TTF Limo-GT User manual

TTF Limo-GT

Service work instructions

1

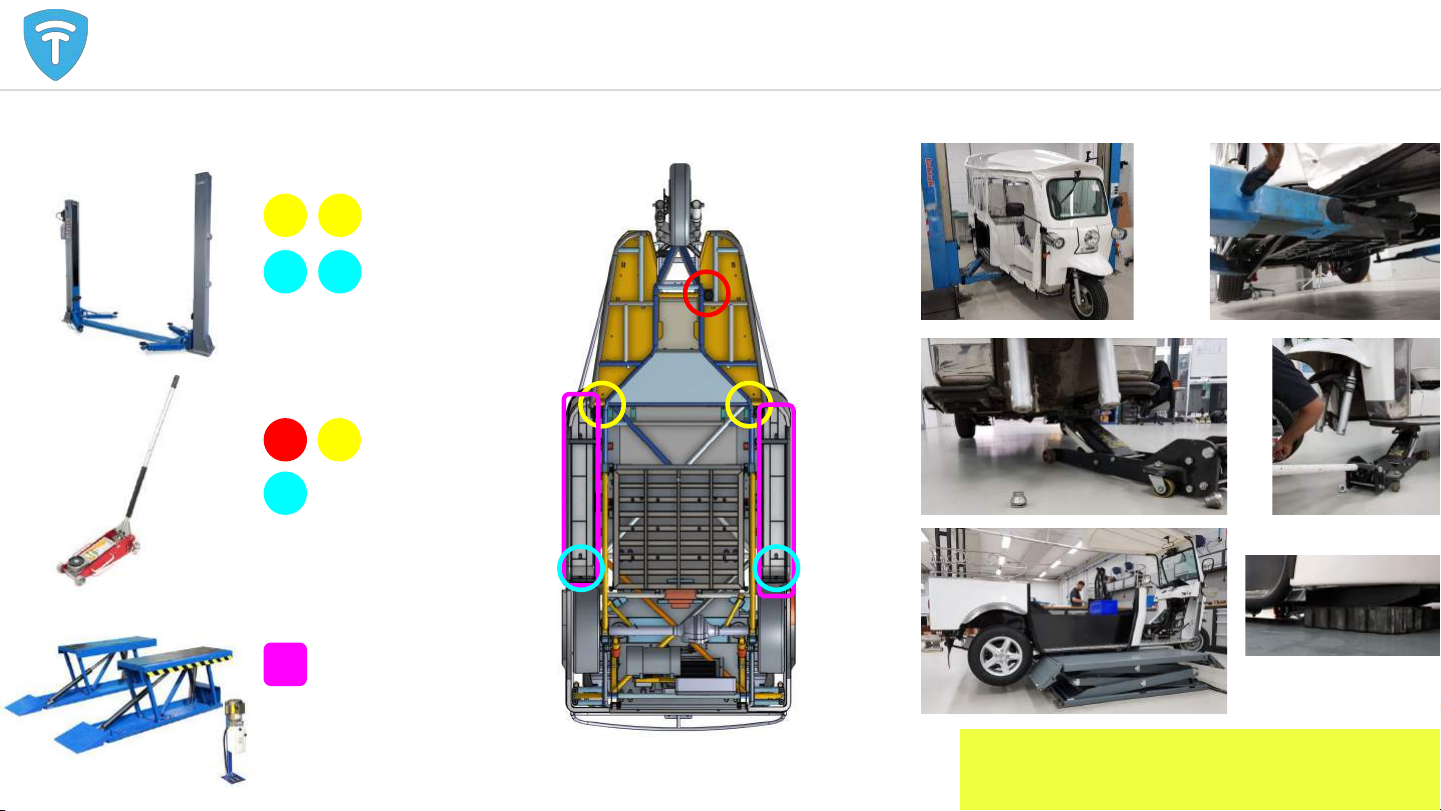

Jacks and lifts: Vehicle Jack point locations:

!Special cases apply for Vendo and pre

2017 vehicles!

2

Workshop guidelines

Lifting:

2 Column lift

Jack

Scissor lift

Handbrake (mechanical,

cables)

Disc Brake (front)

Brake Pedal assembly (hydraulic)

(incl. Brake Fluid res. and Brake

Master Cylinder)

Brake system layout

Drum brake

(rear)

3

Contents:

●Rear suspension overview

●Rear axle and differential

○Overview

○Maintenance

○Replacement

Useful information and

recommendations:

●Use 800ml of oil in the

differential, recommended type

Tranself B 80W90.

