TTI ReelStrike Service manual

Operator’s HandBook

ReelStrike™& Strike™

www.tti.com.au

Manufacturer of “The Safest Tanks in Motion”

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

2

Contents

Safety 4

General Safety Instructions 5

General Information 6

Specifications 6

Description 7

Machine Limitations 10

Driving Stability 10

Spray Boom Calibration 10

Calibration Procedure 10

ReelStrike & Strike Operating Instructions 10

Before first use 10

Filling the ReelStrike & Strike Tank 13

Operating Instructions 16

Clean-up and Decontamination 21

Maintenance 22

Periodic Checks 22

Maintenance Schedule 22

Maintenance Tasks 24

Trouble Shooting 24

Pump 24

Risk Assessment 25

Warranty 26

Warranty Policy 26

What this Warranty Does Not Cover? 26

How to Obtain Service Under this Warranty? 26

Warranty Limitations 26

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

3

Disclaimer

All information, illustrations, and specifications contained in this manual are based on the latest product

information available at the time of this publication’s printing. TransTank International (TTi) reserves the right

to alter and substitute specifications and methods at any time, in line with our commitment to continuous

improvement.

No patent liability is assumed with respect to the use of information contained within this manual. While

every precaution has been taken in the preparation of this manual, TTi assumes no responsibility for errors or

omissions.

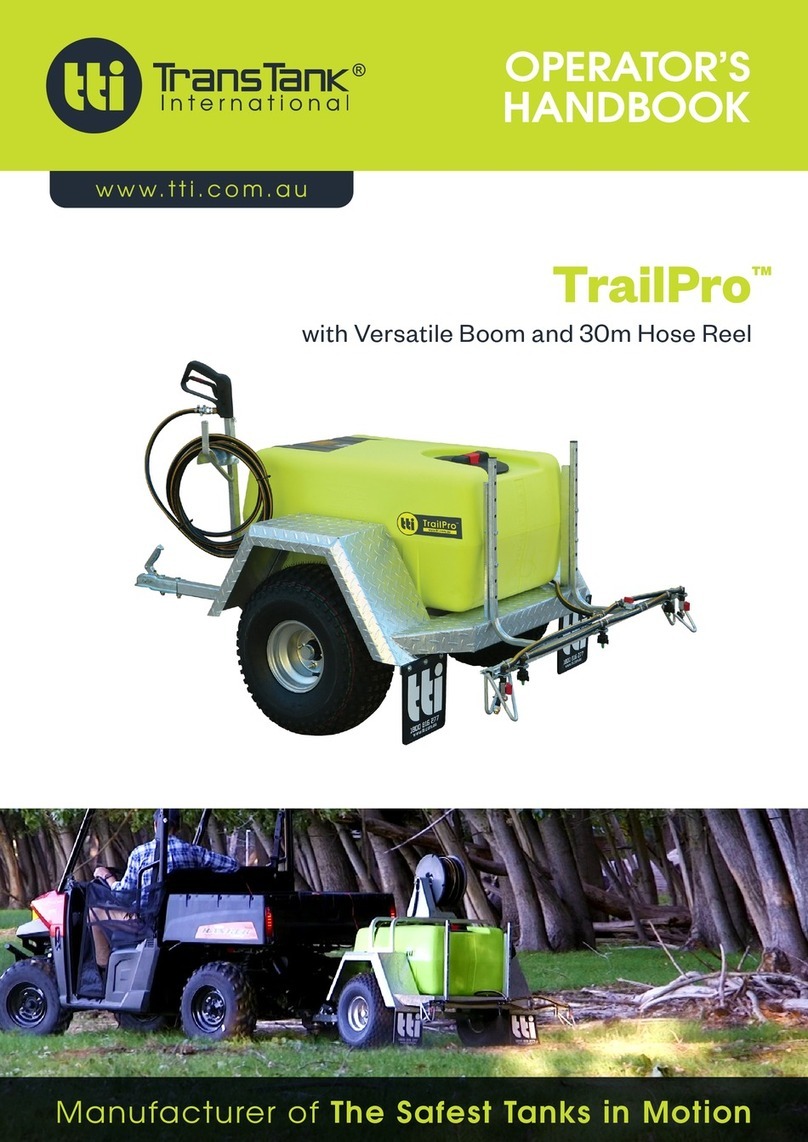

Thankyou forpurchasingaTTi ReelStrike& StrikeSpotSprayerunit, which

will provide many years of reliable service when operated and maintained

in accordance with this manual.

