Tsuruga Electric Corporation 3568 User manual

I-01679

TSURUGA ELECTRIC CORPORATION

MODEL 3568

Digital Ohm Meter

Instruction Manual

2

Contents

1.Preface ………………………………………………………………………………… 3

1.1 Preparations prior to use …………………………………………….…………….. 3

1.1.1 Inspection ………………………………………………………….…………… 3

1.1.2 Storage …………………………………………………………….…….……… 3

1.1.3 Handle …………………………………………………………….…….……… 3

1.1.4 Loading of batteries ………………………………………….…….…………… 4

1.1.5 Battery alarm …………….………………………………….…….…………… 4

1.1.6 Connection of AC adaptor ……………….………………….…….…………… 4

2.Name of parts and functions …………………………………………………………. 5

2.1 Front panel ………………………………………………..……..……….………… 5

2.2 Rear panel …………………………………………………..…………….………... 7

3.Operation ……………………………………………………………………………… 8

3.1 Power supply ……………………………………………...……………..………. 8

3.2 Connection of measuring terminals …….……………………..………..……..…... 8

3.3 Connection of temperature sensor ………………..………….….…………….… 8

3.4 Key lock ……………………………………………………..……….……….…. 9

3.5 Change-over of measuring range ………………………………..…………..….. 9

3.6 Zero adjustment ……………………………………………..……………….…. 10

3.6.1 Key operation ………………………………………………………………... 10

3.6.2 Remote operation ……………………………………………………………. 10

3.7 Selection of sampling rate ………………………………….………..….…….... 10

3.8 Comparator operation …………………………………………………………... 11

3.8.1 Conditions for comparison ………………………….……………..….……... 11

3.8.2 Comparator output ………………………………………..……………………. 11

3.8.3 Setting method …………………………………..……….…………………..… 12

3.9 Buzzer …………………………………………………..………………….……… 13

3.9.1 Setting method …………………………………………………………………. 13

3.10 Manual mode …………………………………………………………………….... 14

3.11 Memory mode …………………………………………………………………..…. 14

3.11.1 Selection of memory …………………………………………………………… 14

3.11.2 Setting of memory ……………………………………………………………… 15

4.Remote control …………………………………………………………………………. 17

4.1 Remote connector …………………………………………………………………. 17

4.1.1 Pin operation …………………………………………………………………… 17

4.1.2 Remote operation of memory mode …………………………………………… 18

4.1.3 Timing chart of remote control ………………………………………………… 19

4.2 Remote control (input & output terminal block) ………………………………….. 20

5.Setting Method ……………………………………………………………………….. 21

5.1 Resistance measurement ………………………………..…………………………. 21

5.2 Temperature measurement ……………………….…………..…………………… 21

5.3 Temperature compensation function …………………………..…………...……… 22

5.3.1 Setting of standard temperature and temperature coefficient ………………….. 23

5.4 Temperature conversion function

(Measurement of risen temperature of copper coil) …………………………….. 24

5.5 Ratio display function …………………………………………..………..….….… 26

5.5.1 Setting of standard value and deviation ……………………………………….. 27

5.6 Character display ………………………………………………………………….. 28

6.Calibration ……………………………………………………………………………. 29

6.1 Materials to prepare …………..……………………………………..…………... 29

6.2 Calibration method …………………………………………………..…………… 29

6.2.1 Calibration of resistance measuring range …………………..………….……… 29

6.2.2 Calibration of temperature measuring range ……………………....…….…….. 30

7.Specifications …………………………………………………………………………. 31

7.1 Model name ………………………………………………………………..……… 31

7.2 Measuring range & accuracy ……………………………………………...….…… 31

7.3 General specifications ……………………………………………………..….…… 32

7.4 Table of initial set values (at delivery from factory) ………………………..…….. 33

7.5 External dimensions ……………………………………..…………………..……. 33

7.6 Interface (option) …………………………………………………………….….… 33

3

1. Preface

We thank you for your purchase of our MODEL 3568. For safety and proper use of this product,

please carefully read this instruction manual before the initial operation.

Model 3568 is is provided with a wide range from 300mΩto 300kΩand it can perform high precision

measurement of high resolution 10μΩ.

Also provided as standard are the temperature compensation function, ratio display function and

temperature conversion function which allows to measure the risen temperature of coil resistance.

With a comparator memory function of 30 patterns, it is also possible to preset the test conditions for

plural numbers of test samples.

Four different types of optional data output interfaces such as RS-232C etc. are provided for

the meter to serve a wide range of applications from stand alone use to systematized operation.

CAUTION

●To avoid break-down, malfunction or deterioration of life time,

do not use this product in such places where:

◆exposed to rain, water drops or direct sunlight.

◆high temperature or humidity, heavy dust or corrosive gas.

◆affected by external noise, radio waves or static electricity.

● Where there is constant vibration or shock

●Do not dismantle or modify this product.

1.1 ●Preparations prior to use

1.1.1 Inspection

When the meter is delivered, please check whether it conforms to the ordered specifications and has

not been damaged in transit. If any damage or inconvenience in operation is found, please inform

us of the model name and serial number of the product.

1.1.2 Storage

When the meter is not in use for long time, store it in the place of low humidity where the meter is

not exposed to the direct sunlight.

When the meter is stored for a long term, remove the batteries

1.1.3 Handle

Set up the handle, by slightly expanding it as the arrows show and inserting it into the locking slot.

handle

Lock ditch

4

1.1.4 Loading of batteries

①Attachment/detachment of rear battery lid

②Loading of batteries

1.1.5 Battery alarm

1.1.6 Connection of AC adaptor

Full charged

A little discharged

Less charged

(Blink)Batteries need to be replaced

Battery lid

SCREW

++

+

+

+

+

−

−

−

−

−

−

Box poles

Box poles

Attach or detach the lid by screwing

Put a six LR6 or R6P batteries in the battery

compartment, paying attention to their

direction.

Insert the battery box, bringing its poles

far side, and close the lid.

AC adaptor

Take a power supply from the commercial power source

with the AC adaptor.