●Always thoroughly clean the

differential and its components

before reassembly.

●Be sure to use correct spacer (there

are similar, but different versions

with different length and diameter)

●Check free wheel movement after

installing differential components

and/or motor

●Always re-torque wheel bolts after

100km.

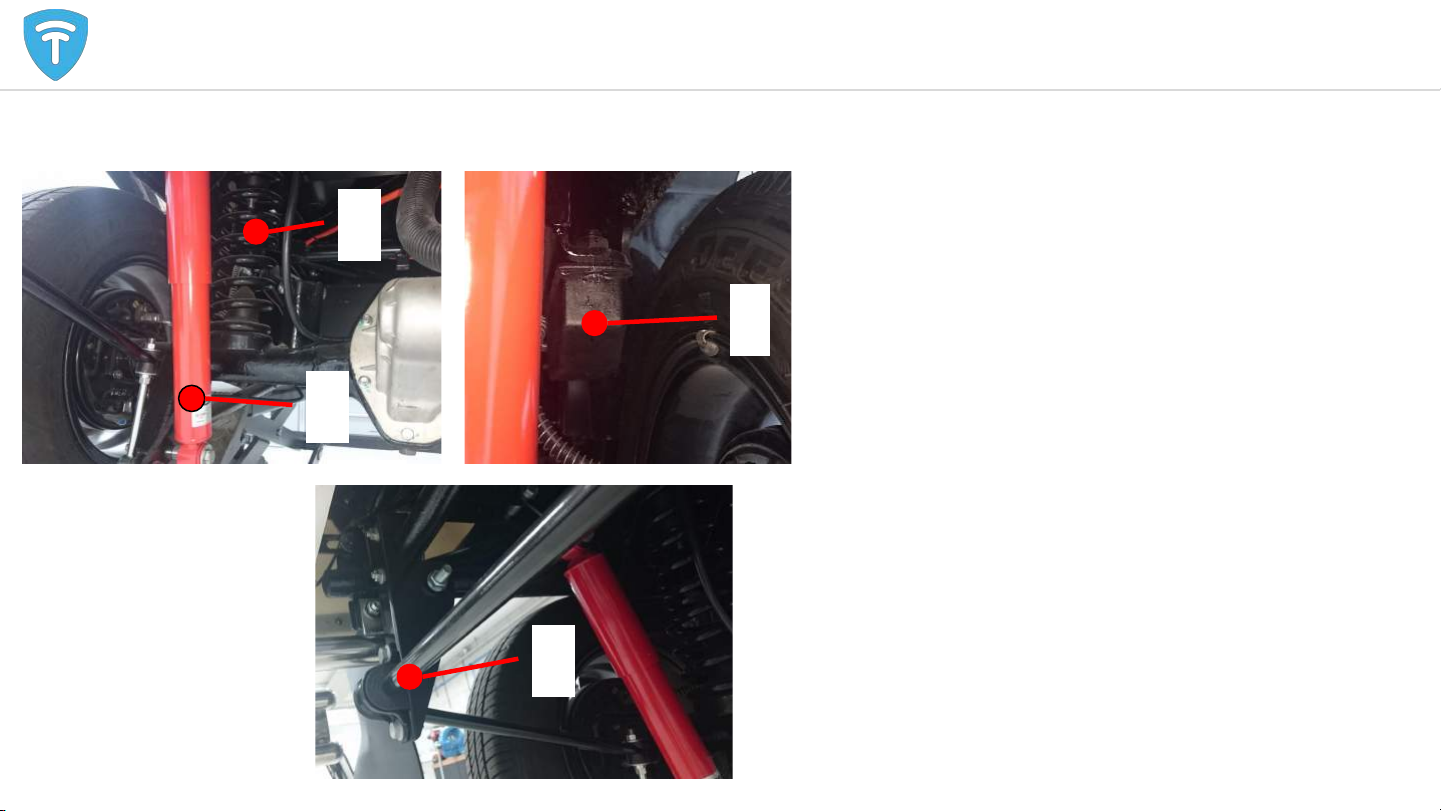

Rear suspension

Things to look out for:

●Noise and vibrations coming

from the rear axle while driving.

●Metal residue and dirt on the

filler cap or in the differential oil.

