INSTALLATION INSTRUCTIONS FOR RAIL MOUNTED REGENERATIVE DRYERS

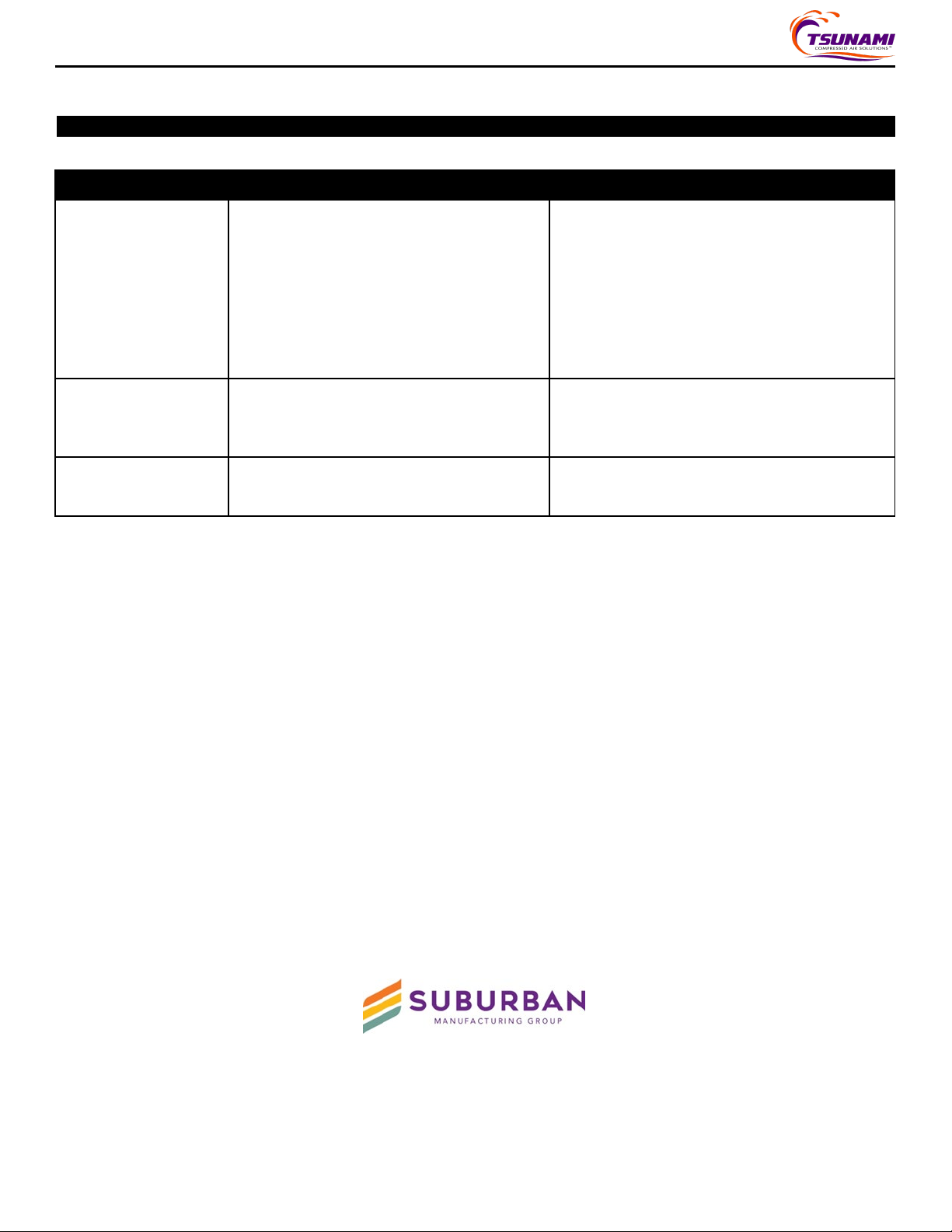

INSTALLATION INSTRUCTIONS -BYPASS CIRCUITINSTALL

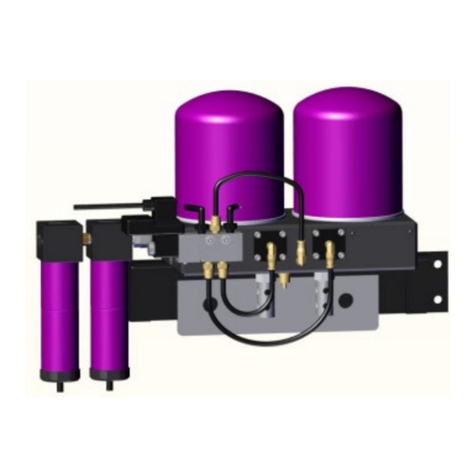

IMPORTANT: Tsunami Regenerative Dryers are configurable in multiple

variations. Before beginning installation it is important to determine the

direction of air flow which best meets your installation application

requirements.