Supply voltage of AC adaptor: 100~240V AC 50/60Hz

5

2. Name of parts and functions

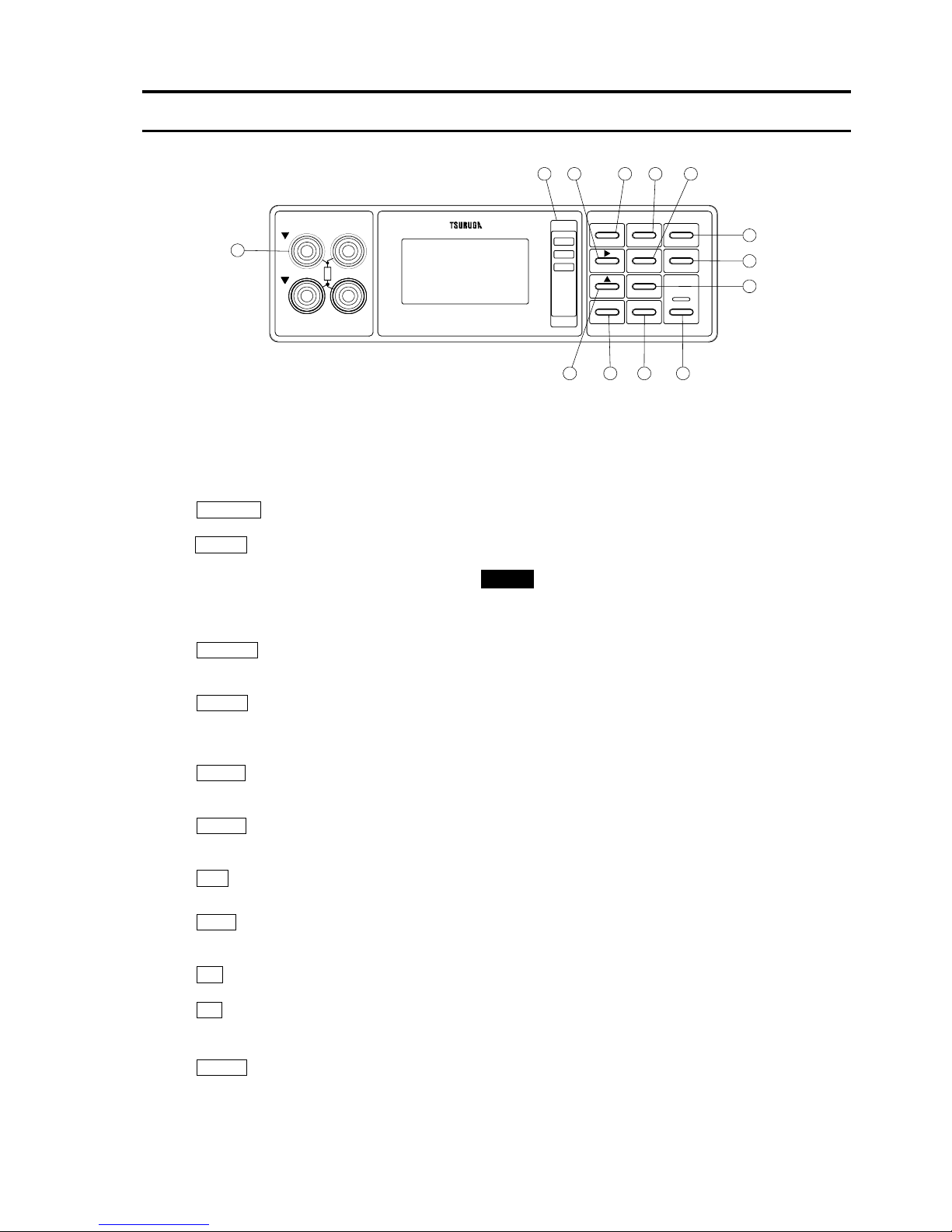

2.1 ●Front panel

①Measuring terminals SENSE Hi:+side terminal of voltage input.

SENSE Lo:−side terminal of voltage input.

SOURCE Hi:+side terminal of current output.

SOURCE Lo:−side terminal of current output.

②POWER key Key for power supply. The green lamp is lit up when the tester is turned ON.

③

SHIFT key Pressed when the functions indicated in orange color in ( ) are used.

(LOCK) When the key is pressed again, the function is cancelled.

While functioning, SHIFT mark is indicated.

(Switch to prohibit switch operation on the front panel. When it is pressed

continuously for 3 seconds or more, prohibition or release can be done.

During the prohibition,

LOCK lamp is lit up.)

④RANGE key Key to select range 300mΩ~30kΩor AUTO range.

(BUZZER) (Key to select buzzer operation and volume setting.)

⑤FUNC key Key to switch over to the resistance measurement / temperatur measurement

(SET) / temperature compensation /temperature conversion / ratio display.

(In memory mode, it is used to set the memory.)

⑥RATE key Key to select a sampling rate.

(MAN’L/MEM)) (Key to switch over manual-mode/memory-mode.)

⑦0 ADJ key ON/OFF key for zero adjustment function.

(ONLINE) (On-line key for RS-232C.)

⑧TE key Key to select the memory and finish of temperature conversion.

⑨SEL key Used for various setting.

COMP SET Key to use for the comparator setting.

⑩

key Used for various setting.

⑪▲ key Used for various setting. Also, it functions as print key when a printer

interface is fitted.

⑫LAMP key Key to turn ON/OFF the LCD back light.

⑬HI Lamp Red LED is lit up when the measured value is higher than high limit.

GO Lamp Green LED is lit up with good judgement.

LO Lamp Red LED is lit up when the measured value is lower than low limit.

COMP.

LO

GO

HI

SEL FUNC SHIFT

(LOCK)(SET)COMP.SET

RATE RANGE

(BUZZ)

0ADJ. POWER

(ONLINE)

LAMP T.E

(MAN′L/MEM)

Lo

Hi

SOURCESENSE

1

281211

7

4

3

6591013

LCD部

6

LCD WINDOW

⑭MEM It displays it in the memory mode.

MAN’L It displays it in the manual mode.

⑮ONLINE It displays it in the remote controlled.

⑯LOCK It displays it in the key lock.

⑰0 ADJ It displays it in zero adjustment operation.

⑱*** Battery Alarm.

⑲SHIFT Linked with SHIFT key.

⑳Resistance range Displays the range 300mΩ~30kΩbeing measured.

AUTO Displayed in AUTO range.

UNIT Displays the unit being measured.

LO SET Display Window Low limit of comparator is displayed.

DEV SET Deviation in ratio display is displayed.

HI SET Display Window High limit of comparator is displayed.

STD SET Standard value in ratio display is displayed.

No. Display Memory No. of memory mode is displayed.

It is not displayed in the manual mode.

Display Window Displays the measurement values and characters.

OHM Resistance measurement.

TEMP Tmperature measurement.

T.C Tmperature compensation function.

T.C RATIO Ratio display of tmperature compensation function.

OHM RATIO Ratio is display of resistance measurement.

TE T1 T1 action of the temperature conversion.

TE T2 T2 action of the temperature conversion.

FLit up at sampling rate 20 times/sec.

SLit up at sampling rate 4 times/sec.

*(Orange key) is enabled while the SHIFT key is displayed.

123.45

mΩ

mΩmΩ

HI SET LO SET

113.45

AUTO

300mΩ

0 ADJ.LOCK

30

No.