●Oil leaks

Possible issues:

●Broken differential gears

●Broken drive axle

●Leaking differential seals

●Work or leaking bearings

●Worn suspension bushings

4

E

D

A

B

Rear suspension overview

A. Springs

B. Dampers

C. Arms

D. Swaybar

E. Rubber stop

F. Brackets and spacers

Springs and arms connected to the frame

Dampers connected with brackets and spacers spacers

Stabilizing rod also connected with brackets and spacers

5

●Known issues with the rear axle

○Noise when pushing tuk (low tone) indicative of a

broken differential

○Motor turning, but vehicle does not move

■Either differential or drive shafts are broken

○Contaminated oil will lead to differential failure

(make sure there are no loose metal parts in the oil)

○When replacing the differential, it is advised to also

replace the drive shafts. Old and new components

may not be mix&match

○Oil leaks can be caused by bad seals:

■Drive shaft seals

■Differential gasket

■Differential side seals

■Differential motor seal

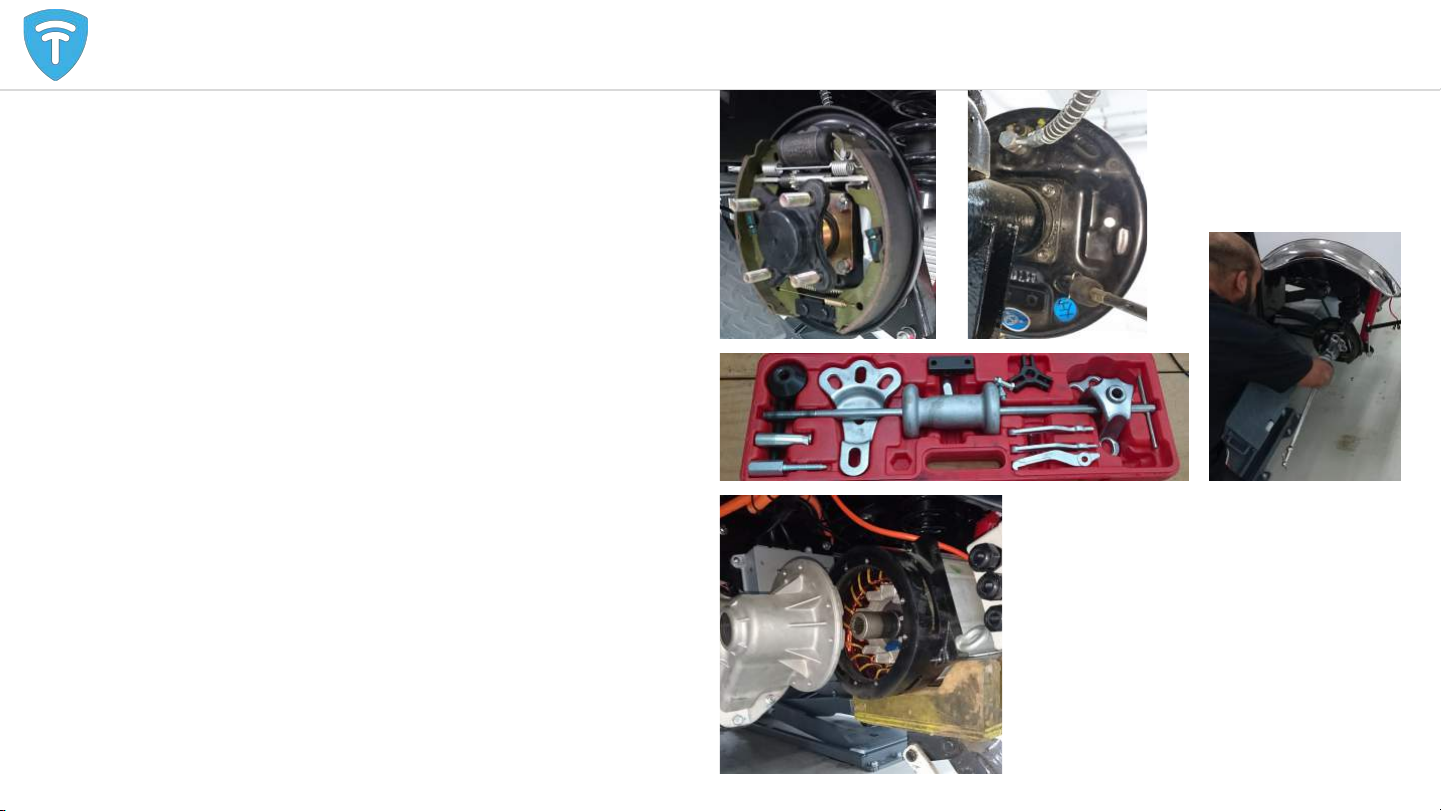

Rear axle and differential: Maintenance 6

Differential removal and installation part 1

1. Disassemble drive shafts

a. Remove wheels and brake drums to reveal drive shaft.

