Page 2 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

Table of content

2.0.0 GENERAL INFORMATION...................................................................................................................... 3

2.1.0

P

REFACE

................................................................................................................................................ 3

2.2.0

A

REAS OF USE

........................................................................................................................................ 3

2.3.0

I

NCORRECT USE

...................................................................................................................................... 3

2.4.0

S

COPE OF DELIVERY

............................................................................................................................... 3

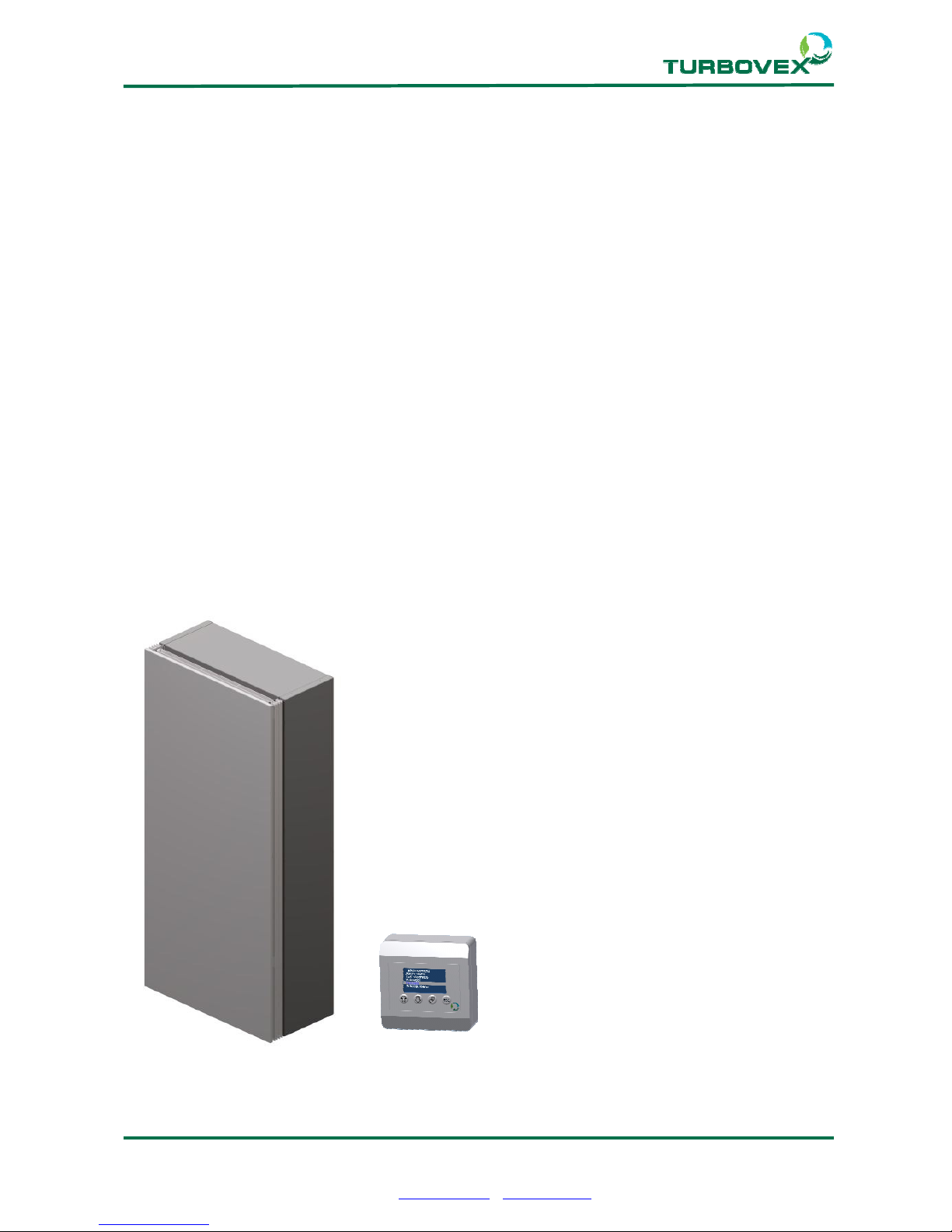

2.5.0

M

AIN COMPONENTS

: ............................................................................................................................... 4