ONLINE

S

123.45

SHIFT

MEM

14 15 16 17 18

19

20

21

22

232425

26

27

28

OHM

7

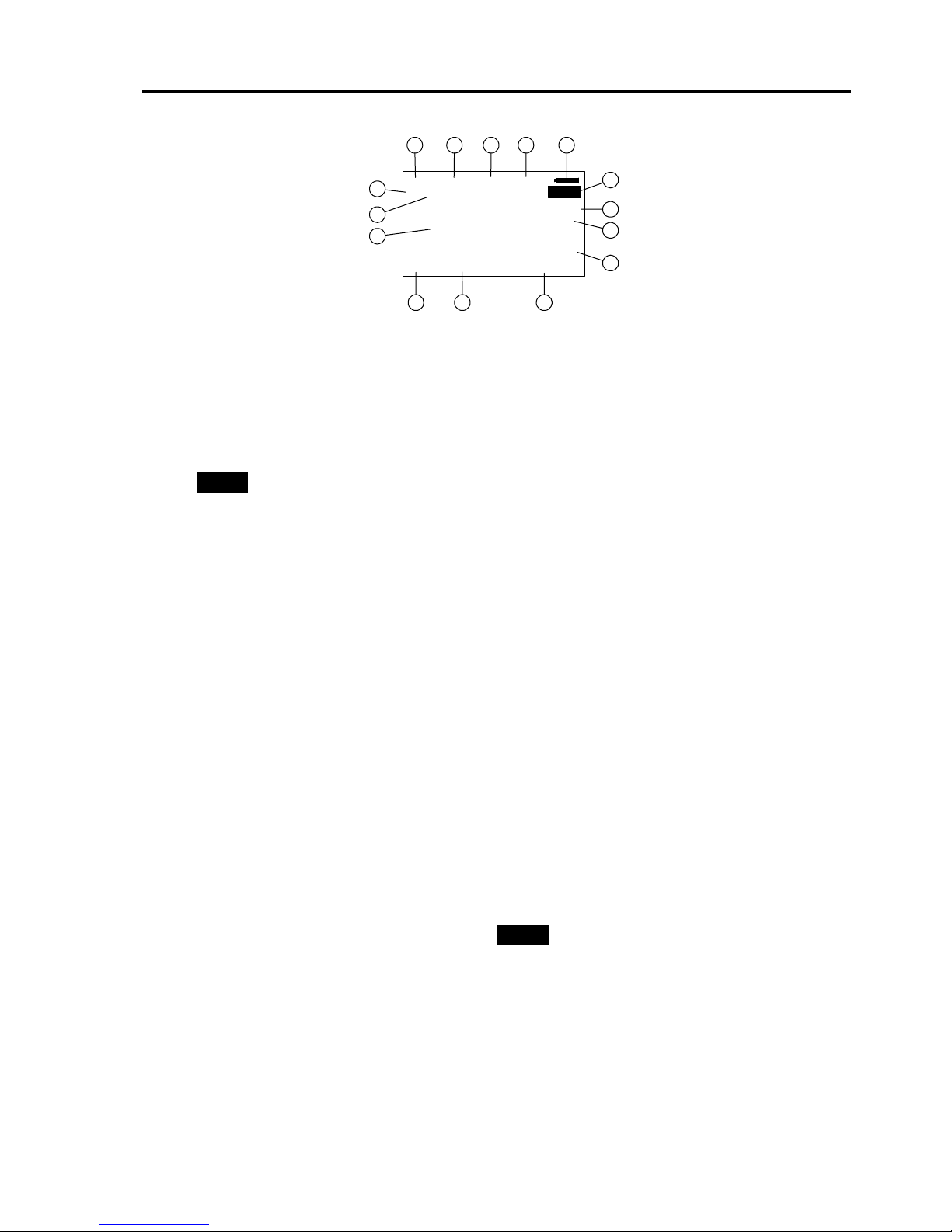

2.2 ●Rear panel

Battery Box

AC adaptor jack

REMOTE connector

Connector for remote control.

Input, output terminal blocks

Terminals for input of hold and input, and output of comparator.

Pt100Ωconnector

Connector for connection of 3-wire system Pt100Ωresistance bulb.

Inlet for interface board

Section to fit an optional interface board.

29

31 32 33

34

30

DC 9V 1.2A

REMOTE

Pt100Ω

GCOM

GO

LCOM

LO HI

HCOM HOLD

COM RST

8

3. Operation

3.1 ●Power supply

Turn ON the power switch on the front panel. A pilot lamp is lit up and the meter immediately

enters the operable condition.

Although the meter will immediately be in operating status,

it is recommended to have a pre-heating time for 30 minutes or more.

The meter is provided with the function to retain the parameters, so it

memories the status of the followings even after the meter is switched OFF.

(1) Measuring function and range.

(2) Set values of comparator (30 program memories).

(3) Standard temperature and temperature coefficient of temperature compensation function.

(4) Standard resistance value of ratio display function.

(5) Status of key lock.

(6) Status of buzzer.

(7) Status of zero adjustment.

3.2 ●Connection of measuring terminals

Make a connection to the measuring terminals on the front panel (or rear panel) as Fig.3.2.1shows.

Fig.3.2.1

Note: Penetration of disturbing noise to the measuring terminals may cause instability or display

or auto range operation. Prevent the noise by connecting with shield wire the shield side

to

SOURCE Lo.

Fig.3.2.2 Connection of optional Kelvin clip (MODEL 5811-21).

3.3 ●Connection of temperature sensor

When the functions of temperature

measurement, temperature compensation

or temperature conversion is used,

connect an optional Pt100Ωsensor

(MODEL 5803-11) to the Pt100Ω

connector on the rear panel.

Black

Red

E

D

B

C

A

BCD

E

A

B

B

S(Shield)

SOURCE Hi

SENSE Hi

SENSE Lo

SOURCE Lo

Object

3568 Lead wires

Shield wire

be measure

d

9

3.4 ●Key lock

This is the switch to prohibit the key operation on the front panel so that the measuring condition

can not be carelessly altered.

LOCK lamp is lit up during the key locking. When required to operate other switch, do it after

releasing the key lock.

To make key lock

The key is locked when the SHIFT (LOCK) key is pressed for more than 3 seconds.

While the key is locked, LOCK mark is displayed at the upper side of the LCD.

To release key lock

When the SHIFT (LOCK) key is pressed again for more than 3 seconds, the key lock is

cancelled.

3.5 ●Change-over of measuring range

Select a measuring range (auto range or manual range) of resistance measurement.

This operation is disabled in memory mode and when the status is ONLINE or HOLD.

(1) Auto range

●The measuring range automatically steps up when the display value is 35000 or higher

and steps down when the display value is less than 3000.

●AUTO mark and the resistance range automatically detected are displayed at the right of the

LCD.

Selection of

AUTO range

When the RANGE key is pressed at the 300kΩrange, AUTO lamp is lit up and the

meter enters the auto ranging.

(2) Manual range

●The range is fixed at 300mΩ~300kΩ.

●The lamp of the selected range is lit up.

Change-over of range

Every time the RANGE key is pressed, the range mark (300mΩ~30kΩ) at the right of

the LCD changes.Select the desired range.

SHIFT

(LOCK)(SET)COMP.SET

FUNCSEL

ONLINE 0 ADJ.MAN'L

AUTO

300mΩ

123.45

S

123.45

mΩ

mΩmΩ

No. HI SET LO SET

30

(ONLINE)

(MAN′L/MEM)

(BUZZ)

POWER

T.ELAMP

0ADJ.

RANGERATE

LOCK

LCD

113.45

OHM

Keys to use

(SET)COMP.SET

FUNCSEL

0 ADJ.MAN'L

SHIFT

123.45

S

123.45

mΩ

mΩmΩ

HI SET LO SET

(ONLINE)

(MAN′L/MEM)

(BUZZ)

POWER

T.ELAMP

0ADJ.

RATE

LCD

113.45

(LOCK)

SHIFT

RANGE

300mΩ

AUTO

OHM

Keys to use

10

3.6 ●Zero adjustment

This is the function to suppress the resistance of tools and so on in resistance measurement.

The value currently measured is memorized as zero set value into the non-volatile memory and

afterwards, the value from which the zero set value is suppressed is displayed.