b. Unbolt the 4 M8 bolts from the back of the drum brake

anchor plate.

c. Use an axle puller set to remove the axle

2. Remove the motor

a. Perform service power disconnect and disconnect the

main battery B- from the motor controller (see safety

instruction section)

b. Open the motor cable enclosure and disconnect all

cables and connectors. Remove the motor cable

enclosure.

c. Unbolt 6 M6 hex bolts from the motor.

d. Support the motor with a garage jack and slide it from

the drive axle (to the right).

e. Installation is the reverse procedure

f. Apply grease on the spline before installing the motor

g. Torque values:

i. Motor flange M6: 14Nm

ii. Motor cable terminal: 12Nm

Rear axle and differential maintenance 7

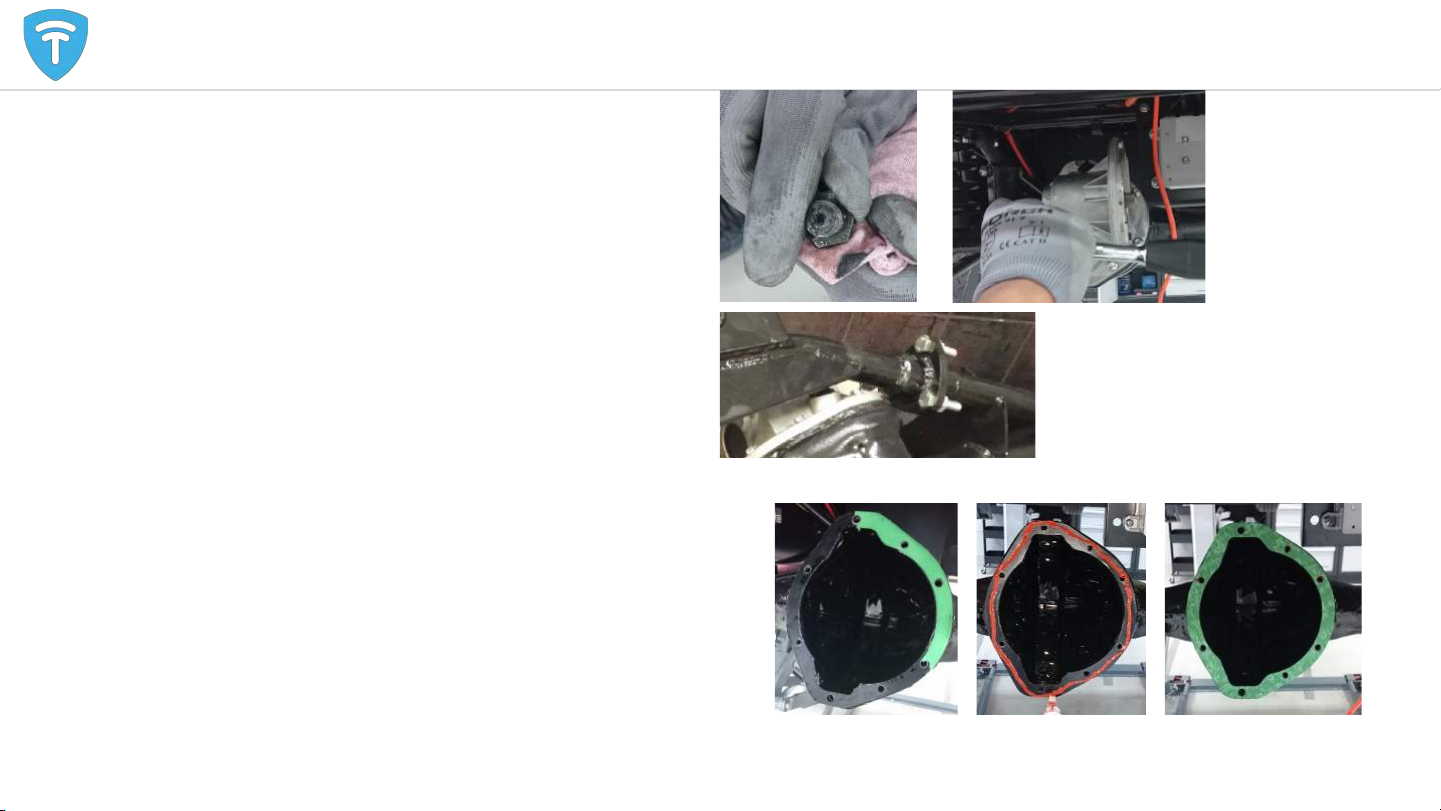

Differential removal and installation part 2

3. Remove the draining plug (underside differential bell housing)

and drain all differential oil, check the inside of the plug for

metal debris (there is a magnet here). Lots of debris indicates

excessive gear wear.

4. Unbolt all differential bolts and remove the differential. (Pre

2017 vehicles have axle structure that needs to be removed as

well. If this structure is welded in place it needs to be cut away

and reinstalled using a retrofit flange kit)

Installation:

1. Thoroughly clean the inside of the axle and all parts to remove

all debris and dirt.

2. Clean the contact surface of differential and axle and put

silicone gasket sealer paste on the flange and install the green

gasket.

3. Fit new differential, use lock bonding material on the bolts and

tighten the bolts with 14Nm. (TTF recommends to install new

drive shafts whenever installing a new differential)

4. Fill the differential with 80ml Tranself B 80W90.

5. Reassemble all other parts.

Rear axle and differential maintenance 8

●The Tuk Tuk has several body parts that can be

replaced in case of damage.

●Please check type of e-tuk before ordering spare

parts, older Tuk Tuks have different body parts

than the Limo GT.

Body replacement 9

Old Tuk Tuk has a small step-in and a

continuous body around the passenger

section

New Limo GT Tuk Tuk has a large step-in

and smaller body panels surrounding the

passengers

10

Electrical, hardware

Safe working on the electric drive train - work procedure 11

Work on the motor, battery or controller After an accident or when in

doubt of hazard

Call Tuk Tuk

Factory first!

Dashboard

1. Remove rear bench

2. Open controller box

3. Remove blue relay

Back

1. Put the vehicle in neutral

2. Use the parking brake

3. Turn the vehicle off

4. Mark the spot

Dashboard

Battery

type?

