2

Read this manual before installing the battery and follow the instructions

carefully during installation process.

Content

1. Scope ...................................................................................................................... 3

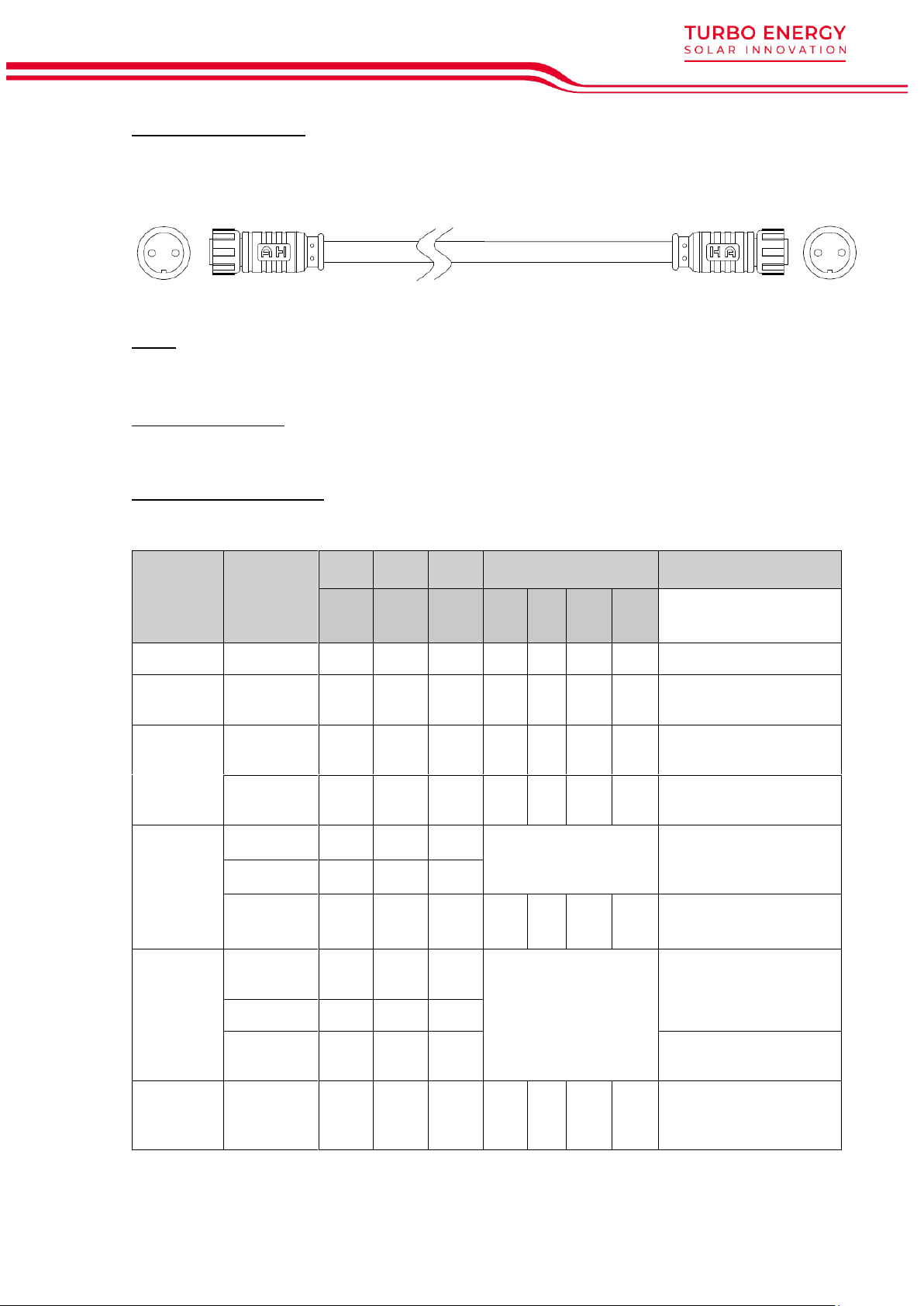

2. Specifications.......................................................................................................... 3