Display value = Measured value - Zero set value

●This function is enabled in manual mode and memory mode of the resistance measurement,

temperature compensation function, temperature conversion function and ratio display function.

●Zero set value is effective in all ranges.

●In case that the zero adjustment is made in the higher range, it may over-range in the lower range.

●Remote control is possible for this function.

●Remote control through the interface GP-IB, RS-232C or RS-485 is also possible.

Note: ●This function can not be operated during the temperature measurement and the hold.

●Zero adjustment is not released even if the memory is changed in memory mode.

3.6.1 Key operation

A press of the 0 ADJ. key activates the operable condition of zero adjustment.

During the zero adjustment, 0 ADJ. mark is displayed at the upper side of the LCD.

Pressing again of the 0 ADJ. key cancels the zero adjustment.

3.6.2 Remote operation

The zero adjustment is operable while the 0 ADJ pin on the rear panel REMOT connector is being

ON.

When the pin is turned OFF, the function is released.

Note: Zero adjustment work set up with the key operation is released by making this pin OFF.

3.7 ●Selection of sampling rate

Make a choice of sampling rate with key operation on the front panel.

●Remote control through the interface GP-IB, RS-232C or RS-485 is possible.

●Selection is not possible during the hold function.

The sampling rate changes by pressing the RATE key

S→M→F→SSlighting : 4 times/sec.

Mlighting : 20 times/sec.

(SET)COMP.SET

FUNCSEL

MAN'L

AUTO

300mΩ

123.45

S

123.45

mΩ

mΩmΩ

HI SET LO SET

(ONLINE)

(MAN′L/MEM)

(BUZZ)

POWER

T.ELAMP

RANGERATE

LCD

113.45

OHM

(LOCK)

SHIFT

0ADJ.

0 ADJ.

Keys to use

(SET)COMP.SET

FUNCSEL

MAN'L

AUTO

300mΩ

123.45

123.45

mΩ

mΩmΩ

HI SET LO SET

(ONLINE)

(MAN′L/MEM)

(BUZZ)

POWER

T.ELAMP

RANGE

LCD

113.45

OHM

(LOCK)

SHIFT

0 ADJ.

Keys to use

S

RATE

0ADJ.

11

3.8 ●Comparator operation

This is a digital comparator to make a comparison between displayed value and high or low limit

value. 30 pairs of high and low limit value (No.1~No.30) can be memorized.

●Memory can be selected by REMOTE connector.

●Selection of memory can also be done through the interface RS-232C.

Note: ●During the setting of high or low limit and recalling of the memory, the sampling is

stopped and the comparator output is held.

●Comparator does not operate at the temperature display.

3.8.1 Conditions for comparison

Display value ≧High limit value (HI SET) HI output

High limit (HI SET) >Display value >Low limit (LO SET) GO output

Display value ≦Low limit (LO SET) LO output

Note: Comparator makes comparison with absolute value.

As an example, in case that the high limit is set to 100.00mΩ,

HI is output when 10.00Ωis displayed in the 300Ωrange.

3.8.2 Comparator output

Open collector or relay contact output is output through the input/output terminals on the rear panel.

(refer to the article 4.2)

Display :

HI and LO : Red

GO : Green

12

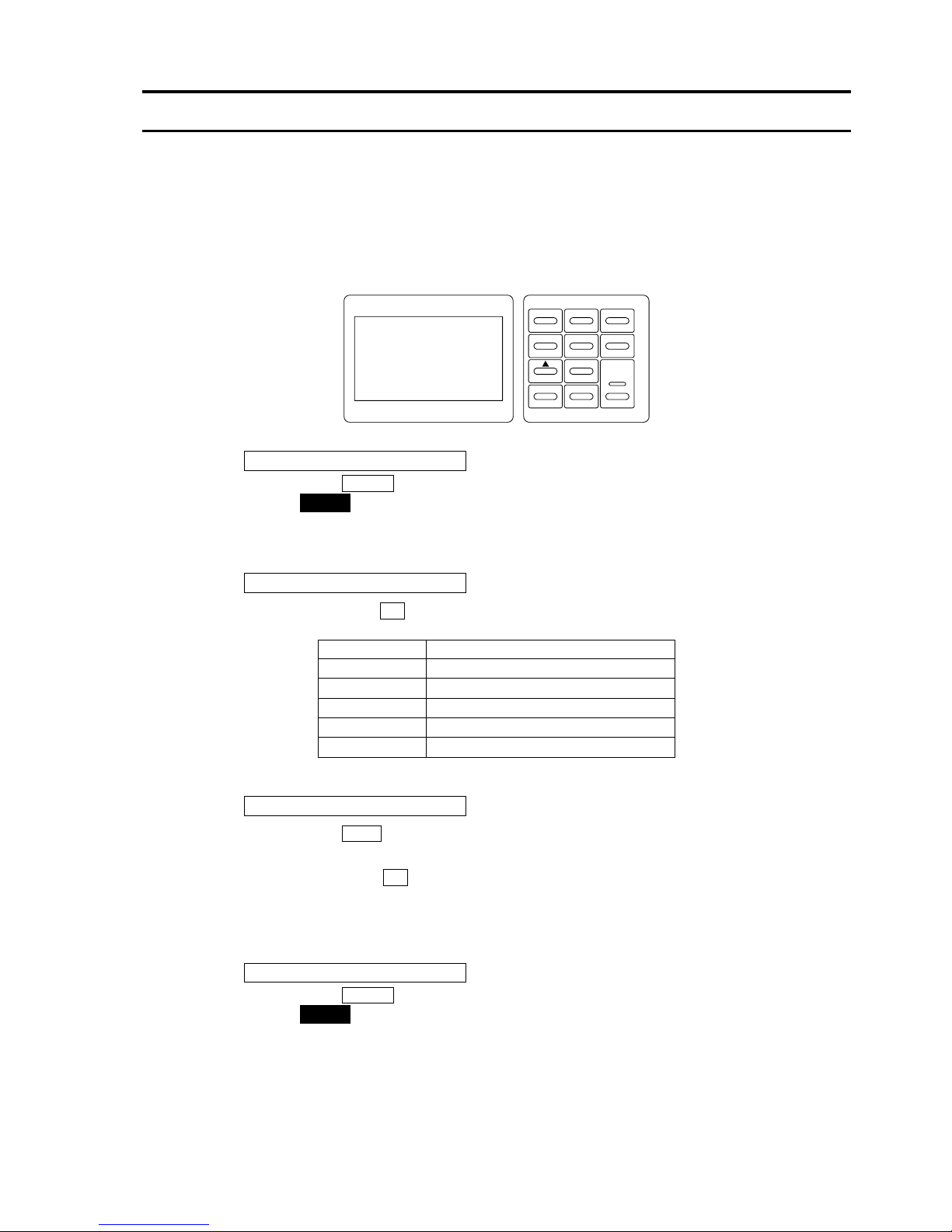

3.8.3 Setting method

Comparator can not be set during the ONLINE, remote control through BCD data output interface

and hold.

Adjustable range High limit : -19999~35000 Note: The unit and decimal point are

Low limit : -19999~35000 set by

RANGE key.

This article explains the method how to set the high and low limit values for the resistance value in

manual mode.

●Refer to the article 5.5 for the setting of ratio display function.

