Date Printed: 5/3/2021 4 INST-Pure 5 Regenerative Dryer Series

USER MANUAL Pure 5 Regenerative Dryer Series

MAINTENANCE INSTRUCTIONS -COALESCING ELEMENT MAINTENANCE INSTRUCTIONS -PISTON LUBRICATION

Recommended every6 months

•Lubrication of pistonspooland piston bore

Recommended annually

•Piston Replacement Kit (21999-0707)

Your safety is very important. Read all instructions before beginning any

service or installation on your Tsunami Regenerative Dryer. Always

wear safety eye protection when working with compressed air products.

Failure to follow maintenance instructions could result in operating

failure or product damage. System pressure must be released prior to

any installation or service.

Mandatoryevery6 months

•Oil CoalescingFilter Element Replacement (P/N: 21999-0394)

Your safety is very important. Read all instructions before beginning any

service or installation on your Tsunami Regenerative Dryer. Always

wear safety eye protection when working with compressed air products.

Failure to follow maintenance instructions could result in operating

failure or product damage. System pressure must be released prior to

any installation or service.

1. Unplug unit from power source.

2. Release all system pressure.

3. (21999-1105-MM MODELS ONLY) Disconnect the pilot line located at

the bottom of the oil coalescing filter.

4. Remove filter tube from filter head by holding filter head and

rotating tube counter-clockwise.

5. Using a 5/16” wrench, remove baffle nut from threaded rod below

element.

6. Remove bottom baffle, filter element, top adaptor, and O-ring.

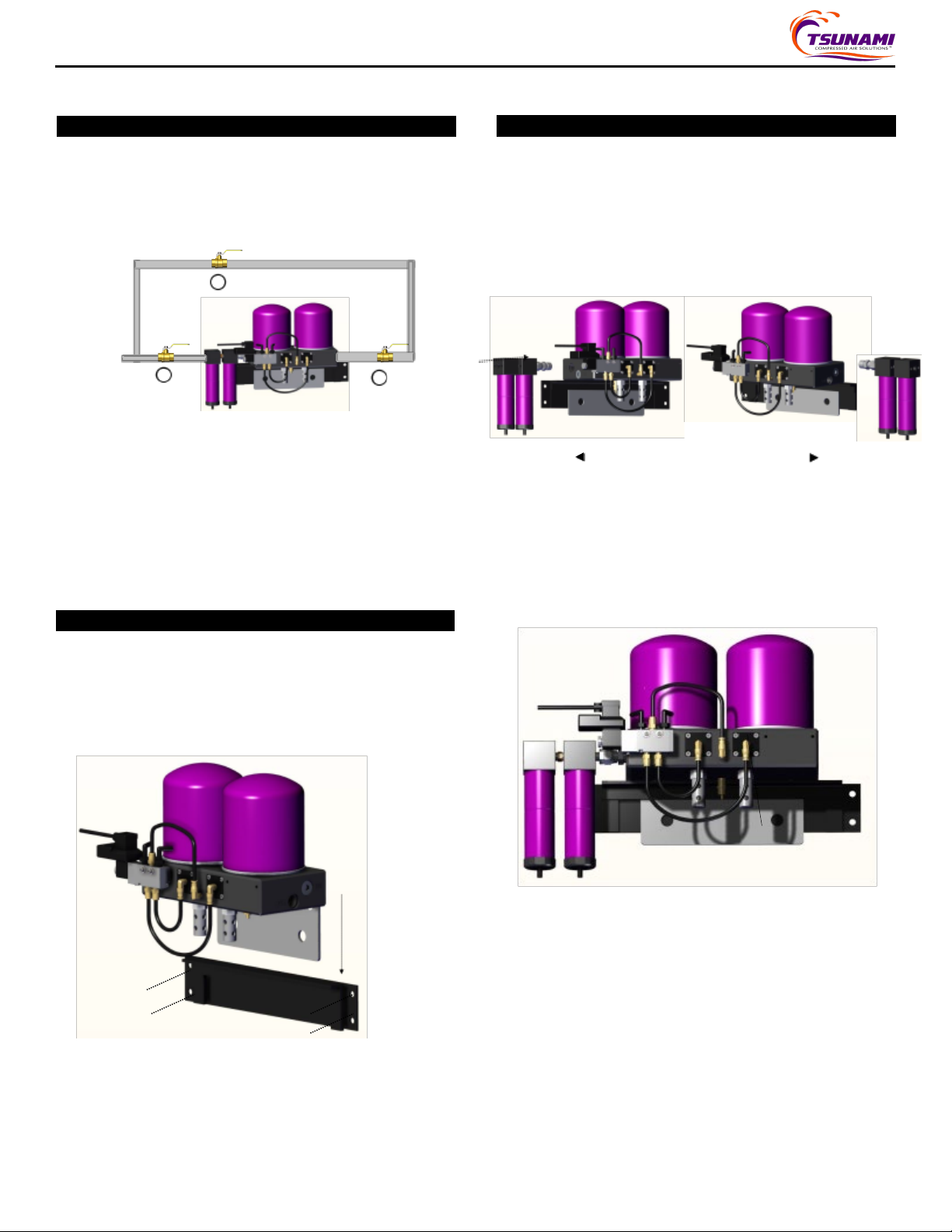

Figure 5

Figure5

7. Replace filter element and hardware in reverse order from previous

steps. Tighten baffle nut until filter element can no longer spin freely.

