1

Table Of Contents

Safety Issues ...........................................................................................................................................................2 - 3

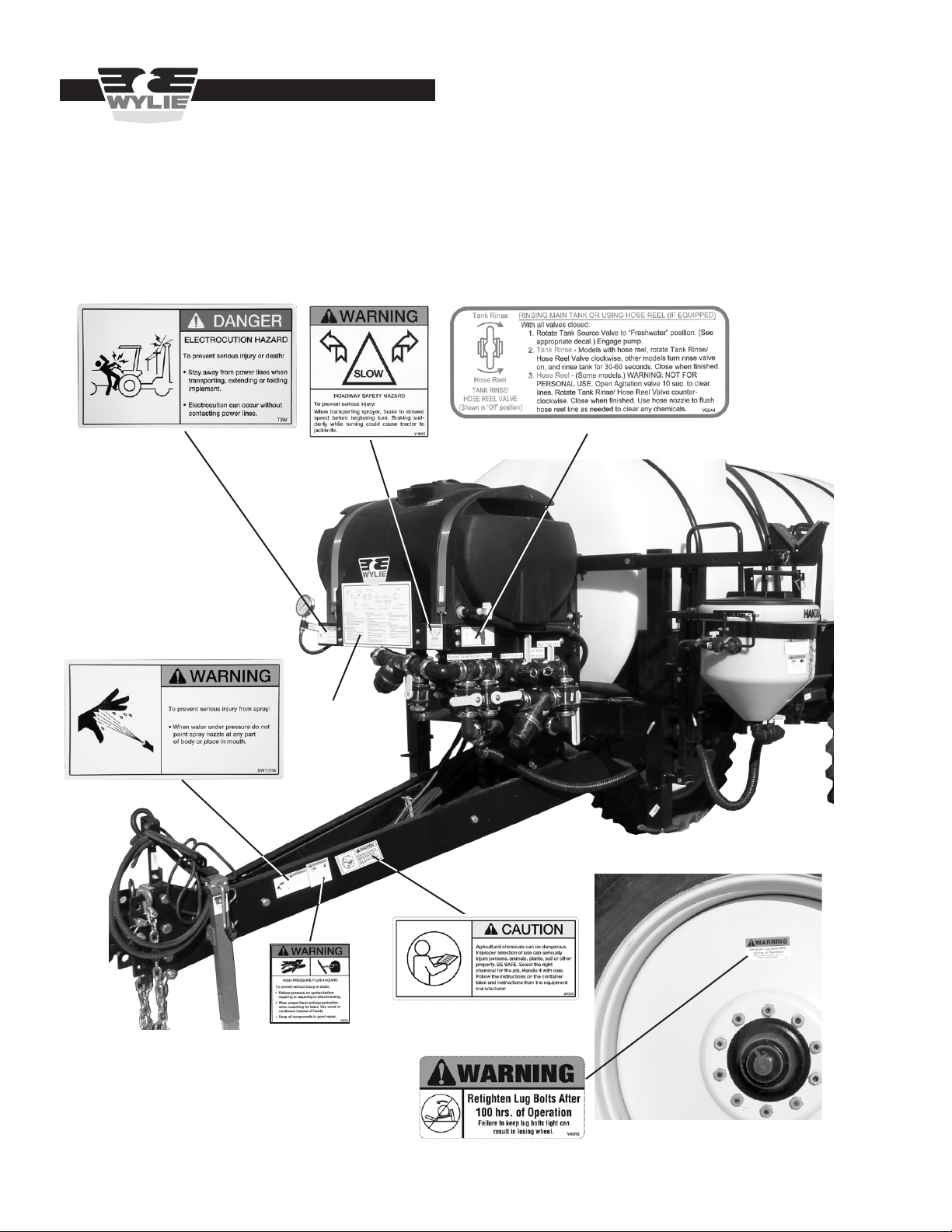

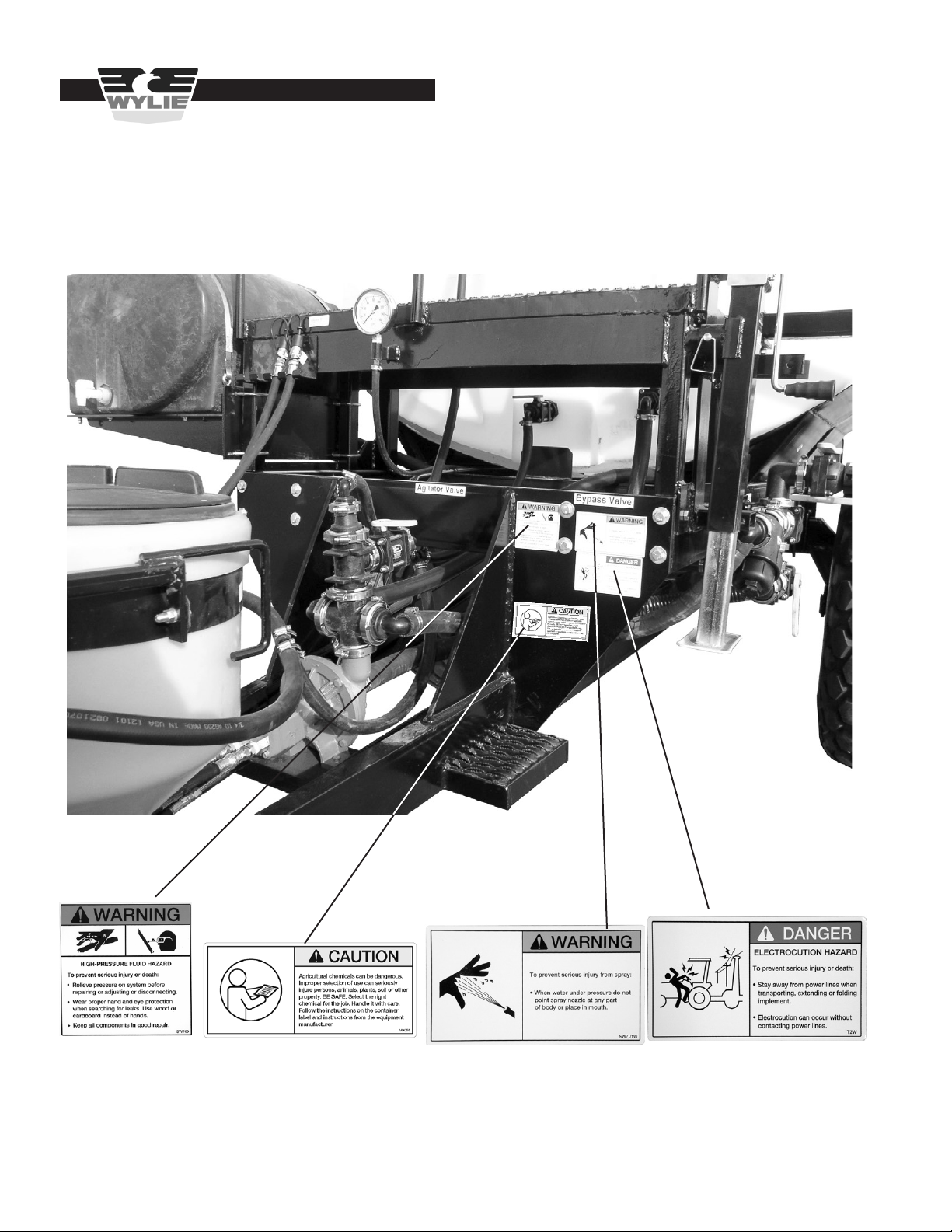

Safety Decals & Placement .....................................................................................................................................4 - 7

Introduction ................................................................................................................................................................... 8

Inspection & Setup ................................................................................................................................................9 - 10

Boom Operation .................................................................................................................................................. 11 - 13