●Refer to the article 3.11.2 for the setting in memory mode.

●When no key operation has been done for about 5 minutes during the setting, the meter returns

to measurement mode.

Change over to manual mode

①(refer to the article 3.10)

Selection of function

②Change over to resistance measurement or temperature compensation function by

FUNC key.

Setting of high limit

③Press COMP.SET key.

A cursor moves to the highest digit of HI SET high limit value, at the lower side of

the LCD.

Set a numeral with

and ▲keys.

Move the cursor with

key, then the selected characters are reversely displayed.

Setting of low limit

④Press COMP.SET key.

The highest digit of LO SET display blinks.

Set a numeral with

and ▲keys.

Move the cursor with

key, then the selected characters are reversely displayed.

Setting of comparator range

⑤Select the decimal point and unit with RANGE key.

Example shows that the HI SET is set to 123.45 mΩ, LO SET to 113.45m mΩ.

Finish of setting

⑥Press COMP.SET key.

Note 1:When the high limit and low limit value is out of the range to set, ERROR mark is

displayed at the item being out of the range, and the setting returns to ③or ④.

(SET)

FUNCSEL

MAN'L

AUTO

300mΩ

S

123.45

mΩ

(ONLINE)

(MAN′L/MEM)

(BUZZ)

POWER

T.ELAMP

RANGERATE

LCD

OHM

(LOCK)

SHIFT

113.45

LO SETHI SET

mΩ mΩ

123.45

COMP.SET

0ADJ.

0 ADJ.

Keys to use

13

3.9 ●Buzzer

Setting of buzzer is done with (BUZZ) key on the front panel.

●During the setting of buzzer, the sampling is stopped and the comparator output is held.

●Setting is disabled during ONLINE and hold.

●When no key operation has been done for about 5 minutes during the setting, the meter returns

to measurement mode.

3.9.1 Setting method

Setting of buzzer

①Press SHIFT key.

SHIFT is displayed at the right of the LCD.

②Press (BUZZER) key.

The LCD changes to the screen for setting.

Selection of buzzer operation

③Select with ▲key.

Display Operation

Buzzer sounds at GO output.

Buzzer sounds at HI output.

Buzzer sounds at LO output.

Buzzer sounds at HI and LO output.

Buzzer is turned OFF.

Adjustment of sound volume

④Press SEL key.

Buzzer sounds.

Adjust with

▲key to a proper sound volume.

The volume is adjustable in 10 steps.

Example) Adjusted to buzzer OFF, sound volume 8.

Finish

⑤Press SHIFT key.

SHIFT is displayed at the right of the LCD.

⑥Press

(BUZZER) key.

LCD

BUZZER SET

MODE

VOL OFF

08

SHIFT

(BUZZ)

Keys to use

14

3.10 ●Manual mode

In this mode, the temperature measurement, temperature conversion function etc. can be operated.

●It is not possible to change over to manual mode when the ONLINE is lit up by remote operation.

Operating procedures

●Make a change of manual mode / memory mode with SHIFT key and (MAN’L/MEM) keys.

In the manual mode, MAN’L mark is displayed at the upper side of the LCD, and the memory No.

is not displayed.

3.11 ●Memory mode

In this mode, the measurement with either one of 30 stored memories is possible.

The sampling rate is common in this case.

3.11.1 Selection of memory

●By means of operation on the front panel

To enter memory mode

①Press SHIFT key.

SHIFT lamp is lit up.

②Press (MAN’L/MEM) key.

Memory No. is displayed.

To recall memory

③Press SEL key.

Select a memory No. and call it.

To finish memory mode

④Press SHIFT key.

SHIFT lamp is lit up.

⑤Press (MAN’L/MEM) key.

●By means of remote operation

Refer to Remote Connector (article 4.1).

LCD

(SET)

SEL

S

mΩ

(ONLINE)

(BUZZ)

POWER

T.ELAMP

RATE

(LOCK)

AUTO

300mΩ

RANGE

0ADJ.

0 ADJ.

SHIFT

(MAN′L/MEM)

MAN'L

mΩ

123.45

123.45

mΩ

HI SET LO SET

113.45

COMP.SET

FUNC

OHM

Keys to use

LCD

(SET)

S

mΩ

(ONLINE)

(BUZZ)

POWER

T.ELAMP

RATE

(LOCK)

AUTO

300mΩ

RANGE

0ADJ.

0 ADJ.

SHIFT

(MAN′L/MEM)

COMP.SET

FUNC

MEM

113.45

LO SETHI SET

mΩ

123.45

mΩ

30

No.

123.45

SEL

OHM

Keys to use

15

3.11.2 Setting of memory

Set the meter to memory mode. When the memory mode is engaged by MEM signal through

REMOTE connector, the setting of memory is not allowed.

The parameters which can be memorized into the memory are following three:

●Function (temperature measurement and temperature conversion function can not be set).

●Comparator setting

(high limit and low limit value, standard value of ratio display function, deviation)

●Range of resistance measurement.

Note: ●Compensation temperature ℃of temperature compensation function and temperature

coefficient

ppm of resistance can not be set. The values set in the manual mode

remain as common value for the respective memory.

●Setting is not allowed in the ONLINE status.

●Setting is not allowed during the hold.

●During the setting, the sampling is stopped and the comparator output is held.

●When no key operation has been done for about 5 minutes during the setting, the

meter returns to measurement mode.

Enter memory mode

①(Refer to article 3.11.1)

To set memory

②Press SHIFT key.

SHIFT is displayed at the right of the LCD.

Press (SET) key.

The LCD changes to the screen for setting.

Selection of memory No.

③The cursor moves to No. mark, memory number.

Select a memory No. with ▲key.

Example shows that the memory No.30 is selected.

Setting of function

④Press SEL key.

The cursor moves to FUNC.

⑤Select either one, OHM, T.C, T.C RATIO, OHM RATIO mark with ▲key.

Example shows that the resistance measurement is selected.

Setting of measuring range

⑥Press SEL key.

The cursor moves to RANGE Resistance Range.

⑦Select either one, 300mΩ~30kΩor

AUTO mark with ▲key.

Example shows that the 300Ωrange is selected.

LCD

(ONLINE)

(BUZZ)

POWER

T.ELAMP

RATE

(LOCK)

0ADJ.

SHIFT

COMP.SET

FUNC

123.45 Ω

30

LO SET

HI SET

RENGE

FUNC

No.

MEMORY SET

(SET)

(MAN′L/MEM)

SEL

RANGE

300 Ω300 Ω

124.45 Ω

OHM

Keys to use

16

Setting of comparator

*④When the OHM, T.C is selected in the setting of functions.*

⑥Press SEL key.

The cursor moves to the highest digit of HI SET high limit value.

Set a numeral with

and ▲keys.

Move the cursor with

key, then the selected characters are reversely displayed.

⑦Press SEL key.

The cursor moves to the highest digit of LOW SET high limit value.

Set a numeral with

and ▲keys.

Move the cursor with

key, then the selected characters are reversely displayed.

⑧Select the decimal point and unit with RANGE key.

Example shows that the high limit value is set to 124.45 mΩ,

low limit value to 123.45m mΩ, and the 300 Ωrange is selected.

Setting of ratio display

*④When the RATIO is selected in the setting of functions.*

⑥Press SEL key.