TTi manufacture a range of ReelStrike & Strike units, either 200 or 400 litre tanks, supplied with a 12-volt

electric pump and fitted with hose, hose reel and spray boom options. This manual describes the operation,

driving stability and maintenance procedures applicable to all units, noting additional requirements to

options where necessary.

All TTi ReelStrike & Strike tanks are rotationally moulded from quality polyethylene, purpose designed and

manufactured to high standards. The ReelStrike & Strike is a Utility Terrain Vehicle (UTV) tub-mounted unit

designed for everything from herbicide or pesticide spraying. The ReelStrike & Strike can also be mounted

on the back of a utility or trailer.

The ReelStrike & Strike unit is supplied complete, tested and ready to mount to your vehicle. TTi warrants

that the ReelStrike & Strike has been designed and built for its intended purpose as a pesticide/herbicide

spray unit.

The owner is responsible to ensure that the equipment is operated in accordance with this manual, with

Australian WorkSafe requirements, applicable road rules and local council regulations. TTi is not liable for

any loss, injury or death resulting from the failure to observe all safe working regulations as required by law.

Included with your ReelStrike & Strike unit is the following documents:

• Operator’s Handbook (this manual, which includes the Warranty Registration Card)

• Tank Quality Check Form. This is your verification that the unit has been quality checked, and verifies

the serial number affixed to the unit.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

4

Safety

This manual is intended for use by personnel experienced in the use of this and similar equipment. Read and

understand this manual before attempting to operate or perform routine maintenance on this equipment.

Your safety is of prime priority.

A WARNING highlights an essential operating or maintenance procedure, practice,

condition or statement, which, if not strictly observed, could result in injury or death

of personnel, or long-term health hazards.

A CAUTION highlights an essential operating or maintenance procedure,

practice, condition or statement, which, if not observed, could result in damage

or destruction of equipment.

A NOTE highlights or clarifies an essential systems description, operating or

maintenance procedure, condition or statement.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

5

General Safety Instructions

1. This unit is designed and manufactured solely for the purpose of carrying and spraying herbicides

and pesticides. Under no circumstances should it be used for any other purpose. It must never be

used for transporting fuel.

2. Only authorised and trained personnel are to operate this equipment. Operators must have read and

fully understood this manual before operating the ReelStrike & Strike unit.

3. Do not operate the ReelStrike & Strike unit anywhere near bystanders, livestock, watercourses or

any non-targeted vegetation that may be in danger from spray drift contamination.

4. Wind direction and speed must be taken into account, as windy conditions may endanger the operator

or damage to adjacent non-target vegetation. Avoid spraying on hot and sunny days or when wind

speed exceeds 6.5km/h.

5. Do not operate this equipment while under the influence of alcohol or any drugs that could impair

your capabilities in any way.

6. PPE appropriate to the chemicals being used must be worn at all times when operating the ReelStrike

& Strike. As a minimum, the PPE should include coveralls, gloves and boots. A face shield and PVC

apron are recommended depending on the task. It is recommended that the following documents

should be read and understood by the operator:

• ⦁Australian Standard for Chemical protective clothing AS3765

• ⦁Australian Standard for Respiratory protection devices AS1715

7. Ensure the capacity of the vehicle is suitable for the loaded mass of the ReelStrike & Strike. Refer

to the vehicle’s operator manual for safe working loads, correct securing points and relevant

safety instructions. Do not exceed the carrying and braking capacity as specified by the vehicle

manufacturer. As a guide, one litre of water weights one kilogram (kg), therefore a full 200 litre

ReelStrike & Strike unit will weigh in excess of 250kg.

8. The unit must be securely restrained on the vehicle. Ensure all fasteners are tightened and secure

before operation.

9. Care should be taken at all times, particularly when operating on rough or steep terrain. Drivers

should be aware of fluid surge affecting the vehicle’s centre of gravity.

10. The ReelStrike & Strike must never be left unattended while being filled with fluids.

11. Do not operate the pump when there is no fluid in the tank.

12. Do not disconnect any hoses, nozzles or filters while the equipment is operating. Disconnecting any

components while under pressure may result in uncontrolled fluid discharge which may be hazardous.

13. Ensure any electrical connections are properly configured, to prevent damage such as shorting or

reverse polarity.

14. At completion of operation, switch the pump off and relieve any residual pressure by squeezing the

spray gun trigger or opening an optionally fitted spray boom valve.