Start procedure 1. Check for visible danger

2. Turn vehicle back on

After procedure

Lithium

Lead acid

1. Unscrew B- terminal

2. Isolate B-terminal

Back

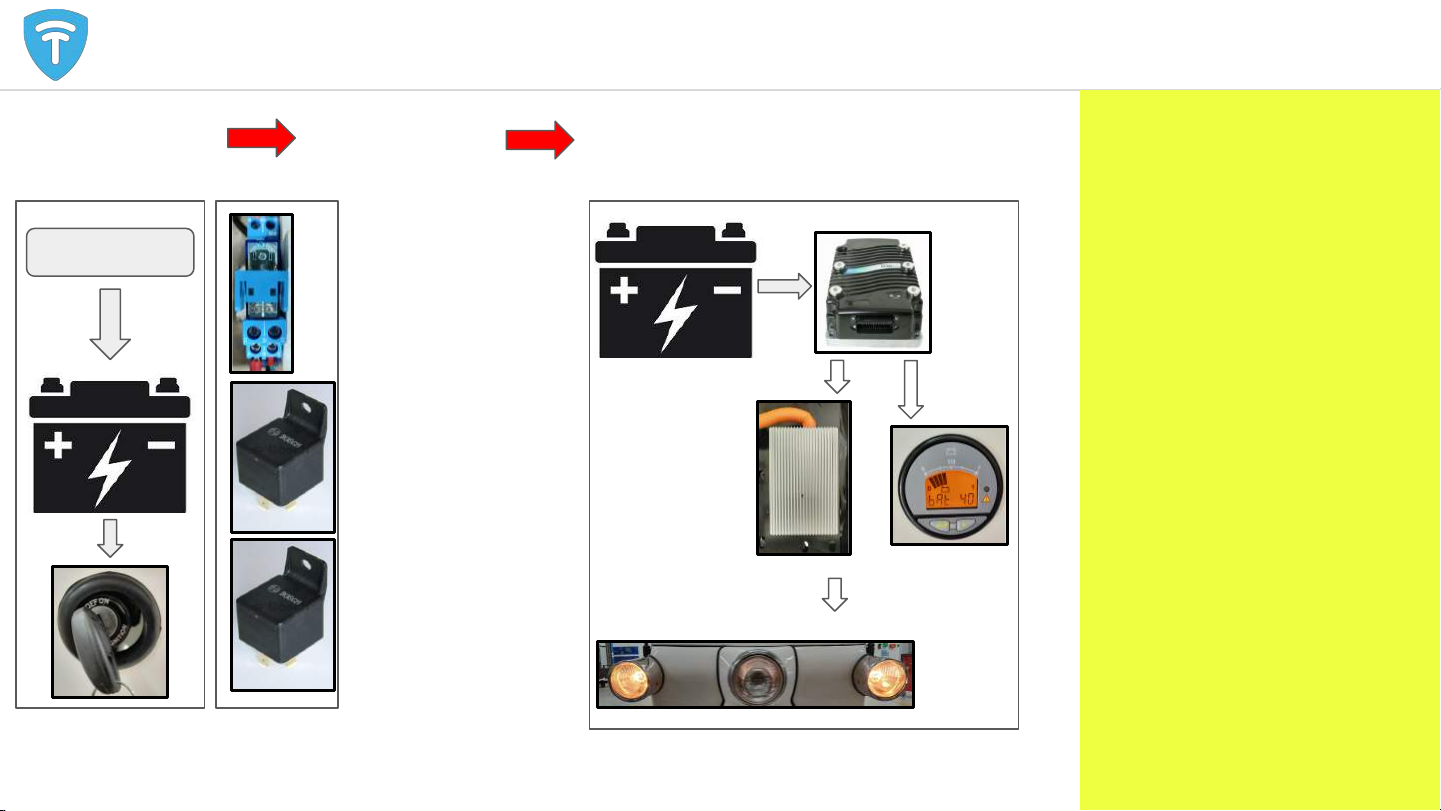

Electric system: Starting sequence 12

12 V

DC-DC

15

Controller

DC-DC

Converter

START

Electric system: Starting sequence

If the starting procedure works,

the controller should turn on. The

yellow LED on the controller

flashes. If it does not work, check

all steps in the sequence.

The controller uses several input

signals to work as desired. If the

controller turns on but does not

respond as expected, check the

input signals with the 1313

handheld controller:

1. KSI

2. DNR switch

3. Throttle

4. Kill switch

5. Brake switch

6. Charger inhibit

7. BDI

8. Motor sensors

9. Speedmode

10. CANbus

1 2 3

12V battery powers

the KEY SWITCH

KEY SWITCH

turns on 3 relays All systems turn on

BDI

Controller key relay (blue)

1. 72V battery

(fused) with

controller key

wire

2. Key wire turns on

controller/DC-DC/

BDI

3. Lithium battery

key input (if

applicable)

In fusebox: 2 relays for

12V system

1. DC-DC -> 15

2. 12V -> 15

72 V

DC/DC relay

connects DC/DC

converter with 15

track.

12V battery will be

charged when

both relays are

engaged

15 switched relay

connects 15 track

with 12V battery.

Useful information and

recommendations:

Possible complaints:

●Tuk does not turn on

●Lights are not bright

enough

●Several devices do not

work

How to identify power supply

issues:

●Measure 12V battery

voltage. Should be higher

than 12V when vehicle is

off, should be over 13.2V

when vehicle is on

●Check function relays; feel

them ‘click’ or measure in

and output

●Check fuses in fuse box

and inline fuses of key

switch and DC/DC

converter

Electric system: Fuse box

*All electric diagrams are available in this course*

13

CONTROLLER

35P

MAIN

CONTACTOR

DC/DC

CONVERTER

KEY FUSE

KEY RELAY

MAIN FUSE

OPTO ADAPTER

DCDC FUSE

COMPONENTS:

●MOTOR CONTROL

○CONTROLLER

○35P

○MAIN CONTACTOR

○MAIN FUSE

●POWER ON

○KEY FUSE

○Controller KEY

RELAY

○DC/DC FUSE

●POWER

○DC/DC converter

○Charger connection

●COMMUNICATION

○CANbus connector

○CAN Optoadapter

○Serial connector

Electric system: Controller board components 14

12V battery empty.