The cursor moves to the highest digit of STD Reference value.

Move the cursor with

key, then the selected characters are reversely displayed.

Set a numeral with

and ▲keys.

⑦Select the decimal point and unit with RANGE key.

⑧Press SEL key.

The cursor moves to the highest digit of DEV deviation.

Set a numeral with

and ▲keys.

Move the cursor with

key, then the selected characters are reversely displayed.

Example shows that the setting is made to 120.00Ω, deviation 5.0%.

Finish

⑨Press SHIFT key.

SHIFT is displayed at the right of the LCD.

Press (SET) key.

LCD

(ONLINE)

(BUZZ)

POWER

T.ELAMP

RATE

(LOCK)

0ADJ.

SHIFT

COMP.SET

FUNC

123.45 Ω

124.45 Ω

LO SET

HI SET

MEMORY SET

(SET)

(MAN′L/MEM)

SEL

No.

RENGE

30

300 Ω

RANGE

FUNC OHM

Keys to use

LCD

(ONLINE)

(BUZZ)

POWER

T.ELAMP

RATE

(LOCK)

0ADJ.

SHIFT

COMP.SET

FUNC

MEMORY SET

(SET)

(MAN′L/MEM)

SEL

STD

DEV 120.00 Ω

005.0 %

No.

RENGE

30

300 Ω

RANGE

FUNC OHM RATIO

Keys to use

17

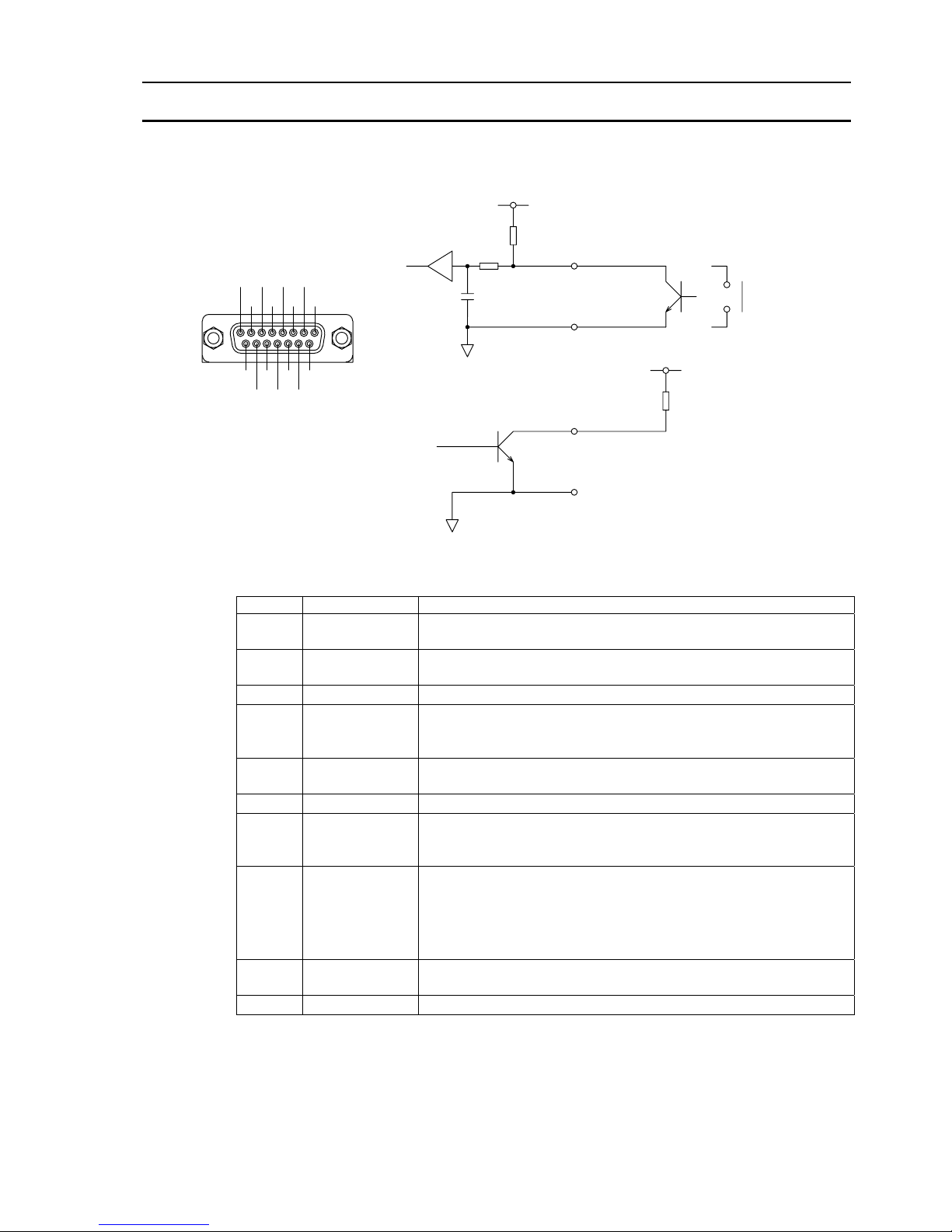

4. Remote control

4.1 ●Remote connector

4.1.1 Pin operation

(Dsub15pin)

Pin No. Signal Function

1 0 ADJ input Zero adjustment is done by making this signal ON.

(Refer to the article 3.6)

2 PRINT input Remote print signal when fitted with printer interface.

(For detail, refer to the instruction manual of printer interface.)

3 MEM input Memory mode is selected by turning this signal ON.

4 TRIG input One shot sampling is done and the judgement result is output

by making this signal ON during the hold,

Min. ON time: 5 ms

5 SW input Broken line detection & self-check is started by making this

signal ON.

6 E0C output Transistor output is turned ON when finishedAD conversion.

7 CC ERR output Transistor output is made ON when the current does not flow

due to open circuit of SOURCE terminal, the error is detected

in broken line detection & self-check and so on.

9

10

11

12

13

M-SEL0

M-SEL1

M-SEL2

M-SEL3

M-SEL4

Input a memory No. and recall memory in memory mode.

14 HOLD input Same action as HOLD on input/output terminals is made.

They are internally connected as common.

8, 15 COM Common for input and output.

15

14

13

12

11

109

87654 2

3 1

COM

Input circuit(L=1.5V or less H=3.5〜5V I

IL

≦‑1mA)

Output circuit

Up to 30V

COM

+5V

18

4.1.2 Remote operation of memory mode

①As long as MEM signal is kept ON, the mode is memory mode.

●When moved to the memory mode, ONLINE lamp is lit up.

●Memory No. being selected is displayed.

Note: In case that the code other than specified is selected, it is not allowed to enter the

memory mode. Make an input of the code 1~30.

②Make an input of code of the memory No. and recall the memory.