15. At completion of the operation, decontaminate the ReelStrike & Strike tank and spray lines. Drain

any residue chemicals and store in a sealed container. Dispose of any unwanted chemicals and tank

rinse residue in accordance with current environmental and workplace health and safety regulations.

16. The ReelStrike & Strike has safety labels affixed to various locations on the unit. These labels should

be kept clean and legible, and replaced if damaged.

17. Any unauthorised modifications to this equipment may affect its function and create a serious safety

risk. Any unauthorised modifications will void any warranty on the unit.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

6

General Information

Specifications

Tank UV resistant polyethylene tank complete – 200 or 400 litres mounted on

galvanised steel forkable frame

Standard Equipment Remco 12V electric pump – 8.3 litres/min 100psi, c/w 3.6m electrical lead with

cigarette plug

Pressure regulator

6m hose with spray gun

Pressure regulator

Options Remco 12V electric pump – 11.4 litres/min 60psi

Remco 12V electric pump – 15.1 litres/min 100psi

Remco 12V electric pump – 19.1 litres/min 60psi

30m hose on hose reel with spray gun

BoomTech nozzle kit with tailgate bracket

HitchIt attachment with boomless nozzle

HitchIt attachment with 4m Versatile Spray Boom

Description

The TTi ReelStrike & Strike Spot Sprayer unit is designed to carry and distribute herbicides or pesticides

using a self-contained pump and various fluid dispensing systems, refer to Figure 1 for a typical example.

The ReelStrike & Strike variants are configured in two different styles, both designed to fit into the trays of

UTVs:

• 200 litre tank unit with:

• 6m hose and spray gun (Strike) or

• 30m hose on hose reel with spray gun (ReelStrike & Strike)

• 400 litre tank unit with:

• 6m hose and spray gun (Strike) or

• 30m hose on hose reel with spray gun (ReelStrike & Strike)

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

7

The Strike is fitted with a 6m hose while the ReelStrike has the hose reel and 30m of hose. Either

configuration is suitable for fitting to a conventional utility tray or trailer.

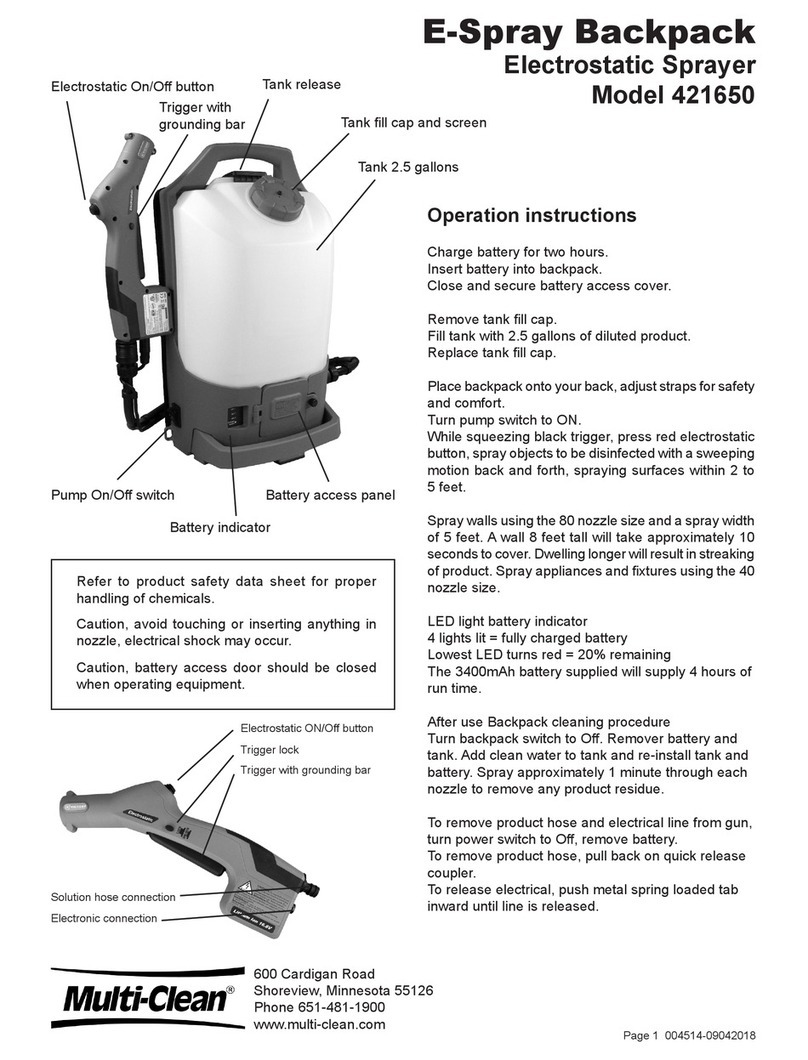

Figure 1 – ReelStrike & Strike Purpose-built UTV Spot Sprayer

The Strike has the features shown in Figure 2, with the ReelStrike is shown in Figure 3.

