lights when CCW direction limit switch is activated.

LED of limit switch blinks when digital limit switch described at 21 page was turned on.

No.

Name

Function

13

JOG switch

Starts CW or CCW JOG operation. Motor drives just

JOG set pulse with one push. If you hold over

0.4 sec., motor drives while holding.

In SETUP mode, changes the page of setup function.

14

MODE button

Select the drive mode when pushing start button.

Bright LED mode is selected mode.

Drive mode changes every pushing.

15

cursor button

Move the cursor position with these keys.

Changes set data at SETUP mode

with “CHG”button.

16

DSPCHG button

Exchanges motor drive screen and mode disp. screen.

17

numeric keys

Entry the numeric data at SETUP mode.

Sign inversion with “±”button, data input cancel

with “CLR”button.

If you push “CLR”button when turning on the

power, pulse value of all channels are reset to zero.

18

TIMING/OUT connector

(LEMO)

TTL level pulse signal or gate signal according to

pulse position data are output. See ”8 Timing out

signal output”(47 Page) in details.

2 Parts names and function

8

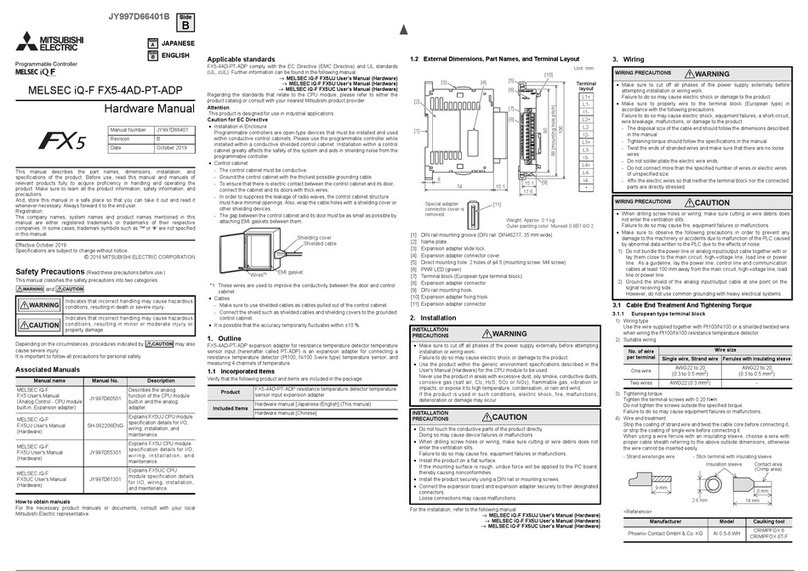

2-2 Rear Panel

Pulse out Dub connector (PULSE)Pin assignment

As pin 8, +5V power supply is available

with red slide switch on the substrate located at

backside of the rear panel.

Factory setting is OFF.

No.

Name

Function

1

Pulse out connector

(PULSE)

Limit switch connector

(LS IN)

CH0 to CH15 pulse output Dsub9 female connector

and limit switch input Dsub9 male connector are

attached. Pin assignment are shown below.

2

GP-IB connector

Connect the GP-IB cable here.

3

RS-232 connector

Connect the RS-232C cross cable here.

4

LAN connector

Connect the LAN cable here.

5

Fuse holder (250 V 3A)

250V, 3A fuse is equipped here.

6

Power cable connector

Insert attached AC cable here.

100 ~ 220VAC power is available.

dotted line is for + common driver

(in this case,

2, 4, 7 Pin are no connection.)

300Ω

+

−

DRIVER

+

−

+

−

OFF ON

+5V

RS-232 C

F3A

AC100V-220V

LAN

PUL SE

GP-IB

LS I N

CH0 PUL S E

LS I N

CH1 PUL S E

LS I N

CH2 PUL S E

LS I N

CH3

PUL SE

LS I N

CH8 PUL S E

LS I N

CH9 PUL S E

LS I N

CH1 0 PUL SE

LS I N

CH1 1

PUL SE

LS I N

CH4

PUL SE

LS I N

CH1 2

PUL SE

LS I N

CH5

PUL SE

LS I N

CH1 3

PUL SE

LS I N

CH6

PUL SE

LS I N

CH1 4

PUL SE

LS I N

CH7

PUL SE

LS I N

CH1 5

1

2

3

4

5

6

Function

Pin No.

