Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

GeneralSafety.................................................5

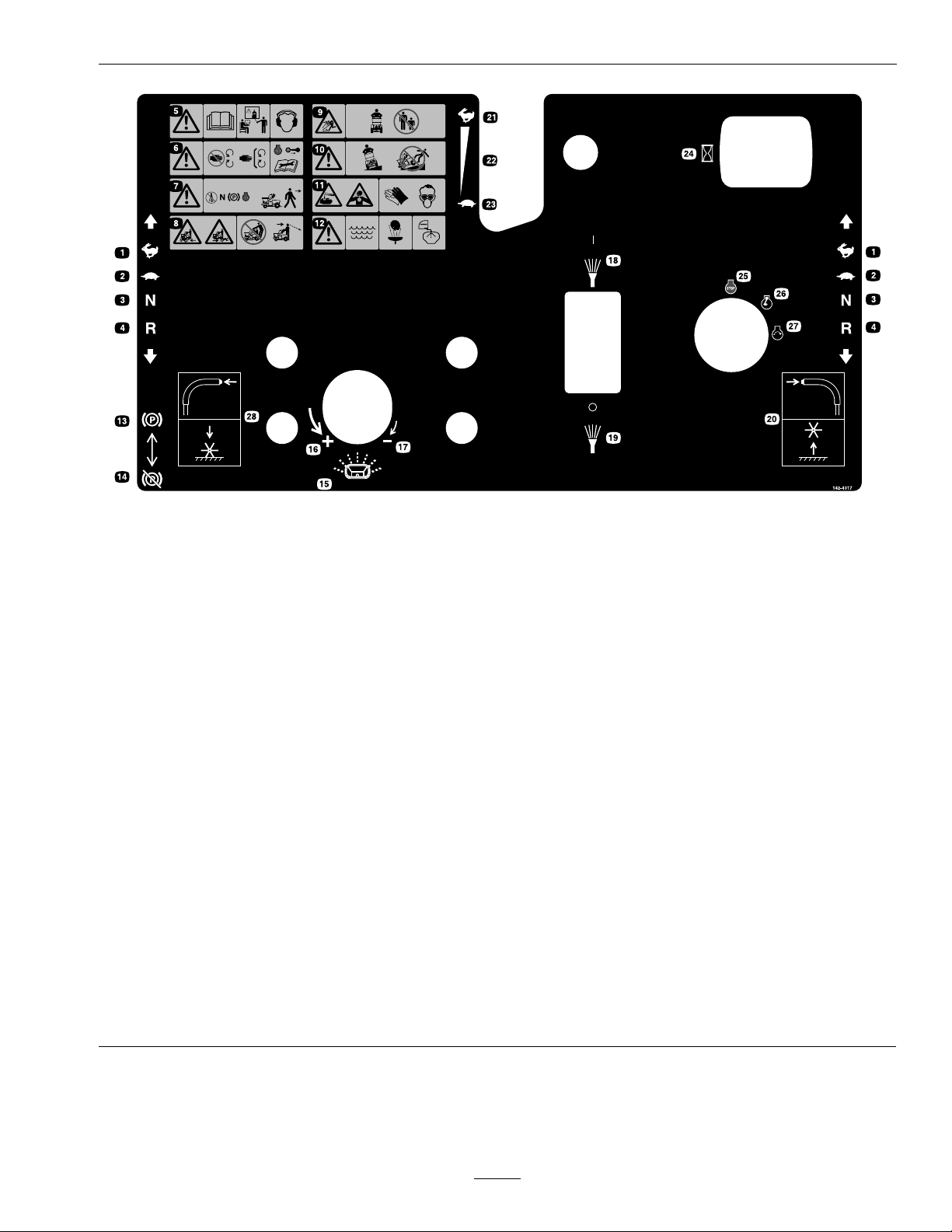

SafetyandInstructionalDecals.......................6

Specications........................................................10

Systems..........................................................10

Dimensions....................................................10

TorqueRequirements.....................................11

ProductOverview.................................................11

Operation..............................................................12

Controls.........................................................12

BeforeOperation...........................................15

Pre-Start.........................................................16

OperatingInstructions...................................18

DuringOperationSafety.................................18

OperatingtheSpreader...................................23

SpreaderCalibration......................................25

AfterOperation..............................................31

Transporting..................................................31

Maintenance..........................................................33

MaintenanceSafety.............................................33

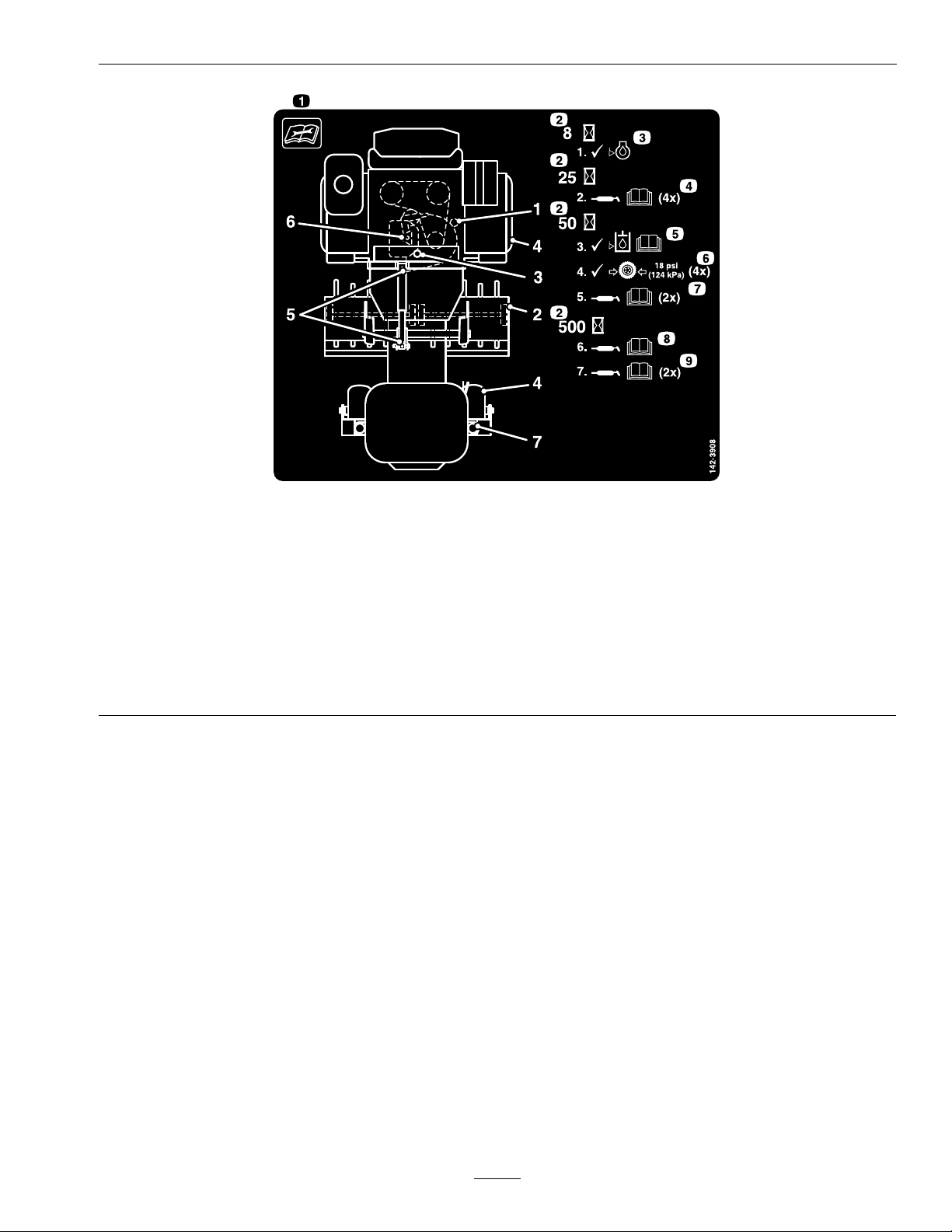

RecommendedMaintenanceSchedule(s)............34

PeriodicMaintenance........................................35

CheckEngineOilLevel..................................35

CheckBatteryCharge.....................................35

CheckTines...................................................37

CheckforLooseHardware.............................37

ServiceAirCleaner.........................................37

ChangeEngineOil.........................................37

CheckHydraulicOilandReservoir

Level..........................................................38

CheckTirePressures......................................38

CheckConditionandTensionOf

Belts...........................................................38

LubricateGreaseFittings................................38

CheckSparkPlug...........................................38

ChangeHydraulicFiltersandFluid.................39

CheckWheelMotorOutputShaftNut

TorqueSpecication...................................39

CheckWheelLugNutsTorque

Specication...............................................39

CheckSparkArrester(ifequipped)..................40

ThreadLockingAdhesives..............................40

Adjustments......................................................40

TransmissionDriveBeltTension....................40

MotionControlLinkageAdjustment..............40

Cleaning............................................................41

CleanEngineandExhaustSystem

Area...........................................................41

RemoveEngineShroudsandClean

CoolingFins...............................................41

CleanDebrisFromMachine...........................41

WasteDisposal...............................................42

Troubleshooting....................................................43

Schematics............................................................45

CaliforniaProposition65Warning

Information...............................................46

4