For ease of service, it is highly recommendedto install a bypass

circuit around the regenerative dryer. Followthe diagram below

when installing a bypass circuit. Verify that system pressure is relieved

prior to preforming installation.

Air Supply

A

A. Inlet Ball Valve B. Bypass Ball Valve C. Outlet Ball Valve

Using the Dryer: Open the inlet (A) and outlet (C) ball valves andclose the

Bypass (B) ball valve to direct air flowthrough the regenerative dryer. This

will provide clean, dry airdownstream.

Bypassing theDryer: Close the inlet (A) and outlet (C) ball valves andopen the

Bypass (B) ball valve to direct airflowaround the dryer. This will allowservice or

maintenance to be preformed without shuttingdown total compressed air

supply.

INSTALLATION INSTRUCTIONS -DRYER INSTALLTION

1. Remove all system pressure.

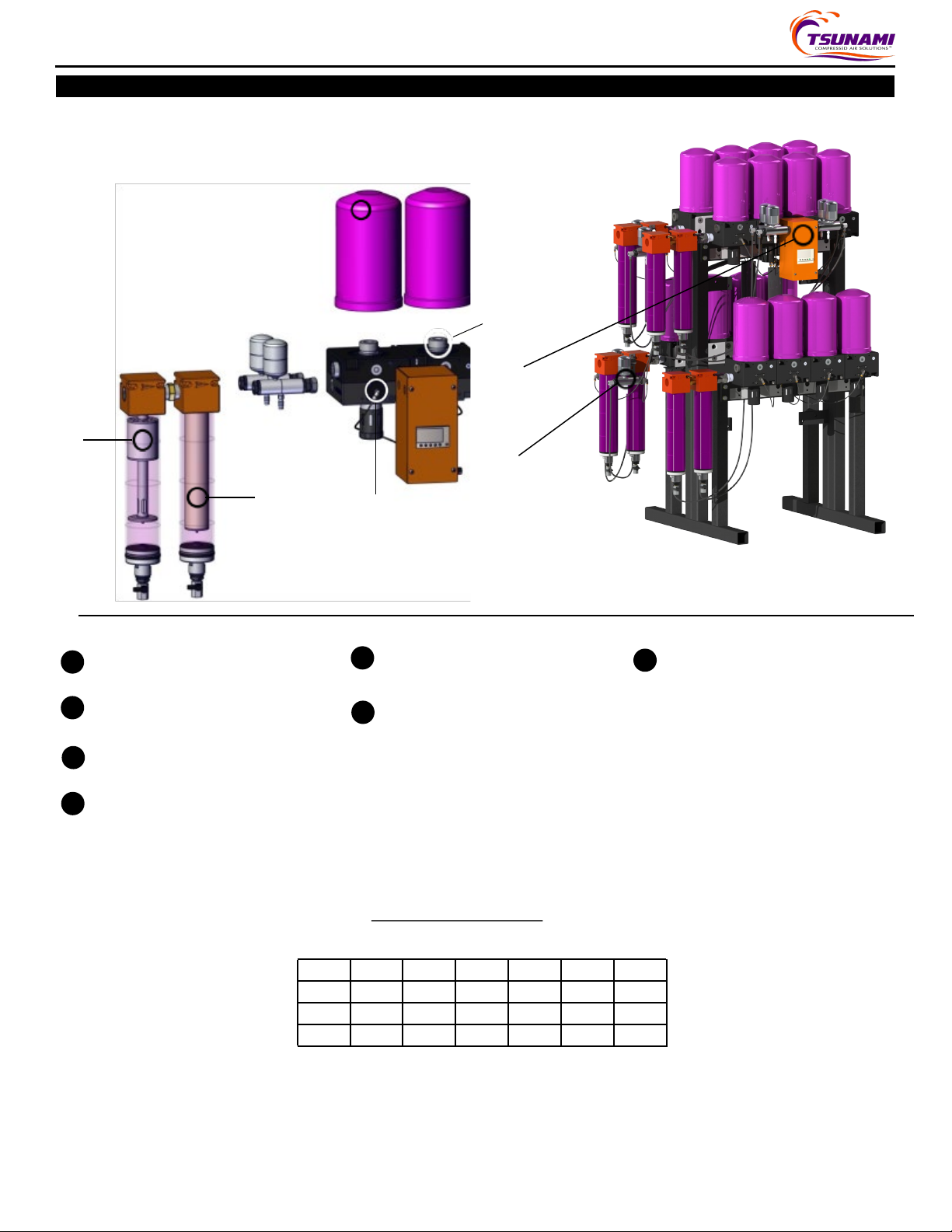

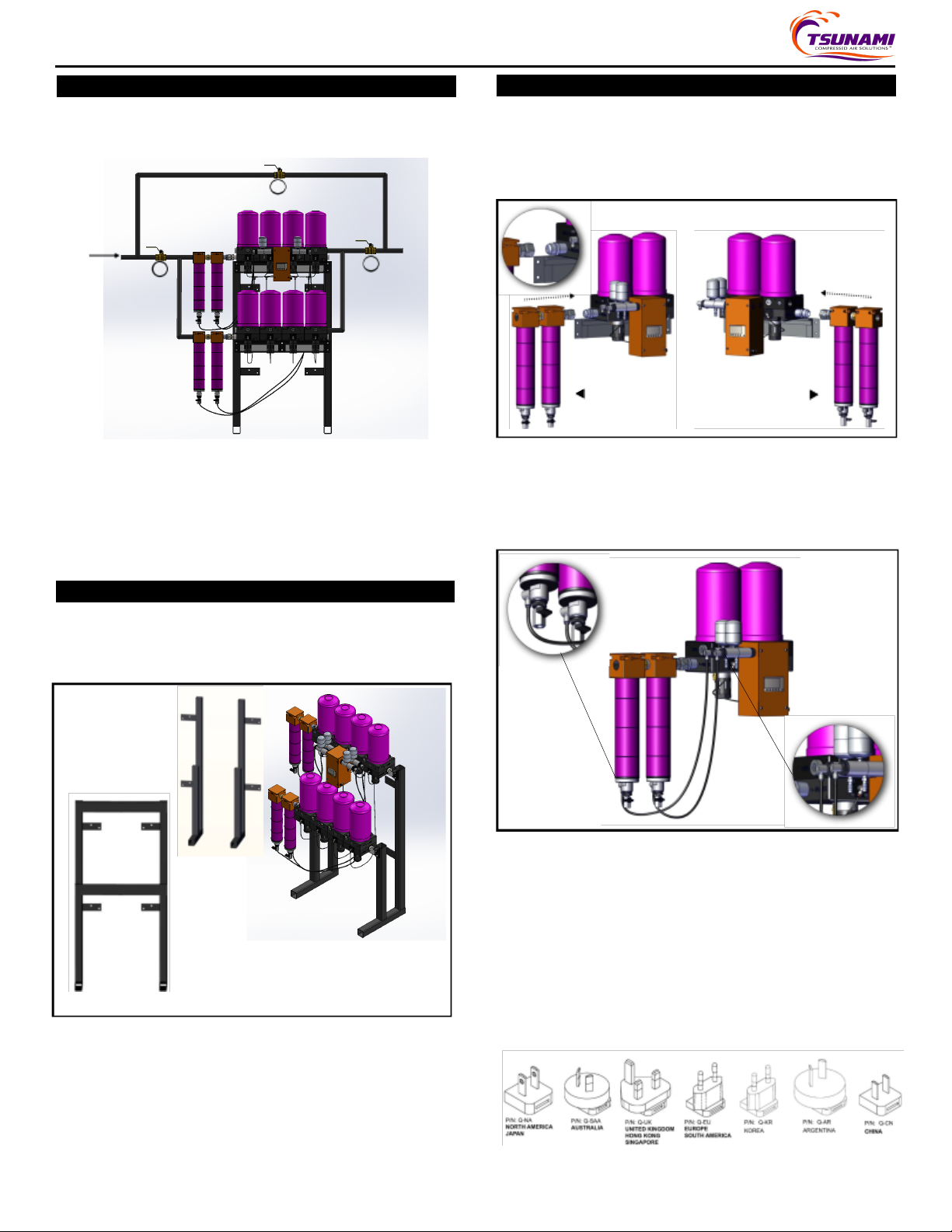

2. Remove hardware from frame. Install cross members withbolt and

lock washer. Square up rack using level or square. Tighten with 9/16”

socket.

3. Using the appropriate hardware (not included), mount dryer bracket to

wall. Figure 1. Can beconfigured with brackets on insideor outsideof

rack. Securing to floor is optional if dryer is also secured to wall.

4. Once the wall bracket has been properly secured to the wall, placethe

dryer mountingrail into the slot(s) of the wall bracket. Figure 1

Figure 1

INSTALLATION INSTRUCTIONS -DRYER INSTALLTION cont.