CWP (PULSE) −

1

CWP (PULSE) +

2

CCWP (DIRECTION) −

3

CCWP (DIRECTION) +

4

F.G

5

HOLD OFF −

6

HOLD OFF +

7

(+5V)

8

F.G

9

2 Parts names and function

9

Limit switch input Dsub connector(LS IN)Pin assignment

Both a-contact limit switch and b-contact are available.

Logic inverting is also available at PM16C-16 settings.

Use Dsub connector which shell width is under 35mm, since each Dsub connector

pitch is 37.6mm. DE-C1-J6 (JAE), XM2S-0911 (OMRON), HDE-CTF (HIROSE)

etc. are recommended connectors.

RS-232C connector

The pin assignment of Dsub 9pin connector at PM16C-16

side is shown right. Use cross cable between PM16C-16 and

your PC.

Function

Pin No.

-

1

RXD

2

TXD

3

-

4

GND

5

-

6

-

7

-

8

-

9

1KΩ

+12V 0V

CW LS

CCW LS

HP LS

using

proximity switch

(

-

)

12V

SIG

0V

1

P

LS

1

2

12V

SIG

0V

3

4

12V

SIG

0V

6

7

Function

Pin No.

CWLS+

1

CWLS-

2

CCWLS+

3

CCWLS-

4

F.G

5

HPLS+

6

HPLS-

7

+12V(MAX 0.8A)

8

F.G

9

3 Preparation of a communication line

10

3 Preparation of a communication line

3-1 The outline of communication control

PM16C-16 is be equipped communication control by LAN, RS-232C, and GP-IB. Initial

setting is required of each communication. Any initial setting can be performed in SETUP

mode.

The display method of a SETUP screen

After Power on, the 1.REM/LOC button is pushed

and a green LED is made turn on.

Since a screen will change if the 2.SETUP button

is pushed, please push down 3.JOG switch in the

direction of CW or CCW, and change a page.

3-2 Configuration of LAN communication

JOG switch is moved to the CW position several

times, and page 10 (right picture) are displayed. Right

photograph is the state of initial setting, and MAC

address different for every equipment.

When you change IP address and port number, the

blinking cursor is moved by CURSOR button and a

number is inputted by the numerical keypad. As for a

port number, 10001 to 10999 is a recommended value.

IF change is completed, the SETUPbutton will be pushed, and escape from SETUPscreen.

The change will be reflected after a while. Please check that communication is established

by the “VER?” command etc.

3-3 Configuration of RS-232C and GP-IB communication

JOG switch is moved to the CW position several

times, and 9 pages (right screen) are displayed. Right

photograph is the state of initial setting.

The blinking cursor is moved on the figure of

B.RATE by CURSOR button. If the central CHG button

is pushed, baud rate can be chosen from 1200, 2400,

4800, 9600, 19200, and 38400. It is only baud rate that can set up and other values are being

fixed to DATA BIT: 8, STOP BIT: 1, NO FLOW CONTROL, NO PARITY.

A configuration of GP-IB only sets up address. A cursor is moved on the figure of

ADDRESS and address is set up within the limits of 2 to 31.

IF change is completed, the SETUP button will be pushed, and escape from SETUP screen.

3-4 About delimiter character

The format of command is ASCII data, and the delimiter is CR + LF (0x0d + 0x0a).

After receiving CR + LF, command interpretation begins. When sending commands, “CR +

LF” must be added at the end of the command, though the “CR + LF”are omitted in the

command.

1

2

3

4 The outline of motor control

11

4 The outline of motor control

4-1 Remote mode and Local mode

PM16C-16 have two ways of control mode, remote mode and local mode. In local mode,

PM16C-16 controls motor with switches attached front panel and hand box. Commands from

communication line which drives motor and overwrite the motor setting are invalid, but

which reads the data are available.

In remote, switches attached front panel are unable except and .

4-2 Drive mode

There are 4 drive modes at motor control, ABS, REL, SCAN, and H.P.

In local mode, you can change the drive mode with . Current drive mode is

indicated by LED above . In remote mode, you can select drive mode with command

directly.

・REL mode … Relative pulse drive mode

LOCAL: Push , and motor drives toward the destination by

preset value from present position.

REMOTE: Motor drives by entered value.

・ABS mode … Absolute pulse drive mode

LOCAL: Push , and motor drives to preset destination value.

REMOTE: Motor drives by entered position.