Figure 2 – Component Identification – 400 litre Strike unit

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

8

Figure 3 – Component Identification – 400 litre ReelStrike & Strike with hose reel

Pump

The ReelStrike & Strike is fitted as standard with an 8.3 L/min 100psi 12V Remco electric pump. Optionally

available are larger capacity Remco electric pumps, with increased delivery from 11.4 L/min to 19 L/min.

If the spray gun or spray boom is not in operation when the pump is running, the fluid bypasses back into

the tank.

BoomTech Nozzle Kit

An optional BoomTech nozzle kit can be mounted to the vehicle or trailer with a tailgate bracket. The

BoomTech has two volume adjustable nozzles, ideal for fence lines, orchard, blanket and end row spraying.

The BoomTech nozzle kit requires a minimum pump capacity of 11.4 L/min, requiring the selection of one of

the three larger pump options available for the ReelStrike & Strike units.

Boomless Nozzle Kit

An optional brass boomless nozzle kit can be mounted to the optional HitchIt attachment, which fits any

50mm Hayman Reece tow hitch. The nozzle is available in four sizes and is ideal for blanket spraying,

especially in rough country spraying and for locust control. By swapping nozzle plates, the nozzle can be

used for either a 90 or 180-degree spray swath.

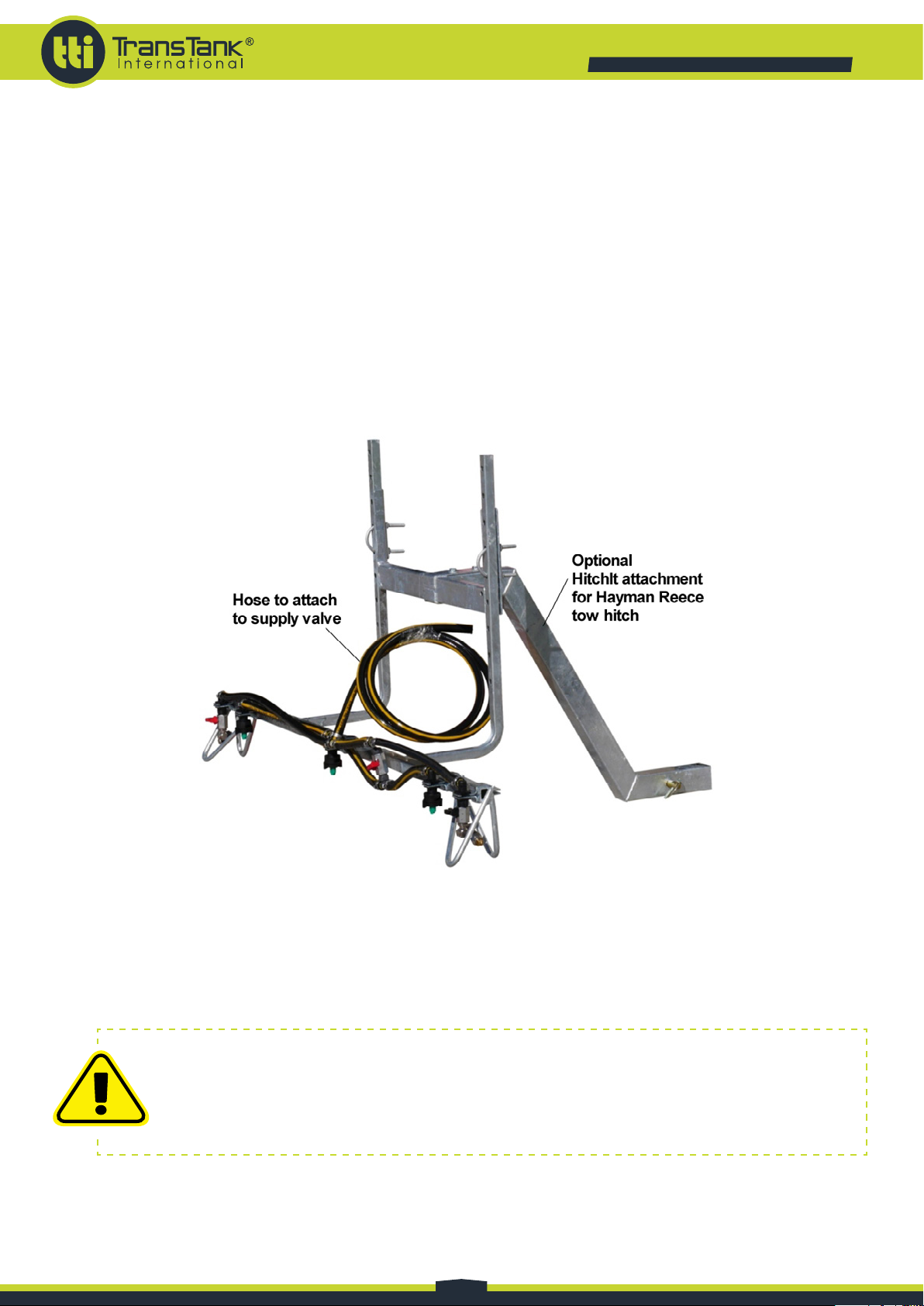

Versatile Spray Boom

An optional 4m Versatile spray boom can be mounted to the vehicle or trailer with U-bolt clamps or using

the optional HitchIt attachment. The 1.2m wide spray boom has three adjustable centre nozzles and two

off-centre end jets to provide a range of spray volumes and patterns, which can achieve a 4m width swath.

The spray boom is operated by a manual valve to start up or stop spray operations. When the valve is

closed, the fluid bypasses back into the tank.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

9

6m Hose and Spray Gun

For the Strike unit, a manually coiled 6m long 10mm diameter hose is connected to a trigger actuated

PowerJet spray gun with adjustable brass nozzle. The nozzle adjusts from jet through to mist sprays

by rotating the nozzle head. When the trigger is squeezed, the fluid is discharged; when the trigger is

released, the fluid bypasses back into the tank. The spray gun is stowed by means of two storage clips

located on the side of the tank.

30m Hose Reel and Spray Gun

The ReelStrike has an manually operated hose reel containing 30m of 10mm diameter hose is connected

to a trigger actuated PowerJet spray gun with adjustable brass nozzle. The hose is pulled out manually