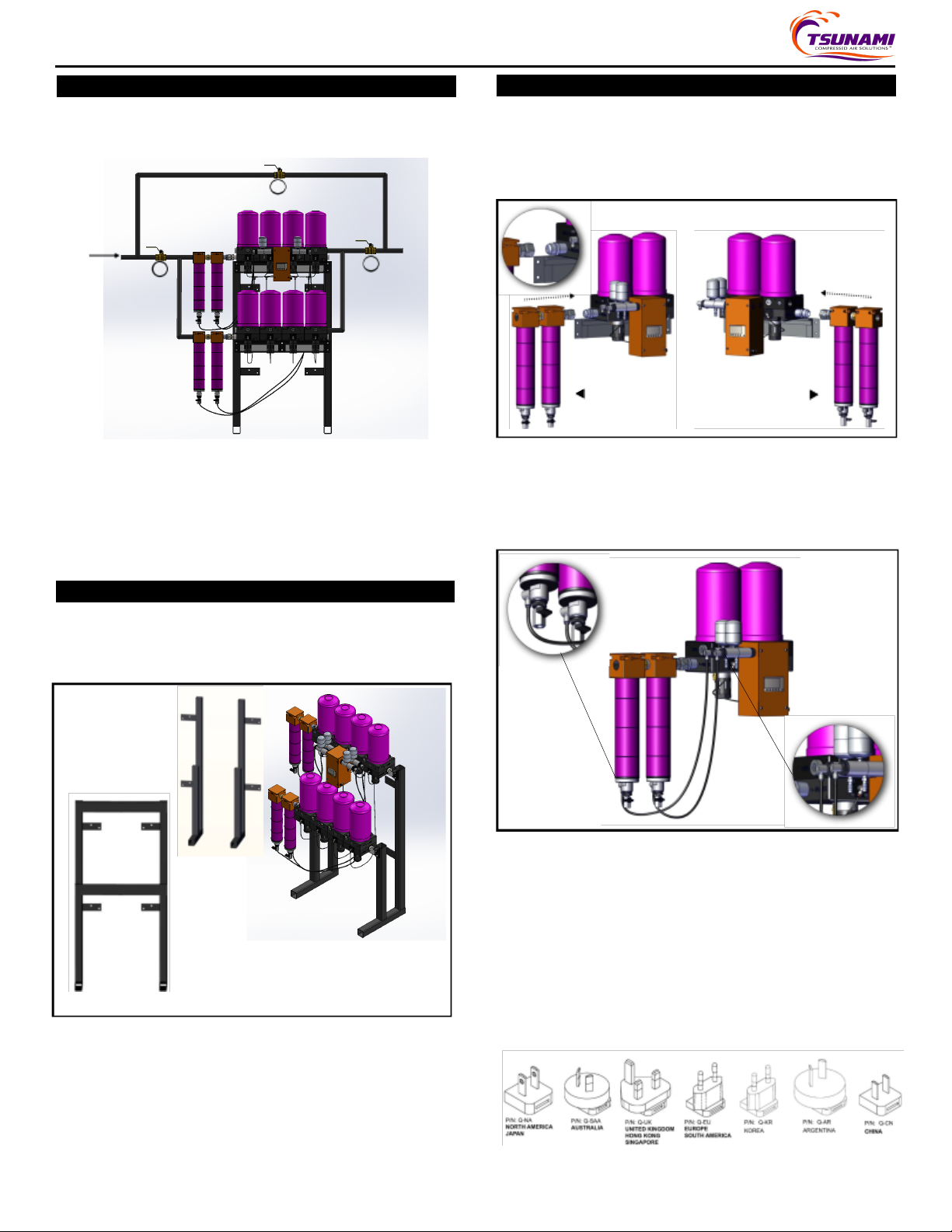

4. Using an adjustable or 1-3/8” wrench, connect thesupplied FEMALE

JIC fitting to the outlet port of the Tsunami pre-filter assembly. Use

appropriate thread sealant. Figure 2

5. Determine preferred direction of flow.

6. Using the appropriatethread sealant, install theMALE JIC connector

to eitherthe left or right INLET / AUXport of the dryer. Figure 2

Flow: L to RFlow: R to L

Figure 2

7. Using an adjustable or 5/8” wrench, plug the remaining open ports

with the provided 1”port plugs and large hextool. Useappropriate

thread sealant.

8. Attached the filter assembly to the dryer housing by connecting the

MALE and FEMALE JIC fittings. Tighten firmly.