・SCAN mode …

Continuous drive mode to CW, CCW direction

LOCAL: Push , and click “CW or CCW” jog switch, motor drives

to dedicated direction continuously.

A push on the PRESET button will set a pulse to the value set

up beforehand.

・HP mode… Drive detecting origin point of pulse count for each channel.

Details are in chap5.3 “Setting the origin of home position”.

All motor drive are stopped with or limit switch or HP switch signal, or enter

motor stop command.

4-3 Drive speed setting

High speed (HSPD), middle speed (MSPD), low speed (LSPD) and acceleration rate is set

individually for each channel. These setting are modified by remote commands or SETUP

mode “Page3 Speed setting (Page 22)”.

Acceleration and deceleration method have the three modes, “Const”, “Trape”, and

“Schar”. These setting are modified by remote commands or SETUP mode “Page3

Acceleration and deceleration modes setting (Page 22)”. Refer to the 40 page for the setting

command of speed.

STOP

REM

LOC

MODE

START

STOP

MODE

START

START

4 The outline of motor control

12

Speed

Time

stop command

start command

MAX SPEED (= HSPD/MSPD/LSPD)

Speed

Time

MAX SPEED(= HSPD/MSPD)

A = 1000pps

B = 3000pps

stop command

start command

START and END

speed (= LSPD)

acceleration curve

(= RATE)

Constant drive (Const)

Motor drives at MAX speed as soon as drive execution, and stops immediately as

soon as stop operation. Too fast drive speed causes motor step out.

Low speed drive is always constant drive at all drive mode.

Trapezoidal form acceleration drive (Trape)

Acceleration operation is carried out until it will reach MSPD or HSPD by making

LSPD into initial velocity, if a motion command is executed.

When a stop command is input, the motor starts deceleration. And the motor stop

when speed reached LSPD. Acceleration and deceleration curve become rapid, and

time to reach maximum speed shortens so that Rate value shown by acceleration and

deceleration code (See page 64) is large.

Large value of "LSPD" may not make smooth start of the motor.

S shaped form acceleration drive (Schar)

stop command

acceleration curve

(= RATE)

Speed

Time

MAX SPEED (= HSPD/MSPD)

START and END

speed (= LSPD)

start command

4 The outline of motor control

13

Although it is fundamentally the same as trapezoidal form acceleration drive, the

velocity change at the time of acceleration and deceleration start and the time of

acceleration and deceleration stop is performed according to S shaped form

approximated to the parabola.

Large value of "LSPD" may not make smooth start of the motor.

The start region A and the stop region B are fixation. When LSPD is more than or

equal LSPD + 4000pps, it calculates automatically so that a curve may become

smooth.

4-4 Control screen

Initial screen

Current firmware version is displayed at screen just after turning on the power.

Motor drive screen

APos.

B Pos.

C Pos.

D Pos.

This is default screen when you control the motors. 4 channels which allocated Pos.

Ato D pulse position are displayed. Colored area means cursor moveable area at local

mode.

No.

Data

Function

1

Channel No.

The display of the allocated channel at Ato D Position.

You can change these channel with “CH SEL”switch

and numeric keys. The same channel at two position is

prohibited.

2

Drive speed

You can select motor driving speed from “HSPD”,

“MSPD”, and “LSPD”with “CHG”button. Please

check the exact speed at SETUP mode Page3 Speed

setting (page 22) or remote commands.

3

Timing signal

The display of timing out signal status.

If displayed “#”here, timing out signal output status is

ready. If not, signal is not outputted.

Each time the “CHG”button is pushed, a state changes.

See “8 Timing out signal output” (page 47) in detail.

* * * * * * P M 1 6 C - 1 6 * * * * * *

S T E P P I N G M O T O R

C O N T R O L L E R V e r < 1 . 0 0 >

T S U J I - D E N S H I C o . L T D ,

0 0 H T P 0 0 1 2 3 4 5 6 7 8 9

0 1 H # T P 1 - 0 1 2 3 4 5 6 7 8 9

0 2 M # T P 2 - 0 1 2 3 4 5 6 7 8 9

1 5 L T P 3 0 1 2 3 4 5 6 7 8 9

1

2

3

4

5

4 The outline of motor control

14

Mode setup screen

Push 1: at motor drive screen, display changes into mode setup screen.

On this screen, various parameter setup at the

time of a motor drive is performed.

Push 2: , changes motor active mode

“REL −> ABS −> SCN −> H.P −> REL”.