from the reel and retracted using the handle on the side. The spray gun is stowed by means of two storage

clips located on the side of the tank.

The nozzle adjusts from jet through to mist sprays by rotating the nozzle head. When the trigger is

squeezed, the fluid is discharged; when the trigger is released, the fluid bypasses back into the tank.

Pressure Regulator

A pressure regulator and pressure gauge are fitted to the pump discharge flange to control line pressure

and prevent pump cavitation. The regulator is adjustable depending on the operation requirements – for

boom spraying, the regulator is to be set to approximately 3 bar; with spot spraying via the hose reel the

regulator is set to approximately 5 bar.

Suction Filter

A filter is installed on the suction line adjacent to the pump. The filter has a removeable filter element for

easy cleaning.

Manually Operated Valve

A manually operated valve is fitted to the optional spray boom feed line. The valve switches from the hose

feed to the spray boom feed.

Frame

The chassis frame of the ReelStrike & Strike unit is an all steel, fully welded construction and hot dip

galvanised for corrosion resistance. The ReelStrike & Strike unit has an additional upper structure to

support the hose reel. The frames incorporate forklift pockets.

Tank

All TTi tanks are constructed from UV resistant, virgin material polyethylene. The tank is fully drainable

and has an internal basket strainer under the filling cap.

⦁

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

10

Machine Limitations

The Strike and ReelStrike & Strike units are subject to operating limitations. It is the operator’s responsibility

to ensure that this equipment is being operated safely and within these limitations.

Driving Stability

The ReelStrike & Strike unit is heavy when filled with fluid. To maintain stability while operating this unit:

• Ensure the vehicle tyres are inflated to their correct pressure at all times. Underinflated tyres can cause

excessive lateral motion of the tyre, which may cause a rollover.

• Allow extra room for braking and turning when the tank is full.

• Ensure any side gradient (slope) is accounted for, especially when the ReelStrike & Strike tank is full, as

the vehicle may have a higher centre of gravity.

Spray Boom Calibration

Accurate calibration is an essential element of any spraying function as it ensures that the chemical is

applied at the rate specified on the product label. Application in excess of the recommended rate may be

dangerous, can damage crops and is uneconomical.

