1.0 Table of contents

1.0 Table of contents ....................................................................................... 2

2.0 General information .................................................................................. 3

2.1 Introduction..........................................................................................................................3

2.2 Fields of application .............................................................................................................3

2.3 Misuse ..................................................................................................................................3

2.4 Contents of delivery .............................................................................................................3

2.5 Operating principle...............................................................................................................4

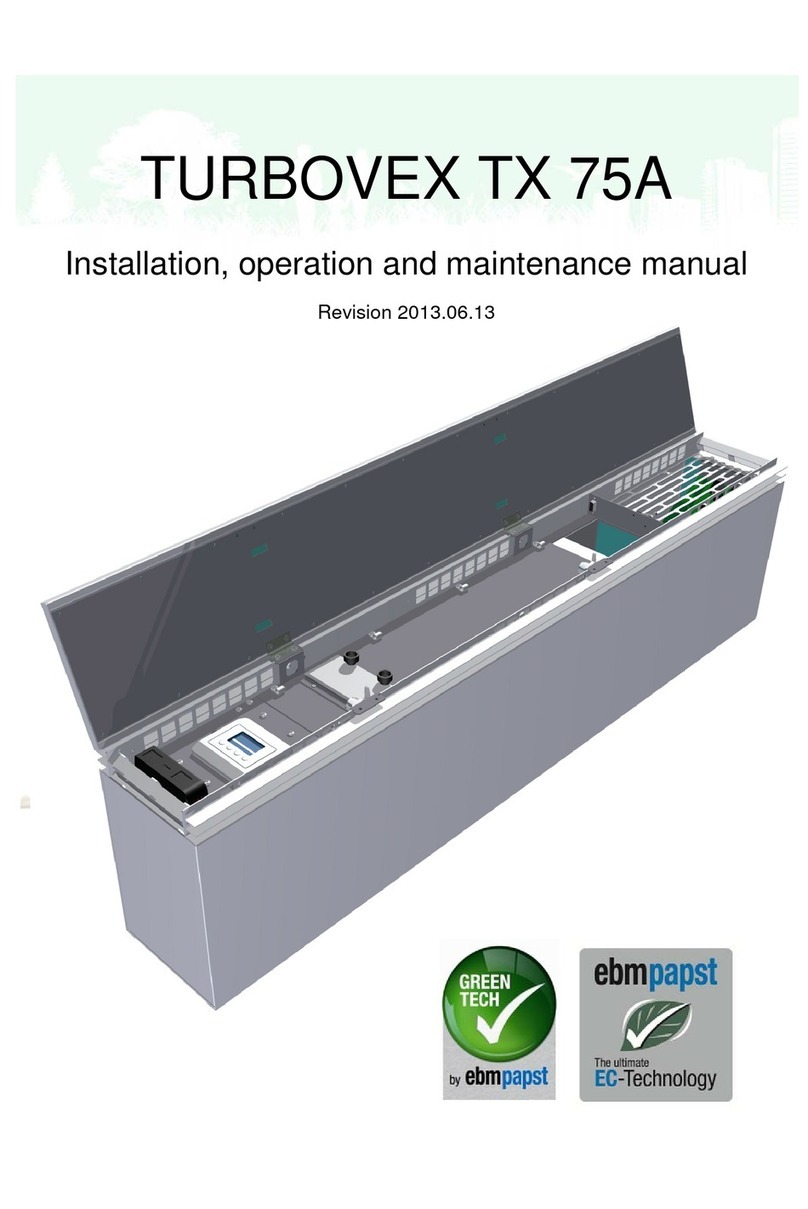

2.6 Main components: ...............................................................................................................5

3.0 Installation................................................................................................. 6

3.1 Dimensions ...........................................................................................................................6

3.2 Placement.............................................................................................................................7

3.3 Minimum distance................................................................................................................9

3.4 Wall- or ceiling mounted unit ............................................................................................10

4.0 Connection............................................................................................... 16

4.1 Water connection...............................................................................................................16

4.2 Frost protection of water heating coil ...............................................................................16

4.3 Power connection ..............................................................................................................18

4.4 Power connection for accessories .....................................................................................19

5.0 Technical specifications............................................................................ 20

6.0 Operation ................................................................................................ 21

6.1 Regulation of airflow..........................................................................................................21

6.2 Heat regulation...................................................................................................................21

6.3 Master / slave.....................................................................................................................21

7.0 Service ..................................................................................................... 22

7.1 Change of filter...................................................................................................................22

7.2 Cleaning of heat exchanger................................................................................................23

8.0 Declaration of conformity........................................................................ 24