Setting value differ in each mode.

LED on the 3: blinks during mode

setup screen.

Display value for each motor active mode are below.

REL : Enter relative drive pulse value when you push .

ABS : Enter absolute drive pulse value when you push .

SCN : Enter preset value when you push .

H.P : If you have found the home position at this position, displays

its data. If not, displays “NO_HOME POS.”. Home position data

is rewritable if you have found it.

When you change these values, move the cursor where you change with cursor button and

enter the new value with numeric keys. Inverts the Sign of value with , resets entering

value with .

Entering value is displayed with zero suppression. If you move cursor up and down, entering

value is fixed and displayed with zero-fill.

No.

Data

Function

4

Timing signal output port

Channel comment

The display of from which port a timing signal is

outputted. In V1.01 or later, “---”is displayed when the

output port is not assigned to all the port. You can select

display data at this area with “CHG”button.

・Timing signal output port

Timing out port 0 to 3 are allocated at displayed

position A to D.

・Channel comment

Each channel is able to be named 3 letter.

See “10-1 Channel comment setting”(Page 55) in

detail.

5

Current pulse position

Displays current pulse position for each position.

DSP

CHG

0 0 M R E L 0 1 2 3 4 5 6 7 8 9

0 1 M R E L - 0 1 2 3 4 5 6 7 8 9

0 2 M R E L - 0 1 2 3 4 5 6 7 8 9

1 5 L R E L 0 1 2 3 4 5 6 7 8 9

1

2

3

START

START

PRESET

±

CLR

SETUP

MODE

4 The outline of motor control

15

4-5 Home Position Set and Search drive

Home position of the unit is set by home position search drive. If the sensor of the origin

point (H.P switch) is detected, motor will stop automatically and the moving direction and

the origin point at the time of detection are memorized on a main unit.

At the beginning

A setup of H.P can be set up by connecting with H.P LS switch of LS connector and

detecting the origin point sensor arranged at the mechanical origin point.

To set H.P, you need to decide the direction of detecting origin point.

In the case of the following figure, detect way is CW.

Once detect the origin point, motor stopped automatically and memorize the direction

and H.Ppulse data. In this case, motor speed must be low within response time of sensor.

You need to check the set speed.

