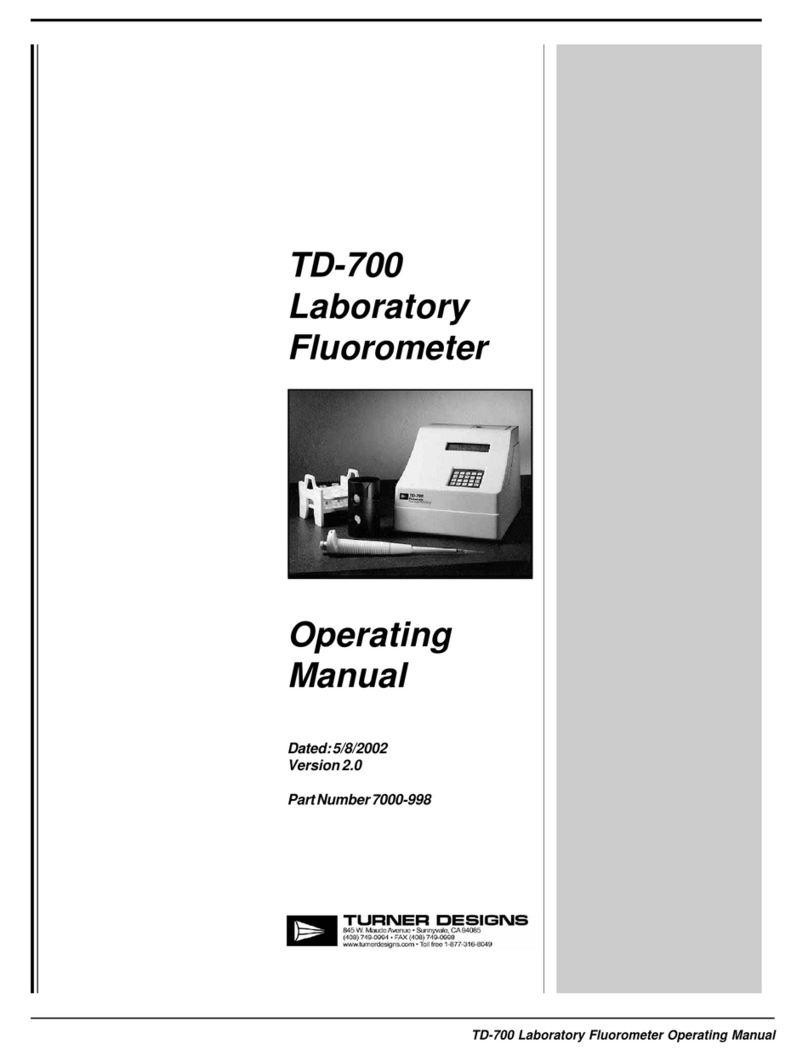

TD1000C™Oil in Water Monitor INTRODUCTION

PN 101687

REV G TD-1000C Oil In Water Monitor

Operation Manual 5

To ensure understanding of proper system operation, Turner Designs Hydrocarbon Instruments strongly recommends

reading this manual in full. After reading the entire manual, please review the following:

INSTALLATION: Prior to installation, completely review APPENDIX A: INSTALLATION

CHECKLIST.

START-UP: Prior to start-up, completely review 4 START-UP.

CALIBRATION: Prior to calibrating the TD1000C™, completely review 5 CALIBRATION.

TROUBLESHOOTING: Prior to calling Turner Designs Hydrocarbon Instruments for assistance,

completely review APPENDIX D: TROUBLESHOOTING.

1 INTRODUCTION

The TD1000C™ on-line oil in water monitor detects aromatic hydrocarbons in water using uorometry

in combination with a proprietary ow cell. The TD1000C™ provides process monitoring through output

signals which may be used to activate control devices to stop, divert, or dilute process streams.

This microprocessor-based uorometer consists of optical components, an on/off controller with

electrical inputs/outputs for a ow switch, a 4–20 mA output signal, two 5 VDC alarm outputs and one

120/240 VAC alarm output. The TD1000C™ is engineered to ensure reliability and pre-assembled to

simplify installation, plumbing and calibration. The monitor is designed to provide trouble-free operation

with only simple, routine maintenance.

1.1 SYMBOLS

The following symbols are used to call attention to specic types of information.

A warning to use caution! In some instances, personal injury or damage to the TD1000C™ may result

if these instructions are not followed properly.

An explanation or information of interest.

An explanation or information of interest.

If the manual instructs the user to press a key on the instrument, the designated key will be

CAPITALIZED in boldface type enclosed by < >.

Display screen names will be in boldface type and in ALL CAPITALS.

References to appendices, tables and gures will be in boldface type and in italics.