●If the 12V battery is not charged, the

vehicle will not start. A starter battery

should be connected to power on all

systems.

●When systems are restarted the cause of

the problem should be determined.

Check if voltage of battery is >13.1V

●Probable causes:

○Too low voltage from DC/DC

converter. Implement DC/DC

rework solution (thicker cable)

○DC/DC fuse broken. Install 30A

fuse

○DC/DC relay broken

○Blue key relay broken

○No power from main battery

○DC/DC converter broken

Blown fuses

●A blown fuse will stop energy flow

to a device. A blown fuse usually

indicates a issue somewhere in the

fused circuit. Whenever a fuse is

blown, the reason for failure should

be verified. Possible causes:

○Wrong fuse value. The right values

can be found in the wiring

diagrams

○Short circuit in a wire, caused by

wire break or cut.

○Too much load on a circuit. Any

auxilary devices should not be

directly connected to one of the

existing circuits. The aux plugs

(for charging phone or navigation

system) can only deliver 120W.

15

Common issues

Isolation error

●The lithium battery measures

the isolation between B- and

the chassis. If measured

values are below 30.000Ohm,

it gives an error and shuts

down.

●Common areas which can

cause isolation errors:

○Canbus optoadapter

○Battery Key or canbus cable

○Speedometer optoadapter

○Wrong contact on B- or

chassis

○Grounding error. Make sure

controller box is mounted

firmly to chassis.