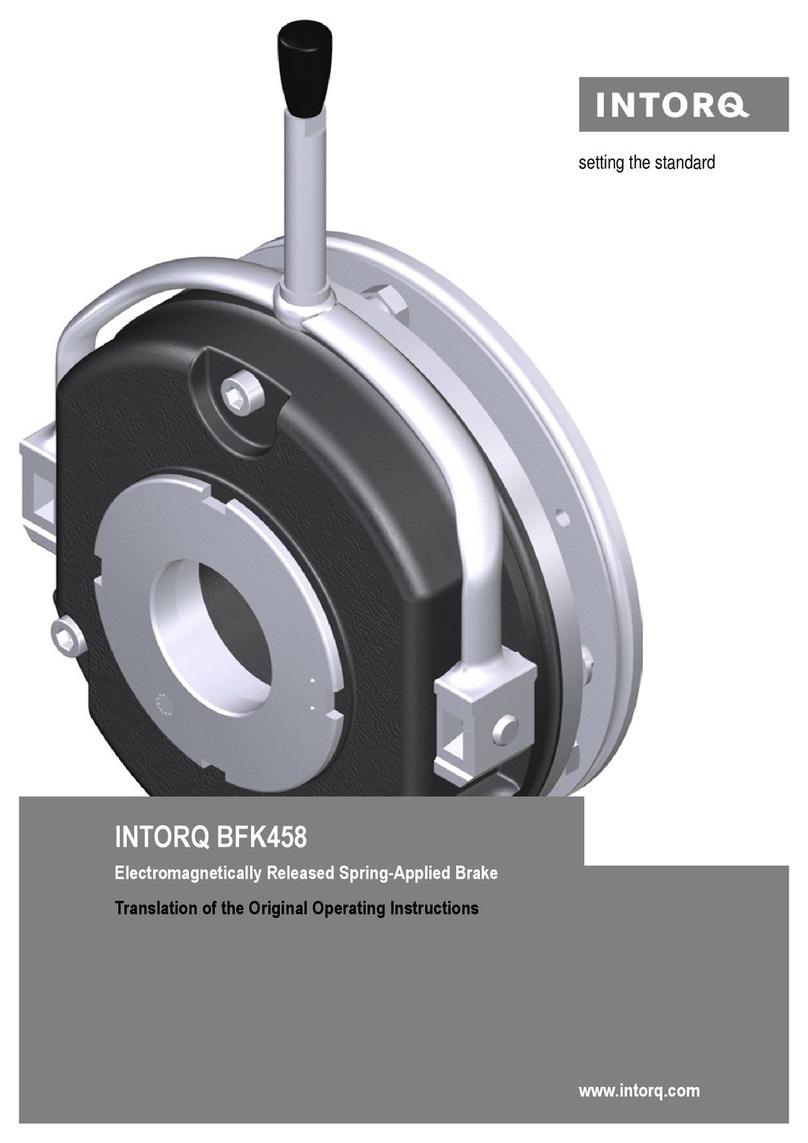

Selection of detecting ways

There are three ways of detecting origin point.

Some are in case of memorized data had existed and another is in case of no memorized

data.

[METHOD A]

METHOD

ORIGINAL

STATE

DETECT WAY

PROCEDURES

ACCURACY

TIME

A

NO

MEMORIZED

DATA

MANUAL

Manual operation

JOG CW, CCW or

START + JOG

CW,CCW

AVERAGE

SHORT

B

NO

MEMORIZED

DATA

SEMI

AUTOMATICAL

Hold “START” switch

more than 1 sec.

GREAT

LONG

C

EXISTED

MEMORIZED

DATA

SEMI

AUTOMATICAL

Push “START” switch.

GREAT

SHORT

CW

CCW

origin sensor (H.P LS)

CW

CCW

origin sensor (H.P LS)

mechanical cam for detect origin point

mechanical cam for detect origin point

4 The outline of motor control

16

When you set H.P to direction CW, you have to set motor position to CCW side

against origin sensor, then move motor from CCW to CW side by operation switch

JOG CW or START + JOG CW.

Once detect the origin point, motor stopped suddenly, origin point procedures

finished.

Then the position of pulse data is memorized and the direction approaching a sensor

is also memorized. (In the case of the above figure the CW direction)

This way is applicable also to the detection in the case of using HP sensor as CWLS

or CCWLS. (In that case, input CWLS or CCWLS also into HPLS)

..................................................................................................................................

[METHOD B]

The following example is the case that the direction of the origin point detection is

CW. The start direction of the origin point detection set in the opposite direction of

the direction of the origin point detection.

(You can set at “Page6 Home position setting” (Page 24))

(a). In case of start position is in CW side against origin point

(b). In case of start position is in CCW side against origin point

If a starting point sensor is detected, it will pass at first. And it will stop, if it passes

Cam

CW

CCW

origin sensor (H.P LS)

2. Detect the origin point then back

to CW side at low speed.

1. It starts present speed H, M, L.

3. Again detect the origin point at low speed.

Cam

CW

CCW

origin sensor (H.P LS)

2. Detect the CCW limit switch then back to CW side.

1. It starts present speed H, M, L.

3. Detect the origin point then goes to

CCW side at low speed.

CCW limit switch

4. Again move to CW side and detect

the origin point and stop.

4 The outline of motor control

17

completely, and it goes to the origin point by LSPD. Motor stopped suddenly, if the

origin point sensor is detected from a direction opposite to the direction which started

detection of the origin point. Then the position of pulse data is memorized and the

direction approaching a sensor is also memorized.

While in this procedures, if you stop this operation by “STOP” switch or command,

H.P hadn't been finished.

If in this procedures, CW or CCW limit switch or digital limit switch is activate,

detecting procedures continue until “STOP”switch on.

[METHOD C]

This way is used when the origin point information is memorized bythe way previously

described. The origin point is detected automatically based on the information

memorized.

If you push START button, motor goes to origin point ± offset pulse area by preset

speed. When motor enter the offset area, then goes to origin point at low speed. Motor

stopped suddenly, if the origin point sensor is detected, and H.P procedures finished.

While in this procedures, CW, CCW limit switch activate or push STOP button, this

procedure stopped. In this case the origin point position information is cleared.

When you want to set up the origin point using old origin point detection data, setting

data can be returned by “Page6 Home position setting” (Page 24) of SETUP screen.