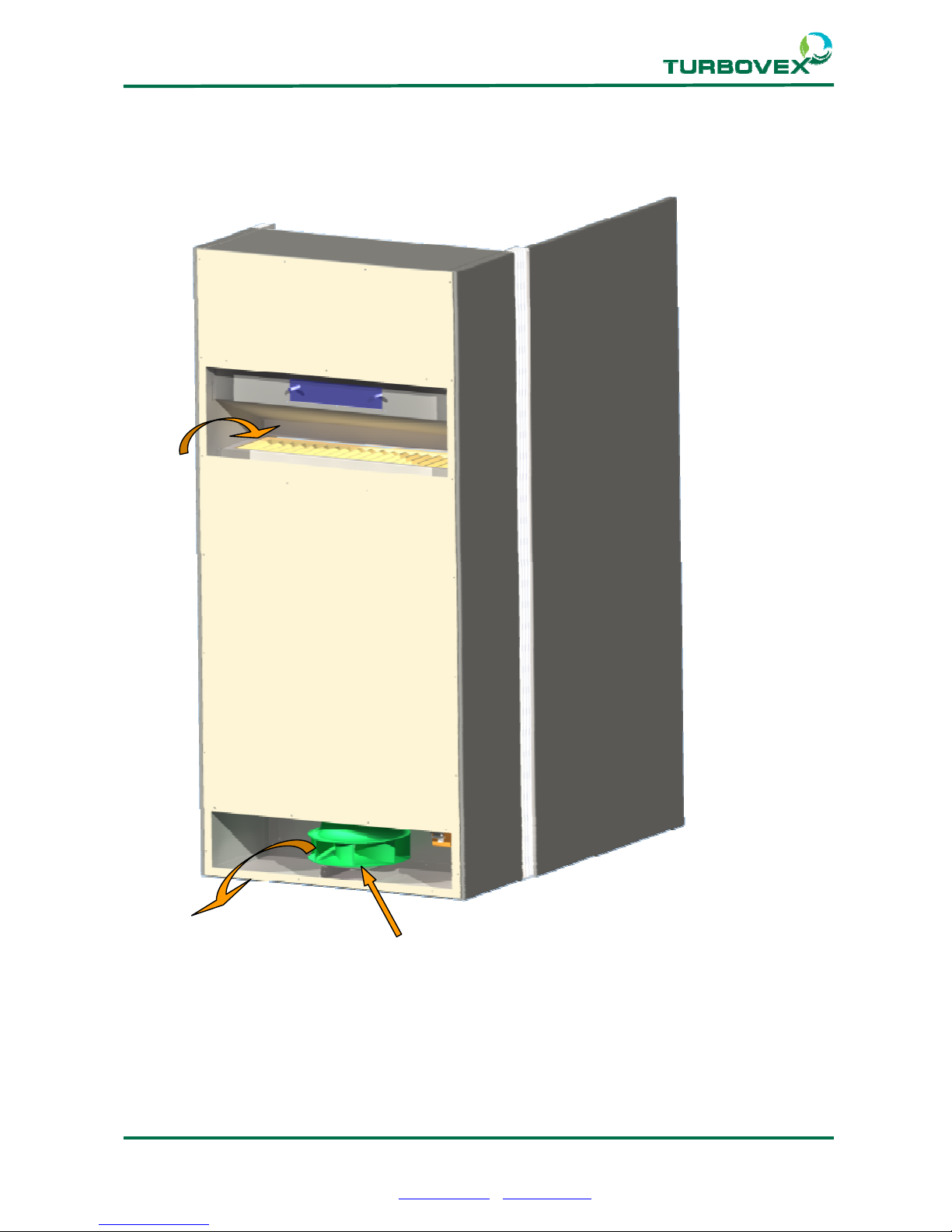

F

IGURE

2:

M

AIN COMPONENTS

......................................................................................................................... 4

F

IGURE

3

M

AIN COMPONENTS

.......................................................................................................................... 5

3.0.0 INSTALLATION OF UNIT........................................................................................................................ 6

3.1.0.