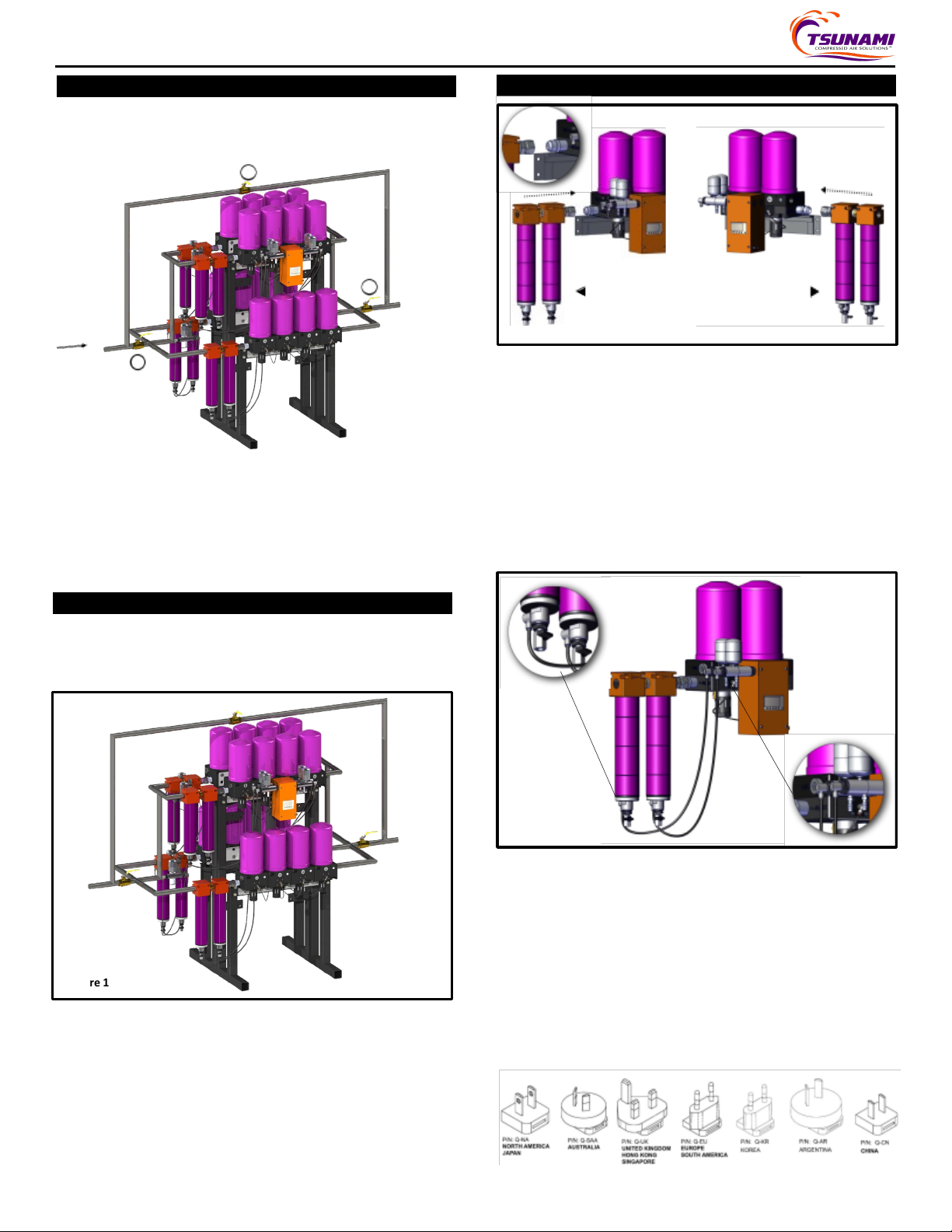

9. Use the provided ¼” black nylon tubing to connect the Moisture Minder®

Piston Drains to the strainers located on the bottom of each filter

housing. Excess tubingcanbe trimmed to length. Figure 3

Figure 3

10. Attach 3/8”clear plastic tubingto the bottom of theMoisture Minder®

PistonDrains. Followall localandstateregulations when routing the drain

lines.

11. a. Connect power. Plug in wall pack adaptor to the PLC Control Box.

Make sure to snugup the lock nut locatedon the PLC endof the

power supply and then plug wall pack into 120v outlet

b. For 24v dryers, plug cord barrel into PLC then connect to power

source; be certain to properly terminate the positive and negative

wires for the correct polarity.

B

C

Date Printed 1/31/2023 764-2095 Rail Mounted Dryer Instructions 2

** Note: For international dryer installations, outside of North America,

choose the correct prong adaptor for the region prior to plugging into any

power outlet. Reference chart below for your specific prong requirement.