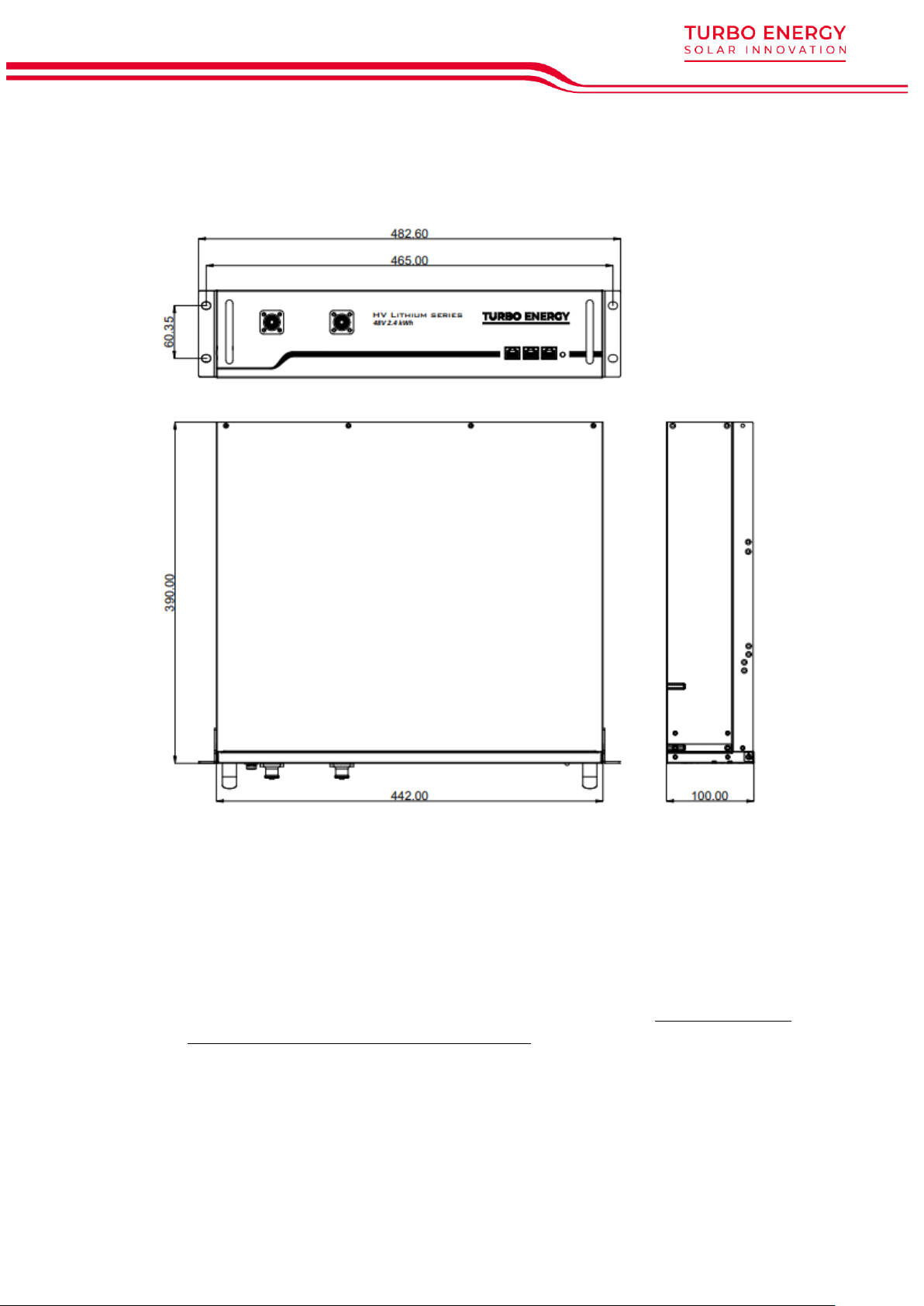

3. Battery Dimensions ................................................................................................. 4

4. Features................................................................................................................... 4

5. Operation................................................................................................................ 5