DO NOT OVER TIGHTEN NUT! Reinstall outer tube by rotating

clockwise onto filter head.

8. (21999-1105-MM MODELS ONLY) Reconnect pilot tubing and plug

unit back into wall.

9. Slowly pressurize the unit.

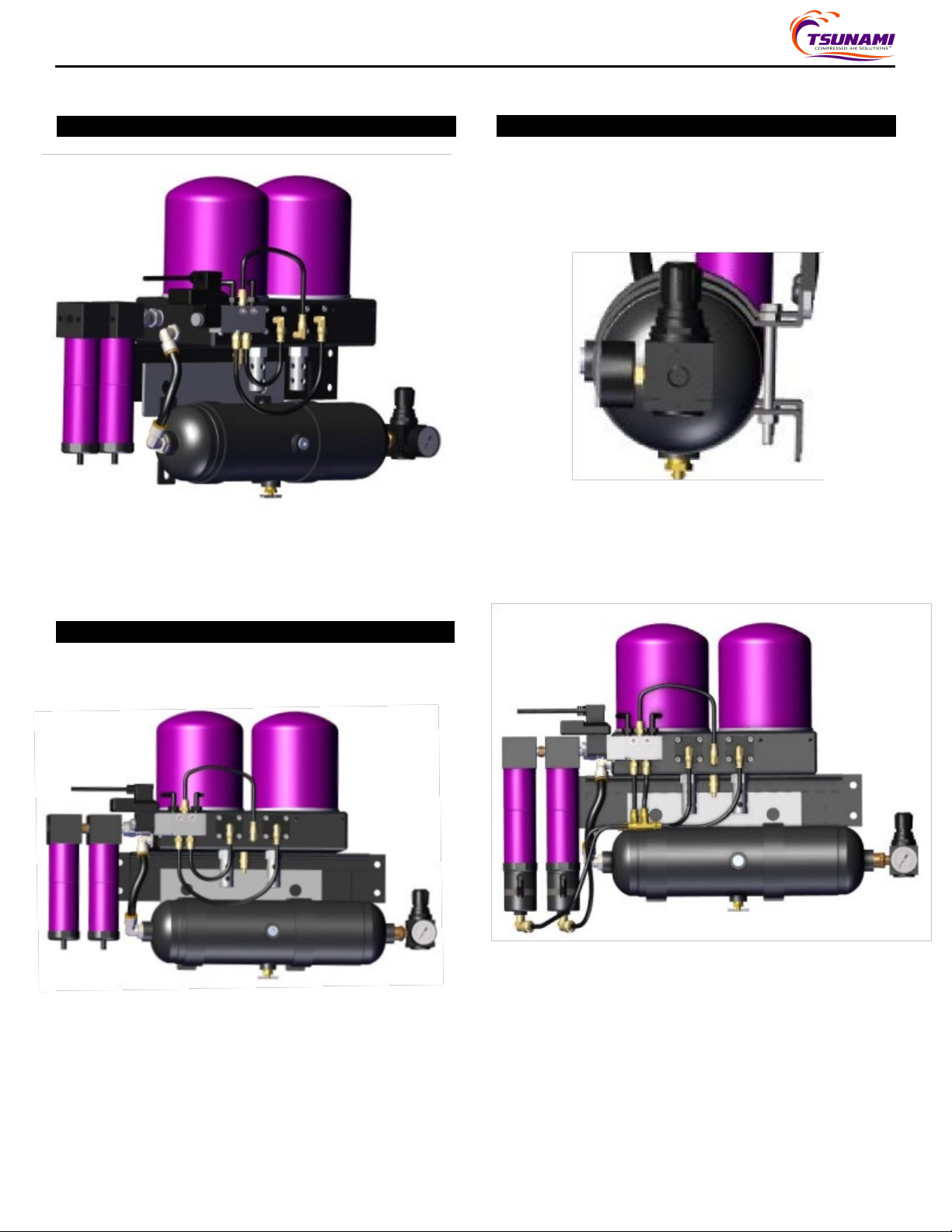

Figure6

Figure7

Note: Eachcanistercontains one piston.

1. Unplug unit from power source.

2. Release all system pressure.

3. Disconnect tubing from quick-connect fitting located on piston cover.

Push in on brass ring. While holding ring in, pull out tubing. Figure 6

4. Using a 4mm hex key wrench, remove the four socket head cap screws

holding the piston cover in place. Figure 7

5. Remove piston cover for access to piston.

6. Using a finger or a 1/2-13 bolt, remove the piston from the piston bore.

Be sure to remove the piston spring. Figure 7

7. Using dielectric grease, lubricate the piston bore. Grease thoroughly.

8. Lubricate the top three O-rings located on the piston.

Note: It is unnecessary to greasebottom O-ring (small diameter).

9. Place spring back onto piston.

10. Carefully insert piston back into piston bore. Press until piston is fully

seated.

11. Replace piston cover for access to piston.

12. Using a 4mm hex key wrench, replace the four socket head cap screws

holding the piston cover in place. Tighten until snug, then add 1/4 turn.

Figure 7

13. Reconnect tubing to quick-connect fitting located on piston cover.

Figure 7

14. Slowly pressurize the unit.

Figure4