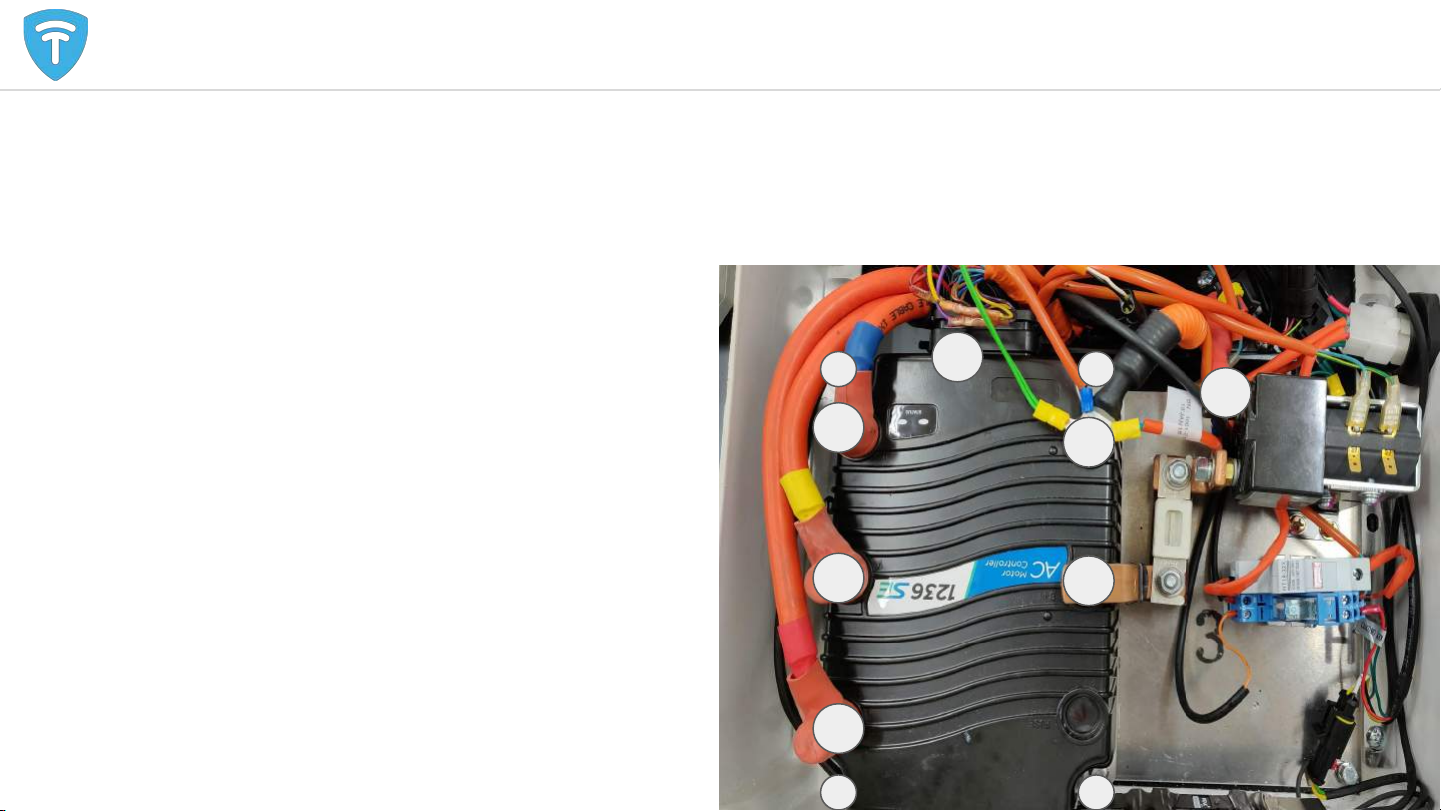

Electric system: Controller replacement procedure 1

Removal

1. Turn vehicle off

2. Disconnect 35P connector

3. Disconnect B- and isolate B- battery cable with

tape.

4. Disconnect all motor cables

5. Disconnect B+ bus bar

6. Unbolt controller 4xm6 hex bolts

7. Remove controller

Placement

●Please follow the previous steps in reverse

●Use torque wrench (14 Nm) for steps 3,4 & 5.

16

2

3

3

4

4

4

6

5

6

66

Electric system: Controller replacement procedure 2

Installation

1. Clean surfaces controller and

aluminium plate

2. Apply heat conductive paste

3. Position controller on alu plate

and bolt down.

4. Connect all cables. Fasten bolts

with 14Nm

5. Connect 35pin connector

Place controller and thermal paste on clean desk. Flip controller and clean surface.

Apply thermal paste in thin lines. Spread with back of tube, evenly over the whole

surface.

17

Source: Curtis

Electric system: Controller thermal issues

Background

The controller’s safe operating

temperature is -25°C to +85°C. During

driving (mainly accelerating and motor

braking) the controller heats up.

Whenever driving in warm climates there

is a chance that the controller temperature

will rise above +85°C. When it does, the

controller will give an error and max speed

will be reduced.

It is best to stop driving and let the

controller cool down.

If the C_hot error occurs regularly, there

might be another problem:

1. Dirt

The controller and heat sink need to be cleaned of dirt.

2. Terminals

These terminals need to be secured properly.

3. Heat sink alignment

- Underneath the heat sink are screws that can be tightened.

- The bolts, securing the controller, can be tightened.