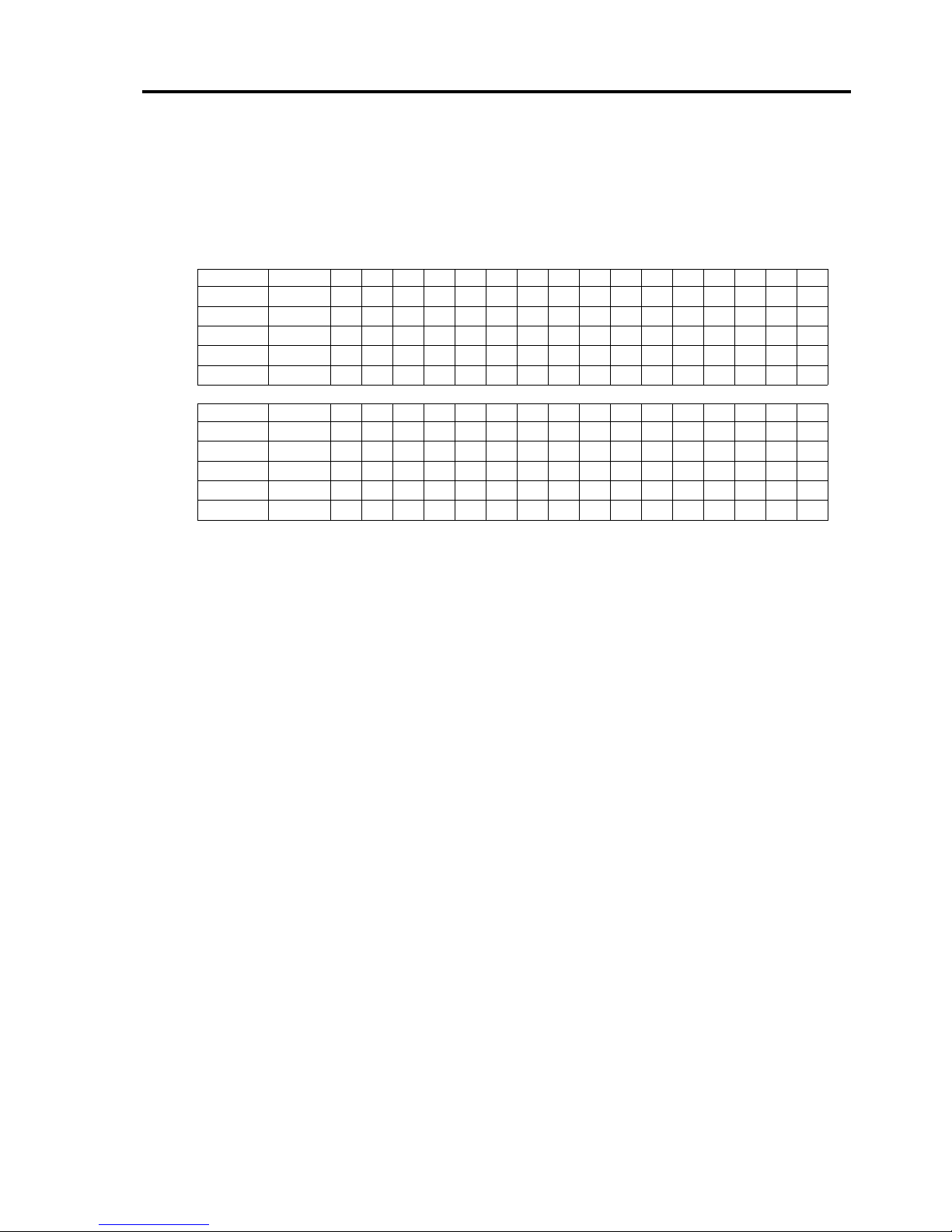

Memory code table

SignalWeight0123456789101112131415

M-SEL0 1

○○○○○○○○

M-SEL1 2

○ ○

○ ○

○○

○ ○

M-SEL2 4

○ ○ ○ ○

○○○ ○

M-SEL3 8

○○○○○○○ ○

M-SEL4 16

Signal Weight 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

M-SEL0 1

○○○○○○○○

M-SEL1 2

○ ○

○ ○

○○

○ ○

M-SEL2 4

○ ○ ○ ○

○○○ ○

M-SEL3 8

○○○○○○○ ○

M-SEL4 16 ○○○○○○○○○○○○○○○ ○

○: Makes ON

Blank:TurnsOFF

0, 31 : No change

③Turn OFF

MEM signal.

●Moving to the manual mode, ONLINE lamp is turned OFF.

●Finishes the memory mode.

19

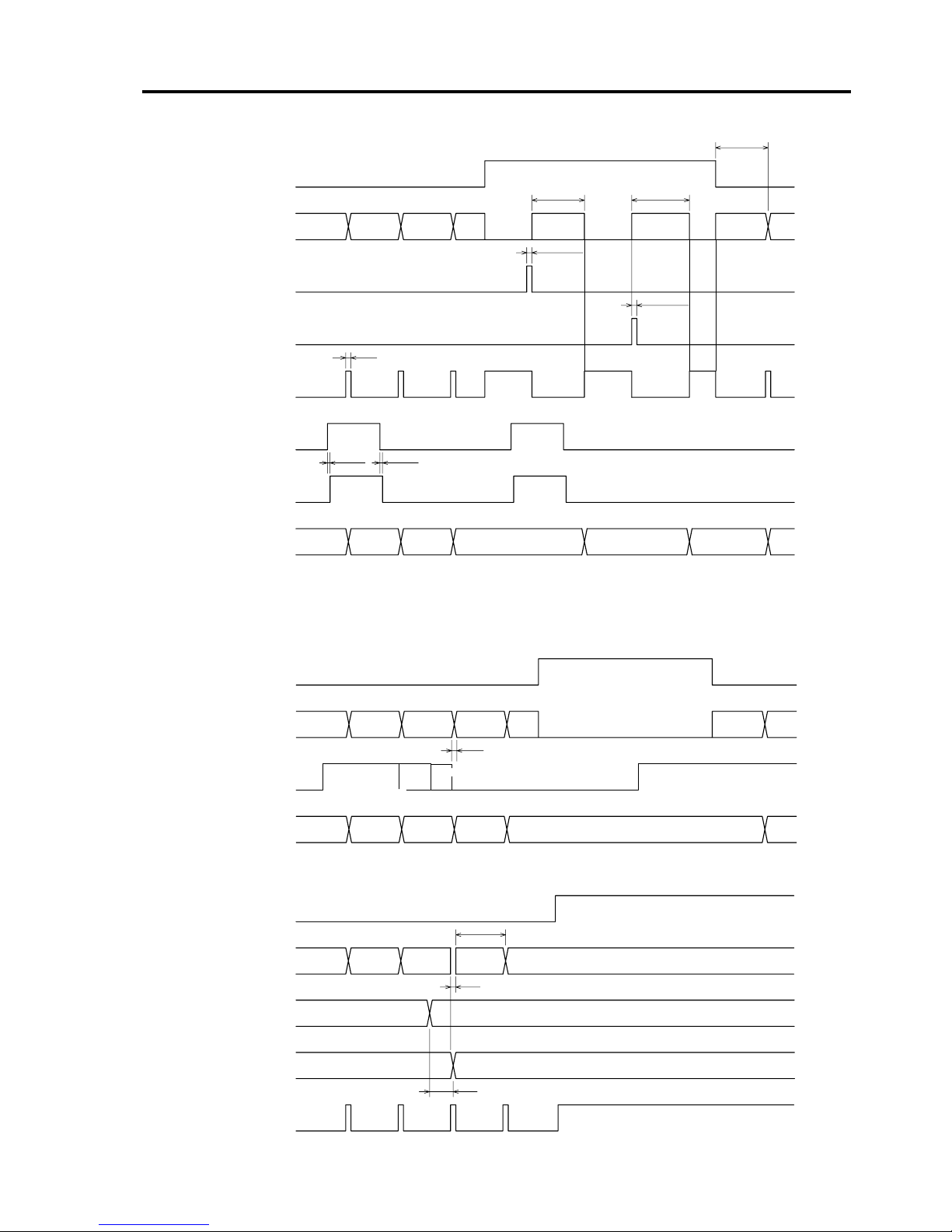

4.1.3 Timing chart of remote control

(1) Measurement action

Tsh = Sampling rate + 3ms

Sampling rate: F = 50ms S = 250ms

(2) Zero adjustment

(3) Change-over of memory (change-over of memory/manual is the same)

