Page 2 of 24

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Telefon: +45 96 98 14 62 – Fax: +45 98 96 42 24

1.0.0 Table of contents

1.0.0 TABLE OF CONTENTS ........................................................................................................................................2

2.0.0 ILLUSTRATIONS ..................................................................................................................................................2

3.0.0 GENERAL INFORMATION.................................................................................................................................3

3.1.0 FOREWORD ........................................................................................................................................................3

3.2.0 FIELDS OF APPLICATION ................................................................................................................................3

3.3.0 MISUSE................................................................................................................................................................3

3.4.0 CONTENTS OF DELIVERY ...............................................................................................................................3

3.4.0 OPERATING PRINCIPLE...................................................................................................................................4

3.5.0 MAIN COMPONENTS:.......................................................................................................................................5

4.0.0 INSTALLATION.....................................................................................................................................................6

4.1.0 SCALE ILLUSTRATION.....................................................................................................................................6

4.2.0 LOCATION..........................................................................................................................................................7

4.2.1 MINIMUM DISTANCE.......................................................................................................................................9

4.2.2 WALL- OR CEILING-MOUNTED UNIT ...........................................................................................................9

4.3.0 INSTALLATION OF UNIT................................................................................................................................11

4.3.1 INSTALLATION WITH 2DUCTS....................................................................................................................11

5.0.0 CONNECTION......................................................................................................................................................16

5.1.0 WATER CONNECTION....................................................................................................................................16

5.1.1 FROST PROTECTION OF WATER HEATING COIL .....................................................................................16

5.2.0 POWER CONNECTION....................................................................................................................................18

5.3.0 POWER CONNECTION FOR ACCESSORIES ................................................................................................19

6.0.0 TECHNICAL SPECIFICATIONS ......................................................................................................................20

6.1.0 VENTILATION SYSTEM .................................................................................................................................20

7.0.0 OPERATION.........................................................................................................................................................21

7.1.0 REGULATION OF AIRFLOW..........................................................................................................................21

7.2.0 HEAT REGULATION........................................................................................................................................21

7.3.0 MASTER /SLAVE.............................................................................................................................................21

8.0.0 SERVICE ...............................................................................................................................................................22

8.1.0 CHANGE OF FILTER........................................................................................................................................22

8.2.0 CLEANING OF EXCHANGER.........................................................................................................................23

9.0.0 DECLARATION OF CONFORMITY................................................................................................................24

2.0.0 Illustrations

FIGURE 1CONTENTS OF DELIVERY .............................................................................................................................3

FIGURE 2MAIN COMPONENTS......................................................................................................................................5

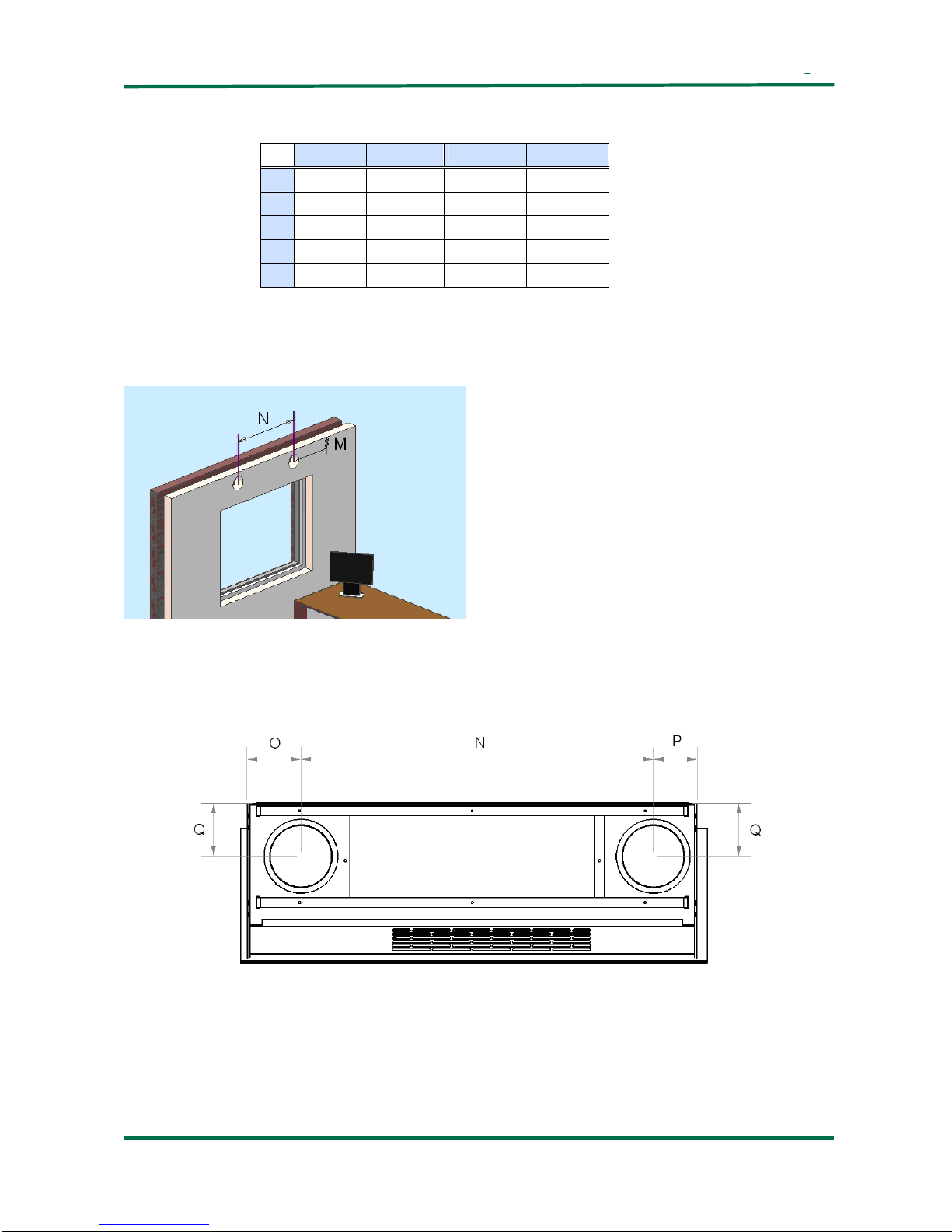

FIGURE 3SCALE ILLUSTRATION...................................................................................................................................6

FIGURE 4LOCATION, CONVENTIONAL.......................................................................................................................7

FIGURE 5LOCATION IN AFALSE CEILING..................................................................................................................7

FIGURE 6MINIMUM DISTANCE.....................................................................................................................................9

FIGURE 7WALL-MOUNTED WITH WALL DUCTS………..........................................................................10

FIGURE 8CEILING-MOUNTED WITH CEILING DUCTS…........................................................................................10

FIGURE 9LOCATION OF DUCTS...................................................................................................................................10

FIGURE 10 MEASUREMENTS FOR MOUNTING THE SUSPENSION BRACKET OF ATX COMFORT UNIT......11

FIGURE 11 WATER CONNECTION................................................................................................................................16

FIGURE 12 CIRCUIT DIAGRAM.....................................................................................................................................18

FIGURE 13 CIRCUIT DIAGRAM FOR ACCESSORIES.................................................................................................18