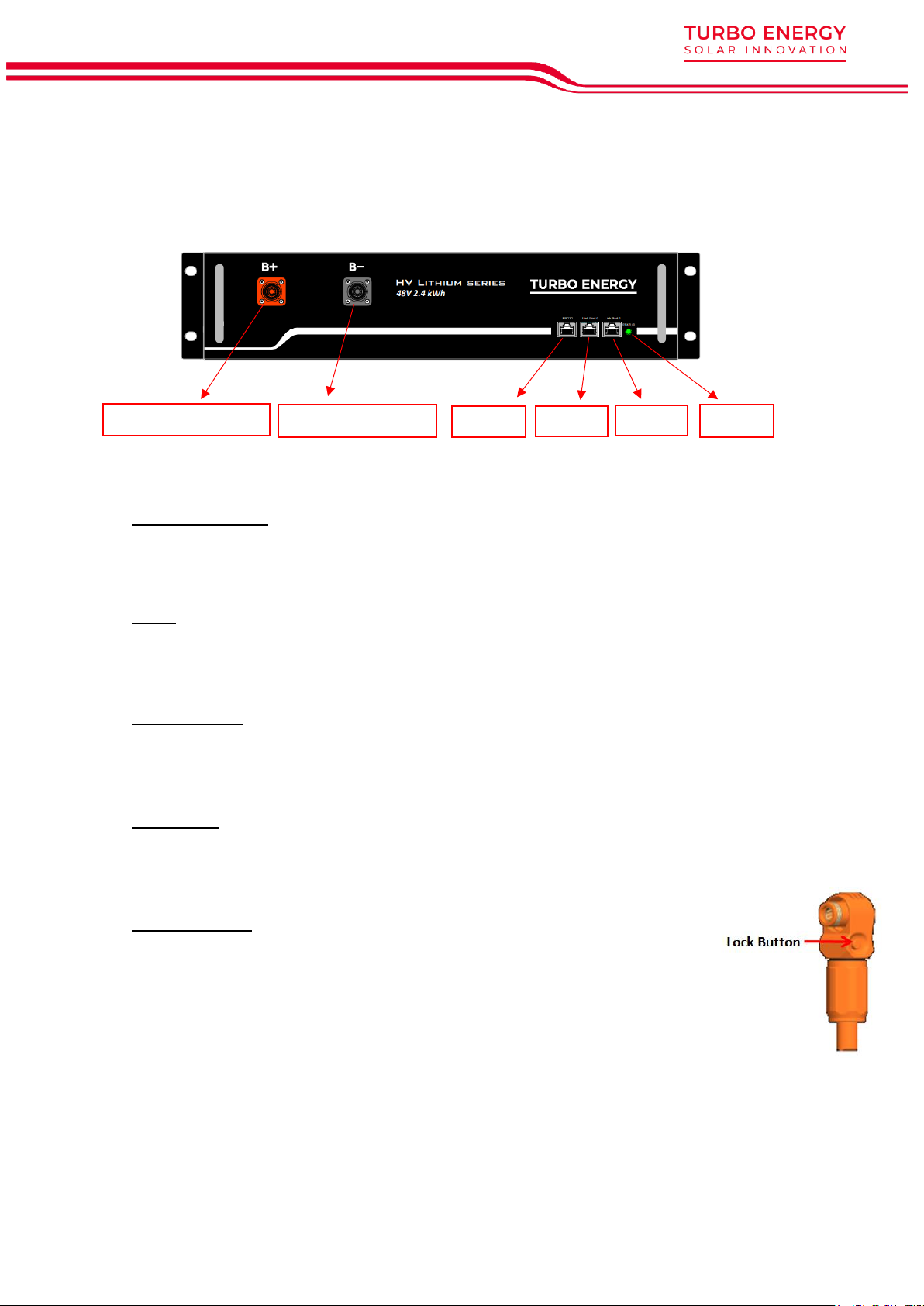

5.1. Battery Front ..................................................................................................... 5

5.2. Control Module ................................................................................................ 6

5.3. Assembly and Connection.............................................................................. 9

5.3.1. Safety..........................................................................................................9

5.3.2. Items in the pack ..................................................................................... 11

5.3.3. Connections............................................................................................. 12

5.3.4. System Diagram...................................................................................... 15

5.4. Configuration of communications ............................................................... 15

5.4.1. Communication for single BMS (battery string qty. 1 set).................... 16

5.4.2. CAN Communication Mode between MBMS and BMS (battery string

qty. ≤6 set).......................................................................................................... 16

5.4.3. Multi MBMS Communication Mode ....................................................... 17

5.5. Power ON and OFF ........................................................................................ 17

5.5.1. Power ON ................................................................................................. 17

6. System Debug....................................................................................................... 20

7. Trouble Shooting ................................................................................................... 21

8. Appendix............................................................................................................... 23

8.1. Security instructions ........................................................................................ 23

8.2. Safety Warnings.............................................................................................. 23

8.3. Environmental Protection .............................................................................. 24

8.4. Contact Details .............................................................................................. 24