Calibration must be carried out:

• When spraying for the first time with new spray equipment

• At the beginning of each season

• After changes of nozzle tips, spraying pressure or vehicle speed

• After every 100 hectares of spraying

PPE appropriate to the chemicals being used must be worn at all times when calibrating the ReelStrike &

Strike. As a minimum, the PPE should include coveralls, gloves and boots. A face shield and PVC apron are

recommended.

Calibration Procedure

Check the label on the chemical container for the application rate and recommended spray nozzle type,

refer to Figure 4, which shows the TeeJet AIXR nozzle application chart. To apply a specific rate of chemical

to the target surface, work out the:

• total sprayer output,

• travel speed, and

• the swath width.

Using these parameters, the application rate is calculate as follows.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

11

Measure Total sprayer output [L/min]

Set the pressure at the correct level for spraying determined by the type of nozzles. All nozzles used for

spraying should be left on. For initial trials, set the pressure regulator at approximately 2 bar and adjust as

needed.

• Fill the spray tank with clean water, refer to Filling the ReelStrike & Strike Tank procedure below. Run the

sprayer at the correct pressure with all nozzles operating.

• Place a measuring jug under first nozzle for one minute, then measure how much water is in the jug.

• Repeat for all nozzles. Nozzle output should not vary by more than 10%. If it does, the nozzle could be

worn or damaged and should be replaced.

• Add all the jug measurements to find the total sprayer output in litres per minute.

Measure the travel speed [km/h]

The normal speed for spraying with small boom sprayers is 4–10 km/h. The slower the travel, the higher the

application rate. Adjust travel speed to suit ground conditions.

• Measure how many seconds it takes to travel 100 metres with the sprayer attached and half full.

• Calculate your travel speed by inserting the time in seconds into the following formula: Travel speed

(km/h) = distance travelled in metres (say 100m) x3.6 / Time taken (in seconds)

Calculate spray application rate [L/Ha]

First, measure the swath width in metres. For general broadcast spraying, the swath width is equal to the

number of nozzles multiplied by the nozzle spacing. For band spraying, the swath width is equal to the total

of all the band widths. Calculate the application rate using the following formula:

Application rate (L/ha) = (600 x total sprayer output (L/min)) / (swath width (m) x travel speed (km/h))

Example: If total sprayer output is 5 L/min, speed is 8 km/h, and swath width is 4m, the application rate =

(600 x 5 = 62.5 L/ha)/(4 x 8)

If the application rate is less than specified, increase the pressure and repeat calibration to achieve the

correct rate. Once the required rate is achieved, note the following parameters for future reference when

using this particular chemical:

• ⦁Nozzle Fitted

• ⦁Type (Drop Size)

• ⦁Application Rate

• ⦁Spray Pressure

• ⦁Forward Speed

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

12

Figure 4 – AIXR Application Chart

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

13

ReelStrike & Strike Operating Instructions

Before first use

Your ReelStrike & Strike Spot Spray Unit is delivered fully assembled and ready to be fitted onto the

vehicle. Before use, it needs to be set up using the following instructions:

• Complete the warranty registration online at ⦁ www.tti.com.au/warranty-registration, or use the

Warranty Registration Card at the back of this handbook.

• Store this handbook, along with the Tank Quality Check Form and pump unit’s manual in a safe and

easily accessible place for future reference.

• Read and thoroughly understand this handbook, paying particular attention to all safety requirements,

before using the ReelStrike & Strike for the first time.

• Check that all fittings, valves, hoses and electrical leads are secure following transit, and are not

damaged in any way.

• Inspect the tank for any damage or abrasions that may occur during transit.

• Position your ReelStrike & Strike unit onto the vehicle and mount securely, either using tie-down straps

to suitable points on the steel frame or other suitable devices, refer to Figure 2 and Figure 3. The tie-

down straps must be rated to at least the total mass of the unit when filled with fluid. Alternatively, the

integrated tank frame may be bolted to the vehicle.

CAUTION: The unit must be securely mounted to the vehicle. Failure to do so may

result in the unit moving or falling off the moving vehicle. Warranty is conditional on

the unit being correctly mounted.

CAUTION: Ensure any electrical connections are configured correctly to prevent

shorting or reverse polarity. Warranty is conditional on the electrical systems being

correctly connected.

WARNING: The operator must fully understand all aspects of this handbook. Do not

operate the ReelStrike & Strike unit if you are unfamiliar with its operation until you

have read this handbook.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

14

• Install the supplied electrical cable and connect it to the vehicle’s power supply (cigarette lighter

socket) or battery (via alligator clips). The ON/OFF switch is cable mounted and easily accessible to

the operator from the driver’s seat.