Ts = Sampling rate

MAX2ms MAX2ms

5ms

5ms or more

Tsh Tsh

Tsh

S

0

SAMPLING

RESET

HOLD

TRG

EOC

INPUT

CC ERR

DISPLAY

OFF

ON

CONNECTED

OPEN

OFF

ON

OFF

ON

OFF

ON

OFF

ON

S

1

S

2

S

3

S

4

S

5

S

6

S

7

S

0

S

1

S

2

S

4

S

5

S

6

5ms or more

S

1

SAMPLING

HOLD

DISPLAY

OFF

ON

S

2

S

3

S

4

S

6

S

7

S

1

‑S

1

S

2

‑S

1

S

3

S

4

S

6

‑S

4

S

5

O ADJ OFF

ON

S

0

1ms

SAMPLING

MEM

HOLD

FUNCTION

EOC

OFF

ON

Ts

6ms

8ms

M‑SEL 0〜4

RANGE

20

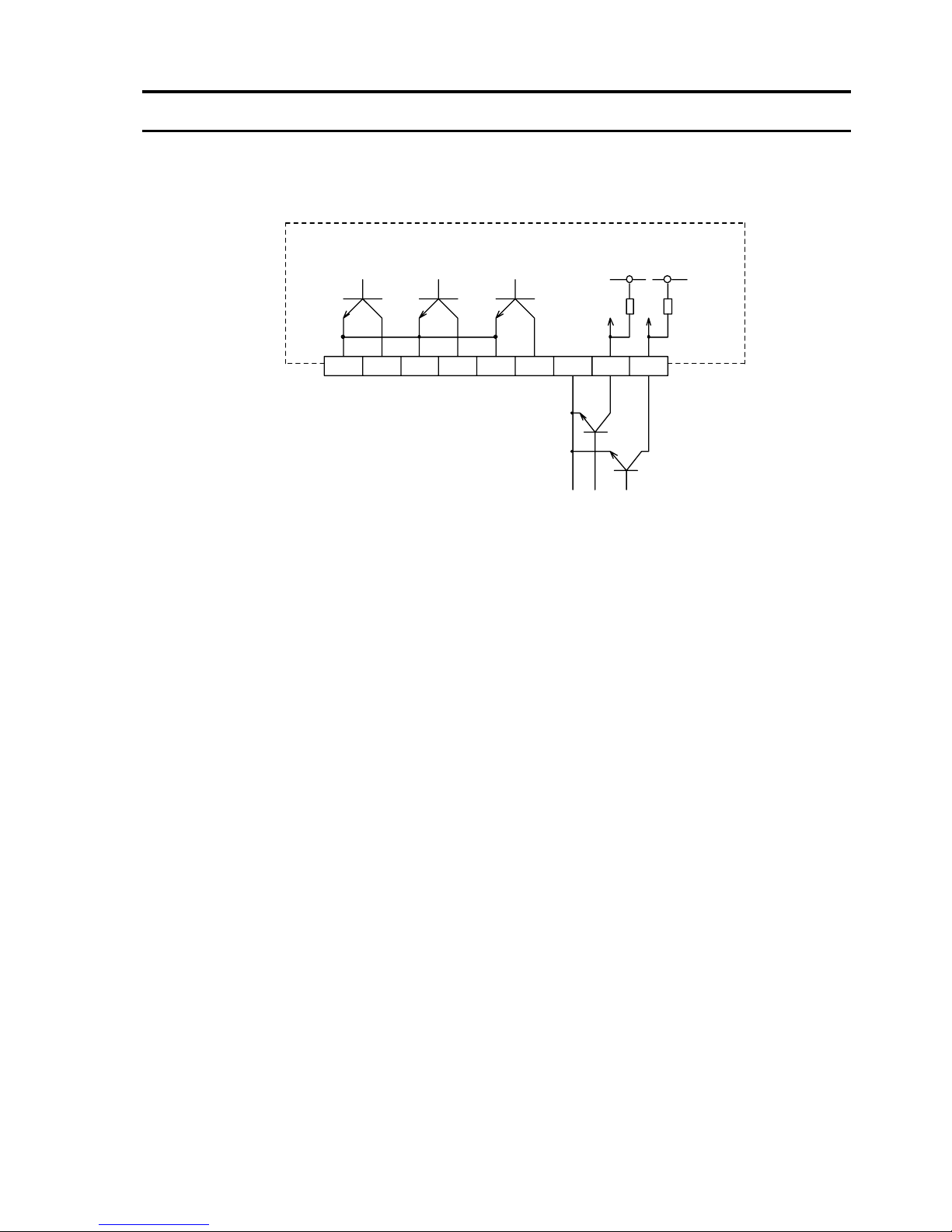

4.2 ●Remote control (input & output terminal block)

Terminal arrangement

(1)

HOLD terminal (hold)

By short-circuiting the

HOLD terminal on the rear panel to COM terminal, the display

value, comparator output and BCD data output are held. During the hold operation,

operation of all the switches is disabled.

(2)

RST terminal (reset)

By short-circuiting the

RST terminal on the rear panel to COM terminal, the comparator

output is reset and the comparator display is turned OFF.

○One shot sampling hold action

With the condition that

HOLD is short-circuited, one shot sampling hold can be done by

switching ON/OFF the

RST. Do one shot sampling hold with the manual range.

In case of auto range, it may cause an error.

(3) Comparator output

Open collector output :

HI, GO, LO, one for each, sink type

30V 30mA Max.

123456789

GCOM GO LCOM LO HCOM HI COM HOLD RST

+5V

3568

+5V

Open collector output

Table of contents

Other Tsuruga Electric Corporation Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Nikon

Nikon Nivo Series instruction manual

Endress+Hauser

Endress+Hauser Levelflex FMP56 operating instructions

Raytech

Raytech TR-MARK III instruction manual

Monitor Technologies

Monitor Technologies TC-1 Installation and Operation Bulletin

Novus

Novus NHDR-6116-H2-II user manual

Rohde & Schwarz

Rohde & Schwarz ESH3-Z6 manual

Xylem

Xylem WTW pH/ION 3310 operating manual

Novatech

Novatech 1635 user manual

SBC

SBC Saia PCD ALD1D5FD Assembly and operating instructions

Termoprodukt

Termoprodukt Node Tele-1 user manual

Piera Systems

Piera Systems Canaree ARUBA quick start guide

PCB Piezotronics

PCB Piezotronics ICP HT352A25 Installation and operating manual