E

XTERNAL DIMENSIONS

.......................................................................................................................... 6

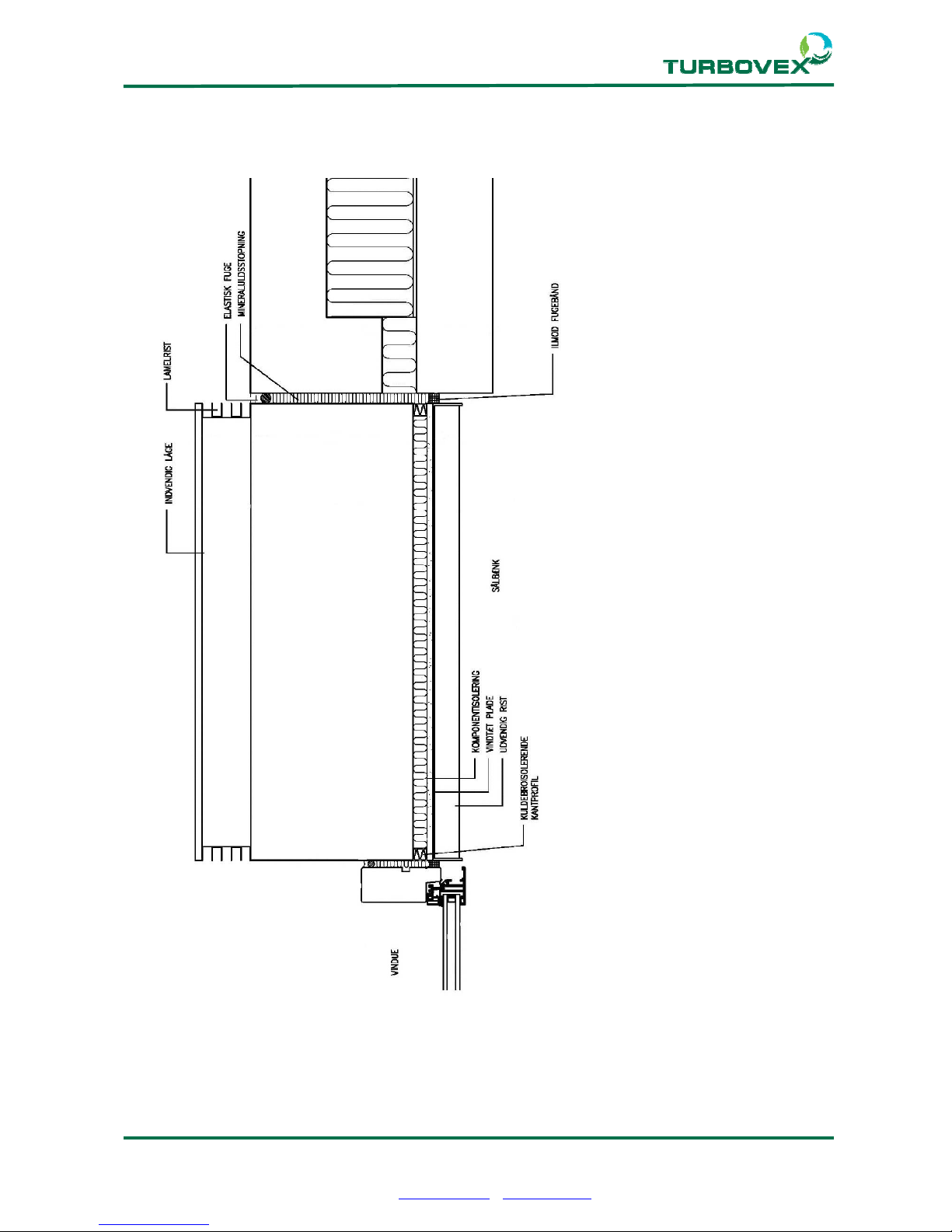

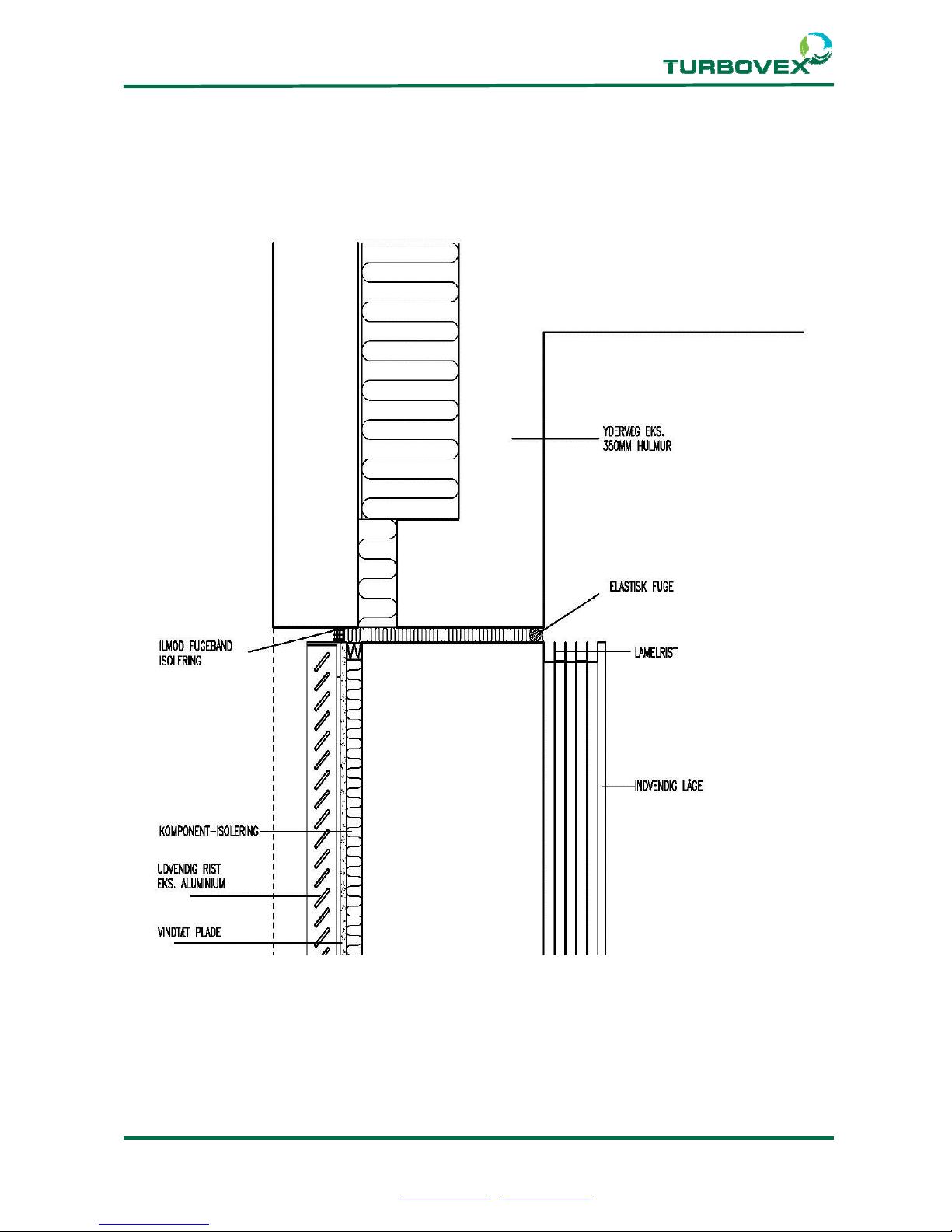

3.2.0

W

ALL

/

WINDOW INSTALLATION

.................................................................................................................. 7

4.0.0 PLACING THE UNIT .............................................................................................................................. 11

PLACING THE UNIT (CONT.) ........................................................................................................................ 12

5.0.0 SERVICE ................................................................................................................................................ 13

5.1.0

F

ILTER CHANGE

.................................................................................................................................... 13

5.2.0

R

EMOVING FILTERS AND EXCHANGER

..................................................................................................... 14

6.0.0 CONNECTING MAINS ELECTRICITY .................................................................................................. 17

6.1.0

C

ONNECTION

........................................................................................................................................ 17

6.2.0

W

IRING DIAGRAM

.................................................................................................................................. 18

7.0.0 TECHNICAL SPECIFICATIONS............................................................................................................ 19

7.1.0

S

OUND TEST

......................................................................................................................................... 20

8.0.0 PRINCIPLE OF OPERATION ................................................................................................................ 21

8.1.0

D

ESCRIPTION

....................................................................................................................................... 21

9.0.0 OPERATION .......................................................................................................................................... 22

9.1.0

R

EGULATING AIR VOLUME

...................................................................................................................... 22

9.2.0

R

EGULATING WARMTH

........................................................................................................................... 22

9.3.0

M

ASTER

/

SLAVE

..................................................................................................................................... 22

10.0.0 DECLARATION OF COMPLIANCE .................................................................................................... 23