• For the optional BoomTech nozzle kit, mount the bracket to the vehicle’s tailgate and connect the

hose to the manually operated valve near the tank.

• For the optional Boomless Nozzle kit, mount the optional HitchIt to the vehicle and securely install the

nozzle kit to the top of the HitchIt.

• Where the optional Versatile Boom is ordered (refer to Figure 5), install it to the vehicle and connect

the hose to the manually operated valve near the tank.

• It is recommended that at first use, the ReelStrike & Strike is filled with water for calibration purposes

and for the operator to become familiar with the characteristics of the unit, refer to Calibration

Procedure.

⦁

Figure 5 – Versatile Boom Arrangement

Filling the ReelStrike & Strike Tank

WARNING: Ensure the filling area is in an open, well-ventilated space if filling with

chemicals. Follow the instructions provided with the chemicals or the applicable

Safety Data Sheet.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

15

Mixing and filling the ReelStrike & Strike unit should be undertaken at a carefully chosen site, away from

any risk of spillages draining into water courses or into environmentally sensitive areas. Children and

animals must always be kept away from mixing and filling operations.

The ReelStrike & Strike unit’s tank is filled as follows:

⦁

CAUTION: If an optional boom or boomless spray nozzle kit is fitted, ensure the

manually operated isolating valve is CLOSED.

• Check that the optional boom kit isolating valve near the pump is CLOSED.

• Open the tank filler by twisting and lifting the cap.

• Withdraw the internal basket strainer and inspect it for any debris. Clean it if required and reinstall it

into the top of the tank.

• Follow the chemical manufacturer’s instructions and safety precautions carefully, taking note of the

order in which the products are added to the tank.

• Measure the correct quantities of chemicals using clean measuring containers specifically for this

purpose only, then add the chemicals to the tank.

• Rinse out the measuring containers and any empty containers and pour all rinsing liquid into the

ReelStrike & Strike tank.

WARNING: Do not overfill the tank. This may result in chemical spillage.

CAUTION: The ReelStrike & Strike must never be left unattended while being filled

with fluid.

• Top up the tank with water to the required level, ensuring it is not overfilled.

• Thoroughly mix the contents by stirring with a suitable paddle or starting the pump to allow

recirculation through the pump and back into the tank.

• Upon completion of filling the ReelStrike & Strike tank, replace the filler cap and twist to tighten.

• Wash off any spillage from outside the tank.

CAUTION: If an optional boom or boomless spray nozzle kit is fitted, ensure the

manually operated isolating valve is CLOSED.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

16

• Close the chemical supply containers and store appropriately. Any empty containers must be

thoroughly rinsed and set aside for collection and disposal in compliance with environmental and

work safety requirements.

Operating Instructions

The ReelStrike & Strike is started and operated as follows:

• Confirm the tank contains the required chemical or water quantity.

⦁

NOTE: Ensure the pressure regulator is set to the minimum position.

• At the pump, check that the pressure regulator is set to the minimum position by turning the knob

anti-clockwise, refer to Figure 6.

Figure 6 – Pressure Regulator

• If fitted with a spray boom option, check that the isolating valve adjacent to the tank is in the CLOSED

position.

• For spraying operations, refer to:

• Hose Spray Operation

• Spray Boom Operation

• BoomTech and Boomless Nozzle Spray Operation

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

17

Hose Spray Operation

Set up and operation of the hose spray system is conducted as follows:

⦁

WARNING: Suitable PPE must be worn by the operator when conducting manual

hose spraying operations.

• Position the vehicle at a suitable point of the operations area.

• If the ReelStrike & Strike unit is fitted with a spray boom option, ensure the isolating valve adjacent to

the tank is in the CLOSED position.

• Check that the pressure regulator is set to its minimum setting. Start up the pump by turning the

electric pump’s cable-mounted switch to ON. The fluid will now be circulating through the system

and returning to the tank via the bypass circuit.

• Set the pressure regulator to approximately 5 bar – this can be fine-tuned as require

• Uncoil the hose manually from the Strike unit, or pull the hose from the ReelStrike & Strike’s hose reel

to unwind it from the reel.

• Aim the hose’s PowerJet spray gun in the required direction and squeeze the trigger. Adjust the spray

pattern by rotating the brass nozzle tip.

• Use a constant speed when spraying and release the trigger at the end of each swath or change

of direction, to prevent overdosing. Work in parallel lines when spraying large areas, rather than

swinging from side to side.