- The cooling paste can be removed and applied (see slide: ‘controller - hardware

replacement procedure’).

4. Wheels

Lift the vehicle to check if the wheels can turn freely (see slides regarding rear

suspension, axle and differential).

18

1. Connect vehicle to PC using CURTIS 1314 cable.

2. Select software version .exe file:

1236, 1238: Folder 123x

Lead Acid_tuktuk135_123x_20170623

1234SE, 1236SE, 1236E: Folder 123xse

Lithium_tuktuk150_123XSE_20180110

Lead Acid_tuktuk141_123XSE_20170623

3. Run .exe file with latest software from PC

4. Select correct COM port (PC specific)

5. FLASH

6. Update user and OS defaults from .exe software

19

Controller - software - installation procedure 1

8. Perform a test drive and check all

functionality using the monitor menu

of the handheld programmer

a. Speeds

b. Driving direction

c. Acceleration and

deceleration

behaviour

d. Throttle response

e. Charger inhibit

f. Foot brake

g. Kill switch

h. Max battery current

(for lithium battery)

7. Open software pack. Verify battery and controller

type.

1236, 1238: Folder 123x

Old motor: 1236_OS12_ADC_Lead Acid_20170623

New motor: 1236_OS12_KDS_Lead

Acid_20170623

8. 1234SE, 1236SE, 1236E: Folder 123xse

1236SE_OS26_KDS_Lithium_20171204

1236SE_OS26_KDS_Lead Acid_20171026

9. Select ‘connect’ in PC programming station

10. Send software to connected controller. Make sure

advanced cloning is selected.

11. Follow on screen instruction: turn vehicle off and

wait 5 seconds before turning it on again.

12. Change parameters manually (values are located

on top of controller box).

a. Can Interface/Baud Rate

b. Motor Control Tuning/IM Motor

Characterization Tests/SlipGain

20

Controller - software - installation procedure 2