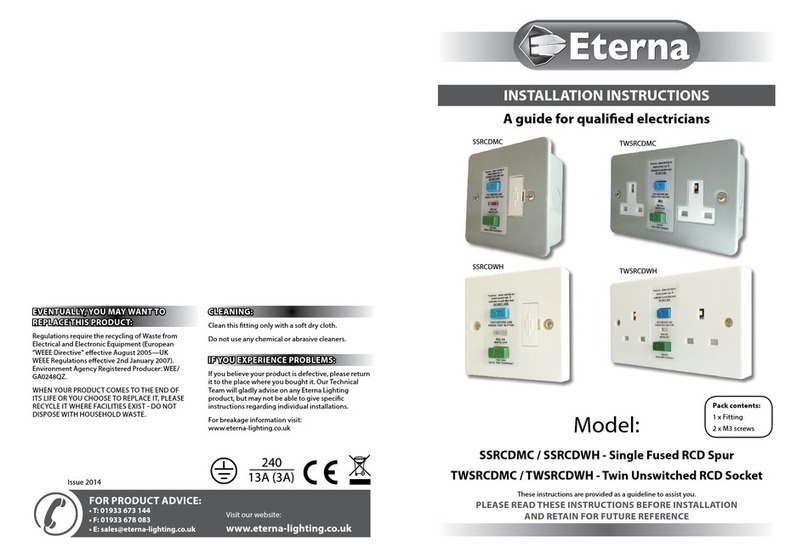

4-6 Hand box (Optional)

In local mode operation, you can control a motor using the panel directly.

In addition, you can control a motor using Hand box

(sold separately).

Connect the Hand box to HAND BOX connector.

And select the type of the Hand box in the item

"HAND BOX CONT" in the 9 page of the SETUP

mode from the below types.

Cam

CW

CCW

origin sensor (H.P LS)

Offset pulse

(An initial value is 100. It can change for

every channel.)

1. It starts to the offset pulse range

at present speed H, M, L.

2. When entering in an offset pulse,

the origin point will be detected

at LSPD.

4 The outline of motor control

18

04TYPE Hand box controller (PM16-HDX 4 axis control)

You can select one channel from A, B, C, D that are displayed on LCD,

and you can control it.

1. Channel select switch

Select one channel from A, B, C, D that are

displayed on LCD.

2. Speed change switch

In local mode, you can change the speed of

the specified channel from HSPD, MSPD and

LSPD.

In remote mode, it becomes the STOP button.

(see below)

3. JOG switch

When you press once, it gives the instruction

once in the direction (CW or CCW) in which

you move the JOG switch.

It is same function of the JOG switch of PM16C-16 front panel.

02TYPE Hand box controller (PM16-HDX 2 axis simultaneous control)

Simultaneous control of channelsAand B, which is displayed on the display is possible.

1. Speed change switch

In local mode, you can change the speed of

the channel A,B from HSPD, MSPD and LSPD.

In remote mode, it becomes the STOP button.

(see below)

2. CH A JOG switch

It is the same function as the JOG switch of the

front pannel of PM16C-16, and it operates the

channel A which is displayed on LCD display.

When you press once, it gives the instruction

once in the direction (CW or CCW) in which

you move the JOG switch.

If press and hold, it continues to operate.

3. CH B JOG switch

It is the same function as the JOG switch of the

front pannel of PM16C-16, and it operates the channel B which is displayed on LCD

display.

When you press once, it gives the instruction once in the direction (CW or CCW) in

which you move the JOG switch. If press and hold, it continues to operate.

1

2

3

1

2

3

4 The outline of motor control

19

16TYPE Hand box controller(PM16-HDX16 16 axis selected control)

Control a channel that is selected from 16 channels.

1. Channel indicated LED

It displays the channel that is controlled, and it

displays a channel as Hexadecimal number (0 ~ F).

2. Channel select switch (useful in local mode)

Select the channel that want to control by

this switch.

3. Speed change switch (useful in local mode)

In local mode, you can change the speed of

the channel A,B from HSPD, MSPD and LSPD.

In remote mode, it becomes the STOP button.

(see below)

4. JOG switch (useful in local mode)

When you press once, it gives the instruction once in the direction (CW or CCW) in

which you move the JOG switch. If press and hold, it continues to operate.

・About Speed change switch

In remote mode, all of LED H/M/Lwill light, if the button is pressed and held more

than 3 seconds. And Speed change switch will act as STOP button at this time.

This feature will be canceled, if the button is pressed and held more than 3 seconds,

again.

1

2

3

4

Table of contents

Other TSUJI ELECTRONICS Controllers manuals