WARNING: Do not spray in windy conditions, where spray drift contamination may

occur.

NOTE: If an optional boom or boomless spray nozzle kit is fitted, ensure the

manually operated isolating valve is CLOSED.

CAUTION: Ensure not to over-run the hose when pulling it out from the reel, as this

may damage the hose or the fittings.

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

18

• At the end of the task, release the spray gun trigger and switch the pump OFF. The fluid will

automatically recirculate through the system and return to the tank via the bypass circuit until the

pump is switched OFF.

• With the pump now turned OFF, aim the spray gun in the required direction and squeeze the trigger.

Thiswill releasethe residualpressurein thehose,which willresultina smallamountoffluid discharging.

• With the hose pressure released, the hose is ready to stow back on the ReelStrike & Strike. Refer to

the following section applicable to the hose option supplied with your unit.

6m Hose

The Strike unit is provided with a 6m hose and spray gun. To stow the hose, simply coil it loosely around

the tank and clip the spray gun into its holder on the side of the tank.

3m Hose Reel

The ReelStrike is provided with 30m of hose on a manually operated hose reel, refer to Figure 7. To

retract the hose, turn the handle at the side of the hose reel to wind it onto the spool, guiding the hose

as necessary to ensure even distribution across the width of the reel. Allow enough slack in the hose to

stow the spray gun in its holder on the side of the tank.

The reel has a four-position locking device to prevent the hose unwinding during transit.

Figure 7 – 30m Hose Reel

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

19

Spray Boom Operation

WARNING: Before commencing spraying, plan the work effectively to minimise

potential contamination of adjacent areas.

Set up and operation of the Versatile Boom is conducted as follows:

WARNING: Do not spray in windy conditions, where spray drift contamination may

occur. Spray drift can be reduced by lower nozzle height, lower pressures or by

fitting larger nozzles.

• Set the required spray selection by opening or closing the individual control valves on the spray nozzle

lines, refer to Figure 8.

• Position the vehicle at the starting point of the operations area.

Figure 8 – Spray Boom Details

Product HandBook

ReelStrike™ & Strike™

1800 816 277www.tti.com.au

20

• Turn the isolating valve (adjacent to the pump) on the boom spray line to the OPEN position.

• Set the pressure regulator to the correct setting as determined during calibration.

• With the vehicle’s engine running and the operator in the driver’s seat, start the pump by turning the

electrical lead-mounted switch to ON. The fluid will now start to discharge from the boom spray

nozzles.

• Commence driving the vehicle at the speed determined during calibration to achieve the required

spray outcome.

• At the end of each swath or before turning around, switch the pump OFF. When commencing the next

swath, turn the pump switch back to ON.

BoomTech and Boomless Nozzle Spray Operation

⦁

WARNING: Before commencing spraying, plan the work effectively to minimise

potential contamination of adjacent areas.

• The optionally fitted BoomTech nozzle kit and boomless nozzle spray kit are operated as follows:

• For the boomless nozzle kit, set the required spray pattern by swapping the nozzle plate for either the

90 degree or 180 degree swath. The BoomTech nozzle kit does not require any adjustment.

• Position the vehicle at the starting point of the operations area.

• Turn the isolating valve (adjacent to the pump) on the boom spray line to the OPEN position.

• Set the pressure regulator to the correct setting as determined during calibration.

• With the vehicle’s engine running and the operator in the driver’s seat, start the pump by turning the

electrical lead-mounted switch to ON. The fluid will now start to discharge from the boom spray

nozzles.

• Commence driving the vehicle at the speed determined during calibration to achieve the required

spray outcome.

• At the end of each swath or before turning around, switch the pump OFF. When commencing the next

swath, turn the pump switch back to ON.

WARNING: Do not spray in windy conditions, where spray drift contamination may

occur. Spray drift can be reduced by lower nozzle height, lower pressures or by

fitting larger nozzles.

This manual suits for next models

1

Table of contents

Other TTI Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

DeVilbiss

DeVilbiss TEKNA TB-1002-D Technical bulletin

WAGNER

WAGNER Power Painter owner's manual

DeVilbiss

DeVilbiss T-AFPV Operation manual

NEW BRUNSWICK SCIENTIFIC

NEW BRUNSWICK SCIENTIFIC G25-KC Guide to operations

Annovi Reverberi

Annovi Reverberi AR Spray 16 Original instructions

Graco

Graco Series B Instructions-parts list