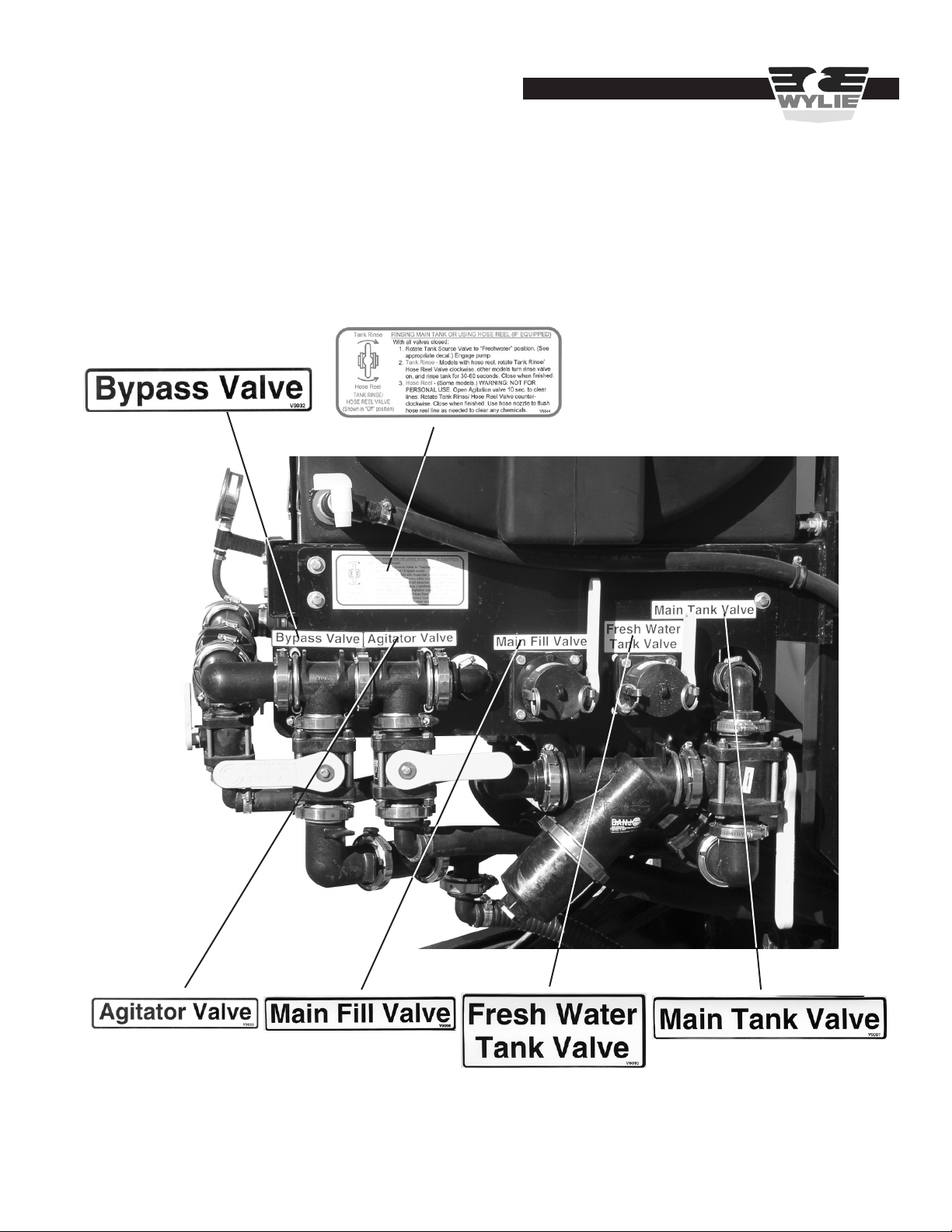

Sprayer Operation ...............................................................................................................................................14 - 22

Maintenance ............................................................................................................................................................... 23

Boom Adjustment ................................................................................................................................................24 - 30

Trailer Adjustment ................................................................................................................................................29 - 30

Lubrication ...........................................................................................................................................................30 - 31

Troubleshooting Guidelines .................................................................................................................................32 - 34

Repair Parts.........................................................................................................................................................33 - 60

Spray Wyng II Center Section .......................................................................................... 34

Spray Wyng II Suspension ............................................................................................... 35

Spray Wyng II Primary Section ........................................................................................ 36

Spray Wyng II Boom Plumbing ........................................................................................ 36

Spray Wyng II Secondary Section .................................................................................... 37

Spray Wyng II Breakaway Section ................................................................................... 38

Spray Wyng II Hi-Lift Linkage ........................................................................................... 39

Spray Wyng II Control System .........................................................................................40

Spray Wyng II Hydraulic Hose Routing ............................................................................ 41

W1510 VersaTrail Trailer .................................................................................................. 42

W1501-16 1,600 Gal. Spray Trailer .................................................................................. 43

SW-1000-SA 1,000 Gal. Single Axle Trailer ..................................................................... 44

SW-1000-ST 1,000 Gal. Tandem Axle Trailer ................................................................... 45

W1515 VersaTrakr Trailer (through 2018) ........................................................................ 46

VersaTrakr Articulated Hydraulic System .........................................................................47

VersaTrakr/VersaTrail Wheels and Axle ........................................................................... 48

VersaTrakr, VersaTrail Pump Kit ...................................................................................... 49

1600 Pump Kit .................................................................................................................. 50

VersaTrakr, VersaTrail, 1600 Tank Plumbing ...................................................................51

VersaTrakr, VersaTrail, 1600 Trailer Plumbing ..........................................................52 - 53

1,000 Tandem/Single Axle Trailer Plumbing ..............................................................54 - 55

Handler™ Mix Assembly/1600 Agitator Assembly ............................................................ 56

Hydraulic System ............................................................................................................. 57

Raven Boom Valves ......................................................................................................... 58

Ace 304 Pump .................................................................................................................. 59

Ace 206 Pump .................................................................................................................. 60

Table of Contents